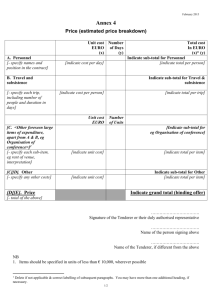

1 Table 1: Standard enthalpy change and Gibbs energy change for

Table 1: Standard enthalpy change and Gibbs energy change for the selected CO

Table 5: Economic evaluation using block analysis method for Cases A and B. ..................... 6

Table 6: Economic evaluation using block analysis method for Cases C and D. ..................... 7

Table 8: Summary results of ETII, energy and cost evaluations for Cases A to E. .................. 9

1

Table 1: Standard enthalpy change and Gibbs energy change for the selected CO

2

reaction pathways.

Reaction

CO

2

( g ) + 4H

2

( g

) → CH

4

( g ) + 2H

2

O ( l )

CO

2

( g ) + 3H

2

( g

) → CH

3

OH ( l ) + H

2

O ( l )

CO

2

( g ) + H

2

( g

) → HCOOH ( l )

CO

2

( g ) + CH

4

( g

) → 2CO ( g ) + 2H

2

( g )

H

R

(kJ/mol)

−253.0

−131.0

−31.2

+247.3

G

R

(kJ/mol) Equation

−130.6

(1)

−9.0 (2)

+33.0

+170.7

(3)

(4)

2

Table 2: Energy auditing using block analysis method for Cases A and B.

Net Energy

Case

Block

Energy Requirement (MW)

1.

Steam requirement for WGS

2.

Oxygen production (ASU)

3.

Steam requirement in CO

2

capture system (Rectisol)

4.

Electricity requirement in CO

2

capture system (Rectisol)

5.

CO

2

compressor

6.

Steam requirement for heating CO

2

feed into methanator

7.

Air and syngas compressor

Sub-total

Energy Generation (MW)

1.

Gasification and syngas cooler

2.

Syngas expander

3.

CO

2

expander

4.

Gas turbine

5.

HRSG

6.

METHANOL and ACEREACT

Sub-total

I

2.42

14.83

17.25

846.77

11.75

Case A

II+III

9.40

4.98

2.52

16.90

IV

9.89

9.89

2.64

3.31

I

2.42

14.83

17.25

846.77

11.75

Case B

II+III

7.63

22.01

0.75

9.40

4.98

IV

858.52 0.00

49.24

55.19 858.52 0.75

49.24

55.19

841.27 −16.90 45.30 841.27 −21.26 45.30

9.89

9.89

2.64

3.31

3

Table 3: Energy auditing using block analysis method for Cases C and D.

Case

Block

Energy Requirement (MW)

1.

Steam requirement for WGS

2.

Oxygen production (ASU)

3.

Steam requirement in CO

2

capture system (Rectisol)

4.

Electricity requirement in CO

2

capture system (Rectisol)

5.

CO

2

compressor

6.

Energy required for tri-reforming process

7.

Air compressor / syngas compressor

8.

Energy for heating feed into GTCOMB.

Sub-total

Energy Generation (MW)

1.

Gasification and syngas cooler

2.

Syngas expander

3.

Methanol gas expander

4.

METHANOL

5.

Gas turbine

6.

HRSG

Sub-total

Net Energy

I

16.48

14.83

31.31

864.61

Case C

II+III

10.44

5.53

7.67

23.64

IV

42.88

14.23

57.11

I

27.50

14.83

Case D

III

8.96

917.12

346.87

IV

23.55

9.25

24.25

42.33 1272.95 57.05

864.61

11.56 11.56

60.71

441.00

85.66

105.54

45.4

83.1

876.17 0.00 191.2 876.17 501.71 128.5

844.86 −23.64 134.09 833.84 −771.24 71.45

4

Table 4: Energy auditing using block analysis method for Case E.

Case

Block

Energy Requirement (MW)

1.

Oxygen production (ASU)

2.

Steam requirement for oxidiser

3.

Air compressor

4.

Heat duty for heating Fe

2

O

3

(make-up and recycle)

5.

Endothermic heat of reducer

6.

Heat duty for heating Fe

3

O

4

Sub-total

Energy Generation (MW)

1.

Gasification and syngas cooler

2.

Syngas expander

3.

CO

2

cooling

4.

H

2

cooling

5.

Exothermic heat of oxidiser

6.

Exothermic heat of combustor

7.

Air cooler

Sub-total

Net Energy

I

14.83

Case E

II+III

74.23

14.83

9.78

56.37

26.01

44.61

211.0

846.77

10.02

141.85

10.57

71.23

12.61

70.41

856.79 306.67

841.96 95.67

5

Table 5: Economic evaluation using block analysis method for Cases A and B.

