LOSS ASSESSMENT OF CONSTRUCTION EQUIPMENT

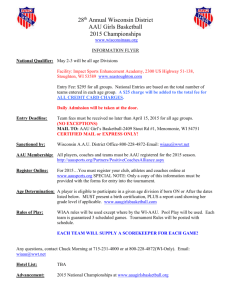

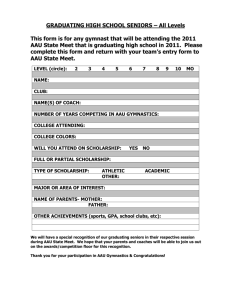

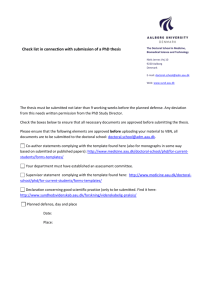

advertisement