Superfloc® Flocculants & Coagulants

advertisement

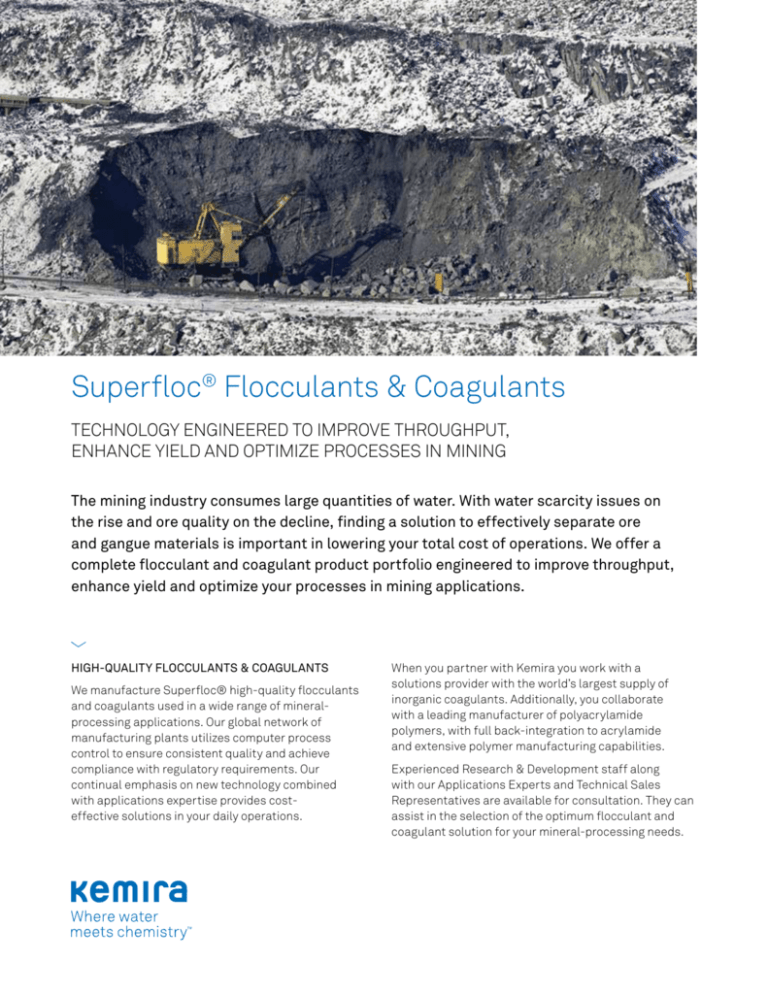

Superfloc® Flocculants & Coagulants TECHNOLOGY ENGINEERED TO IMPROVE THROUGHPUT, ENHANCE YIELD AND OPTIMIZE PROCESSES IN MINING The mining industry consumes large quantities of water. With water scarcity issues on the rise and ore quality on the decline, finding a solution to effectively separate ore and gangue materials is important in lowering your total cost of operations. We offer a complete flocculant and coagulant product portfolio engineered to improve throughput, enhance yield and optimize your processes in mining applications. HIGH-QUALITY FLOCCULANTS & COAGULANTS We manufacture Superfloc® high-quality flocculants and coagulants used in a wide range of mineralprocessing applications. Our global network of manufacturing plants utilizes computer process control to ensure consistent quality and achieve compliance with regulatory requirements. Our continual emphasis on new technology combined with applications expertise provides costeffective solutions in your daily operations. When you partner with Kemira you work with a solutions provider with the world’s largest supply of inorganic coagulants. Additionally, you collaborate with a leading manufacturer of polyacrylamide polymers, with full back-integration to acrylamide and extensive polymer manufacturing capabilities. Experienced Research & Development staff along with our Applications Experts and Technical Sales Representatives are available for consultation. They can assist in the selection of the optimum flocculant and coagulant solution for your mineral-processing needs. Every mineral slurry exhibits a range of particle sizes and charge requirements. Optimum dosages can be achieved and overall performance improved by matching molecular weight and charge to the unique characteristics of the slurry. Our Superfloc line of mineral-processing products covers a wide variety of ionic charges, molecular weights, chemical types and physical forms. FLOCCULANTS AND COAGULANTS FOR MINING APPLICATIONS CATIONIC CATIONIC CATIONIC INORGANIC ANIONIC NONIONIC FLOCCULANT POLYAMINE DADMAC COAGULANT FLOCCULANT FLOCCULANT MINING APPLICATIONS Coal dewatering Sludge dewatering S S S S Phosphate slimes dewatering S Tailings thickening S Tailings rheology modification S Tailings overflow clarification S S S Phosphogypsum filtration S Phosphoric acid clarification S Arsenic/Selenium and other S S S metals removal Cathode smoothing S Alumina washer tray settling Leach plant CCD train S S S S S S clarification Bio leach settling S Flotation concentrate thickening Flotation concentrate S S clarification Oxidative leaching aid S HIGH-QUALITY DRY POWDER FLOCCULANTS Kemira’s Superfloc dry powder flocculants exhibit consistent quality and high active polymer content. Our proprietary sieving process serves to eliminate many dust fines and reduce human exposure and slippery residue in the makedown area. Together with our dry polymer process, which achieves high molecular weights, this often results in a lower overall cost in many mining applications. Powder flocculants are differentiated