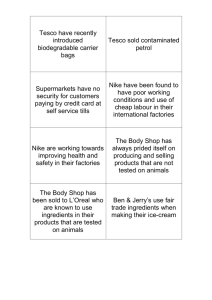

sustainable business performance summary

advertisement