Mass Burning Rate of a Large TBPB Pool Fire

advertisement

853

A publication of

CHEMICAL ENGINEERING TRANSACTIONS

VOL. 31, 2013

The Italian Association

of Chemical Engineering

Online at: www.aidic.it/cet

Guest Editors: Eddy De Rademaeker, Bruno Fabiano, Simberto Senni Buratti

Copyright © 2013, AIDIC Servizi S.r.l.,

ISBN 978-88-95608-22-8; ISSN 1974-9791

Mass Burning Rate of a Large TBPB Pool Fire –

Experimental Study and Modeling

Stefan Schälikea,b, *, Kirty B. Mishraa, Marcus Malowa, Anka Bergera, KlausDieter Wehrstedta, Axel Schönbucherb

a

Federal Institute for Material Research and Testing (BAM), Unter den Eichen 87, 12205 Berlin, Germany

University Duisburg-Essen, Institute for Chemical Engineering I, Universitätsstr. 7, 45141 Essen, Germany

stefan.schaelike@bam.de

b

Data and prediction for the mass burning rate of a tert-butyl-peroxy-benzoat (TBPB) pool fire (pool

diameter = 3 m) is presented. The mass burning rates of TBPB fires are up to six times higher and less

dependent on pool diameter compared to hydrocarbon pool fires caused by an additional heat release rate

due to exothermic decomposition reaction in the liquid phase. This heat release rate is calculated using a

st

1 order reaction kinetic obtained from micro calorimetric measurements. A new model is derived

considering the heat release rate due to the decomposition reaction which is shown to be 100 % of the

heat release rate radiated to the pool surface. With the presented model, including also physical quantities,

especially the limiting fuel concentration for upward flame propagation, it is possible to predict the mass

burning rates of large TBPB pool fires. The predicted values are in very good agreement with the

experiments.

1. Introduction

Pool fires belong to the most frequent accidents when combustible substances are released in the process

industries during transport, handling or storage (Person and Lönnermark, 2004; Mannan, 2005). A pool fire

is defined as a buoyancy controlled non-premixed flame which burns above a liquid pool due to

vaporization with a small initial momentum. A key quantity for hazard calculations relating to pool fires in

fire safety science is the mass burning rate m

fcc . For hydrocarbon pool fires a wide set of experimental

data e.g. (Blinov and Khudiakov, 1957; Burgess et al., 1961; Mudan, 1984) and theoretical studies e.g.

(Hottel, 1959; Hertzberg, 1973; Burgess and Hertzberg, 1974) on the mass burning rates depending on

the fuel and pool diameter d are available. The mass burning rates of other hazardous substances like

organic peroxides are less understood and only a few sets of pool fire data are available (Wehrstedt and

Wandrey, 1993; Chun, 2005; Mishra and Wehrstedt, 2012). Di-tert-butyl-peroxy-benzoate (TBPB) is a

compound of wide industrial use as an initiator for radical reactions, a resin hardener or a cross linking

agent. To close the lack of missing data on the mass burning rates of organic peroxides a large-scale pool

fire experiment with TBPB is conducted. A new model to describe the mass burning rates of TBPB pool

fires taking into account the heat release rate due to the liquid phase decomposition reaction is presented.

2. Experimental setup

The large-scale experiment with the TBPB fire (d = 3 m) has been carried out on the open air BAM Testsite Technical Safety (in Horstwalde, south of Berlin). Steel trays were used with a rim height of 0.08 m,

the fuel layer had a thickness of 0.05 m. The mass loss during the burning of the fuel was measured with a

load cell mounted under the tray as one point of a three-point construction. The mass loss records had a

time resolution of 't = 0.1 s and a precision of 0.25 %. The fuel temperatures during the burning of the

peroxide were measured with NiCr-Ni thermocouples (1 mm in diameter, time resolution of 't = 0.01 s with

a precision of 0.1 K) connected to a multi data recorder. The thermocouples were placed in 1 cm steps on

the radial coordinate r beginning at the flame axis (r = 0) and on three axial positions xtc. The thermocouple

854

measurements are corrected for thermal conduction (Sears, 1954) against what heat losses due to thermal

radiation are negligible. The heat of combustion is measured with an IKA-C5003 using DIN 51900-3 (DIN

51900-3, 2005).