by molecular weight and charge density. Anionic charge density can range from 0-100%. Molecular weight can range from 1–20 million Daltons and is characterized indirectly by Standard Viscosity measurements. Kemira also produces a full range of cationic dry powder flocculants that can be useful in mining applications. Our products are free of nonylphenol and all nonionic and anionic powder flocculants contain less than 500 ppm of acrylamide residuals. ANIONIC CHARGE (MOLE %) STANDARD FILTRATION VISCOSITY BAYER SETTLING/ WASHING CONCENTRATE CCD TRAINS DEWATERING & TAILS THICKENING SUPERFLOC PRODUCTS N100 None Medium N300 None Medium N300 LMW None Low A-95 Low Medium A-100 Low Medium A-100 HMW Low High A-110 Low Medium A-110 HMW Low High A-120 Medium Medium A-120 HMW Medium High A-120 V Medium Very High A-125 V Medium Very High A-130 Medium Medium A-130 HMW Medium High A-130 LMW Medium Low A-130 V Medium Very High A-137 High Medium A-150 High Medium A-150 HMW High High A-150 LMW High Low A-185 HMW High High A-190 K High Medium S S S S S S S S S S S S S S S S S S S S S S S S S S S S S HIGH-PERFORMANCE EMULSION FLOCCULANTS We manufacture an extensive range of high–performance emulsion flocculants designed to lower your overall cost in many mining applications. Years of manufacturing expertise and control of acrylamide feedstock quality have earned us a reputation for high-quality emulsions. Our proprietary emulsion breaker and carrier systems result in reduced polymer emulsion settling rates and low formation of insoluble material. Emulsion flocculants are differentiated by molecular weight and charge densities. Our Superfloc product line offers hydrolyzed anionic emulsions with exceptionally high molecular weight. Molecular weight can range from 1–60 million Daltons and are characterized indirectly by Standard Viscosity measurements. Kemira also produces a full range of cationic emulsion flocculants that occasionally find application in mining. MINING IS A HIGHLY WATER-INTENSIVE PROCESS—KEMIRA’S EXPERTISE IN WATER QUALITY AND QUANTITY MANAGEMENT IS KEY TO OPERATIONAL EFFICIENCY SUPERFLOC® EMULSION FLOCCULANTS FOR MINING APPLICATIONS ANIONIC CHARGE (MOLE %) STANDARD VISCOSITY FILTRATION BAYER SETTLING/ WASHING DEWATERING CONCENTRATE & TAILS THICKENING SUPERFLOC EMULSION FLOCCULANTS N-1986 None High 4788 Low Low A-1882 Low High A-1849 RS Low High 4812 RS Low High 4814 RS Low Very High A-4325 Medium Very High 4916 Medium High A-1883 RS Medium High A-1820 Medium High A-4330 Medium High 4816 RS Medium Very High A-1204 Medium High A-1885 RSP Medium High 4818 RS High Very High 4842 RS High High 4890 Medium High 4891 Medium High 4892 Medium High 4894 High High 4895 High High 4896 Medium High S S S S S S S S S S S S S S S S S S S S S S S S S We offer a range of liquid organic cationic coagulants. Our polyamines often replace or reduce the use of inorganic coagulants for turbidity reduction in process or wastewater streams. Poly diallydimethyl ammonium chloride (PolyDADMAC) is often used in filtration applications or in conjunction with our flocculant products. PolyDADMAC or cationic polyamines can also be