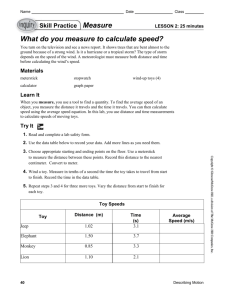

Sample questions

advertisement

Level 6 Professional diploma in procurement and supply PD3 -Strategic supply chain management EXAM EXEMPLAR QUESTIONS QU AL IF 20 ICAT 13 IO N S CASE STUDY AND QUESTIONS Page 1 of 16 PD3 Exam Exemplar Questions July 2013 INSTRUCTIONS FOR CANDIDATES The pre-released case study examination is designed to assess your ability to apply the relevant theories, principles and techniques associated with the unit content to a realistic business situation. The examination is a three hour open-book examination. The examination questions will test each of the learning outcomes from the unit content. You will be expected to demonstrate your knowledge and understanding of relevant theoretical principles, concepts and techniques; to apply these appropriately to the particular situation described in the case study and; above all, to make sound decisions. You will not gain marks by writing a general essay on the topic. Prepared notes may not be included as part of the answer. Please note that all work should be your own. Copying or plagiarism will not be tolerated and could result in no marks being awarded. If quotes or short extracts are used they should be attributed or the source of the information identified. You should acquaint yourself thoroughly with the case study before the examination. You must take your copy of the case study into the examination. Page 2 of 16 PD3 Exam Exemplar Questions July 2013 ‘MATTELS SUPPLY CHAIN’ Play Fair The core values of Mattel, the world’s largest branded toy manufacturer, appear on its company website and on their literature under the heading ‘Play Fair’. “Act with unwavering integrity on all occasions. Treat each other with respect and dignity. Trust each other to make the right decisions. Be accountable for all that passes in front of us.” 1 In 2007 these values would be put to the test, as never before, when it was discovered that substantial numbers of Mattel branded toys had been contaminated with lead paint, with global signature brands such as Barbie™ and Fisher Price™ affected. This followed hard on the heels of a much larger recall of toys containing small magnets when it was discovered that a serious health hazard was posed to children if they became loose. In fact, more than 19 million toys were to be recalled by Mattel, worldwide, including a warning issued on 4th September 2007 covering 675,000 Barbie accessories, making this the largest recall in the history of Mattel, the world’s largest toy manufacturer.2 The cause of this crisis was twofold: the use of non-approved paint by contract manufacturers in China and what turned out to be a design fault in toys containing small magnetic parts. As a result of the publicity surrounding the recall, two Chinese companies had their export licences revoked by the Chinese government and the owner of one committed suicide.3 Other branded manufacturers such as RC2 Corp.4 (Thomas the Tank Engine) and large retail chains such as Toys R’Us5 were also affected by the use of banned lead paint with some of their retailer own-brand toys and children’s jewellery sourced from Chinese manufacturers having to be recalled. The United States National Safety Commission had this to say about the health effects of elevated lead blood levels in children: “There are many different health effects associated with elevated blood lead levels. Young children under the age of six are especially vulnerable to lead’s harmful health effects, because their brains and central nervous system are still being formed. For them, even very low levels of exposure can result in reduced IQ, learning disabilities, attention deficit disorders, behavioural problems, stunted growth, impaired hearing, and kidney damage. At high levels of exposure, a child may become mentally retarded, fall into a coma, and even die from lead poisoning. Within the last ten years, children have died from lead poisoning in New Hampshire and in Alabama. Lead poisoning has also been associated with juvenile delinquency and criminal behaviour.” 