+ T

advertisement

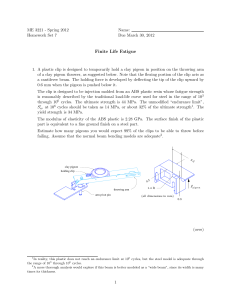

TORSION ! ! Torsion in a Circular Shaft The Torsion Formula ! ! ! ! ! ! Stress Strain Torque Diagram Angle of Twist Power Transmission Statically Indeterminate Torque-Loaded Members 1 Torsion in a Circular Shaft y φ(x) x x deformed plane undeformed plane z The angle of twist φ(x) increases as x increases. 2 The Torsion formula τ τ max = ρ c τ =ρ τ ρ c T τmax τ max c τ max c = constant dA τmax τ c ρ 3 T τ τ dT = ρ (dF ) = ρ (τdA) dF ρ τ dT = ρ [ ρ ( dA c T = ∫( T =( τmax τ c ρ τ max τ max c τ max c c )dA] constant ) ρ 2 dA J ) ∫ ρ 2 dA Tc ) J Tρ τ = J τ max = ( 4 • Solid Shaft τmax T dρ c c 1 J = ∫ ρ dA = ∫ ρ (2πρdρ ) = 2π ∫ ρ 3 dρ = 2π ( ) ρ 4 4 0 0 A 2 c 2 ρ J= π 2 c 0 c4 • Tubular Shaft τmax T τmin co ci J= π 2 4 4 (co − ci ) 5 • Stress strain relationship τ (MPa) G= τ γ γ (rad) 6 • Equilibrium and compatibility condition T1 TA B A LAB T TA di T2 TB C LBC LCD D do TA + T1 TA + T1 - T2 = TB x Equilibrium equation: TA + T1 - T2 - TB = 0 Compatibility equation: φD/A = φB/A + φC/B + φD/C = 0 7 • Torsion and shear stress diagram T1 TA B A C LAB T TA di = 2ci T2 LBC LCD T3 D do = 2co TA + T1 TA + T1 - T2 = T3 + x τ τ AB = (TA )(co ) 4 (π / 2)(co ) τ BC = + (TA + T1 )(co ) 4 (π / 2)(co ) τ CD = (T3 )(co ) 4 4 (π / 2)(co − ci ) x 8 Angle of twist T dφ cdφ γmax Tc ) J Tρ τ = J τ max = ( c dx τ cdφ = γ max dx dφ = γ max dx dφ = τ max dx G= c Gc Tdx dφ = JG φ=∫ Tdx JG = Tcdx JGc φ= TL JG τ τ , γ = G γ γ 9 • Sign Convention φ x x +φ(x) +Τ(x) +φ(x) +Τ(x) Positive sign convention for T and φ 10 • Torsion and angle of twist diagram TA B A LAB T TA di = 2ci T2 T1 C LBC LCD T3 D do = 2co TA + T1 + TA + T1 - T2 = T3 x φC / A = φ B / A + φx/A φB / A (TA )( LAB ) = 4 (π / 2)(co )G (TA + T1 )( LBC ) 4 (π / 2)(co )G φ D / A = φC / A + (T3 )( LCD ) 4 4 (π / 2)(co − ci )G x 11 Example 1 The shaft shown is supported by two bearings and is subjected to three torques. Determine the shear stress developed at points A and B, located at section a-a of the shaft. a 5 kN•m 3 kN•m 2 kN•m a A B z 30 mm y A B 10 mm Section a-a x 12 a 5 kN•m 3 kN•m 2 kN•m 0 0 T (kN•m) a A -2 z 30 mm y A -5 -5 2 kN•m B A B 10 mm Section a-a 47.17 MPa B • Section Property x 47.17 MPa A Top view A 15.72 MPa J = π 4 π c = ( 0 . 03 m ) 4 = 1 . 272 (10 −6 ) m 4 2 2 • Shear Stress τA ( 2 × 10 3 N • m )( 0 . 03 m ) Tc = = = 47 . 17 MPa J 1 . 272 (10 −6 ) m 4 τB Tρ ( 2 × 10 3 N • m )( 0 . 01 m ) = = = 15 . 72 MPa −6 4 J 1 . 