3. Theory

The experimental studies of Blinov and Khudiakov (1957) on liquid hydrocarbon (HC) pool fires have

shown two basic burning regimes are possible: convectively dominated burning for small diameter

d 20 cm and radiatively dominated burning for d 20 cm, particularly for d 1 m. In the convective

regime the flow can be laminar or turbulent and is always turbulent for radiatively driven flames. Flames in

the radiative regime can be optically thin or thick. These distinctions can be made on basis of the pool

diameter (Babrauskas, 1984) shown in Table 1.

Table 1: Burning modes of pool fires depending d

pool diameter d [m]

< 0.05

0.05 to 0.2

0.2 to 1

1

burning mode

convective, laminar

convective, turbulent

radiative, optically thin

radiative, optically thick

For the mass burning rate Hottel (1959) has modelled:

Q

ba,tot (d )

m fcc (d )

where

(1)

AP (Tf,bp c p,v Tf,a cp,a 'hv )

is the total heat release rate back to the fuel surface, AP is the pool area, Tf,bp , Tf,a are the

Q

ba,tot

fuel temperatures at the boiling point (bp) and at ambient temperature (a), c p, v , c p,a are the heat capacities

of the fuel vapor and the liquid fuel at ambient temperature and 'hv is the enthalpy of evaporation. For

safety engineering application the radiative, optically thick regime is of primarily interest, so Eq.(1) can be

simplified to:

m fcc

where

Q

ba,rad

(2)

AP (Tf,bp cp,v Tf,a cp,a 'hv )

is the heat release rate due to radiation back to the fuel surface. For this radiation regime

Q

ba,rad

Burgess and Hertzberg (1974) developed a model based on the following physical quantities, where it is

assumed that the term with the heat capacity difference in the denominator of Eq. (2) is much smaller then

'hv :

m fcc { E

where

'hc

'hv

E

f rad

H F ,f

'hc

'hc

| 10 3

M F ,f c f S u

'hv

'hv

HF

(3)

is a composite factor, f rad is the fraction energy radiated, H F is the flame emissivity, H F,f is the

flame emissivity as viewed by the absorbing liquid fuel reservoir, M F,f is the view factor between the flame

and the fuel surface, cf

upper explosion limit,

UEL U v is the limit fuel concentration for upper flame propagation, UEL is the

U F is the density of the fuel vapor and S u is the limit burning velocity for natural

convection. For hydrocarbon pool fires realistic values for the quantities in E are f rad

M F,f = 0.4 , c f

0.032 3 kg/m³ = 0.096 kg/m³ , Su = 0.06 m/s.

0.5 , H F / H F,f

0 .5 ,

855

4. Results and discussion

4.1 Fuel surface temperature and heat of combustion

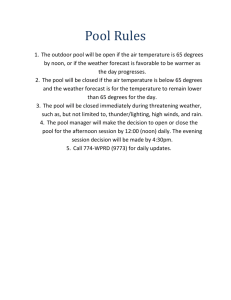

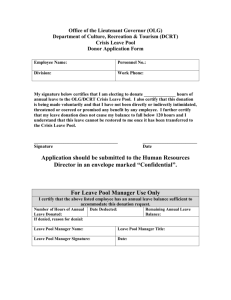

A measurement of the fuel surface temperatures is shown in Figure 1. The arrow indicates the time where

the fuel surface has the same height as the thermocouple. Hence, the fuel temperature of the liquid phase

is given on the left side of the arrow while the right side of the arrow shows the gas phase temperature

short above the fuel surface. An averaged value of the fuel surface temperature T v = 403 K is constant

over the surface area. The depth of penetration of the hot-zone a hz into the liquid fuel indicated by a

temperature increase to 310 K is much lower for TBPB pool fires ( a hz ,TBPB | 4.5 mm at t = 100 s) in

comparison to hydrocarbon pool fires e.g. n-heptane pool fires ( a hz ,HC | 12 mm at t = 100 s) (Nakakuki,

1994; Cheng et al., 2011). The smaller a hz ,HC is caused by the higher energy loss due to the high

evaporation rates in TBPB pool fires which inhibits the heat being conducted deep into the fuel. The sharp

temperature decrease at t = 130 s is due to the effect of a periodic flame oscillation which is not

considered in this paper (Mishra, 2009).