6 In fact, the most common cause of high levels of lead in children is not due to ingesting chips of lead paint, but through lead dust being swallowed when it is dislodged from old paint, or leaded dust created when old buildings are modernised or repainted. Paint containing more than 0.06% (600 ppm) lead was banned for residential use in the United States in 1978 by the U.S. Consumer Product Safety Commission (16 Code of Federal Regulations CFR 1303). Even so, there are some authorities that say there is no safe level of lead where children are concerned because the young child’s central nervous system is developing so rapidly. In the EU lead paint can now only be used for restoring works of art or historical buildings.7 Mattel 2007 Global Citizenship Report downloaded on 17.09.07 from; www.mattel.com/about_us/Corp_Responsibility/ Mattel_07GCReport.pdf 2 Thottam J, Sep 06 2007 Time. 3 Jane Macartney in Beijing, Times Online, Analysis: how toy recall affects Brand China,August 14, 2007, downloaded 15.07.09; 4 See US Consumer Product Safety Commission June 13 2007, a recall affecting 1.5 million various Thomas and Friends wooden railway toys sourced in China was issued due because, ‘Surface paints on the recalled products contain lead. Lead is toxic if ingested by young children and can cause adverse health effects.’ 5 The Toys R’Us issued a recall notice on the USCPC website on August 30th 2007 covering 27,000 wooden colouring cases sourced in China. ‘The printed ink on the outer packaging of the wood case contains lead. Also, some of the black watercolor paint contains excessive levels of lead, which violates the federal lead paint standard.’ 6 Lead Poisoning, National Safety Council (USA), Downloaded on 02.10.07 from; http://www.nsc.org/library/facts/lead.htm 7 Royal Society of Chemistry, downloaded on 02.10.07 from; http://www.rsc.org/chemistryworld/News/2007/August/21080701.asp 1 Page 3 of 16 PD3 Exam Exemplar Questions July 2013 Eighty percent of the world’s toys are manufactured in China by more than 10,500 toy manufacturers, with Mattel alone using around 3,000 to manufacture sixty five percent of its children’s products there.8 The Chairman and CEO of Mattel, Robert Eckert, assured a US Senate Appropriations Subcommittee that wherever Mattel toys are manufactured their standards are enforced and that the problem was not necessarily connected to the toys in question being manufactured in China, but to the subcontractors not being monitored or checked rigorously enough.9 At the same senate hearing the Chairman, Dick Durbin, stated that more than twenty five million Chinese manufactured toys had been recalled that summer alone (ibid) and also called for all toys imported from China into the United States to be inspected.10 A visit to the U.S. Consumer Product Safety Commission (CPSC) website, www.cpsc.gov provides details of the millions of products recalled bearing the ‘made in China’ designation. An alarming number of these products are aimed at children and involved the use of lead either as paint or in children’s jewellery or the use of small magnetic parts that could become detached and pose intestinal problems to children if swallowed. On the Mattel company website (http://www.mattel.com/safety/en/) worried consumers were able to discover exactly what products are affected and what action they needed to take, in other words, how to return the product and get their money back. Given the global nature of Mattel’s business it was not surprising to see that this facility is available in many different languages. A short video of Bob Eckhart (CEO Mattel) was also posted on the web page dealing with the recalls in which he informed viewers about the size and nature of the recall and where to find details of the products and also told of the action taken by Mattel to increase and make more rigorous its quality assurance and inspection processes. Apparently, as a result of the implementation of this more stringent testing and checking regime, further product with some lead paint contamination was discovered and a voluntary notification and recall communicated to the relevant agencies and stakeholders and affected product removed from retailers’ shelves. Bob Eckhart assured parents that the safety of children who play with Mattel toys is his personal primary concern and reaffirmed Mattel’s absolute commitment to product safety and the safety of children. He also clearly identified the steps taken to ensure no repetition of this quality crisis by assuring the viewer that all Mattel products will be tested. The following message was posted on the company website: “We Take Our Promises Seriously. As promised, in recent weeks, we have been busy testing and retesting toys before they leave factories. Our recent voluntary recalls are part of our ongoing promise to ensure the safety of your children. We have strengthened our testing worldwide with a mandatory 3-stage safety check of paint used on our toys. 1. All paint must be tested before it is used on our toys. No exceptions. 2. We have significantly increased testing and unannounced inspections at every stage of production. 3. We are testing every production run of finished toys to ensure compliance before they reach you. We encourage you to keep coming back to our website where you can learn about additional affected toys, what we are doing, and to find answers to your questions. At Mattel, the safety of your children is our utmost priority. That is our promise.” 