Safe Water for Everyone Using Effective Technology (SWEET)

advertisement

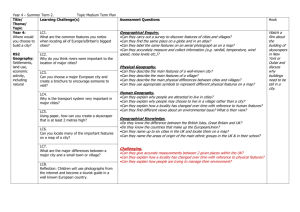

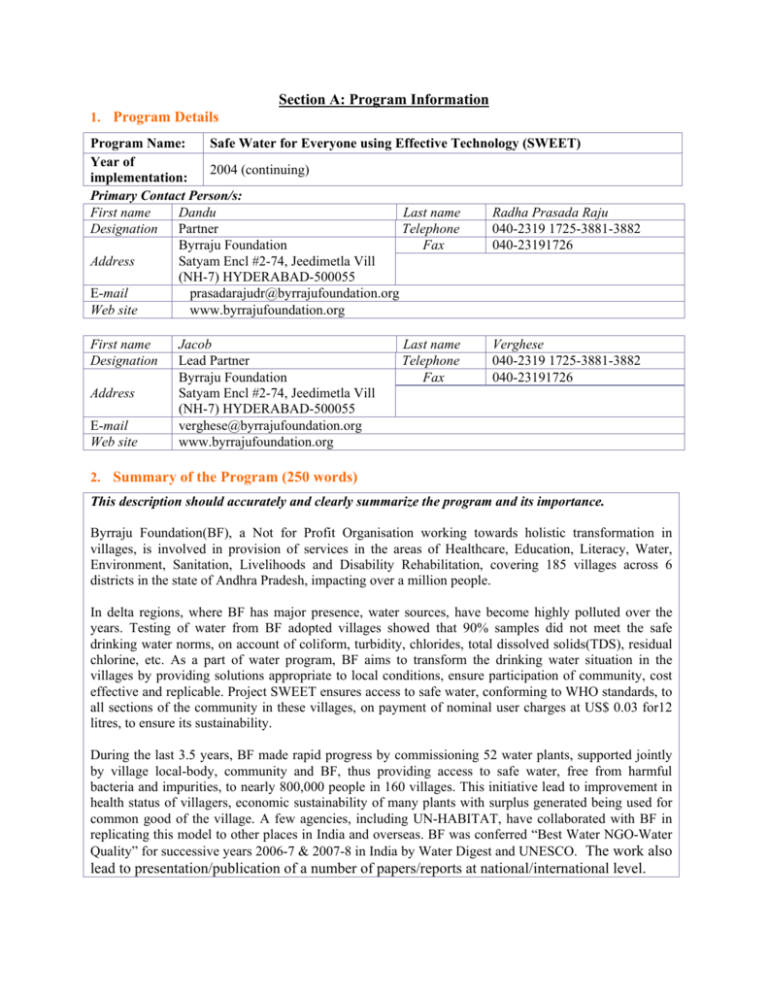

Section A: Program Information 1. Program Details Program Name: Safe Water for Everyone using Effective Technology (SWEET) Year of 2004 (continuing) implementation: Primary Contact Person/s: First name Dandu Last name Radha Prasada Raju Partner 040-2319 1725-3881-3882 Designation Telephone Byrraju Foundation 040-23191726 Fax Satyam Encl #2-74, Jeedimetla Vill Address (NH-7) HYDERABAD-500055 E-mail prasadarajudr@byrrajufoundation.org www.byrrajufoundation.org Web site First name Designation Address E-mail Web site Jacob Lead Partner Byrraju Foundation Satyam Encl #2-74, Jeedimetla Vill (NH-7) HYDERABAD-500055 verghese@byrrajufoundation.org www.byrrajufoundation.org Last name Telephone Fax Verghese 040-2319 1725-3881-3882 040-23191726 2. Summary of the Program (250 words) This description should accurately and clearly summarize the program and its importance. Byrraju Foundation(BF), a Not for Profit Organisation working towards holistic transformation in villages, is involved in provision of services in the areas of Healthcare, Education, Literacy, Water, Environment, Sanitation, Livelihoods and Disability Rehabilitation, covering 185 villages across 6 districts in the state of Andhra Pradesh, impacting over a million people. In delta regions, where BF has major presence, water sources, have become highly polluted over the years. Testing of water from BF adopted villages showed that 90% samples did not meet the safe drinking water norms, on account of coliform, turbidity, chlorides, total dissolved solids(TDS), residual chlorine, etc. As a part of water program, BF aims to transform the drinking water situation in the villages by providing solutions appropriate to local conditions, ensure participation of community, cost effective and replicable. Project SWEET ensures access to safe water, conforming to WHO standards, to all sections of the community in these villages, on payment of nominal user charges at US$ 0.03 for12 litres, to ensure its sustainability. During the last 3.5 years, BF made rapid progress by commissioning 52 water plants, supported jointly by village local-body, community and BF, thus providing access to safe water, free from harmful bacteria and impurities, to nearly 800,000 people in 160 villages. This initiative lead to improvement in health status of villagers, economic sustainability of many plants with surplus generated being used for common good of the village. A few agencies, including UN-HABITAT, have collaborated with BF in replicating this model to other places in India and overseas. BF was conferred “Best Water NGO-Water Quality” for successive years 2006-7 & 2007-8 in India by Water Digest and UNESCO. The work also lead to presentation/publication of a number of papers/reports at national/international level. 3. Social Impact of the Program Describe the overall context and severity of the issue that the program addresses. • What facet of development is this program addressing? • What are the key characteristics of the problem addressed and of the overall environment? • Is it a fundamental aspect of poverty alleviation and development in the short and long term? How does the institution assess this impact? Survey along the irrigation canals revealed that water sources have been polluted due to various contaminants. Tests conducted on water, supplied through Rural Water Supply, in villages adopted by BF, showed that 138 out of 159 villages, i.e., 79%, with surface water as the main source, did not conform to the safe water norms, on account of Coliform, Turbidity, Chlorides, TDS, etc,. If the need for maintaining 0.2 ppm of residual Chlorine is also considered, 143 of them, viz, 90%, failed. In upland areas, which depend on ground water, 16 out of 20 villages have TDS in excess of permissible limit of 500 ppm. Ten of these villages also have fluorides beyond the norm of 1 ppm. Realizing this situation, BF, on interacting with community and local-bodies, launched Project SWEET to address the problem. Though, the Project does not directly address income generation of the population being catered to, consumption of safe water yielded two significant outcomes, viz, (a) by improving health condition, there is reduction in expenditure on treatment of water borne diseases, which reportedly account for 80% of ailments, resulting in saving of income, and (b) with the improvement in health, productive time is enlarged. These two have helped the people in enhancing better living and purchasing capacity. 4. Detailed Description of the Program Describe the overall goal(s) of the program. • Describe the program design and methods. • How does the program present an innovative approach to addressing the issue? Highlight the innovative features of the program. To mitigate people’s sufferings due to consumption of un-safe water, BF has conceived Project SWEET, with an aim to supply drinking water to 100% people in all the adopted villages, at a cost that the poorest of the poor can also afford. In providing solution, the key factors considered are (a) output quality as per prescribed norms, (b) scalable technology and sustainable processes, and (c) community participation. The solution involves setting up of community-based water treatment system at the village level. The raw water goes through various steps of purification-coagulation for settling suspended matter, chlorine dosing for killing the bacteria, pressure sand filtration for screening fine particles, activated carbon filtration for removal of smell and odour, micron filtration for removal of extra fine particles and ultraviolet sterilization for inactivating the residual bacteria. In case the source water has high TDS (in excess of 500 ppm), the outlet from micron filters is passed through Reverse Osmosis (RO) membrane at highpressure for removing dissolved solids, including bacteria. This water is sent through an ozonator, to maintain oxygen level and improve shelf life. The processed water, before filling in the cans, is subjected to another stage of ultraviolet radiation to arrest bacteria, if any, that may generate in the storage tank. The