Figure 1: Fuel surface temperatures of a TBPB pool fire at the pool center, where xtc is the height of the

thermocouples over the pool surface

The measured heat of combustion is 'hc = 30,113 kJ/kg.

4.2 Mass burning rate

The mass burning rate of the TBPB pool fire (d = 3 m) during the steady burning time is measured to be

m cfc 0.37 kg/(m² s). It can be seen that the mass burning rate of the TBPB pool fire is up to six times

higher than mass burning rates known from hydrocarbon pool fires m

cfc ,TBPB (d

3 m) / m cfc , HC (d

3 m) | 6 .

In the following it can be shown that Eqs.(1-3) are not applicable for TBPB pool fires without modifications.

due to the decomposition reaction of the liquid TBPB which has

This is caused by a heat release rate Q

d

856

to be introduced into Eqs. (1-3). Using the energy balance of Burgess and Hertzberg (1974) modified by

, leads to:

including the additional heat release rate Q

d

Q

ba,rad Q d

m fcc

(4)

AP (Tv cp,v Tf,a cp,a 'hv )

Eq. (4) is valid for radiatively controlled pool fires (d 1 m) which occur during an accident and show a little

variation of the mass burning rate with increasing diameter. Therefore it is only necessary to predict one

critical value for the mass burning rate in a range d 1 m.

in Eq.(4) can be calculated using the model assumption of an ideal, isotherm,

The heat release rate Q

d

continuous stirred tank reactor (CSTR). This model can be used, because the decomposition reaction

occurs only in a thin liquid layer. During the combustion process this layer sinks down, whereby the

products formed in the liquid phase by the decomposition reaction are vaporized and fresh liquid TBPB

enters into the reaction zone. The expected conversion is very small, so that the liquid is ideal mixed. The

thickness G rz of the reaction zone for a TBPB pool fire d = 3 m can be calculated using Eq.(5):

G rz

v a ( d ) W ( d ) | 3.6 10 4 m/s 9 s | 3 10 3 m

where v a

(5)

m fcc / U l is the burning velocity, W is the residence time and equal that time the liquid phase has a

temperature at which a significant conversion can occur (365 K < T < 403 K). A 1st order (n = 1) reaction

kinetic with a reaction rate constant k 9.5 10 3 s-1 at T v = 403 K is taken from measurements of ChungPing et al. (2012). For the CSTR a residence time can be calculated by:

W (d )

Vrz

V

in

where Vrz

G rz

(6)

va ( d )

G rz AP is the volume of the reaction zone, Vin

va (d ) AP is the volume flow rate entering the

reaction zone. With known W and with a stoichiometric coefficient

be calculated by:

Q

1 the Damköhler number Da can

Da W k

(7)

The Damköhler number is directly connected to the conversion U in a CSTR for n = 1:

U

Da

1 Da

(8)

With the enthalpy of the exothermic decomposition 'hd = 1,377 kJ/kg obtained from measurements of

can be calculated as:

Malow and Wehrstedt (2005) the heat release rate Q

d

(m cc ) U (m cc ) m cc A ('h )

Q

d

f

f

f

P

d

(9)

Using Eqs. (4-9) and the heat capacities for TBPB cp,v = 1.4 kJ/(kg K) (Goos and Burcat, 2010),

cp,a = 1.7 kJ/(kg K) obtained from Gimzenski and Audley (1993), the enthalpy of vaporization 'hv = 205

kJ/kg (Lide, 1996), the heat release rate

for the radiative optical thick regime and the heat

Q

ba,rad,TBPB

can be calculated for the TBPB pool fire (Table 2). It can be recognized that the heat

release rate Q

d

. The fire is controlled by two different mechanism given by the

Q

ba,rad,TBPB

. The heat release rate Q

and the heat release rate Q

is about two

is § 100 % of

release rate Q

d

heat release rate

Q

ba,rad,TBPB

d

ba,rad,TBPB

times higher than those of hydrocarbon pool fires. The exothermic decomposition reaction plays a major

role in peroxide pool fires directly affecting the fuel surface area.