11 In response to the recall of around 1.5 million Thomas and Friends™ railway toys RC2 Corp. instituted a ‘multi-check toy safety system’ to “reduce potential future risks to children and preserve parents’ trust.”12 RC2, like Mattel, retested a large number of toys similar to those previously recalled and, as a result, issued a voluntary recall in cooperation with the US CPSC for a further five toys (ibid) found to be contaminated with lead paint. Jane Macartney in Beijing, Times Online, Analysis: how toy recall affects Brand China, August 14, 2007, downloaded 15.07.09; Dart B., Mattel CEO Defends Toy Manufacturing Operations in China, Cox News Service, Thursday September 134 2007, downloaded on 16.09.07 from; www.coxwashington.com/hp/content/reporters/stories/2007/09/13/BC_CHINA... 10 BBC News 245, Wednesday, 15 August 2007, 09:41 GMT 10:41 UK, Toy woes prompt China checks call, downloaded on 17.09.07 from: http://news.bbc.co.uk/1/hi/business/6947420.stm 11 Mattel, we take our promises seriously, downloaded on 18.09.07 from; http://www.mattel.com/safety/en/ 12 Downloaded on 30.09.07 from; http://recalls.rc2.com/ 8 9 Page 4 of 16 PD3 Exam Exemplar Questions July 2013 Corporate Social Responsibility Companies are coming under public and political scrutiny as never before. Disasters such as the Union Carbide explosion in Bhopal and the collapse of institutions such as Barings Bank, Enron and the Bank of Credit and Commerce paved the way for a raft of legislation and scrutiny from political regulators and consumer organisations. There are few areas of business where this scrutiny is higher than in those areas affecting health and safety and particularly the health and safety of children. Many countries and regions have stringent standards governing the manufacture of toys and a list of these can be found on the website of the ICTI13 (International Council of Toy Industries). Mattel has stated publicly as a policy that its manufacturing standards and specifications for toys exceed all the health and safety standards for toys in every country in the world. This is no mean feat since there are over 100 different regional or national standards for toys worldwide. Al Verrechia, CEO of Hasbro, a large global toy manufacturer, also stated that: “At Hasbro, we are proud that our own safety standards meet or exceed all federal regulations and that we set the highest standards for our own factories as well as our vendors wherever they may be located, including China.” 14 The UK government sees corporate social responsibility as the voluntary actions that business can take, over and above compliance with minimum legal requirements, to address both its own competitive interests and the interests of wider society. CSR (Corporate Social Responsibility), therefore, concerns much more than a company’s obligations to its consumers. In Mattel’s 2007 GRI (Global Report Initiative) report the company stated that it has a vision to become a ‘role model for global citizenship’ and has developed and widely published a set of core values that will enable it to fulfil this mission: • “We “play to grow” by seeking continuous improvements in the business and rewarding excellence. • We “play together” through dynamic teamwork and collaboration. • We “play with passion” by infusing unparalleled creativity and innovation into every aspect of work, loving what we do and having the courage to make a difference. • We “play fair” by treating others with dignity and respect and acting with integrity each and every day.” 15 Mattel’s intention behind developing a set of core principles is to ensure that everyone in the organisation is ‘united to a common purpose’. In 2003 Mattel implemented or ‘rolled out’ a code of ethical conduct to all employees covering a comprehensive range of issues such as; conflict of interest situations, corporate opportunities, responsibilities to other employees, consumers, shareholders, business partners, competitors, communities, government and compliance with laws and how to get help and raise concerns.16 Mattel has also stated that it wishes to be a good global citizen by carefully balancing the needs of people, planet and profit and has developed three core strategic initiatives in order to succeed in this goal: • “Sustainable product design and development. • Sustainable manufacturing and procurement processes. • Creating a sustainability culture at Mattel.” http://www.toy-icti.org/info/toysafetystandards.html Downloaded on 30.09.07 from; http://www.hasbro.com/default.cfm?page=letter 15 Mattel 2007 GRI (Global reporting Initiative) Report (PDF), Downloaded