system, effectively eliminating impurities and harmful bacteria, produces 1000-2000 liters an hour. The plant design was evolved in-house with the team consisting of Dr-Ing VS Raju(formerly Professor of Civil Engineering in Indian Institute of Technology(IIT)-Madras and Director of IIT Delhi, with over 4 decades of experience in teaching, research and consultancy) and Dr DR Prasada Raju (a mechanical engineer with 28 years of experience in design, project management and promotion of research and development programs). Discussions were held with experts in IIT-Madras, Water Systems International Limited, Chennai and National Environmental Engineering Research Institute, Nagpur, on technological interventions for reducing the cost of plant and operational expenses. The concepts and technology Global Development Network Japanese Award for the Most Innovative Development Project 2 proposed for treating water have been reviewed for effecting changes, where necessary. BF set up plants, on these lines, initially one for every 3 villages, subject to economies of scale. To place health at the center of the broader development agenda is a conscious strategy adopted by BF, as this is an area where beneficiary receptiveness is quite high. Credibility established through the success of health activities did translate into goodwill for BF’s other initiatives, including drinking water. When the water plants were conceptualized, members of Gram Vikasa Samithi (Village Development Committee) (GVS), a body of volunteers representing different sections of community (including women and youth), formed to oversee implementation of activities taken up by BF, were involved in the decision making process. They play a key role in mobilizing community support and take up regulatory issues with the local authorities. The project, a public-private partnership model, involving Gram Panchayat(village local body), GVS and BF, has a clear role clarity on the following aspects: Gram Panchayat • Allotment of Land (free of cost) • Permission to draw water from main source • Obtain power connection at concessional tariff • • • • Gram Vikasa Samithi Collection of contribution from community and supervision on construction of building Identification of youth from village for operation of plant Oversee operation of plant and distribution of water Offer creative solutions to increase utilization of water • • • • Byrraju Foundation Awareness creation, mobilization of resources, develop criteria and identification for eligibility Identify suppliers of equipment and its procurement and train operators Process framework for sustenance and maintenance of project; assess, document and disseminate the impact Quality monitoring and assurance In this back drop, project SWEET is unique and innovative, owing to the following features: Affordability: It delivers drinking water meeting WHO standards available at US$ 0.003 per liter to 100% of the population in the villages covered by the project. Technology for rural poor: It takes advanced technology for producing safe drinking water to an untapped rural market. Innovative practices: Agreement with local government institution for use of raw water and supply of purified water within and couple of neighboring villages. People centered approach: Poor friendly pricing, door delivery and providing livelihoods to men and women groups within the villages and above all improved quality of life. Encouragement of behavioral change: Opinion leaders from within the community can create awareness on benefits of safe drinking water and how to use it judiciously. Flexible timings of operation: In villages, availability of single-phase and 3-phase power is restricted to 12-16 hours and 6-7 hours, respectively, in a day. To overcome the power outages, plant operation is staggered over the day and working hours of the staff are adjusted accordingly. Maintenance of plant: 100% standby for all main components and adequate stocks of consumables are always ensured. Maintenance contract is entered into with plant supplier to take care of both preventive and break-down maintenance, by locating a maintenance team for every 5 plants. Quality assurance: Quality check is carried out at both plant level for key parameters(bacteria, TDS, etc., on daily basis) and in a well-equipped Laboratory for detailed analysis(on weekly basis). Sustainability: It is ensured through collection of user charges for delivery of product water. Ozonation: Use of ozone and hydrogen peroxide controls natural organic chemicals, pesticides, etc., and improves shelf life of water. Low cost and reusable vial: H2S vial, used for detecting harmful bacteria in water, was developed inhouse, which costs US$ 0.05 (17% market price). The glassware of the vial is reused for further testing. Global Development Network Japanese Award for the Most Innovative Development Project 3 Environmental Benefits: Project SWEET addresses environmental issues through treatment of contaminated water thus providing safe water for drinking purpose. The refuse and wash water, after purification (usually 4% of total production in case of conventional process and up to 50% in case of RO system), is recycled to charge the ground water table or used for irrigation purpose or in its absence let into drain. In RO process, the reject water is used for irrigation (lawns, kitchen garden, etc). The HDPE food-grade can, safe for distribution and storing water lasts a year, and glassware for H2S vial is recycled without posing problem of degrading the environment. Consumption of safe water improved health leading to reduced expenditure incurred otherwise towards treatment of water borne diseases, reportedly accounting for 80% of ailments, thus enlarging productive time. Consumption of safe water will lead to children growing in a healthy environment and community contributes to the well being of its own people. Quality Assurance and Control: Quality of product water is tested everyday at plant for key parameters, like, bacteria, TDS, residual chlorine, pH, etc. Elaborate tests are carried out in a well-equipped Laboratory in a Degree College for these as well as other chemical and physical parameters on weekly/fortnightly basis. In addition, the presence of crucial parameters, like fluorides and nitrates, which require costly and sophisticated apparatus with high level of skill, is analyzed in other laboratories accredited by National Board of Accreditation for Laboratories and Test Houses(NABL) on six-monthly basis. Based on these test results, it has been observed that the water samples passed quality tests, 99.8% times across all the plants, during the last two years, against the a set target of 99.5%. 