CONSTRUCTION MATERIAL RAVI KANT MITTAL DEPARTMENT

advertisement

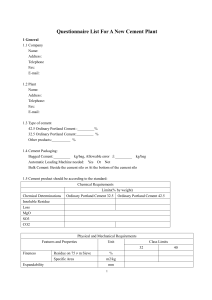

CONSTRUCTION MATERIAL RAVI KANT MITTAL DEPARTMENT OF CIVIL ENGINEERING ROOM NO. 2107 Email: ravimittalcivil@gmail.com Mobile: 9887692025 01596-244090 Dr. Ravi Kant Mittal, BITS, Pilani CEMENT • 33 Grade ordinary Portland cement conforming to IS 269 (OPC 33) • 43 Grade ordinary Portland cement conforming to IS 8112 (OPC 43) • 53 Grade ordinary Portland cement conforming to IS 12269 (OPC 53) • Rapid hardening Portland cement conforming to IS 8041 • Portland slag cement conforming to IS 455 (PSC) Dr. Ravi Kant Mittal, BITS, Pilani CEMENT • Portland pozzolana cement (fly ash based) conforming to IS 1489 (Part 1) (PPC) • Portland pozzolana cement (calcined clay based) conforming to IS 1489 (Part 2) • Hydrophobic cement conforming to IS 8043 • Low heat Portland cement conforming to IS 12600 • Sulphate resisting Portland cement conforming to IS 12330 • White cement conforming to IS 8042 Dr. Ravi Kant Mittal, BITS, Pilani Main Constituents of Cement • • • • Calcium (Ca)/ Lime(CaO) (Lime stone) Silica (SiO2) (Sand) Alumina (Al2O3)(Clay) Iron oxide (Fe2O3) (Iron ore) Dr. Ravi Kant Mittal, BITS, Pilani Main Constituents of Cement • • • • • Lime /Calcium (CaO) (60-67%) Silica (SiO2) (17-25%) Alumina (Al2O3) (3-8%) Iron oxide (Fe2O3) (0.5-0.6%) Magnesia (MgO) (0.5- 4%) • Soda and Potash alkalies (Na2O + K2O) (2 - 3.5%) • Sulphar trioxide(SO3) (0.3-1.2) Dr. Ravi Kant Mittal, BITS, Pilani Dr. Ravi Kant Mittal, BITS, Pilani Bogue Compound (R.H. Bogue) • Tricalcium Silicate (3CaO.SiO2) C3S 25 – 50% • Dicalcium Silicate (2CaO.SiO2) C2S 20 – 45% • Tricalcium Aluminate (3CaO.Al2O3) C3A 5 – 12% • Tetra Calcium aluminao ferrite (4CaO.Al2O3.Fe2O3) C4AF 6 – 14% Dr. Ravi Kant Mittal, BITS, Pilani Hydration and Structure of Cement Paste • The chemical reactions of cement components and water are collectively called hydration. • The two main types of components are the silicates and the aluminates. Dr. Ravi Kant Mittal, BITS, Pilani • The reaction of cement compounds with water may be separated into two main groups. • The first stage is the aluminates with water contributing to the high heat of hydration. The added gypsum goes into solution to react with tricalcium aluminate forming a product known as ettringite. • C3A + Gypsum + Water → Ettringite (tri-sulphate hydrate) + Heat • As sulphate is depleted, ettringite is converted into monosulphate. • C3A +Ettringite + water → Monosulphoaluminate • Responsible for setting action but makes only small contribution to strength. • C3A high value undesirable , due to maximum heat generate Dr. Ravi Kant Mittal, BITS, Pilani • The silicates react with water to form crystalline calcium hydroxide and a low crystalline calcium silicate hydrate called C-S-H gel. • This structure has a typical gel porosity of about 26 to 28% with a very high specific surface (surface area per unit mass). • The amount of water needed for full hydration of cement is about 20 to 25% by mass of cement. . Dr. Ravi Kant Mittal, BITS, Pilani Dr. Ravi Kant Mittal, BITS, Pilani • C3S hydrates quickly and responsible for most of first seven days strength of concrete. • C2S starts contributing after 7 days, responsible for long term strength. Generates minimum heat. Dr. Ravi Kant Mittal, BITS, Pilani Dr. Ravi Kant Mittal, BITS, Pilani b) Fineness v Fineness of cement is a measure of the sizes particles of cement. v It is expressed in terms of specific surface of cement. v Most important factor that will determines the properties of cement v Process of Hydration • Since hydration starts at the surface of the cement particles it is the total surface area of cement that represents the material available for hydration •The finer the cement is ground, the greater will be its specific surface. •So the rate of hydration depends on the fineness of cement particles & for rapid development of strength higher fineness necessary. Dr. Ravi Kant Mittal, BITS, Pilani b) Fineness v Fineness cement leads to a stronger reaction with alkali reaction aggregate & makes a paste though not necessarily concrete, exhibiting a higher shrinkage & a creates proneness to cracking. •However, fine cement bleed less than a coarse one. •The fineness is the most important factor which determines the properties of cement: •Finer grinding increases the speed with which the various constituents reacts with the water •Fineness of grinding is of some importance in relation on the workability of concrete mixes. •Greater fineness increases the cohesiveness of a concrete mix •Finer grinding reduces the chances of bleeding of concrete •In some special type of cement the strength increases slowly than normal though they are finely grounded. Dr. Ravi Kant Mittal, BITS, Pilani RAPID HARDENING PORTLAND CEMENT • RAPID hardening Portland cement has similar properties as that of ordinary Portland cement, except that the former is more finely