272 (10 ) m 13 Example 2 The pipe shown in has an inner diameter of 30 mm and an outer diameter of 60 mm. If its end is tightened against the support at A using a torque wrench at B, determine the shear stress developed in the material at the inner and outer walls along the central portion of the pipe when the 80-N forces are applied to the wrench. A C 80 N di = 30 mm 80 N B do = 60 mm 200 mm 300 mm 14 di = 30 mm y T 80 N do = 60 mm C z ∑M A x = 0; 80 N (0.5 m) − T = 0 T = 40 N•m 80 N • Section Property B 200 mm 300 mm x D 1.006 MPa τD = 1.006 MPa τE = 0.503 MPa E • Internal Torque 40 N•m Section C 0.503 MPa J = π [( 0 . 03 m ) 4 − ( 0 . 015 m ) 4 ] = 1 . 193 (10 −6 ) m 4 2 • Shear Stress - For any point lying on the outside surface of the pipe, ρ = co = 0.03 m τo = Tco 40 N • m(0.03 m) = = 1.006 MPa 1.193(10 −6 ) m 4 J - For any point located on the inside surface, ρ = ci = 0.015 m τi = Tc i 40 N • m ( 0 . 015 m ) = = 0 . 503 MPa J 1 . 193 (10 −6 ) m 4 15 Example 3 A solid steel shaft shown in the figure (G = 80 GPa), having an inner diameter of 30 mm and outer diameter of 60 mm. Draw the quantitative torsion, shear stress and the angle of twist diagram of the shaft. 1.0 m 0.6 m 1200 N•m C di = 30 mm A 800 N•m B do = 60 mm 16 1.0 m 0.6 m 1200 N•m C A B di = 30 mm do = 60 mm T (N•m) JAB = (π/2)(0.034 ) 800 N•m = 1.272 (10-6) m4 JBC = (π/2)(0.034 - 0.0154 ) = 1.193 (10-6) m4 400 400 x (m) + -800 -800 Tc J τ AB = 9.43 + τ (MPa) τ = J = (π/2)(co4 - ci4) 20.12 τ BC = ( 400 N • m )( 0 . 03 m ) = 9 . 43 MPa (1 . 272 × 10 −6 m 4 ) x (m) ( −800 N • m )( 0 . 03 m ) = −20 . 12 MPa (1 . 193 × 10 −6 m 4 ) 17 1.0 m 0.6 m 1200 N•m C A J = (π/2)(co4 - ci4) B di = 30 mm do = 60 mm T (N•m) JAB = (π/2)(0.034 ) 800 N•m = 1.272 (10-6) m4 JBC = (π/2)(0.034 - 0.0154 ) = 1.193 (10-6) m4 400 400 x (m) + φB/A = -800 -800 0.00393 ( 400 )(1 . 0 ) (1 . 272 × 10 −6 )( 80 × 10 9 ) = 0 . 00393 rad = 0 . 23 o φ (rad) φ = TL JG ( −800 )( 0 . 6 ) x (m) φC /B = = −0 . 00503 rad = −0 . 29 o −6 9 (1 . 193 × 10 )( 80 × 10 ) 0.00393 - 0.00503 = -0.0011 18 Example 4 A solid steel shaft shown in the figure(G = 80 GPa), having an inner diameter of 30 mm and outer diameter of 60 mm. Draw the quantitative torque, shear stress and the angle of twist diagrams of the shaft. 400 N•m A B 0.5 m 2800 N•m C 0.4 m di = 30 mm 1500 N•m D 0.6 m do = 60 mm 19 400 N•m TA B A T (N•m) TA 2800 N•m C 0.5 m 0.4 m TA + 400 di = 30 mm 1500 N•m D do = 60 mm 0.6 m TA + 400 + 2800 = 1500 + x (m) Equilibrium equation: TA + 400 + 2800 -1500 = 0 TA = -1700 N•m 20 400 N•m 1700 N•m A T (N•m) B 0.5 m 2800 N•m C 0.4 m JAC = (π/2)(0.034 ) = 1.272 (10-6) m4 di = 30 mm 1500 N•m D do = 60 mm 0.6 m JCD = (π/2)(0.034 - 0.0154 ) = 1.193 (10-6) m4 1500 + - ( −1700 N • m)( 0 . 03 m ) (π / 2 )( 0 . 03 4 ) m 4 = −40 . 08 MPa τ AB = x (m) -1300 -1700 τ (MPa) 37.73 + -40.08 -30.65 ( −1300 N • m )( 0 . 03 m ) (π / 2 )( 0 . 03 4 ) m 4 = −30 . 