5. Impact/Outcomes of the Program Discuss in detail the outcomes and achievements of the program to date. • How has the program achieved its targeted outcomes? • Capacity Building: Is one of the fundamental goals of the project to help people help themselves? Has the targeted population demonstrated an increase in skill development or an increased willingness to learn new skills? Access to clean drinking water has transformed the village landscape in many ways. The impact is quite perceptible among the children, with reduction in absenteeism in attending School due to sickness and improved learning, as water from these plants is supplied free of cost to the schools and health center. The initiative benefited the community in the following aspects: • 52 water plants were set up (as on Jan 1, 2008). • Access to safe drinking water provided to nearly 160 villages benefiting about 800,000 people. • In the participant villages, about 46% on regular basis and 10-15% on and off consume BF water. • Over 200 million litres of water, free from harmful bacteria and physical/chemical impurities, distributed to the poorer sections of the society. • Number of patients visiting BF health clinic in the villages with access to BF water dropped by 15-30% and the expenditure on medicines declined by 10-22% after consumption of BF water, leading to improved quality of life, attributed mainly due to relief from water borne diseases. • After stabilization period and ensuring break-even, operation of plant is handed over to GVS. As on date, 6 plants are already running so with BF taking care of quality issues and technical guidance, etc. • The surplus generated from the plant is used for common good of the village. • Provided livelihood opportunities to nearly 260 youth within villages. Capacity building of the community in identification and solving of problem by participation in a systematic manner and enhancing operational capabilities within the communities. To facilitate this, BF Global Development Network Japanese Award for the Most Innovative Development Project 4 organizes regular programs imparting skills to the community on self-reliance in setting up and meeting operational expenses for running rural services through user charges and/or mobilization of funds and also leadership development for efficient and systematic implementation of delivery modules. For operation of plant, unemployed youth, identified by GVS, are imparted adequate training on various aspects, such as, technical aspects, operation, hygiene and cleanliness, testing, account keeping, marketing, simple repairs, distribution of water, etc. Initially, BF through its field staff, oversees operation and maintenance of water plant. After stabilizing the unit, creating awareness on drinking safe water, planning of logistics for delivery of water and ironing out any deficiencies in the operational and distribution matters, running of the plant is handed over to GVS or an entrepreneur or a self-help group, with first option given to plant operators to form as entrepreneur of SHG. BF has already handed over maintenance of 9 plants through local entrepreneurs under the close supervision of GVS and more are in the pipeline to be handled so. The surplus generated is used for common good of the village. 6. Discuss the Specific Scope of the Program for Replication/Scaling Describe how the program has potential for replication in other countries, regions, sectors, and cultures. Discuss in detail how the additional funds provided by this award would be used in either replicating or scaling up the program. • What activities are to be undertaken with this award and the methodology for these and what outputs they will deliver as a means of achieving project outcomes. • What are the implications and costs of replicating/scaling the program up? This project has a tremendous potential for replication since it ensures freedom from water borne diseases. Consumption of safe water will lead to children growing in a healthy environment and the community contributes to the well being of its own people. The program can be easily replicated in other places because (a) The technical design of the plant, the process and the choice of equipment are very sound (b) The recurring cost of running the plant is not a burden on the donor/sponsor, and (c) Willing participation of the community is possible. The model, with incipient potential of generating income, is replicable across other regions/countries in a sustainable manner. BF guided/is guiding the following agencies in implementing such plants which prove this point: a. Dow Chemical Intl Ltd&Suven Life Sciences Ltd, Dasiagudem (Nalgonda District, AP)(Nov’06) b. Dow Chemicals Intl Ltd, Solipet (Nalgonda District) (Oct’07) c. Gavarasana Foundation, Gollaprolu (East Godavari District, AP)(May’07) d. Nayudamma Foundation, Chimidithapadu (Prakasam District, AP)(Oct’07) e. Centre for Water and Sanitation, Hyderabad: Gajula Malkapaur (Nalgonda District) (Jul’07) and Railapur (Ranga Reddy District, AP) (Aug’07) f. UN-HABITAT, Nairobi: BF signed agreement of cooperation, for commissioning four plants, one each in Indore (Jan’08), Jabalpur(to be operational in Feb/Mar’08) (both in Indian State of Madhya Pradesh), Laos PDR and Uganda. g. CCF India, Bangalore: 3 plants, one each at Kollegal, Gulbarga and outskirts of Bangalore (Tibetian settlements in the State of Karnataka, India) (likely to be operational by Feb/Mar’08) h. NCL Industries Ltd: 2 plants, one each in Kodada (Nalgonda Dist) and Kondapalli (Krishna Dist) (to be operational in Feb’08) BF has so far set up 52 plants, providing access to safe water to 160 out of 185 participant villages. This facility is proposed to be extended to remaining 25 villages. Another 15 villages are likely to added to the present list