ground and slightly altered in chemical composition. • Rapid hardening cement gains strength more rapidly at earlier ages, but has a strength comparable to that of ordinary Portland cement at 28 days. • Its fineness leads to increase in shrinkage which should be accounted for in design. Dr. Ravi Kant Mittal, BITS, Pilani PORTLAND SLAG CEMENT(IS455:1989) • Portland slag cement is manufactured either by intimately intergrinding a mixture of Portland cement clinker and granulated slag with addition of gypsum, or by an intimate and uniform blending of Portland cement and finely ground granulated slag. • The resultant product has physical properties similar to those of ordinary Portland cement. • To qualify for a cement as PSC slag content should be any where from 35 to 70 % Dr. Ravi Kant Mittal, BITS, Pilani IRC:15-2011 • Portland sag cement is recommended for use near where marine environment is likely to be encountered or where chances of corrosion exist. For slag cement maximum limit of granulated blast furnace slag constituent recommended is 50% against the IS 456 recommendation for maximum 70% of the Portland slag cement, on strength consideration as above. Dr. Ravi Kant Mittal, BITS, Pilani PORTLAND SLAG CEMENT… • In addition, it has low heat of hydration and with favourable slag contents has relatively better resistance to soils and water containing excessive amounts of sulphate, as well as to acid waters and can, therefore, be used for marine works with advantage. • Resistance to sulphates attack Dr. Ravi Kant Mittal, BITS, Pilani PORTLAND POZZOLANA CEMENT IS 1489 (Part 1) : 1991PORTLAND-POZZOLANA CEMENT- SPECIFICATION PART 1 FLY ASH BASED • Pozzolana used in the manufacture of Portland pozzolana cement may be either a natural material such as diatomaceous earth or materials processed by calcination of soil (for example, burnt clay pozzolana) or artificial material such as fly ash. • Portland pozzolana cement can be produced either by grinding together Portland cement clinker and pozzolana in proportions of 15 to 35 percent with the addition of gypsum, or by intimately and uniformly blending ordinary Portland cement and fine pozzolana. Dr. Ravi Kant Mittal, BITS, Pilani •When mixed with ordinary Portland cement the silica of the puzzolana combines with the free lime released during the hydration of cement. This action is called puzzolanic action. •The silica in the puzzolana reacts with the lime produced during hydration of Portland cement and contributes to development of strength. •Slowly and gradually additional calcium silicate hydrate is formed which is a binder and fills up the space, gives impermeability, durability and ever increasing strength. Dr. Ravi Kant Mittal, BITS, Pilani PORTLAND POZZOLANA CEMENT….. • This cement produces less heat of hydration and offers greater resistance to the attack of aggressive waters than ordinary Portland cement. • It is particularly useful in marine construction and other mass concrete structures. • It can generally be used whenever ordinary Portland cement is usable under normal conditions. Dr. Ravi Kant Mittal, BITS, Pilani IS 1489 (Part 1) : 1991PORTLAND-POZZOLANA CEMENT —SPECIFICATION PART 1 FLY ASH BASED • Portland-pozzolana cement produces less heat of hydration and offers greater resistance to the attack of aggressive waters than normal Portland cement. • Moreover, it reduces the leaching of calcium hydroxide liberated during the setting and hydration of cement. • It is particularly useful in marine and hydraulic construction and other mass concrete structures. • Portland-pozzolana cement can generally be used wherever 33 grade ordinary Portland cement is usable under normal conditions. Dr. Ravi Kant Mittal, BITS, Pilani IS 1489 (Part 1) : 1991PORTLAND-POZZOLANA CEMENT —SPECIFICATION PART 1 FLY ASH BASED • However, it should be appreciated that all pozzolanas need not necessarily contribute to strength at early ages. • In view of this fact, this specification has been prepared to enable manufacturers to produce Portland-pozzolana cement equivalent to 33 grade ordinary Portland cement on the basis of the 3, 7 and 28-days compressive strength. (next slide) Dr. Ravi Kant Mittal, BITS, Pilani IS 1489 (Part 1) : 1991PORTLAND-POZZOLANA CEMENT —SPECIFICATION PART 1 FLY ASH BASED • Compressive strenght of 1cement, 3 sand mortar • a) At 72 ± 1 h , 16 MPa, Min • b) At 168 ± 2 h , 22 MPa, Min • c) At 672 ± 4 h , 33 MPa, Min For construction of structures using rapid construction methods like slipform construction, Portland-pozzolana cement shall be used with caution since 4 to 6 hour strength of concrete is considered significant in such construction. Dr. Ravi Kant Mittal, BITS, Pilani HYDROPHOBIC CEMENT • HYDROPHOBIC CEMENT- deteriorates very little during prolonged storage under unfavourable conditions. • This cement is obtained by intergrinding ordinary Portland cement clinker with certain hydrophobic agents (such as oleic acid, stearic