on 19.09.07 from; http://www.mattel.com/about_us/ Corp_Responsibility/cr_csreport.asp 16 Downloaded on 30.09.07 from; http://www.mattel.com/about_us/Corp_Governance/ethics.asp 13 14 Page 5 of 16 PD3 Exam Exemplar Questions July 2013 As part of its core values Mattel has published its intention to maintain an ongoing effort to ensure that their products are manufactured under ‘safe, fair and environmentally safe conditions’ and in 1997 implemented a set of detailed Global Manufacturing Principles (GMP) to help achieve these goals and ensure ethical practices. In order to ensure compliance with these Global Manufacturing Principles and related manufacturing standards, Mattel engages third party assurance (since 1988) by the International Centre for Corporate Accountability (ICCA). This not for profit, independently incorporated organisation, performs selected audits and publishes (publicly on mattel.com) reports on all Mattel manufacturing facilities including all those owned by Mattel and some of its contractors. Mattel Manufacturing Operations Mattel has offices in 43 countries and territories and Mattel products are sold to consumers in 150 countries mainly via retailers but also with some direct sales. Around half of all Mattel’s products are manufactured in wholly owned or Mattel managed facilities, located in China, Indonesia, Malaysia, Mexico and Thailand. The remaining products are produced in approximately 75 contract factories or by vendors, with the majority of all products including those outsourced being manufactured in China. Around one thousand licensees produce Mattel branded products such as clothing, software, durable goods and other children’s products. Mattel manufactures approximately half of all its products in eleven manufacturing and tooling facilities which it either owns, operates or manages located in China, Indonesia, Malaysia, Thailand and Mexico. The remaining products are either manufactured under license in around one thousand factories worldwide or are manufactured in contract factories or by vendors located mostly in China with some contract manufacturing also taking place in India and Brazil. Some of these contract manufacturers are heavily dependent on Mattel business, with the company estimating that production of Mattel products accounts for between thirty to ninety percent of their vendor’s annual production. Licensed products are, however, estimated to account for a much smaller percentage of vendor production at around five percent. Vendor Operations started outsourcing production for Mattel in 1988 following a report by McKinsey and Company17 that recommended Mattel keep all its core products in-house in wholly owned and controlled manufacturing operations and outsource all non-core products. Barbie™ was originally one of the products designated as core by Mattel with Hot Wheels™ and some Disney™ and Fisher Price™ lines also being added to the list at a later stage. In those early days vendors were selected, based upon their lead time for new toys, manufacturing competence, unique process capabilities and price (ibid). One of the main benefits to Mattel of this approach to manufacturing was that this enabled it to produce toys with relatively short product life-cycles more cost effectively, because it did not need to make an expensive capital investment in new plant. The ability to respond rapidly to changes in demand by producing and supplying new products quickly is a core competence in the toy market and there is a very profitable market related to non-core toys such as those associated with television series or movie characters, for example. Time to market for products associated with a new movie, for example, is critical because the demand may be high initially but it is often relatively short-lived. Having a combination of wholly owned manufacturing, outsourced contractors and licensees provides Mattel with a degree of flexibility and agility in this volatile marketplace. 17 Johnson M.E. & Clock T, (2000), Mattel Inc: Vendor Operations in Asia, Indiana University CIBER Case Collection. Page 6 of 16 PD3 Exam Exemplar Questions July 2013 With so many manufacturing facilities located in so many different countries and such a large network of contractors and licensees, Mattel has set itself a formidable task in ensuring compliance to its Global Manufacturing Principles and adherence to every national and regional toy product standard around the world. Monitoring and reporting on factories does take place and detailed reports are published on Mattel’s website. Follow-up action in the form of further reports from the independent auditors and management response are also published and the tone of these reports reflects a