by Mar 2008. So, it is planned to put up 10-13 plants, supported jointly by community and BF, in 3:1 to 1:1 ratio to cover all the 40 villages during the next 3-5 months. Since a few villages are unable to raise complete share of their funds, it is intended to avail the GND’s Award money to fill in the gap, where necessary, thus providing access to safe drinking water to 200,000 people, covering all the participant villages by June 2008. Global Development Network Japanese Award for the Most Innovative Development Project 5 7. Cost Effectiveness of the Program. Discuss the impact/outcomes of the program in comparison to the cost of the program. • Has the program cost more or less than planned? Compare the program’s progress against its costing schedule. • Were the program’s outputs and outcomes achieved in the most cost-effective way? Could they have been achieved with lower associated costs? The Equipment costs US$ 7320 in case of conventional (non-RO) process and US$ 9760 for RO System. In addition, construction of building (500 sq feet) costs US$ 8600. The economics of operation of plant, which is result of improvement over the years, is depicted below: No Item Non-RO RO 1 Production of water per day in liters (average-minimum) 5500 5500 2 Distribution of water per day in liters (average-minimum) 5000 5000 3 User Charges in US$ 5625 5625 4 Annual Recurring costs in US$ -Manpower: 1800 1800 -Power, Consumables, Maintenance charges, etc 1355 2015 -Depreciation @ 10% of the cost of equipment 750 1000 TOTAL 3905 4815 5 SURPLUS per year 1720 810 The above cost schedule has been maintained in installation and operation of all the plants with an emphasis on possible reduction of both fixed and variable costs due to better knowledge management and process improvement. With increased levels of distribution, the revenue generated will proportionately go up, thus allowing incremental amount of surplus. Each plant would attain operational break-even point within 4-6 months of going on stream. It is also evident from the charges of US$ 0.003 collected for 12litres of water, which is most affordable and acceptable by the community. When compared to other brands of packaged water, it works out roughly to 1/100th of the market rates. 8. Additional Sources of Support. How is the program currently funded? If other sources of funding currently exist for the expansion/ scaling up process, provide details on the sources, amounts and size of contribution • Is the program already receiving funding or partial funding and what is the likelihood of it being funded elsewhere? • Is the planned program expansion already receiving funding and what is the likelihood of it being funded elsewhere? Water Plant is put up by inviting partners after a village comes forward. The external funding of the Project is case specific. The first phase of 7 plants, each costing US$ 16000, set up during July-Dec 2004, was funded by a grant of US$ 20000 from British Petroleum, US$ 15000 from the BF and the balance from the Community with village local-body allotting land (free of cost). In all for 52 plants, funding was provided by Community: US$ 595900, BF: US$ 278300, Donors: US$ 79700 (including US$ 45000 from Non-resident Indians). For future plants, BF, besides active involvement of the community, is looking for prospective partners/donors limiting the role of BF to facilitation and guidance. 9. Sustainability Briefly discuss the sustainability of the program and its activities. • How likely are the operations of the program to continue over time and what are are the specific plans to ensure it? • To what extent will the benefits arising from the activities of the program likely to continue after Global Development Network Japanese Award for the Most Innovative Development Project 6 the activities have been completed? Project SWEET is designed as a financially sustainable model, involving community in the investment. The plant costs, US$ 16250 in case of conventional process and US$ 18750 for RO System, are shared by the community and BF. It believes that, in the absence of an effective taxation mechanism, the villages need to generate their own economic surplus to achieve financial sustainability for social initiatives. Traditionally, issue of enhancing rural access to safe drinking water has been approached with subsidy driven models. The key factors required to realize rural India’s economic potential are (a) Financial deepening (presently only 21% of rural India has access to formal financial markets) (b) Market access, the crucial link to generate revenues and sustain growth, and (c) Knowledge management, the exposure to modern systems and process driven approach. SWEET connects the formal financial markets with rural economy thus becoming a working evidence for link between social capital and financial intermediation. BF would facilitate economic sustainability of the villages so that the social leadership can implement holistic transformation programs effectively. Our strategy in this regard has three aspects, viz, (a) Bring down the cost of delivering services using best practices and technology, (b) Increase the incomes of villagers through livelihood interventions, and (c) Pool common economic surplus, through Village Level Productive Enterprises, to sustain services. Water Plant is a profit-oriented enterprise, a part of the surplus generated is ploughed back into the village for implementing various activities. Water Plant can also be run as an enterprise model, which breaks even at distribution of 4000-4500 liters daily, through supply of 12 litres to each family, within 3 months of going on stream. Those running the Plant can manage it by linking user charges to the volume of water distributed. Unemployed youth from village are provided training for operating the plant. One helper is engaged, for delivering 150 water cans (1800 litres), by rickshaw at the door-step of consumer within the village, on charging US$ 0.01-0.03 per can, in a day. A van is deployed for carrying water cans to neighboring villages. In all, employment for 5-6 persons is ensured per each plant within the village. 