857

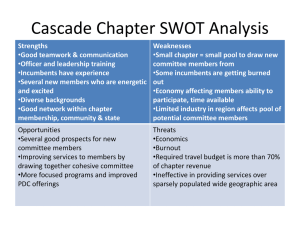

Table 2: Heat fluxes of a radiatively controlled TBPB pool fire (d = 3 m)

Q

ba,rad,TBPB

Q

d

364 kW

366 kW

/Q

Q

d

ba,rad,TBPB

0.99

Q

ba,rad,HC

Q

ba,rad,TBPB / Q ba,rad,HC

190 kW

1.93

/A

Q

d

P

51 kW/m²

Based on Eqs. (3),(4),(9) a new model for m

fcc for TBPB pool fires is developed and leads in the radiatively

controlled limit (d 1 m) to:

m fcc

§ E

·

1¸¸ Q

d / AP

© S u cf

¹

c p, v Tv c p,a Ta 'hv

E ('hc ) ¨¨

(10)

For the calculation of E from the quantities given in Eq.(3) the values of HC pool fires are used, but the fuel

concentration

cf is calculated using specific data for TBPB. This peroxide is flammable over a wide range

of mixtures up to < 100 % (Brandes and Möller, 2008). High concentrations of ignited TBPB do not yield in

carbon dioxide and water as main products. New investigations (Schälike et al., 2012) show that organic

peroxides have two different ignition steps in the fuel rich region. The first ignition step happens as a

thermal decomposition of the TBPB which leads in the gas phase mainly to the products benzene, carbon

dioxide, acetone and ethane (Tobolski and Mesrobian, 1954). The second ignition step is a high

temperature ignition of the decomposition products leading to chain branching. Hence, for flame

propagation not only the decomposition, but also the high temperature ignition has to be taking into

account. Therefore, the benzene concentration at

T v = 403 K is chosen as the limiting species for a

sustainable flame. Using the ideal gas law for density calculation U v and the upper explosion limit UEL

(8.6 vol.%, (Brandes and Thedeus, 2003)) of benzene leads to a limit benzene concentration of

cf = 0.086 ·2.4 kg/m³ = 0.21 kg/m³. With this value of cf for TBPB pool fires the constant E is calculated

as E = 1.32 10 3 kg/(m² s). With the new model Eq. (10) it is for the first time possible to predict the mass

burning rates for large pool fires of liquid peroxides, e.g. TBPB or DTBP. Substituting the discussed values

for the influencing quantities into Eq.(10) a mass burning rate m

fcc, pred = 0.39 kg/(m² s) for a TBPB pool

fire (d = 3 m) in the radiatively controlled limit can be predicted in very good agreement with

measurements m

fcc,exp = 0.37 kg/(m² s). This model can be used to describe the mass burning rates of

large TBPB pool fires which is very helpful in safety science applications. For safety science it is also

important to have conservative values from the model which should not under predict the experimental

results.

5. Conclusions

In this study the mass burning rate of a TBPB pool fire is studied and a new model is developed. The

major results can be summarized:

1. The mass burning rate of a TBPB pool fire in the radiatively controlled optically thick regime is six times

higher than those of hydrocarbon pool fires.

due to an exothermic decomposition reaction in

2. For a TBPB pool fire an additional heat release rate Q

d

is based on a 1st order reaction kinetic

the liquid phase of the fuel is introduced. The calculation of Q

d

which depends on the conversion, mass burning rate, pool cross section, and the heat of decomposition.

is § 100 % of the heat release rate

It can be shown that Q

d

radiated back to the fuel surface.

Q

ba,rad,TBPB

a new model is developed to predict the mass burning rates for large pool

With the heat release rate Q

d

fires of liquid peroxides.

3. Further can be shown from the new model that the radiated heat release rate to the fuel surface of

TBPB pool fires is two times larger than that heat release rate for hydrocarbon pool fires.

858

References

Babrauskas, V., 1983, Estimating Large Pool Fire Burning Rates, Fire Technol., 19, 251-261.

Blinov, V.I., Khudiakov, G.N., 1957, Certain Laws Governing Diffusive Burning of Liquids, Doklady

Academiia Nauk SSSR. 113, 1094-1097 (in Russian).

Brandes, E., Möller, W., 2008, Safety Characteristic Data, Volume 1: Flammable liquids and gases.

Wirtschaftsverlag NW, Bremerhaven.

Brandes, E., Thedeus, M., 2003, Parameters for Explosion Protection at non Atmospheric Conditions, PTB

report, 113(2), 115 (in German).

Burgess, D.S. and Hertzberg, M., 1974, Pool Fires. In: Heat Transfer in Flames, Afgan, N.H. and Beer,

J.M. (Ed.), J. Wiley, London, Chap. 27.

