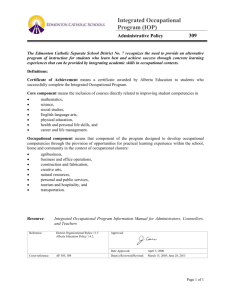

framework of the master plan

advertisement