10. Ownership and Management Details of the Programs Provide a brief description of the organization's history, ownership and management details. Please attach CVs with the application. BF, with a mission to create a world-class platform for sustainable rural transformation, aims to improve quality of life in villages. It has embraced 6-Sigma as the tool for designing new processes and making improvements in the existing processes by involving people, applying knowledge and making things happen. Since its inception in July 2001, BF made rapid strides in implementing holistic rural transformation programs in 185 villages, with water as one of the core modules, as highlighted below: Healthcare: BF established Health Centre in each adopted village providing primary healthcare, through deployment of 68 doctors having 2-3 hours of presence in each village and 200 trained health workers residing full-time within the assigned village, and administering 20 basic drugs meeting 80% of the requirements of patients. Facilities for secondary care are provided through network of alliances. Identification and treatment of villagers for Hypertension, Diabetes, mobile facility for dental and eye care, medical checkup for school children, HIV/AIDS awareness Programs (jointly with Government & Gates Foundation) and joint research with George Inst of Intl Health, Sydney for low cost solutions for cardio-vascular diseases, are some of the other initiatives. Disability Rehabilitation: It provides comprehensive access, rehabilitation and empowerment of persons with disabilities (PWD) through community based rehabilitation mode. In alliance with various organizations, BF focuses on transformation rather than transaction through early intervention, education, livelihood programs, provision of assistive/augmentative devices, creating enabling environment, etc, to cover 100% PWDs. Needs assessment for various kinds of disability in 163 villages was carried out covering 10,600 PWDs. With the support of government, aids and appliances were provided to nearly 400 such persons so far. Global Development Network Japanese Award for the Most Innovative Development Project 7 Education: Access to quality education is ensured by improving infrastructure, collaborations with similar agencies and effective parent-teacher and school–community interactions. A School Improvement Plan for each school is developed and monitored through Model School Composite Index in 260 government run schools benefiting nearly 82,000 children. 78 KidSmart (computer-based early learning) centers, supported by IBM, and 77 high schools with Virtual Lab Programs, were set up to benefit the students. IBM conferred ‘Most Outstanding Achievement for Innovative Rural Education Award’ to BF in the year 2006. Adult Literacy: Its aim is to ensure total literacy, as per UNESCO norms. Apart from imparting literacy skills, it provides continuing education and also train neo-literates in appropriate livelihood skills. So far 55,000 people, mostly women, in 160 villages were enrolled, out of which 42,000 people in 135 villages, with 100% conversion, have become neo-literates. Sanitation and Waste Management: The sanitation program aims to bring in a self-owned, manageable sanitation facility for each family the below poverty line. With major contribution from government, 44,500 Individual Sanitary Latrines were built and additional 40,000 ISLs are being facilitated to achieve 100% satisfaction soon. Through continuous awareness programmes, 95% usage of the facility is ensured. 10 villages were awarded ‘Nirmal Gram Puraskar’ by Government of India for 100% sanitation and its usage. 170 villages are provided with waste removal systems and 80 vermi-culture units were setup to convert organic waste from the households. Livelihoods: This aims to bring people from below the poverty line to the desired prosperity level, meaning an income of Rs 3500(US$ 850) per month for a family of four. In partnership with relevant agencies, unemployed youth are trained in villages itself to improve skills thereby ensuring income for them through self-employment, wage employment or increased productivity. 2500 youth received training in various trades in the last 3.5 years, out of which 95% were employed. Besides, 9000 women, trained in tailoring, embroidery, lace-making, fabric painting, handicrafts, etc. were linked up with market and also facilitated establishment of units providing them work within the villages. Rural BPO: In an effort to generate livelihoods within villages, Rural BPOs, named GramIT, have been established, offering the educated youth business process outsourcing services. Selected youth are trained in IT skills, soft skills, general awareness, etc, are employed in GramIT centers that are engaged in the back office processes of Indian corporates, government, etc. Presently, 5 GramIT centers, employing 100 youth each in centre, are operational handling a few jobs of overseas customers as well. This concept and initiative won ‘Asian CSR Award for Poverty Alleviation’ conferred by in the year 2007. ICT Centers: It provides a virtual platform for the villagers to interact with experts from various disciplines, i.e., health(tele-medicine), education(including spoken English and soft skills), agriculture, livelihood training, etc. 53 ICT Centers, named Ashwini, partnered by UNDP/National Institute of Smart Governance, Media Lab Asia, National Association of Software and Service Companies(NASSCOM) Foundation, Indian Space Research Organization and village community, are in operation. This concept won ‘India Development Market Place Award’ of World Bank for the year 2004-05. Agri Services: Farmers are advised on the right and timely practices to be adopted for healthy growth of plant. They are also encouraged on use organic manure, bio-pesticides, adoption of mass rodent control practice, reduced water usage, etc. Using Ashwini, advice of experts from Agriculture University and Research/Extension Centers, is conveyed to farmer for taking curative steps and remedial measures. Community Involvement: BF’s vision that all processes are owned, managed and led by the community is facilitated through Gram Vikasa Samithi in every village, having 9 members (with 9 alternates), each one looking after a particular initiative. GVS is encouraged to develop its own Vision for village’s