Presentation Outline

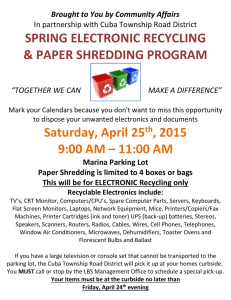

advertisement

Electronics Recycling in the U.S. Market Driven But Constrained Metal Recycling Symposium Convention Hall, ISS, Komaba Campus of Tokyo U. Hosts: METI and JOGMEC Co-Hosts: MIAM, Tohoku U.; RtoS Res. Inst.; ISS, Tokyo U. October 28, 2009 David L. Wagger, Ph.D. Director of Environmental Management Institute of Scrap Recycling Industries Washington, DC, USA Presentation Outline • Overview of U.S. Electronics Recycling • Electronics Sources and Values • Electronics Recycling Technologies • What’s Next for U.S. Electronics Recycling? Institute of Scrap Recycling Industries Trade association of 1,550+ member companies with 2800+ facilities that process, broker & consume scrap metals, paper, plastics, glass, textiles, electronics & rubber U.S. Scrap Industry (2008) • Profit-driven $86 billion industry • 85,000 employees • 150 million tonnes (Mt) of scrap materials handled – 85 Mt iron & steel – 47 Mt paper and paperboard – 5.5 Mt aluminum – 3.2 Mt glass – 2.0 Mt stainless steel – 1.8 Mt copper – 1.8 Mt electronics – 1.2 Mt lead – 1.0 Mt tires (2005) – 0.63 Mt plastic (bottles only, 2007) – 0.42 Mt zinc Overview of U.S. Electronics Recycling • Limited Federal regulation of recycled electronics – General Federal environmental and health & safety (EH&S) regulations still apply to electronics recycling. • Regulation in some (19) states with different approaches – General state EH&S regulations still apply to electronics recycling. • Most reuse and many commodities markets overseas • Complex electronics to be reused/recycled • Net cost (negative value) to responsibly recycle? • Result → Market Driven But Constrained E-Recycling U.S. Electronics Recycling Industry • ~2.8 billion lb (~1.3 Mt) recycled in 2005 – ~65 million units of computer equipment – ~75% computer and consumer equipment • ~1.3 billion lb (~0.6 Mt) of recyclable materials • Quantities expected to double from 2005–2010 based on use and retirement rates – ~1.8 Mt recycled in 2008 (best estimate) Electronics Sources and Values • Commercial, Industrial, Automotive, Defense & Aerospace, Consumer Sectors • Values from Recycling Electronics – Complex “mixture” of materials – Valuable materials to be recovered at low concentrations – Cost of necessary separations may exceed recovered material values. Components in Electronics (wt%) DEVICE VCRs Ferrous Non-Ferrous PWB Plastics Wire Other 45 9 21 23 2 0 1 0 17 82 0 0 Printers 41 5 7 46 1 0 Smoke Detectors 13 2 17 67 1 0 Keyboards 27 0 11 55 7 0 Cell Phones 8 0 40 45 0 7 Computer Monitors 3 1 12 18 4 62 (CRT) Computer CPUs 68 5 16 8 3 0 Flat Panel Displays 25 9 10 24 4 28 Laptops 7 11 16 38 1 27 Computer Mice 5 0 11 52 32 0 Color TVs 6 0 10 22 2 60 (CRT) 11 0 6 72 2 10 Remote Controls Electronic Toys Source: Musson, J. et al., Environ. Sci. Technol. 2006, 40, 2721-2726 Composition of CPU and CRT Material CPU Lead (Pb) CRT Monitor 10.8% Copper (Cu) 5.6% 6.1% Steel (Fe+) 26.9% 9.1% Aluminum (Al) 23.9% Zinc (Zn) 3.7% Precious metals 0.05% Other metals 3.0% HIPS 1.3% ABS 15.2% PPO 9.5% 2.6% Glass 64.1% Source: Kang, H.-Y.; Schoenung, J. Environ. Sci. Technol. 2006, 40, 1672-1680 Metal Content of Desktop/CRT Amount (g) Value Aluminum (Al) 680–960 $2.0–2.80 Antimony (Sb) 2.4–17.5 <$0.10 Arsenic (As) 0.06 - Bismuth (Bi) 0.23 <$0.10 Cadmium (Cd) 3.28 <$0.10 Chromium (Cr) 0.05 <$0.10 1,370–2,640 $12–22 0.39–0.67 $12–20 Element Copper (Cu) Gold (Au) Source: Williams, E. et al. Environ. Sci. Technol. 2008, 42, 6446–6454 Metal Content of Desktop/CRT (2) Amount (g) Value Indium (In) 0.04 <$0.1 Steel (Fe+) 7,300–8,880 $6.40–7.70 Lead (Pb) 620–1,373 $1.70–3.80 Nickel (Ni) 4.5–30 $0.10–0.90 Platinum (Pt) 0.066 $4.30 0.86–2.64 $0.5–1.5 Tin (Sn) 67 $1.40 Zinc (Zn) 21 <$0.1 10,070–13,904 $40.40–59.30 Element Silver (Ag) TOTAL Source: Williams, E. et al. Environ. Sci. Technol. 2008, 42, 6446–6454 Values and Recycling Complex Electronics • The effort needed to recycle a complex product can be conceptually related to a product’s “material mixing”. – “Material Mixing”: H = 䋭㺌 ci log2(ci) where ci = mass concentration of component i in a product (Dahmus, J. B.; Gutowski, T. G.; Environ. Sci. Technol. 