Purchasing Structures in the Construction Industry

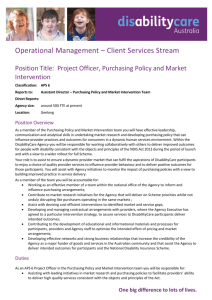

advertisement