selfreliance, which determines priorities as seen by the community, so as to get what it needs. This system driven and metric oriented approach ensures identification of roles, responsibilities, dependencies and also in estimation of effort and costs required to ground the facility. Team Foundation: Professionals drawn from the corporates, social sector, academia and government, who are led by passion and creativity, lead BF’s activities. A few prominent personalities, to name, are Shri B Ramalinga Raju (Founder and Chairman of Satyam Computer Services Ltd and Chairman of Global Development Network Japanese Award for the Most Innovative Development Project 8 Board of Trustees of BF), Mr Verghese Jacob (formerly Vice President-Godrej), Dr-Ing VS Raju (formerly Professor of Civil Engg at IIT-Madras and Director-IIT Delhi), Dr K Rama Raju (formerly Professor of Urology in Osmania Medical College), Prof K Prathap Reddy (formerly Director, Institute of Rural Management, Anand), Prof KVS Rama Rao (formerly Professor of Physics and Dean, IIT-Madras), Commodore (Retd) Prof Harsh Bhargav (formerly with Indian Navy, Defense Research and Development Organization and ICFAI Business School) and Dr L Govinda Rao (formerly Director of National Institute for Mentally Handicapped). To review the progress and advise on various issues of relevance, a Module Advisory Board for each of the major programs is constituted. The members of this Board are domain experts and noted social scientists from academia, government, corporates and NGOs, within as well as outside the country. They meet (even virtually) every 3-6 months and advise on future course of action that the Foundation can initiate in respective fields to achieve rural transformation. Section B: Budget 1. Current Annual Budget: (Only for Water Module) Program operators are required to provide below the current annual budget of the program. Item Details Cost (US $) Total(US$) Personnel International Professionals Prof VS Raju National Professionals Dr DR Prasada Raju Dr K Varahala Raju Consultants Administrative Personnel Nil PBV Satyanarayana KSR Subba Raju Others ( please specify) Travel (indicate line items) Contractual Services (indicate line items) Nil Total Personnel 21000 4000 Nil 3000 3000 Nil 31000 $ Train/air travel in India Total Travel 2500 2500 $ 0$ Nil Total Contractual Services Meetings and training Fellowships Nil Seminars, workshops, training Workshop on Drinking Water Others (please specify) Documentation Total Meetings and training Supplies (indicate line items) Honorary Chemicals, H2S vials, etc Total Supplies Nil 0$ Nil 2000 2000 4000 $ 1000 1000 $ Equipment Global Development Network Japanese Award for the Most Innovative Development Project 9 IT Equipment Transport Equipment Other Acquisitions Nil Nil Water Plants: Equipment Total Equipment Other Costs Rental Institutional Overheads Hiring of taxi, vehicle System support, etc Total Other Costs Nil Nil 72000 72000 $ 500 2000 2500 $ Total Direct Costs Indirect Costs 104000 $ 6500 $ Total Project Cost 2. Budget Proposal 110500 $ Program Operators are required to provide a budget proposal to show how the prize money would b used in the table provided below and a brief narrative. The budget must clearly outline and link the use of funds to the program expansion/replication plans described in the earlier section (Section A). All expected costs including travel and equipment must be included. Item Details Cost (US $) Total (US $) Personnel International Professionals National Professionals Consultants Administrative Personnel Others ( please specify) Nil Nil Nil Nil Nil Total Personnel Nil Nil Nil Nil Nil Nil Nil Travel (indicate line items) 0$ Total Travel Contractual Services (indicate line items) 0$ Nil Total Contractual Services Meetings and training Fellowships Nil Seminars, workshops, training Workshop on Drinking Water Others (please specify) Nil Total Meetings and training Supplies (indicate line items) 0$ Nil Total Supplies Nil 0$ Nil 3000 Nil 3000 $ Nil 0$ Equipment Global Development Network Japanese Award for the Most Innovative Development Project 10 IT Equipment Transport Equipment Other Acquisitions Other Costs Rental Institutional Overheads Nil Nil Water Plant Equipment Total Equipment Nil Nil Total Other Costs Nil Nil 27000 27000 $ Nil Nil 0$ Total Direct Costs Indirect Costs (15%) 27000 $ 3000 $ Total Project Cost 30000 $ GDN Award money will be used for meeting partial cost of Equipment to set up 10 water purification plants. The cost sharing per each plant by various stake-holders is proposed on the following lines: 1. Land (1500 Sq feet) : free of cost by Gram Panchayat 2. Construction of building (500 Sq Feet) : US$ 8540 by community(GVS) 3. Equipment : US$ 2440 by community (incl Non-resident villagers/Indians) US$ 2440 by BF US$ 2440 by GDN (Award Money) Going by the above proposition, GDN’s Award money facilitates setting up of 11 water plants, in as many villages, providing access to nearly 165,000 people in about 33 villages. BF ensures that GVS pools up required amount for construction of building and also deposits community’s share for equipment(part) with BF, before committing its own grants. In some instances, GVS pays to BF for building as well, thus allowing donors the facility of Income Tax exemption. Evaluation by Independent Experts: a. Prof M Ravindran, Special Advisor(Rural Technology Action Group), IIT-Madras, Chennai-600036 (former Director, National Inst of Ocean Tech, Email:ravindranvanaja@gmail.com) (Aug’07): I have interacted with the water mission group of BF and presently I am also in the Advisory Board of Water module. Dr DR Prasada Raju, who looks after the program, has combined his knowledge and experience in science with ‘down to earth’ and realistic approach to design, erect and commission the water treatment plants in various villages. I have visited some of their plants also and giving below my impressions on this program: Innovativeness: This is innovative as the program ensured community participation and made them the proud owner of the plant. So the rural community is getting a better quality of water compared to city water almost at no cost. The technical and other decisions on the plants are made at the community