desire on the part of Mattel to encourage and help manufacturers located in developing countries to improve rather than to punish or withdraw business. One of the reports published by Mattel concerns the audit of a vendor identified only as ‘Vendor Plant 18’. This plant had received an’ informal consultation visit’ by ICCA in 2000 with a first formal audit in 2005. The 2005 audit was, however, terminated by ICCA when it discovered that, in the words of the report, ‘certain actions on the part of Plant 18’s management, immediately prior to the day of the audit, had compromised the integrity of the audit process’.18 The second formal audit took place in 2006 with some serious concerns identified regarding environmental health and safety standards. The Mattel response report, which is also published on the company website, details a robust response requiring the vendor to adequately address the compliance issues and to sustain this compliance at a satisfactory level before any new business is issued. From the report it is clear that Mattel is also involved with the ICTI, which has also placed the factory ‘on probation’, and that both organisations have been working with the plant management to help them to try to meet the required standards for compliance. The Toy Business According to United Nations Industrial Development data it was estimated that the global market for toys would touch $150 billion by 200519 and although Indian manufacturing in this sector is growing rapidly, China accounts for the bulk of global manufacturing, producing nearly eighty percent of the total. Toys can be roughly categorised as either video (computer games, video games, internet games etc.) games or traditional toys (dolls, plush, action figures, building bricks, vehicles, puzzles etc.) and the market is characterised by its volatility and seasonality. The bulk of toy sales occur during the final quarter of the year with up to seventy percent of sales in the three month run up to Christmas. Because of this highly seasonal demand pattern it has been estimated that manufacturers need substantially increased capacity if they wish production to keep pace with actual customer demand. The problem with that approach, of course, is that much of the capacity would be unused earlier in the year when demand is much lower. The sector is highly competitive with many innovative new product introductions every year. These can take the form of well known branded products such as Barbie or Fisher Price or toys that are associated with television series, movies or books, such as Batman action figures or Thomas the Tank Engine train sets, for example. It is almost impossible for a manufacturer to be able to accurately gauge the level of demand for a new product or the longevity of this demand because of the seasonality of trade and also because most new products fail and the actual lifecycle of new toy products has been experiencing a steady decline. Success for new toys is mainly driven by fashion and even those toys related to movies have seen a decline in the period of demand from up to six months down to two months or less. Competition tends to be intense and to centre on innovation and falling retail prices, with many toy manufacturers relying on older toys that may have a higher level of brand awareness in the market place. Uncertainty in the market place is compounded by all the above factors and also by the changing nature of consumer preferences and a high degree of impulse buying. These uncertainties make it very difficult for manufacturers to predict demand with any degree of accuracy. The long ordering and supply lead times coupled with these factors and also the different ways in which retailers and other distributors place orders in this market result in low supply reliability. Mattel Independent Monitoring and Transparency Asia reports, downloaded on 18.09.07 from; http://www.mattel.com/ about_us/Corp_Responsibility/cr_mimco.asp 19 TOYS, Rediff.com 18 Page 7 of 16 PD3 Exam Exemplar Questions July 2013 One of the factors contributing to the intense price competition is the growing power and concentration of retailers and their ability to integrate backwards up the supply chain. Many Chinese manufacturers can produce whole toys and large retailers are increasingly seeking to resource own retailer branded products rather than purchase branded product from toy suppliers. Retailers’ own brands are usually sold at lower prices and this further fuels the price competition in the market. Difficulties in forecasting demand with any degree of accuracy, particularly for new and innovative products, together with the highly seasonal nature of the business results in very high levels of obsolescence and