65 MPa τ BC = x (m) τ CD = (1500 N • m )( 0 . 03 m ) ( π / 2 )( 0 . 03 4 − 0 . 015 4 ) m 4 = 37 . 73 MPa 21 400 N•m 1700 N•m A T (N•m) B 2800 N•m C 0.5 m 0.4 m D do = 60 mm JCD = (π/2)(0.034 - 0.0154 ) = 1.193 (10-6) m4 1500 + - φx/A (rad) 1500 N•m 0.6 m JAC = (π/2)(0.034 ) = 1.272 (10-6) m4 -1700 di = 30 mm ( −1700 )( 0 . 5 ) ( π / 2 )( 0 . 03 4 )( 80 × 10 9 ) = −0 . 00835 rad φB/A = x (m) -1300 ( −1300)(0.4) (π / 2)(0.034 )(80 × 109 ) = −0.00511 rad φC / B = -0.00835 -0.00835 -0.00511 = -0.0135 x (m) -0.00403 (1500)(0.6) (π / 2)(0.034 − 0.0154 )(80 × 109 ) = 0.00943 rad φD / C = 22 The meshed gears T A D L d CD E CD L AB d AB F C rB B rC 23 T T TD A TD = T rC D rB Fz A D E Ez L CD Ex F L AB C rB B F = Fx T rB C B rC F´ = rB T rB rC • Internal torque + Σ MAB = 0: T - F(rB) = 0 T F= rB F'= F = + Σ MCD = 0: TD − T rB T rC = 0 rB TD = rC T rB 24 T TD A D E L CD F L AB • C rB B rB P φB P´ φC P´´ • rC rC Direction of motion • Angle of twist arc PP´ = arc PP´´ φB rB = φC rC φB = rC φC rB 25 T Ez TD = T rC rB D Fz A Start at D → C → B → A rC T ) LCD rB = J CD GCD ( Ex φC / D T F= r B Fx B C T F´ = r B rB rC φ C = φC / D φA rC T ) LCD rC rC rB φ B = φC = [ ] rB rB J CD GCD TLAB φ A/ B = J AB G AB ( φ A = φ A/ B + φB = TLAB J AB G AB rC rC )( T ) LCD rB rB +[ ] J CDGCD ( 26 Example 5a The two solid steel shafts are coupled together using the meshed gears. Determine the shearing stress in two solid and the angle of twist of end A of shaft AB when the torque T = 45 N•m is applied. The upper shaft has a diameter of 17.5 mm and the lower shaft has a diameter of 22.5 mm. Take G = 80 GPa. Shaft AB is free to rotate within bearings E and F, whereas shaft DC is fixed at D. T = 45 N•m A D E 1. 5 m F 2 m C B 150 mm 75 mm 27 • Internal Torque G = 80 MPa. T = 45 N•m Ez T = 45 N•m D A φ =1 7. 5 φ F AB =2 2 m 2. 5 m TD A CD E Fz 1. 5 m m m B 150 mm E Fx C m Ex 75 mm D F rC =75 mm FB=300 N C FC = 300 N rB =150 mm B r 75 mm ( 45 N • m) TD = C T A = 150 mm rB = 22 . 5 N • m • Shearing Stress τ AB = T AB c AB ( 45 N • m )( 0 . 01125 m ) = = 20 . 12 MPa ⇐ 4 J AB ( π / 2 )( 0 . 01125 m ) τ CD = T CDc CD ( 22 . 5 N • m )( 0 . 00875 m ) = = 21 . 38 MPa ⇐ 4 J CD (π / 2 )( 0 . 00875 m ) 28 • Internal Torque G = 80 MPa. T = 45 N•m Ez T = 45 N•m D A CD 2 m φ F AB =2 2. 5 m Fz TD D A φ E TD = T A = =1 7. 5 1. 5 m m m Fx C m B 150 mm Ex E FB F rB =150 mm 75 mm • Angle of twist of end A 75 mm ( 45 N • m ) 150 mm = 22 . 5 N • m rC =75 mm φB φC B φB = C FC rC φ C = 0 . 5φ C rB φA = φA/B + φB = φA/B + 0.5φC T LAB rC rC T LCD TAB LAB rC TCD LCD φA = + ( )[ ] = + ( )[( ) ] J AB G rB rB J CD G J AB G rB J CD G φA = ( 45 N • m )( 2 m ) (. 5 )( 45 N • m )(1 . 5 m ) 0 . 5 [ ] + 4 9 4 9 ( π / 2 )( 0 . 