acid, naphthenic acid, pentachlorphenol,etc) which will impart a water repelling property to the cement. (Hydrophobic cement should not be confused with water proofing cements.) • With the use of hydrophobic cements, a longer period for mixing may be necessary. Dr. Ravi Kant Mittal, BITS, Pilani PORTLAND LOW HEAT CEMENT, • 6.1 Fineness • When tested for fineness by Blaine’s air permeability method as described in IS 4031 ( Part 2 ) :1988, the specific surface of cement shall be not less than 320 m2/kg. Dr. Ravi Kant Mittal, BITS, Pilani LOW HEAT CEMENT • 6.2 Soundness • 6.2.1 When tested by ‘Le Chatelier’ method and autoclave test described in IS 4031 ( Part 3 ) : 1988, unaerated cement shall not have an expansion of more than 10(5 for aerated) mm and 0.8% (0.6 for aerated), respectively. Dr. Ravi Kant Mittal, BITS, Pilani SULPHATE RESISTING PORTLAND CEMENT-IS : 12330 - 1988 • Use of sulphate resisting Portland cement is particularly beneficial in such conditions where the concrete is exposed to the risk of deterioration due to sulphate attack, for example, in contact with soils and ground waters containing excessive amounts of sulphates as well as for concrete in sea water or exposed directly to sea coast. Dr. Ravi Kant Mittal, BITS, Pilani Sulphate resisting Portland cement • Sulphate resisting Portland cement is a type of Portland cement in which the amount of tricalcium aluminate is restricted to an acceptably low value (Max.C3A is 5%). • This cement should not be mistaken for supersulphated cement, which is produced by intergrinding or intimately blending a mixture of granulated blast furnace slag, calcium sulphate and a small amount of Portland cement or Portland cement clinker or any other source of lime. Dr. Ravi Kant Mittal, BITS, Pilani • Sulphate resisting Portland cement can be used for structural concrete wherever ordinary Portland cement or Portland pozzolana cement or Portland slag cement are useable under normal conditions. • Use of supersulphated cement is, however, generally restricted where the prevailing temperature is below 40ºC. The later is not recommended for producing steam-cured products. Dr. Ravi Kant Mittal, BITS, Pilani Dr. Ravi Kant Mittal, BITS, Pilani Dr. Ravi Kant Mittal, BITS, Pilani Dr. Ravi Kant Mittal, BITS, Pilani HIGH ALUMINA CEMENT • High alumina cement is usually used when durability against extreme sulphate or acid attack is desirable, and when very early development of strength is required. • About 80% strength is developed at age of 24 hrs even at 6 to 8 hrs. • It has initial set of 4 hrs and final set of about 5hrs • However, this type of cement undergoes conversion or a sudden change of volume under humid and hot environments (> 27°C), thereby leading to loss of strength and disintegration. Dr. Ravi Kant Mittal, BITS, Pilani • Therefore, in tropical countries, such as India high alumina cement should be used with extreme care and caution, both in workmanship as well as in structural design. • High alumina cement should always be used in accordance with the manufacturer’s recommendations. • It should not be mixed with either other hydraulic cements, lime, calcium chloride or with sea water. Dr. Ravi Kant Mittal, BITS, Pilani SUPERSULPHATED CEMENT-IS 6909 : 1990 • Supersulphated cement (SSC) shall be manufactured by intergrinding or intimately blending a mixture of granulated blast furnace slag, calcium sulphate and a small amount of 33 grade ordinary Portland cement, Portland clinker or any other source of lime ( see Note ). • The dry granulated blast furnace slag component of the mixture shall not be less than 70 percent by mass. Dr. Ravi Kant Mittal, BITS, Pilani • When tested by Blaine’s air permeability method given in IS 4031 (Part 2) : 1988, the SSC shall have a fineness (specific surface) of not less than 400 m2/kg; Dr. Ravi Kant Mittal, BITS, Pilani Quick Setting Cement: • Quick setting cement is produced by reducing the percentage of gypsum and adding a small amount of aluminium sulphate during the manufacture of cement. • Finer grinding also adds to quick setting property. This cement starts setting within 5 minutes after adding water and becomes hard mass within 30 minutes. • This cement is used to lay concrete under static or slowly running water. Dr. Ravi Kant Mittal, BITS, Pilani Dr. Ravi Kant Mittal, BITS, Pilani • it is amazing to note the versatile nature of Abram's law as it is applicable even today! mixing water should not be confused with curing water, which is applied on concrete surface only, after the initial setting period of concrete. The absolute min. quantity of W/c ratio required for hydration as per literature is 0.25. But it will make the mix quite stiff. We should use superplastizers, in order to make the mix workable, if we are adopting such water cement ratio. • In practice, we adopt a W/c ratio of 0.40-0.5. Less W/c ratio is often required in high-strength concretes only. Dr. Ravi Kant Mittal, BITS, Pilani