level discussions giving it a 'bottoms-up approach', which is essential for the success of such programs. Sustainability: The program has a high potential for success in terms of continuity and sustainability because (a) The community owns and runs the plant (b) Operation and maintenance cost of the plant is met from the user charges, and (c) The equipment in the plant are chosen to be of high quality. Detailed procedures have been worked out for preventive and breakdown maintenance, and (d) the program is being managed by a competent team of specialists. Potential for replication: The program can be easily replicated even in other countries because (a) The technical design of the plant, the process and the choice of the machineries are very sound (b) The Global Development Network Japanese Award for the Most Innovative Development Project 11 recurring cost of running the plant is not a burden on the sponsor and (c) Willing participation of the community is ensured. Social impact: This project has a tremendous social impact since it ensures freedom from water borne diseases, accounting for about 85% of all the diseases in villages. Children will grow in healthy environment and the community contributes to the wellbeing of its own people. Based on my impressions, I am sure that the BF has taken up a very, very important social cause and implementing the program effectively where the government systems have failed for a variety of reasons. This team is devoted to the cause, deserving all support, recognition and encouragement. b. Prof PV Indiresan, B-57, Hill View Apts, Vasant Vihar, New Delhi-110057 (former Director of IITMadras and Chairman-Naval Research Board, Govt of India) Email: indiresan@gmail.com) (Oct’06): BF has introduced several innovative developments in a number of villages in Godavari Districts of AP. I had the privilege of visiting the villages twice, including the time I accompanied President Dr APJ Abdul Kalam (Jan’06), who chose to visit the project because it satisfied his ideas of the scheme PURAProviding Urban Amenities in Rural Areas. BF demonstrated before President Kalam a low cost RO process for providing potable water at an affordable price. Many of the rural poor have settled on the banks of canals where land is cheap because the water is not drinkable. BF has been particularly concerned about the welfare of such people. Providing potable water depends only partially on cleaning up water: preventing contaminants is no less important. In that respect, BF has made commendable contribution by building hundreds of toilets at subsidized prices. Every toilet is one less family contaminating water supply, one less family spreading disease. BF has also introduced good quality healthcare which is expected to become self supporting in due course of time. Thus, rural development, as operated by BF, is multi-dimensional, comprehensive. In our country, there is insufficient awareness of inter-dependence of factors of development. Educated, healthy people demand better water, better sanitation. Without public demand, mere provision of amenities is of little use. BF’s approach breaks new ground and this change is long over due. Pioneering efforts of the BF deserve every possible encouragement and every kind of recognition. c. Dr Shrikant V Joshi, Associate Director, International Advanced Research Centre for Powder Metallurgy & New Materials, Balapur, Hyderabad-500005(Email:shrikantjosh@gmail.com) (Aug’07): The BF water scheme, a remarkable initiative, has made a noteworthy contribution in providing safe drinking water to households in many villages. Community involvement, I believe, is particularly crucial to ensure sustainability of the scheme in the long term. This innovative project has led to awareness creation among rural folk and demonstrated that such well conceived schemes have significant potential for replication, not only in other parts of the country but also in other developing countries. Recently, we developed nano-silver based low cost ceramic candle filters for enhancing the performance by imparting anti-bacterial function, besides particulate impurity removal. Following a series of lab trials, we found in BF an able and willing ally for its field testing. Our decision to approach BF for this measure was based on their efforts and success rate in providing safe drinking water to rural poor. I am glad to share my view that their pro-active approach has been responsible to a very large extent in generating invaluable field data from 100 test centers on the sustained performance of these filters, which can potentially have implications in providing bacteria-free water without any need of electricity. I was impressed by BF’s utilization of IT tools for staying connected with the rural community. One of my colleagues visited the villages where silver-modified filters are installed and also seen working of plants of BF. He commended BF for not just installing the above, but for making community participate very effectively. BF is a shining example of what an NGO can achieve through their vision and actions to bring path-breaking rural transformation. The scheme exemplifies how BF has been striving tirelessly to improve conditions in rural India. Global Development Network Japanese Award for the Most Innovative Development Project 12 Alliance Partners and their Contribution: • AP Pollution Control Board, Government of AP: Awareness on Environmental issues, supply of material (including short films/videos) on preserving environment for distribution in villages. • AP Transmission Corporation Ltd, Government of AP: Power connection under concessional tariff (10% of usual tariff) for operation of water plants as public water schemes. • DNR College, Bhimavaram and Sapthagiri Aqua Lab, Amalapuram: Infrastructure facilities for testing of Biological, Chemical and Physical parameters in the water samples. • Indian Inst of Chemical Technology, Hyderabad: Testing of water for fluorides, nitrates and chemicals. • Indian Institute of Technology-Madras, Chennai: Review of performance of plants, study design features and other technical aspects and study on treatment of sullage water in villages. • Intl Advanced Research Center for Powder Metallurgy and New