01125 m ) ( 80 × 10 Pa ) ( π / 2 )( 0 . 00875 m ) ( 80 × 10 Pa ) φA = 0.0447 + 0.0229 = 0.0676 rad = 0.0676(180/π) = 3.87o 29 Example 5b The two solid steel shafts are coupled together using the meshed gears. Shaft AB is free to rotate within bearings E and F, whereas shaft DC is fixed at D. The upper shaft has a diameter of 17.5 mm and the lower shaft has a diameter of 22.5 mm. Determine the maximum torque the shaft can have if it is restricted not to twist more than 10o and the allowable shear stress is τallow = 50 MPa. Take G = 80 GPa. T A D E 1. 5 m F 2 m C B 150 mm 75 mm 30 • Internal Torque τallow = 50 MPa. T T Fz D A φ CD E 2 m 2. 5 m TD rC 75 mm T = = 0 . 5T rB 150 mm D A =1 7. 5 φ F AB =2 TD = Ez 1. 5 m m m Fx C m B 150 mm Ex E F rB =150 mm 75 mm FB B rC =75 mm C FC • Allowable Shearing Stress: τ = Tc/J (τAB)allow = 50x106 Pa = (T)(0.01125 m) (π/2)(0.01125 m)4 , T1 = 111.8 N•m (τCD)allow = 50x106 Pa = (0.5T)(0.00875) (π/2)(0.00875 m)4 , T2 = 105.2 N•m 31 G = 80 MPa. Angle of Twist (φ) = 10o T T Fz D A φ CD E φ F AB =2 2 m 2. 5 m TD = Ez TB rC rB T = D A =1 7. 5 1. 5 m m m Ex C m E Fx B 75 mm 150 mm FB F rB =150 mm 75 mm = 0 . 5T 150 mm rC = 75 mm φB φC B ϕB = C FC rC ϕ C = 0.5ϕ C rB • Angle of twist φA = φA/B + φB = φA/B + 0.5φC 10 ( 10 ( T L π T L ) rad = A AB + 0 . 5 [ D CD ] 180 J AB G J CDG ( 0 . 5T )(1 . 5 m) T ( 2 m) π ) rad = 0 . 5 [ ] + 4 9 4 9 180 (π / 2 )( 0 . 01125 m) ( 80 × 10 Pa ) (π / 2 )( 0 . 00875 m) ( 80 × 10 Pa ) T3= 116.15 N•m The maximum torque at A is 105.2 N•m 32 Power transmission T Power = Work performed per unit of time dF dθ ρ P = Power in N•m/s, or W or watts 1 W = 1 N•m/s τ dA c dP = (dF) ρ (dθ)/(dt) =(dT) ω P=Tω ω = Angular velocity, in rad/s P = 2π f T f = Frequency, in Hz Note 1 hp = 745.7 N•m/s 33 Example 6a A solid steel shaft AB is to be used to transmit 5 hp from the motor M to which it is attached. If the shaft rotates at ω = 175 rpm and the steel has an allowable shear stress of τallow = 100 MPa, determine the required diameter of the shaft. 34 Solution 5 hp ω = 175 rpm τallow = 100 MPa φ =? ⇒ τ allow = ⇒ P = Tω 175 rev 2π rad 1 min 745 . 7 N • m/s (5 hp )( ) =T × × 1 hp min 1 rev 60 s T = 203.4 N • m Tc Tc 2T = = J (π / 2)(c 4 ) π (c 3 ) 2T c = πτ allow 1/3 2 ( 203 . 41 N • m ) = 6 2 π (100 × 10 N/m ) = 10 . 90 mm 1/ 3 d = 2c = 2(10.90 mm) = 21.8 mm Select a shaft having a diameter of 22 mm 35 Example 6b A tubular shaft, having an inner diameter of 30 mm and an outer diameter of 42 mm, is to be used to transmit 90 kW of power. Determine the frequency of rotation of the shaft so that the shear stress will not exceed 50 MPa. Solution τ max = 50 × 10 6 N/m 2 = Tc J T ( 0 . 021 m) (π / 2) ( 0 . 