Lifecycle of Imported Retail Products

advertisement

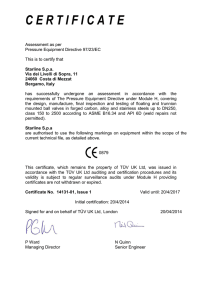

Lifecycle of Imported etail Products •Importing Products forImporting Retail Products for Retail Presented by Mark Penton Senior Consultant, TÜV Product Service TÜV Product Service Ltd © Who Am I? Name Mark Penton Title: Senior Consultant Employer: TÜV Product Service Ltd Experience: 20 Years experience in product testing and approvals History: Worked for Electrolux, TÜV Product Service, Underwriters Laboratories (UL) Telephone: 01489 558214 E-mail: mpenton@tuvps.co.uk TÜV Product Service Ltd © Product Lifecycle Contents • • • • Overview of imported retail product lifecycle Brief overview of CE marking Issues faced with imported products Combating these issues – – – – – Compliance testing of products Factory and shipping inspections Retailer product checks Complaints and returns Minimising your risks • What can happen if you don’t protect yourself TÜV Product Service Ltd © PRODUCT LIFECYCLE TÜV Product Service Ltd © Product Lifecycle Lifecycle Overview Country of Origin TÜV Product Service Ltd © Sales Territory CE MARKING TÜV Product Service Ltd © CE Marking • What is CE Marking? 1. Designed to enable free trade and movement of goods around Europe. 2. Places responsibility with the manufacturer or importer of goods. (The organisation which actually places the goods for sale in the EU). 3. Relates to EU directives designed to ensure quality on the market place (Eg: LVD, EMC, Toy). 4. It is “self certification”, i.e. there is no mandatory 3rd Party involvement. 5. It is NOT evidence of compliance in itself. TÜV Product Service Ltd © CE Marking • What is Due Diligence? 1. Knowing what is required. 2. Demonstrating compliance with relevant directives. 3. Being properly prepared for if things go wrong. Ready to defend yourself in court. Being able to produce a technical file. Being confident in your safety case. TÜV Product Service Ltd © CE Marking and the European Market Place • What is a Declaration of Conformity? 1. A formal statement that the product complies with: Relevant Directives Applicable Standards 2. Signed by responsible person. 3. It is not evidence of compliance in itself. 4. Minimum legal requirement. TÜV Product Service Ltd © ISSUES FACED WITH IMPORTED PRODUCTS TÜV Product Service Ltd © Testing of Products • Have products been properly tested at source? – Are relevant reports and certificates available? – Do they match the product? – Are they still valid? – Are they to latest versions of the standard? – Less than 2 years old? – Are they ‘tested’ or ‘certified’? – Are all relevant testing requirements met? (All applicable directives covered) TÜV Product Service Ltd © Quality of Products Typical Quality issues experienced – Products supplied not the same as ordered. – Product not of the same build standard as the samples submitted for testing. – Products are cost reduced for production. – Mass production not made in the same factory. – Products do not function properly or are unreliable. – Instruction manuals are poor. TÜV Product Service Ltd © Own Branding Do you really want to apply your brand onto imported products? • Are reports & certificates valid for your products? – Not if the make and model number on the products is different – Co – licence certificates may be needed – Have you changed the product specification • Brand association – If consumer is not happy they will associate that with brand – Do you want to have your name on poor quality goods TÜV Product Service Ltd © The Result • High product complaints and returns • Products unsafe / dangerous • Product recall or withdrawal from the market • Consumer dissatisfaction • Loss of brand integrity LOSS OF REVENUE TÜV Product Service Ltd © COMBATING THESE ISSUES TÜV Product Service Ltd © Product Lifecycle Compliance Testing Importer arranges relevant testing and certification to be carried out. Vendor has already tested and certified the product TÜV Product Service Ltd © Buyer requests relevant testing and certification to be carried out as a contract condition. Retailer arranges relevant testing and certification to be carried out. Product Lifecycle Compliance Testing Consideration relating to product testing • Has all relevant testing been conducted to meet CE marking requirements? (eg: Safety, EMC, Toy, Telecom, Environmental, Pressure) • Ensure that product buyers are aware of testing requirements for the products they are selecting. • It is best to select products that have already had suitable testing and certification. (eg: products with a GS mark or third party certification mark) • Have you ensured that you have met the requirements of the General Product Safety Directive (GPSD) • Declarations of Conformity are not evidence of testing or compliance. TÜV Product Service Ltd © Product Lifecycle Factory and Shipping Inspections Factory Inspection:- Pre-Shipment • Certification • Quality Management System • Ethical Auditing TÜV Product Service Ltd © Post Shipment Product Lifecycle Factory and Shipping Inspections Typical Objectives of Factory Inspections • Ensuring the ongoing compliance of certified products. Inspections are conducted on a regular basis by the certification body (eg: TÜV Product Service, SEMKO, VDE). • Checking the Quality Management System implemented (eg: ISO 9000). • Ethical auditing to review working conditions and treatment of employees (eg: minimum age of employees, treatment of staff, living conditions and facilities provided). • Checking