NORSOK INDUCTION MOTOR EDS-004 E

advertisement

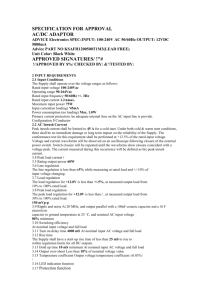

NORSOK INDUCTION MOTOR E-001 DATA SHEET PA112200-M1 Tag nr: Contract no.: Doc. no.: EDS-004 Rev. 4, July 2001 Page 1 of 4 Rev. HNI-05-A-SU-00881 Motor Vendor Data 4.01 Manufacturer LV Motors 4.02 Type M3KP 250 SMA 4 Ex de IIB T4 4.03 Serial No. 3GF10040196 4.04 Degree of Protection IP IP56 4.05 Rated Shaft Power kW 63 4.06 Rated Voltage V 440 4.07 Rated Frequency Hz 60 4.08 Winding Connection Star/Delta VD 4.09 Asynchronous Speed rpm 1775 4.10 Temperature Rise K 80 4.11 Rated Current, In A 102 4.12 Start Current at 1.0 Un % x In (p.u.) 670 4.13 4.14 Start Time at 1.0 Un with driven equipm s 4.15 4.16 Allowable Locked Rotor Time, Cold s 30,0 4.17 Allowable Locked Rotor Time, Hot s 16,7 4.18 Efficiency at 1/1 load % 94,1 / IE2 4.19 Efficiency at 3/4 load % 94,4 4.20 Speed/Torque Curve Ref. No.(Frame <= 315) 4.21 Power Factor at 1/1 load cos Phi 0,86 4.22 Power Factor at 3/4 load cos Phi 0,83 4.23 Starting Power Factor cos Phi 0,41 4.24 Allowable Starting Voltage %Un 80 4.25 No. of Allowable Consecutive Starts, Cold 4.26 No. of Allowable Consecutive Starts, Hot 4.27 te time constant at 1.0 Un s 4.28 te time constant at 0,8Un s Construction 4.29 Insulation Class Stator/Rotor F 4.30 Mounting Arrangement (acc. to IEC 600 IM IM1001, B3(foot) 4.31 Cooling Method IC IC411 self ventilated 4.32 Cooling Water Flow Rate m3/hr NA (continued) Notes 403 Protection class IP56 797 Stainless steel SPM nipples 002 Restamping 448 Draining holes with metal plugs 755 Zinc-coating and epoxy painting according to NORSOK M-501 178 Stainless steel screws 194 lifetime bearings 2Z on DE and NDE 451 Heater, 200-240V 745 Painted grey steel cable flange NORSOK INDUCTION MOTOR DATA SHEET EDS-004 Rev. 4, July 2001 Page 2 of 4 Package no.: Motor Vendor Data Construction (continued) 4.33 Cooling Water Design Pressure bar g 4.34 Cooling Water Leakage Detector Yes / No 4.35 Motor Housing Material 4.36 Terminal Box Material 4.37 Heat Exchanger Material 4.38 Cooling Fan Material 4.39 Frame Size 4.40 Space Heater Voltage V 4.41 Space Heater Power W 4.42 Exp method Pressurisation/Purge 4.43 Instrument Air Flow Rate m3/hr 4.44 Painting Specification Type/ No.of 4.45 Temp. detectors in Bearing Type/ No.of 4.46 Temp. detectors in Windings Mechanical 4.47 Inertia J=GD² /4 kg-m2 4.48 Rated Torque Nm 4.49 Locked Rotor Torque % 4.50 Breakdown Torque % 4.51 Bearing Drive End Type/ No.of 4.52 Bearing Non Drive End Type/ No.of 4.53 Oil Quantity for Bearings l/min 4.54 Type of Vibration Detectors 4.55 Lubrication System 4.56 Sound Pressure Level at 1 meter, with Si Lp dB(A) 4.57 Weight Total kg 4.58 Rotor Weight for Frame Size <= 250 kg 4.59 Shaft d/Double End/Extended Various 4.60 Ex Certificate Issued by 4.61 Ex Certificate Number 4.62 Ex Classification 4.63 Dimensional Drawing No. 4.64 Main power cable entry sizes 4.65 Heating/Cooling time constant (HV moto min Notes NA NA Cast iron Cast iron NA 250 NA 0,72 339 220 290 6315/C3 6313/C3 NA SPM Grease nipples 70 430 93 Std LCIE 00 ATEX 6030 LCIE 00 ATEX 6030 Ex de IIB T4 NA ABB Motors Load Curves Project Location Department/Author 13251-S-987 Customer name Customer ref. Item name Hans Åge Our ref. Fluid Control Services AS Rev/Changed by Date of issue Christer Saving ident Pages A untitled.xls 2(3) N009511 30.06.2010 Product TEFC, 3-phase, squirrel cage induction motor Type/Frame M3KP 250 SMA 4 Ex de IIB T4 Product code 3GKP 252 210-ADG Rated output PN 63 Type of duty S1(IEC) 100% Voltage (V) Frequency (Hz) 440 60 1,00001 kW Current IN (A) Speed (r/min) 102 1775 Power factor at PN 0,86 Efficiency (%) at PN 94 1,4 1,3 1,2 1,1 1 0,9 0,8 0,7 0,6 0,5 0,4 0,3 0,2 0,1 0 0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1 1,1 1,2 P2/Pn Current Efficiency Data based on situation 02.05.2010 All data subject to tolerances in accordance with IEC Cosinus 1,3 1,4 ABB Motors Starting Curves Project Location Department/Author 13251-S-987 Customer name Customer ref. Item name Hans Åge Our ref. Fluid Control Services AS Rev/Changed byDate of issue Christer Saving ident Pages A untitled.xls 3(3) 30.06.2010 Type of product TEFC, 3-phase, squirrel cage induction motor Type/Frame M3KP 250 SMA 4 Ex de IIB T4 Product code 3GKP 252 210-ADG Frequency (Hz) 60 Rated output PN 63 Rated current IN 102 Type of duty S1(IEC) 100% Jmotor (kgm2) 0,72 kW Jload (kgm2) A Voltage (V) 100% 440 Voltage (V) 440V(100%) Tstart/TN 2,2 Tstart/TN 2,2 Speed (r/min) 1775 Starting time (s) Run-up time (s) TN (Nm) 339 Speed (r/min) Speed (r/min) Is/In 6,7 Is/In 6,7 Tmax/Tn 2,9 Tmax/Tn 2,9 Ts/Tn Tload (Nm) Nbr. of consecutive starts 4 8 3,5 7 3 6 2,5 5 2 4 1,5 3 1 2 0,5 1 0 0 250 500 750 1000 1250 1500 1750 Speed (r/min) TMotorUn 440V TMotorU2 440V(100%) IMotorUn 440V IMotorU2 440V(100%) Data based on situation 02.05.2010 All data subject to tolerances in accordance with IEC 0 2000 Is/In N009511 1,00001