Case

Block

Capital Cost (million Euro)

1.

GASIFIER

2.

WGS

3.

SYNGCOOL

4.

ASU

5.

Expander

6.

Rectisol

7.

CO

2

transport and storage

8.

Compressor

9.

Methanator

10.

Gas turbine

11.

HRSG

12.

Methanol reactor

13.

Acetic acid reactor

14.

H

2

/CO separation

Sub-total (million Euro)

Annualised capital cost (million Euro/year)

Operating Cost (million Euro/year)

1.

Coal

2.

Hydrogen

Sub-total (million Euro/year)

17.5

53.4

53.4

Value of Products (million Euro/year)

1.

Electricity

2.

Methanol

3.

Acetic acid

4.

Hydrogen

5.

Methane

Sub-total (million Euro/year) 0.0

Economic Value (million Euro/year) [value of product – (capital cost + operating cost)]

−70.9

Total Plant Investment (million Euro/year) [(capital cost + operating cost)] 70.9

I

73.4

9.2

33.0

40.3

3.3

159.2

0.0

−7.5

7.5

0.0

7.5

61.0

4.5

2.4

67.9

Case A

II+III

0.0

1.5

72.8

4.8

107.0

20.0

201.3

0.5

7.3

14.6

13.2

43.7

6.0

2.2

IV

196.5

4.8

8.9

164.1

164.1

71.1

71.1

−101.9

173.0

61.0

19.8

81.3

Case B

II+III

0.5

0.0

−70.9

70.9

17.5

53.4

53.4

159.2

I

73.4

9.2

33.0

40.3

3.3

0.0

1.5

72.8

4.8

107.0

20.0

201.3

0.5

7.3

14.6

13.2

43.7

6.0

2.2

IV

196.5

4.8

6

Table 6: Economic evaluation using block analysis method for Cases C and D.

Case

Block

Capital Cost (million Euro)

1.

GASIFIER

2.

WGS

3.

SYNGCOOL

4.

ASU

5.

Expander

6.

Rectisol

7.

CO

2

transport and storage

8.

Compressor

9.

Tri-reformer

10.

Gas turbine

11.

HRSG

12.

Methanol reactor

13.

PSA

Sub-total (million Euro)

Annualised capital cost (million Euro/year)

Operating Cost (million Euro/year)

1.

Coal

2.

Natural gas

Sub-total (million Euro/year)

172.5

19.0

53.4

53.4

Value of Products (million Euro/year)

1.

Electricity

2.

Methanol

Sub-total (million Euro/year) 0.0

Economic Value (million Euro/year) [value of product – (capital cost + operating cost)] −72.4

Total Plant Investment (million Euro/year) [(capital cost + operating cost)] 72.4

I

73.4

18.4

37.1

40.3

3.3

0.0

−9.8

9.8

88.5

9.8

0.0

77.1

6.4

5.0

Case C

II+III

61.1

6.7

0.0

48.2

48.2

16.0

29.8

15.3

IV

41.5

6.7

0.0

−71.4

71.4

163.3

18.0

53.4

53.4

I

73.4

9.2

37.1

40.3

3.3

181.4

20.0

383.0

383.0

1246.7

1246.7

64.8

43.4

31.8

Case D

III

31.3

10.1

843.7

403.0

25.5

25.5

−35.3

60.8

131.7

14.5

46.3

46.3

5.7

18.5

12.0

44.7

IV

50.8

7

Table 7: Economic evaluation using block analysis method for Case E.

Case

Block

Capital Cost (million Euro)

1.

GASIFIER

2.

SYNGCOOL

3.

ASU

4.

Expander

5.

Chemical looping system

6.

CO

2

transport and storage

7.

Compressor

Sub-total (million Euro) 149.7

Annualised capital cost (million Euro/year)

Operating Cost (million Euro/year)

1.

Coal

Sub-total (million Euro/year)

16.5

53.4

53.4

Value of Products (million Euro/year)

1.

Hydrogen

Sub-total (million Euro/year) 0.0

Economic Value (million Euro/year) [value of product – (capital cost + operating cost)]

−69.9

Total Plant Investment (million Euro/year) [(capital cost + operating cost)] 69.9

I

73.4

33.0

Case E

II+III

40.3

3.0

70.6

82.0

9.4

8.3

5.9

84.8

9.4

0.0

91.4

91.4

8

Table 8: Summary results of ETII, energy and cost evaluations for Cases A to E.