2007, 41, 7543-7550) • Products with low material values and high “material mixing” are more likely to have lower recycling rates. – This seems to hold for some recycled electronics. Product Data Analysis Product Material Value H Recycling Rate $10.95 1.30 96% Automobile $358.61 2.22 95% Catalytic Converter $107.54 0.699 95% $34.69 1.67 90% Automobile Battery Refrigerator Newspaper $0.028 0.095 70% Automobile Tire $1.850 0.575 66% Steel Can $0.004 0.060 63% Aluminum Can $0.019 0.001 45% HDPE Bottle (#2) $0.008 0.163 27% PET Bottle (#1) $0.002 0.476 23% Source: Dahmus, J. B.; Gutowski, T. G.; Environ. Sci. Technol. 2007, 41, 7543-7550 Product Data Analysis (2) Product Glass Bottle Material Value Recycling Rate 0.003 20% $17.69 2.36 11% Television $7.05 2.09 11% Laptop $2.79 2.89 11% Aseptic Container $0.005 1.10 6% Cell Phone $0.908 2.91 1% $12.19 2.27 0% Fax Machine $6.43 2.09 0% Coffee Maker $0.535 1.93 0% Cordless Screwdriver $0.130 1.80 0% Desktop Computer Work Chair $0.002 H Source: Dahmus, J. B.; Gutowski, T. G.; Environ. Sci. Technol. 2007, 41, 7543-7550 Electronics Recycling Processes OEMs Users Leasing Cos. TRIAGE As-Is / Repair / Refurbish RESALE Scrap Equipment Disassembly / Recover Parts / Separate Materials RESALE Materials Shred, Grind, Separate, Refine, Smelt, Melt, Pelletize Metals, Glass, Plastics Materials Processors Data Security EDT Digital Shredder Portable data sanitization Courtesy of EDT SCSI Array-100+ Drives Courtesy of Lifespan Refurbishment and Repair Resale Parts & Equipment In addition to recycling and materials recovery, reuse & services are a significant portion of what the electronics recycling industry does. Shredding Technology Produces consistent and well liberated materials at the highest possible processing capacity. Courtesy of SSI Shredding Most common systems are designed to process either 4-6 ton/hr or 10-12 ton/hr. Courtesy of SSI Shredding Vibrating Feeder & Screen Vibrating Feeder receives shredded electronic scrap from an inclined belt conveyor and uses a vertical air column to separate the shredded packing and cardboard from the shredded electronic scrap. Courtesy of Kinergy Corp. The heavy material falls vertically onto a Vibrating Screen, which makes a 3/4" (1.9 cm) separation. Courtesy of Kinergy Corp. Sorting and IR Technology MSS e-Sort •Sorting device that is used in several installations worldwide •Sorts e-scrap after shredding and ferrous/non-ferrous removal •Positively identifies specific plastic resins (ABS, HIPS, PC, etc.) •3,000 kg/hr (after shredding) Courtesy of MSS Mechanical Processing for Pb Recovery Processes glass to prepare for lead recovery, often outside of the U.S. Courtesy of SRS Hard Drive Shredders Q55ED Hard Drive Shredder Q55ED Hard Drive Output Courtesy of SSI Shredding Precious Metals Refining Courtesy of Colt Refining Thermal Processing Unit Courtesy of Colt Refining • Reduces Combustibles, Metallic Output • Handles all types of materials (e.g., manufacturing and electronics scrap) • 550 lb/hr (250 kg/hr) • Environmental Controls – dry scrubber Secondary Precious Metals Refining • Samples batches of e-scrap to determine concentrations and values of precious metals. • Produces small volumes of precious metals. • Consolidates larger volumes to ship to copper smelters outside of the U.S. What’s Next for U.S. Electronics Recycling? • Growing volumes of electronics reaching end-of-life • Growing business interest in recycling electronics • Increased use of electronics recycling standards and certification? – Voluntary or required by law? • How to pay for responsible electronics recycling? – Required by law or market approach? ISRI’s Program for Responsible Electronics Recycling • Third-Party Certification of Two Complementary Standards Implemented Together – Responsible Recycling (R2) Practices • Consensus standard of electronics recycling stakeholders • Voluntary principles and specific practices for electronics recyclers – Recycling Industry Operating Standard (RIOS) • ISRI’s Quality, Environmental, and Health & Safety (QEH&S) Management System Standard for the recycling industry • Continual Improvement in QEH&S performance Questions? Thank you! David L. Wagger, Ph.D. Director of Environmental Management Institute of Scrap Recycling Industries (ISRI) 1-202-662-8533 DavidWagger@isri.org