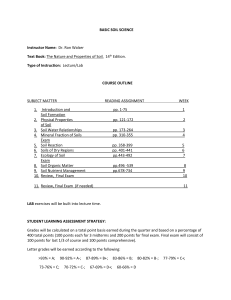

Military Soils Engineering

advertisement