Survey of Pulp and Paper Industry in Washington and Oregon

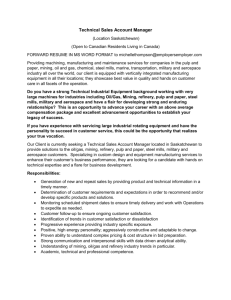

advertisement