Case

ETII

Block I

Coal (MW)

Net energy from process units (MW)

Overall Net Energy (MW/MW coal)

Total Plant Investment (million Euro/year)

Total Plant Investment (Euro/MWh coal)

Block II+III+IV

Syngas LHV (MW)

Additional feed LHV (MW)

Product LHV (MW)

Net energy from process units (MW)

Net energy from streams (product – additional feed) (MW)

Overall Net Energy (MW/MW syngas)

Total Plant Investment (million Euro/year)

Total Plant Investment (Euro/MWh syngas)

A

Polygeneration with CCS

0.47

B

Polygeneration with methanation

11.19

648.1

841.3

1.30

70.9

13.7

412.6

0.0

330.8

28.4

330.8

0.87

12.3

3.7

648.1

841.3

1.30

70.9

13.7

412.6

619.8

749.1

24.0

129.3

0.37

177.9

53.9

C

Cogeneration with CCS

0.58

648.1

844.9

1.30

72.4

14.0

405.7

0.0

0.0

110.4

0.0

0.27

16.5

5.1

D

Polygeneration with trireforming

8.74

648.1

833.8

1.29

71.4

13.8

400.9

2802.6

2852.8

−699.8

50.2

− 1.62

463.8

144.6

E

Chemical

Looping

0.38

648.1

842.0

1.30

69.9

13.5

424.7

0.0

345.4

95.7

345.4

1.04

9.4

2.8

9

Table B.1: Standard heat of formation and standard Gibbs energy of formation for various components. (Atkins and Paula, 2005)

Component

CO

2

( g )

H

2

( g )

CH

3

OH ( l )

H

2

O ( l )

CH

4

( g )

HCOOH ( l )

CO ( g )

Standard heat of formation at 298.15 K,

H

f

(kJ/mol)

−393.51

0

−238.66

−285.83

−74.81

−424.72

−110.53

Standard Gibbs energy of formation at 298.15 K,

G

f

(kJ/mol)

−394.36

0

−166.27

−237.13

−50.72

−361.35

−137.17

10

Table C.1: Economic parameters for evaluating capital cost, operating costs and value of products.

Capital cost

No. Process unit

1 Gasifier (GE type) a

2 Water-gas shift reactor a

3 Rectisol b, i

4 CO

2

transport and storage c

5 Methanol reactor b

6 Acetic acid reactor d

7 H

2

/CO separation b, ii

8 Gas turbine a

9 HRSG a

10 SYNGCOOL a

11 ASU a

12 Compressor a

13 Expander a

14 Tri-reformer/ Methanator b, iii

Operating cost

Base Cost

(million USD)

62.92

12.24

54.1

28

56

41.2

25.4

35.6

4.83

2.41

9.4

Scale factor

0.67

0.67

0.7

5.6 Euro/t CO

2

7

2 times of (5)

0.6

0.7

0.75

1

0.6

0.5

0.67

0.67

0.6

Base scale

Scale unit

716 MW coal input

1377 MW LHV coal input

9909 kmol CO

2

/h

87.5

9600

266

355

77 t MeOH/h kmol/h feed

MW

MW heat duty

MW heat duty

76.6 t O

2

/h

10

10

1390

MW

MW kmol/h feed

No. Raw material

1 Natural Gas e

2 Coal e

3 Hydrogen f

Market price

Cost Estimation

18 Euro/MWh

2.86 Euro/GJ

1104 Euro/t

No.

1 Electricity e

2 Methanol g

3 Acetic acid

h

4 Hydrogen f

5 Methane e

Product Price

70.29 Euro/MWh

305 Euro/t

550 Euro/t

1104 Euro/t

18 Euro/MWh

Note: a

Larson et al., 2005. Economic parameters taken from year 2003. Assume 1USD = 0.9 Euro (2003). b

Hamelinck and Faaij, 2002. Economic parameters taken from year 2001. Assume 1 USD = 1.1 Euro (2001). c

IPCC, 2005. Cost of CO

2

transport: 0-5 USD/t CO values of CO

2

transport and storage are taken.

2

; Cost of CO

2

storage: 0.6-8.3 USD/t CO

Assume 1 USD = 0.8 Euro (2010).

2

. Average d

Cost of acetic acid reactor is estimated based on 2 times of the cost of methanol reactor, as suggested by Zhu and Jones, 2009. e

DECC, 2010. f

Stigel and Ramezan, 2006. g

Methanex, 2011. Contract price valid from April to June 2011. h

ICIS pricing, 2010. i

Cost of Rectisol is assumed to be 2 times of Selexol, as suggested by Denton, 2003. ii

Cost of H

2

/CO separation unit is estimated based on the cost of PSA. iii

Costs of tri-reformer and methanator are assumed to be the same as the cost of steam reformer.

CEPCI

2001= 394.3; 2003=402.0; 2010 (November)=556.8

11