021 m) 4 − ( 0 . 015 m ) 4 [ ] T = 538 N • m P = 2π fT 90 × 10 3 N • m/s = 2π f (538 N • m ) f = 26 . 6 Hz 36 Example 7 The two solid steel shaft are coupled together using the meshed gears. Shaft CD connected to the machine which required power of 35 kW at frequency 10 Hz, whereas shaft AB connected to motor to rotate within bearing E. (a) Determine the required power and frequency of motor. (b) If the allowable stress in both shafts must be limited to 200 MPa, determine the size of the diameter required for each shaft. Motor (Input) A E rC = 150 mm B C rB = 75 mm D Machine (Output) Pout = 35 kW fout = 10 Hz 37 Motor (Input) A E rC = 150 mm B C D Machine (Output) rB = 75 mm Pout = 35 kW fout = 10 Hz • Internal torque -Output (Machine) -Input (Motor) FB = FC P = Tw = T (2πf ) TB TC = rB rC 35 × 103 = TD ( 2π × 10) T C= T D = 557 N • m TB = rB 75 TC = (557 N • m ) = 278 . 5 N • m rC 150 38 Motor (Input) A T A = T B = 278 . 5 N • m E rC = 150 mm B C rB = 75 mm allowable stress in both shaft : τallow = 200 MPa D Machine (Output) Pout = 35 kW fout = 10 Hz T C= T D = 557 N • m • (a) The power and frequency of motor fB = rC fC rB = 2f C = 2(10 Hz) = 20 Hz Pinput = T B ( 2π f B ) = ( 278 . 5 N • m)( 2π × 20 Hz) = 35 kW Comment : Pinput = TB (2πf B ) T = ( C )(2π × 2 f C ) = TC ( 2πf ) 2 39 Motor (Input) T A = T B = 278 . 5 N • m A E rC = 150 mm B C D Machine (Output) rB = 75 mm Pout = 35 kW fout = 10 Hz allowable stress in both shaft : τallow = 200 MPa T C= T D = 557 N • m • (b) Allowable diameter for each shaft - Shaft AB (τ AB ) allow = 200 × 10 6 Pa = c AB = [ - Shaft CD TB c AB J AB ( 278 . 5 N • m )c AB 4 ( π / 2 )c AB ( 278 . 5 N • m) 1/ 3 ] (π / 2)( 200 × 10 6 Pa ) TC cCD J CD ( 557 N • m )c CD 200 × 10 6 Pa = 4 ( π / 2 )c CD (τ CD ) allow = c CD = [ = 9 . 6 × 10 −3 m d AB = 19 . 2 × 10 −3 m ≈ 20 mm ⇐ d CD ( 557 N • m ) 1/ 3 ] (π / 2 )( 200 × 10 6 Pa ) = 0 . 0121 m = 0 . 0242 m ≈ 25 mm ⇐ 40 Statically Indeterminate Torque-Loaded Members A TA C LAC L B T TB LBC • Equilibrium equation + Σ Mx = 0: - TA + T + TB = 0 ----------(1) • Compatibility equation: φA/B = φA/C + φB/C = 0 TA LAC TB LBC − =0 JG JG − − − − − −( 2) 41 Example 8 A solid steel shaft shown in the figure(G = 80 GPa), having an inner diameter of 30 mm and outer diameter of 60 mm. (a) Determine the reactions at the fixed supports A and D. (b) Draw the quantitative torsion,shear stress and the angle of twist diagram of the shaft. 