used in combination with our flocculant products to lower overall treatment costs. Our portfolio of coagulants also includes inorganic coagulants in various concentrations in liquid or dry form. ORGANIC COAGULANTS MOLECULAR WEIGHT POLYAMINES Superfloc C-572* Low Superfloc C-4007* Low Superfloc C-573 Low Superfloc C-569* Medium Superfloc C-577 Medium Superfloc C-581 High * North American manufacturing only PHYSICAL STATE BULK VISCOSITY (CPS) Superfloc C-587 Liquid 100–300 Superfloc C-591 Liquid 1600–3200 Superfloc C-592 Liquid 1500–3200 Superfloc C-595 Liquid 8000–13000 POLYDADMAC INORGANIC COAGULANTS KEMIRA ALUMINUM SERIES Aluminum Sulfate Polyaluminum Silica Sulfate Polyaluminum Chloride Aluminum Chlorohydrate Sodium Aluminate KEMIRA IRON SERIES Ferric Sulfate Ferrous Sulfate Ferric Chloride Ferrous Chloride Ferric Chloride Sulfate GLOBAL REACH, LOCAL PRESENCE Kemira’s extensive network of manufacturing and logistics centers around the globe provide cost-effective solutions for many mining applications. No matter where you are in the world, we have a location to serve your needs. EUROPE Our extensive European network of more than 25 manufacturing sites provides you with numerous options for sourcing our products locally. SOUTH AMERICA Kemira has 3 coagulant manufacturing sites in Brazil to serve your needs. AFRICA Our dedicated sales office in Johannesburg, South Africa, along with our warehouse in Ndola, Zambia, are committed to servicing your needs in this fast-growing region. Kemira makes this information available as an accommodation to its customers and it is intended to be solely a guide in customers’ evaluation of the products. You must test our products to determine if they are suitable for your intended uses and applications, as well as from the health, safety and environmental standpoint. You must also instruct your employees, agents, contractors, customers or any third party which may be exposed to the products about all applicable precautions. All information and technical assistance is given without warranty or guarantee and is subject to change without notice. You assume full liability and responsibility for compliance with all information and precautions, and with all laws, statutes, ordinances and regulations of any governmental authority applicable to the processing, transportation, delivery, unloading, discharge, storage, handling, sale and use of each product. Nothing herein shall be construed as a recommendation to use any product in conflict with patents covering any material or its use. Superfloc is a registered trademark of Kemira Oyj or its subsidiaries. Kemira Mining Two Briarlake Plaza 2050 West Sam Houston Pkwy. S. Houston, Texas 77042 +1 832 941 0090 www.kemira.com Africa Johannesburg, South Africa Tel. +27 11 470 2904 North America Houston, Texas Tel. +1 832 941 0090 Europe Frankfurt, Germany Tel. +49 692 561 280 South America São Paulo, Brazil Tel. +49 692 561 280 v . 9.4 NORTH AMERICA We have 10 coagulant manufacturing sites in the USA and Mexico. No matter where you are in the region, we have a local site providing the most cost effective solution for your application.