Burgess, D.S., Strasser, A., Grumer, J., 1961, Diffusive Burning of Liquid Fuels in Open Trays, Fire Res.

Abstr. Rev., 3, 177-192.

Cheng, B., Lu, S.-X., Li, C.-H., Kang, Q.-S., Lecoustre, V., 2011, Initial Fuel Temperature Effects on

Burning Rate of Pool Fires, J. Hazard. Mater., 188, 369-374.

Chun, H., 2007, Experimentelle Untersuchung und CFD-Simulation von DTBP-Poolfeuern. PhD Thesis,

BAM dissertation series, Berlin, ISBN 978-3-9811655-0-0.

Chun-Ping, L., Jo-Ming, T., Yi-Ming, C., 2012, Green Thermal Analysis for Predicting Thermal Hazard of

Storage and Transportation Dafety for tert-butyl peroxy benzoate, J. Loss Prevent. Proc., 25(1), 1-7.

DIN 51900-3, 2005, Prüfung fester und flüssiger Brennstoffe - Bestimmung des Brennwertes mit dem

Bomben-Kalorimeter und Berechnung des Heizwertes - Teil 3: Verfahren mit adiabatischem Mantel.

Beuth-Verlag, Berlin.

Goos, E., Burcat, A., 2011, Overview of Thermochemistry and its Application to Reaction Kinetics. In:

DaCosta, H. (ed.), Rate Constant Calculation of Thermal Reactions: Methods and Applications. Wiley

& Sons, New York.

Gimzenski, E., Audley, G., 1993, Thermal Hazards: Calculating Adiabatic Behavior from Differential

Scanning Calorimetry (DSC) Data, Thermochimica acta, 214, 129-140.

Hertzberg, M., 1973, The Theory of Ambient Fires, Combust. Flame, 21(2), 195-209.

Hottel, H.C., 1959, Certain Laws Governing Diffusive Burning of Liquids, Fire Res. Abstr. Rev., 1, 41-44.

th

Lide, D.R. (ed. ), 1996, Handbook of Chemistry and Physics. CRC Press, New York, 76 ed..

Mannan, S., 2005, Fire. in Lee's Loss Prevention in the Process Industries, Elsevier ButterworthHeinemann, Oxford, Vol. 3.

Malow, M., Wehrstedt, K.-D., 2005, Prediction of the Self-accelerating Decomposition Temperature

(SADT) for Liquid Organic Peroxides from Differential Scanning Calorimetry (DSC) Measurements, J.

Hazard. Mater., A120, 21-24.

Mishra, K.B., 2009, Experimental investigation and CFD simulation of organic peroxide pool fires (TBPB

and TBPEH). PhD Thesis, BAM dissertation series, Berlin, ISBN 1613-4249.

Mishra, K.B., Wehrstedt, K.-D., 2012, Decomposition Effects on the Mass Burning Rate of Organic

Peroxide Pool Fires, J. Loss Prevent. Proc., 25(1), 224-226.

Mudan, K.S., 1984, Thermal Radiation Hazards from Hydrocarbon Pool Fires, Proc. Energ. Combust.,

10(1), 59-80.

Nakakuki, A., 1994, Heat Transfer in Hot-zone Forming Pool Fires, Combust. Flame, 109, 353-369.

Person, H., Lönnermark, A., 2004, Tank Fire Review of Fire Incidents 1951-2003, Brandforsk Project 513021, Swedish National Testing and Research Institute, Boras, Sweden.

Schälike, S., Chun, H., Mishra, K. B., Wehrstedt, K.-D., Schönbucher, A., 2012, Mass Burning Rates of

DTBP Pool Fires ņ Experimental Study and Modeling, Combust. Sci. Technol., in press, DOI:

10.1080/00102202.2012.726664.

Sears, W.R., 1954, High Speed Aerodynamics and Jet Propultion. Princeton University Press, New

Jersey.

Tobolsky, A.V., Mesrobian, R.B.,1954, Organic Peroxides. Interscience Publishers, New York.

Wehrstedt, K.-D., Wandrey, P.A., 1993, Burning Behavoir of Liquid and Explosive Compounds in

Dependence of the Pool Diameter. PTB-report W-54, ISBN 0341-6739, 97.