Boiling rate, heat transfer and viscosity of cane molasses Presentation

advertisement

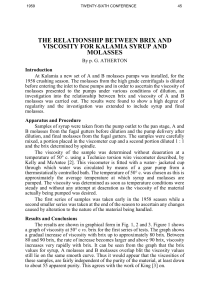

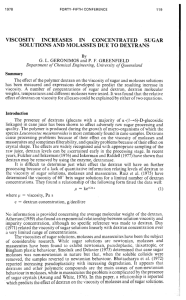

Boiling Rate, Heat Transfer And Viscosity of Cane Molasses Audubon Sugar Institute Michael Saska 2001 REPORTS FROM ONE MILL OF INTERMITTENT PROBLEMS WITH BOILING SUGAR 2002 REPEATED REPORTS FROM SEVERAL MILLS OF SEVERE PROBLEMS WITH BOILING SUGAR LARGE SAMPLES TAKEN TO AND STUDIED AT AUDUBON FIELD OBSERVATIONS: WET/RAIN WARM LACK OF SUN COULD NOT BURN LODGED CANE (MUSHROOM CANE) “PUTRID SMELL IN THE FURROWS ANAEROBIC CONDITIONS IN THE FIELD” “ROTTING BROWN WET LEAVES ON CANE IN WET & WARM WEATHER” FACTORY OBSERVATIONS: STARCH AND DEXTRAN NORMAL MASSECUITE CONSISTENCY NORMAL SYRUP pH > CLEAR JUICE pH (?) FILM LEFT ON PAN TUBES – SOLUBLE IN WATER MEASURE EVAPORATION RATE @ CONSTANT BRIX (µWAVE) ABS. PRESSURE STEAM PRESSURE LEVEL STIRRER SPEED CALCULATE BOILING HEAT TRANSFER COEFFICIENT. CHEMICAL CHARACTERIZATION SUGARS, COLOR, pH, ANIONS, CATIONS, AB AND HAZE DEXTRAN, STARCH, FAT, FREE FATTY ACIDS, PHYSICAL PROPERTIES VISCOSITY, SURFACE TENSION, CONTACT ANGLE HEAT TRANSFER MEASUREMENTS AFFECT OF BRIX AFFECT OF ADDITIVES TO POOR BOILING MOLASSES (ANTIFOAMS, SURFACTANTS, SODA ASH, ACID) POTENTIAL CULPRITS TO WELL BOILING MOLASSES (DEXTRAN, STARCH, CALCIUM ACETATE, ..) AFFECT OF TREATING POOR BOILING MOLASSES PRIOR TO HEAT TRANSFER TEST WITH ADSORBENT RESIN GRANULAR ACTIVATED CARBON CLARIFICATION WITH ETHANOL 4 Brix levels 0 30 60 2000 90 1201800 150 180 210 240 270 300 330 360 1600 1400Tim e, m in 1200 1000 800 600 400 200 0 0 30 60 90 120 150 180 210 240 270 300 330 360 Feed rate, m L/m in RDS Test “SM ‘A’” Molasses (1/17/03) 88 87 86 85 84 83 82 81 80 79 78 77 76 75 Time, m in H eat tran sfer co efficien t, W /m 2/C Heat transfer properties of three Louisiana 'A' molasses St. Martin 10/28/02 1400 1200 St. James 2001 1000 800 600 Iberia 12/12/02 400 200 0 75 77 79 81 83 85 87 89 91 93 RDS Austmeyer Low Grade Beet AFTER BOILING COLLECT & ANALYZE MOLASSES AND PAN WASHINGS NO SIGNIFICANT DIFFERENCE FOUND SUCROSE GLUCOSE FRUCTOSE 14 ANIONS Na, K, Mg, Ca CONCLUSIONS HTB IS NOT DIRECTLY CAUSED BY DEXTRAN, STARCH, CALCIUM IONS OR ORGANIC ACIDS, IS UNRELATED TO FACTORS THAT AFFECT MOLASSES VISCOSITY HTB IS CAUSED BY PRECIPITATION ON THE HEATING SURFACE OF A WATER SOLUBLE LAYER OF UNKNOWN CHEMICAL NATURE AT ABOUT 79-81 Bx (SS ~ 0.9 - 1.1 FOR ‘A’ MOLASSES) - CONCLUSIONS SMALL IMPROVEMENT (~ 2x) IN BOILING FROM ANTIFOAMS, ETHANOL CLARIFICATION & POLYMERIC ADSORBENTS SUBSTANTIAL IMPROVEMENT (~2-5x) FROM GAC CONCLUSIONS DRASTIC IMPROVEMENT – HEAT TRANSFER COEFFICIENT INCREASED 6-8 x - BY ACIDIFICATION WITH HYDROCHLORIC ACID 87 Iberia 12/12/02 86 84 83 ACID ADDITIONS 82 81 80 0 30 60 90 120 150 180 210 240 270 300 330 360 2 levels of Bx followed by 3 levels of acid addition, 0.5 kg each Time, min Feed rate, mL/min RDS 85 2000 1800 1600 1400 1200 1000 800 600 400 200 0 AVERAGE WATER FEED RATE 82 231 592 584 147 0 30 60 90 120 150 180 210 240 270 300 330 360 Time, min HTC, W/m2/K Effect of Acidification on Heat Transfer Properties of Iberia 12/12/02 'A' Molasses 800 6.5 600 6.0 400 5.5 200 5.0 0 4.5 0.0 0.5 1.0 Acid added, kg HCl/100 kg DS 1.5 HTC @ RDS 84.6% HTC @ RDS 85.2% pH @ 65% RDS 2003 – 2004 DRY WEATHER IN 2003 NO INCIDENTS OF SEVERE SUGAR BOILING PROBLEMS REPORTED STUDY AT AUDUBON FACTORS THAT AFFECT BOILING HEAT TRANSFER OF FINAL MOLASSES ARE RESPONSIBLE COMPONENTS ALWAYS PRESENT IN CANE MOLASSES ALBEIT IN LOWER AMOUNTS? EXPERIMENTAL ADVANTAGES OF WORKING WITH FINAL MOLASSES - HIGHEST CONCENTRATION OF IMPURITIES - EASY STORAGE AND TRANSPORT HTC, W/m2 /C 1200 Lafour 1000 Enterp 800 St.Mary Cora 600 400 200 0 78 80 82 84 86 88 90 Viscosity (cP) @ 50C, 2sec-1 600000 R2 = 0.365 500000 86 88 400000 90 92 300000 R2 = 0.450 200000 R2 = 0.510 100000 R2 = 0.455 0 0.7 0.9 1.1 1.3 Calcium, % DS 1.5 1.7 CONCLUSIONS THE INVERSE POWER AFFECT OF VISCOSITY ON HTC HTC (W/m2C) = 75,176 (µ-0.53) INTERPRETATION OF DATA ON AFFECTS OF CANE POLYSACCHARIDES ON VISCOSITY IS COMPLICATED BY USE OF ENZYMES AND NATURE OF ANALYTICAL TECHNIQUES CONCLUSIONS POSSIBLE AFFECT OF CALCIUM ION ON VISCOSITY - IMPLICATIONS FOR SODA ASH CLARIFICATION OR IX SOFTENING OF JUICE APPARENT TOTAL ABSENCE OF THE CULPRIT COMPOUNDS. THESE SEEM TO BE TRIGGERED ONLY DURING EXTREME CONDITIONS AS IN 2002 ACKNOWLEDGMENTS AMERICAN SUGARCANE LEAGUE DEDICATED RESEARCH FUNDING COOPERATION AND SUPPORT OF LOUISIANA SUGAR INDUSTRY