500 N•m B di = 30 mm 800 N•m C A D 0.5 m 0.4 m 0.6 m do = 60 mm 42 500 N•m TA B 800 N•m di = 30 mm TD C A D 0.5 m T (N•m) TA 0.4 m 0.6 m TA + 500 do = 60 mm TA + 500 + 800 = TD + x (m) Equilibrium equation: TA + 500 + 800 = TD Compatibility equation: φ D / A = φ B / A + φC / B + φ D / C = 0 TA (0.5) (TA + 500)(0.4) (TA + 1300)(0.6) + =0 + 4 9 4 9 4 4 9 (π / 2)(0.03 )(80 × 10 ) (π / 2)(0.03 )(80 ×10 ) (π / 2)(0.03 − 0.015 )(80 ×10 ) TA = -670.17 N•m, TD = -670.17+500+800 = 629.8 N•m 43 500 N•m 670.17 N•m B 800 N•m 629.83 N•m C A D 0.5 m T (N•m) di = 30 mm 0.4 m JAC = (π/2)(0.034 ) = 1.272 (10-6) m4 0.6 m JCD = (π/2)(0.034 - 0.0154 ) = 1.193 (10-6) m4 629.83 + - τ (MPa) 15.84 + -15.80 ( −670 . 17 N • m)( 0 . 03 m) (π / 2 )( 0 . 03 4 ) m 4 = −15 . 80 MPa τ AB = x (m) -170.17 -670.17 - do = 60 mm -4.01 ( −170 N • m)( 0 . 03 m ) (π / 2 )( 0 . 03 4 ) m 4 = −4 . 01 MPa τ BC = x (m) τ CD = ( 629 . 83 N • m )( 0 . 03 m ) ( π / 2 )( 0 . 03 4 − 0 . 015 4 ) m 4 = 15 . 84 MPa 44 500 N•m 670.17 N•m B 800 N•m 629.83 N•m C A D 0.5 m T (N•m) di = 30 mm 0.4 m JAC = (π/2)(0.034 ) = 1.272 (10-6) m4 0.6 m JCD = (π/2)(0.034 - 0.0154 ) = 1.193 (10-6) m4 629.83 + - do = 60 mm φB/A = ( −670 . 17 )( 0 . 5 ) (π / 2 )( 0 . 03 4 )( 80 × 10 9 ) x (m) = −0 . 00329 rad = −0 . 593 o -170.17 -670.17 φC /B = φx/A (rad) ( −170 . 17 )( 0 . 4 ) (π / 2 )( 0 . 03 4 )( 80 × 10 9 ) o 0 . 000669 rad 0 . 12 = − = − x (m) - 0.00329 (629.83)(0.6) (π / 2)(0.034 − 0.0154 )(80 ×109 ) - 0.00329 - 0.000669 = -0.00396 = 0.00396 rad = 0.713° φD / C = 45 Example 9 The shaft shown is made form a steel tube, which is bonded to a brass core. If a torque of T = 340 N•m is applied at its end, plot the shear-stress distribution along a radial line of its cross sectional area. Take Gst = 80 GPa, Gbr = 35 Gpa. 15 mm 1m 30 mm T = 340 N•m 46 Tbr • Section Properties Tst π π 4 c br = ( 0 . 015 m ) 4 = 7 . 952 × 10 −8 m 4 2 2 π π 4 4 = (c st − c br ) = [( 0 . 03 m ) 4 − ( 0 . 015 m ) 4 ] 2 2 J br = 15 mm 1m = 1.193(10-6) m4 30 mm x J st T = 340 N•m • Equilibrium Tst + Tbr = 340 ----------(1) • Compatibility φ = φst = φbr Tst L T L = br J st Gst J br Gst T st L T br L = (1 . 193 × 10 −6 m 4 )( 80 × 10 9 Pa ) ( 7 . 952 × 10 −8 m 4 )( 35 × 10 9 Pa ) Tst = 34.29 Tbr Solving (1) and (2) , Tst = 330.4 N•m, ----------(2) Tbr = 9.63 N•m 47 1.82 MPa Tst = 330.4 N•m, 4.15 MPa 8.31 MPa Tbr = 9.63 N•m Jbr= 7.952(10-8) m4 , Jst= 1.193(10-6) m4 • Shear Stress Tρ J ( 9 . 63 N • m )( 0 . 015 m ) = = 1 . 82 MPa ( 7 . 952 × 10 −8 m 4 ) τ= 0.015 m A B 0.03 m Shear stress distribution γmax = γB = 1.039(10-4) rad A B (τ br ) max (τ st ) min = (330.4 N • m)(0.015 m) = 4.15 MPa −6 4 (1.193 × 10 m ) (τ st ) max = (330.4 N • m)(0.03 m) = 8.31 MPa (1.193 × 10 −6 m 4 ) • Shear Strain γA = γA = 5.2(10-5) rad γA rA Shear strain distribution = γB rB (τ br ) A (τ st ) A = G br G st =( 1 . 82 MPa −5 ) = 5 . 2 × 10 rad br 3 35 × 10 MPa γ max = γ B = 8 . 31 MPa = 1 . 039 × 10 −4 rad 3 80 × 10 MPa 48