high costs incurred in the form of discounts used to liquidate inventory. Sales of toys fall very sharply after the Christmas peak and it is often difficult for manufacturers to introduce new toys at this time. Well known branded toys such as Barbie™ that are market leaders and have been around for a very long time (50 years +) create a very strong market pull and are therefore more resistant to some of these pressures. Published research into toy supply chains (Wong C Y et al, 2005)20 has found that most retailers of toys also sell a wide variety of other merchandise. They tend to order toys infrequently and in batches, and usually expand the space allocated to toys for the fourth quarter in the run up to Christmas. These retailers, unlike some of the toy specialists, tend not to be involved in sharing POS (point of sales) information or in collaborative SCM practices such as JIT (Just In Time), QR (quick response) or CPFR (collaborative, production, forecasting and replenishment) although some are starting to consider initiatives such as VMI (vendor managed inventory), cross-docking, CPFR and RFID. Many of these retailers have deliveries directly from the manufacturer to their own RDCs (regional distribution centres). Because they tend to have 60-80 percent of their orders pushed by the manufacturer they often commit to early orders if the supplier gives them a discount. The second most common form of retailer of toys includes discounters, hypermarkets and supermarkets and some department stores selling a wider variety of merchandise product categories in addition to toys. These retailers in general receive deliveries into their RDCs (Regional Distribution Centres) from their toy supplier’s RDCs on a weekly or monthly basis and order early in response to discount incentives from the suppliers. A number of these retailers deploy collaborative SCM practices with suppliers in other categories of FMCG (Fast Moving Consumer Goods) but very few have attempted such practices with toy suppliers, although some have initiated discussion with toy suppliers with regard to accurate response, CFPR, cross-docking and RFID. More advanced discounters and toy specialists attempt to adopt more of a ‘pull’ approach to SCM and collaborative information sharing practices are more common with this type of retailer. The above research and an earlier study concluded that “use of technology and information sharing (for example bar-coded merchandise, product data information sharing, POS (Point of Sale) data sharing, EDI (Electronic Data Interchange), sales captured at item levels etc.) by the toy sector is relatively lower than other sectors.” 21 Because of the factors identified above and in particular, the unpredictability of demand, the use of JIT type approaches are very rare and manufacturers tend to rely on ordering large quantities in advance and taking discount if necessary to clear slow moving or obsolete inventory. It is quite common for manufacturers to offer retailers large discounts to place bulk orders ahead of the season. Wong Chee Yew, Jan Stentoft Arlbjørn, John Johansen (2005), Supply chain management practices in toy supply chains, Supply Chain Management, Volume: 10 Issue: 5 Page: 367 - 378. 21 Ibid. 20 Page 8 of 16 PD3 Exam Exemplar Questions July 2013 Toy manufacturers tend to adopt one of three types of approach in managing their supply chain strategy. The first of these focuses on lean production and supply, producing large quantities in low labour cost locations on long lead times at very low cost. This type of manufacturer tends to rely on a push type approach22 because they are not so responsive and to use marketing and discounting to encourage demand. Clearly those with the most popular brands will be in the best position. Mattel and RC2 Corp. would be considered as this type of manufacturer since most of their products are made in low cost countries. The second SCM approach is similar to the first type but the manufacturers are located closer to their customer markets. They have a problem because they are theoretically better able to respond more quickly to changes in demand, but they are still attempting to adopt a mass-production strategy even though they have higher fixed costs. The third type of approach is really a chase demand or more responsive SCM strategy with some orders produced ahead of the season but the remainder of the capacity used to adjust to actual demand and to supply on a QR basis. This approach requires innovation in product design and a high degree of collaboration and information sharing. Published research23 found relatively few successful examples of this although there were signs of manufacturers moving towards this system, with