Materials, Hyderabad: Study efficacy of nano-silver coated candle filters for water purification in villages. • National Environmental Engineering Research Institute, Hyderabad/Nagpur: Technical advise and conduct study on purification of pond water using different methods. • Water, Environment and Sanitation Network (WES-Net), United Nations Development Program, New Delhi: Solution Exchange forum for sharing technical knowledge on drinking water. • Rural Technology Action Group (RuTAG), Office of Principal Scientific Adviser to the Government of India, New Delhi for taking up projects aimed at rural development in the state of Andhra Pradesh. Awards/Recognitions: a. BF was awarded ‘Best Water NGO-Water Quality’ for successive years 2006-07 and 2007-08 by Water Digest and UNESCO, for outstanding work in the field of water in India, . b. Dr DR Prasada Raju, FLCL(Water Program) in BF, was conferred ‘Andhra Pradesh Scientist Award2007’ by AP Council of Science &Technology, Govt of AP for contributions in social sciences area. Technology Awareness: The experience gained on implementation of Project SWEET has been disseminated through seminars, publication of papers in journals/reports, as listed below: Presentations in Conferences/Seminars: a. 9th All India Workshop of Science and Technology Councils/Departments on Drinking Water by Government of Andhra Pradesh & Government of India, Hyderabad, Nov’05 b. XIII World Water Congress by International Water Resources Association and Central Bureau of Irrigation and Power (Govt of India), New Delhi, Nov’05) c. 93rd and 95th Indian Science Congress by Indian Science Congress Association, Hyderabad, Jan’06 & Visakhapatnam, Jan’08 d. International Seminar on Water by Rotary International, Jaipur, Nov’06 e. Water Summit-2007 by Confederation of Indian Industry, UNDP & USAID, Hyderabad, Nov’07 Publications: a. WES-Net e-newsletter, published by UNDP, Aug’06 b. WAC e-newsletter, published by UN-HABITAT, Aug’06 c. Catalyst for Human Development, published by Association for Human Development, Mar’07 Chapters/Articles in Reports: a. Detailed Process Document (Binder), Aug’06 b. Local Actions for Sustainable Development on Water and Sanitation in Asia-Pacific Region by UN- HABITAT, ADB, and Asia-Pacific Water Forum, Dec’07 c. 6 Edited Anthologies by Atlantic Publishers, Jan’08 d. Business Models of Future: India Infrastructure Report-2008 by Oxford University Press (Edited by 3i Network: IIM-Ahmedabad, IIT-Kanpur and Infrastructure Finance Development Co, Jan’08 e. Manual on Community-based Water Bottling Plant for Pro-Poor by UN-HABITAT(to be ready by Feb’08) Global Development Network Japanese Award for the Most Innovative Development Project 13 CV of Verghese Kurudamannil Jacob Verghese is an Electronics engineer, who opted to take up a Management career and did his MBA specializing in Marketing and Finance from XLRI, Jamshedpur in 1979. Verghese has over 25 years of corporate and general management experience. He worked for the Godrej group of companies, one of the largest industrial groups in India, for twenty years handling multifaceted assignments such as Head of Machine tools division, Vice President (HRD), CEO of Godrej Telecom etc. After moving on from Godrej, he served as a Director and head of International operations of a subsidiary company of Swissair and also as a director of ACCEL ICIM and Avient Technologies ,UK. During the last four years, he has been serving the social sector and spearheads the activities of Byrraju Foundation, which is one of India’s largest NGOs focused on rural transformation. Byrraju Foundation has adopted 175 villages and runs several programs in rural healthcare, education, literacy, livelihoods, women empowerment, drinking water, waste management, community leadership, rural enterprises, research and training etc impacting over 2 million people. In a short span of five years, .Byrraju Foundation has created one of the largest public private partnership platforms for rural development with over 120 active alliance partnerships, 700 employees and over 10000 volunteers. Verghese also served as the Chairman of Bombay Round Table, where his passion for social causes found expression, while still serving in the corporate sector. Verghese is a keen tennis and bridge player and has played both the games at the national level. He is also a Six Sigma black belt and Byrraju Foundation is the first NGO in the world to adopt Six Sigma methodologies. He also espouses other charitable causes such as National Kidney Foundation, Friends of Trees etc. CV of Dandu Radha Prasada Raju D R Prasada Raju, pursued bachelors, masters and doctoral degrees, all in mechanical engineering, and got trained, as a British Council Fellow, for a year in environmental engineering at University of Newcastle upon Tyne, UK. Prasada Raju served public sector, National Small Industries Corporation Limited and NTPC Limited, in the project management area for 6 years. Subsequently, he joined Government of India and looked after monitoring and evaluation of various activities related to port and shipping operations for nearly 4 years while in the Ministry of Surface Transport. He has been with Department of Science and Technology for the last 18 years engaged in formulation of various research programmes and promotion of research and development activities in engineering sciences. For the most part of the last 4 years, he has been on sabbatical with Byrraju Foundation, associated with rural drinking water programme. His contribution lead to setting up community-based water purification plants, in public-private partnership mode, providing access to safe drinking water to nearly 800,000 people in 160 villages in Andhra Pradesh, where Byrraju Foundation has presence. Prasada Raju published over a dozen papers in the fields of mechanical engineering and drinking water. He was and continues to be a member of various technical bodies involved in academics and social sector. Andhra Pradesh State Council for Science and Technology, Govt of AP, conferred ‘Andhra Pradesh Scientist Award-2007’ for his noteworthy contributions in social sector (rural drinking water area). Global Development Network Japanese Award for the Most Innovative Development Project 14