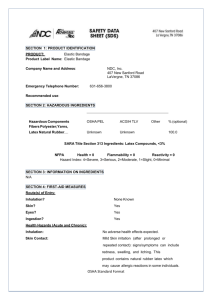

OSHA - Sign In

advertisement