quality assurance manual

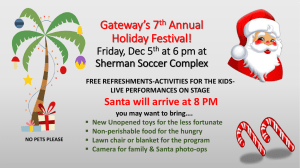

advertisement