of retailer specific supplier requirements. • Ensuring products meet the expected quality and safety standards. TÜV Product Service Ltd © Product Lifecycle Typical Objectives of Pre/Post Shipping Inspections (PSI) • Inspection of the goods, to appraise whether or not what you actually receive matches your purchase order and your contractual requirements. • Assessment of overall build quality. • Checks to ensure that mandatory requirements are satisfied, e.g. CE marking. • PSI scope covers build quality, packing, marking and labelling, audit against customer purchase order / requirements. • supervision of loading / unloading. “Essentially PSI protects you as the importer and ensures that what you actually receive is what you were expecting.” TÜV Product Service Ltd © Product Lifecycle Retailer Product Checks Pre-production samples released for inspection TÜV Product Service Ltd © Samples sent for independent inspection to verify product quality and approvals Product Lifecycle Retailer Product Checks Typical Objectives of Retail Product Checks • Review of product by independent expert • Check that testing reports & certificates are to the correct and current version of the standards • Check the competence of the testing laboratory / organisation • Checking of user guide for language and suitability • Check overall build and product quality • Check product for essential markings and warnings • Check for correct mains plug, cord and fuse • Conduct basic functionality checks • Check packaging of product TÜV Product Service Ltd © Product Lifecycle Complaints and Returns • Customer unhappy with product quality • Product defective • Product Unsafe TÜV Product Service Ltd © Product Lifecycle Complaints and Returns • Complaints from customers and enforcement authorities can be highly damaging to your business and could well result in costly legal action. • Seek independent investigation of complaints on your behalf to find if the complaint is unsubstantiated or legitimate. • Ensuring that the correct testing and inspection are implemented at an early stage minimises the risk. • Managing your product integrity protects your brand name. • OEM branding is an increasing market and carries higher risks as price is often the overriding factor in initial product selection. High returns or product recalls can ruin brand name and reduce or destroy profitability. TÜV Product Service Ltd © Product Lifecycle Minimising Your Risks Select products which have already been tested and certified. Pre and/or post shipment to ensure the goods shipped are acceptable. Seek independent investigation and advise in the event of returns or complaints Request pre-production samples and compliance documentation for evaluation. Ensure that the factory has QMS and is regularly Audited. TÜV Product Service Ltd © Samples sent for independent retail check Product Lifecycle What Can Happen if you Don’t Protect Yourself? TÜV Product Service Ltd © Product Lifecycle Defective products can catch fire in the consumers home! TÜV Product Service Ltd © Product Lifecycle Poor quality products that break whilst in use and injure the consumer TÜV Product Service Ltd © Product Lifecycle Toaster Danger 1. Insufficient insulation. 2. Excessive case temperature >100 C. 3. Inadequate Earthing Measures Remove from market Prohibition of sale TÜV Product Service Ltd © Product Lifecycle Toy Pistol Danger Swallow able arrows Lethal accident of a Swedish boy Measures Recall Prohibition of sale TÜV Product Service Ltd © Product Lifecycle Laserpointer Danger Laser power is 4 mW, 1 mW is allowed Burn hazard of eyes Measures Recall Prohibition of sale TÜV Product Service Ltd © Product Lifecycle Cord Extension Set Danger • Incorrect outlet socket dimensions • Excessive temperature >150 C under full load • Insufficient insulation distances • Insufficiently rated mains cord Measures Stop of sale Recall TÜV Product Service Ltd © Product Lifecycle Hot-water bottle for Children Danger Bottle lid too small Choking hazard to children Measures Destruction Prohibition of sale TÜV Product Service Ltd © Product Lifecycle Teddy Bear Danger Detachable eyes Suffocation Measure Recall TÜV Product Service Ltd © Product Lifecycle Expanding Spider Danger Suffocation Measure Prohibition of sale TÜV Product Service Ltd © Product Lifecycle Pizza Oven Danger Missing label Missing CE marking Fire hazard Power hazard Measure Stop of sale TÜV Product Service Ltd © Product Lifecycle Trampoline Danger Collapsing of frame Injury to user Measure Stop of sale Product recall TÜV Product Service Ltd © Product Lifecycle Steam Cleaner Danger Escaping Steam Scalding of user Measure Stop of sale TÜV Product Service Ltd © Product Lifecycle Summary • • • • Overview of imported retail product lifecycle Brief Overview of CE Marking Issues faced with imported products Combating these issues – – – – – Compliance testing of products Factory and shipping inspections Retailer product checks Complaints and returns Minimising your risks • What can happen if you don’t protect yourself TÜV Product Service Ltd © Product Lifecycle Mark Penton Senior Consultant, TÜV Product Service Tel: +44(0) 1489 558214 mpenton@tuvps.co.uk www.tuvps.co.uk TÜV Product Service Ltd ©

![Safety Testing [ DOC 56 kB ]](http://s3.studylib.net/store/data/007541457_2-1e35ac3d9b0d00ecf7468f41ecb1dcb1-300x300.png)

![Corporate Health Management offers relief [ DOC 243 kB ]](http://s3.studylib.net/store/data/007570320_2-98e1a9a7e4eb257a836f434f5a211c0c-300x300.png)