low labour cost production in Eastern Europe particularly well placed to supply the EU. There is also some evidence that a mixed model is being employed by some manufacturers with more innovative (risky) product development manufacturing in local short lead time markets and the mass volume more traditional product being manufactured in low cost longer lead time markets. Agile and adaptive supply chains in the toy industry would appear to be rather elusive24 but this is not surprising given that most of the toys for European and American consumers are manufactured many thousands of miles away. Doing Business in China On the 11th September 2007, in response to public concern and pressure regarding the recall of toys made in China, a joint statement was issued by the U.S. Consumer Product Safety Commission and the General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (GAQSIQ) titled ‘Enhancing Consumer Product Safety’. This statement affirmed the desire of both parties to protect consumers in both countries from unreasonable risks of serious injuries or deaths arising from products originating within their respective jurisdictions. The statement further sought to enhance bilateral cooperation between the two countries in consumer product safety and the effectiveness of regulatory oversight for consumer products. Fireworks, toys, lighters and electrical products were singled out for particular attention with regard to safety standards. GAQSIQ proposed in the statement to create and implement a plan to eliminate the use of lead paint on Chinese manufactured toys exported to the United States. The USCPC for its part agreed to offer training to Chinese government and industry representatives in regulatory and compliance matters and undertake ‘outreach efforts’ to US importers stressing their role in quality and safety assurance. The acting chairperson of the US CPSC, Nancy Nord, stated: “this is an important signal from the Chinese Government that it is serious about working with CPSC to keep dangerous products out of American homes. We will be looking for meaningful cooperation on the ground – that means not just with the Chinese government but also with industry at both ends of the supply chain.” 25 Although it could be argued that marketing a well known brand creates a powerful pull from the consumer. The more powerful the pull the less trade discount and trade promotion or ‘push’ type marketing is needed. 23 Wong Chee Yew, Jan Stentoft Arlbjørn, John Johansen (2005), Supply chain management practices in toy supply chains, Supply Chain Management, Volume: 10 Issue: 5 Page: 367 - 378. 24 Much of the research and information quoted in this section comes from, Wong Chee Yew, Jan Stentoft Arlbjørn, John Johansen (2005), Supply chain management practices in toy supply chains, Supply Chain Management, Volume: 10 Issue: 5 Page: 367 – 378, obtainable from Emerald On Line, the entire article is obtainable on the internet from; http://www.emeraldinsight.com/ Insight/ViewContentServlet?Filename=Published/EmeraldFullTextArticle/Articles/1770100504.html 25 www. CPSC.gov, Release #07-305, September 11 2007, downloaded on 15.09.07 from; www.cpsc.gov/cpscpub/prerel/ prhtml07/07305.html 22 Page 9 of 16 PD3 Exam Exemplar Questions July 2013 Shortly after this statement Mattel was forced to make a humiliating apology to China and admit that most of the Mattel products recalled were faulty because of a problem with Mattel’s own design. “It’s important for everyone to understand that the vast majority of those products that we recalled were the result of a flaw in Mattel’s design, not through a manufacturing flaw in Chinese manufacturers. Mattel takes full responsibility for these recalls and apologises personally to you, the Chinese people and all of our customers who received the toys.” 26 Of course, the majority of the Mattel and Fisher Price recalls concerned toys with small magnetic parts that could become detached and swallowed by a child. A smaller proportion, nevertheless quite substantial in volume, concerned Mattel and Fisher Price branded toys that had been finished with lead paint which is banned in the USA and also in the EU. Other manufacturers and retailers also had to recall substantial volumes of toys contaminated with lead paint that had been produced in China including RC2 Corp. recalling about one and a half million ‘Thomas and Friends’ wooden railway toys contaminated with lead paint.27 The Chinese government had, in fact, already taken steps to eliminate or reduce the use of lead and banned leaded petrol in 2000. Wu Yi, the Chinese Vice Premier, and most senior female official in the country was also appointed to head a new cabinet panel on product safety, in an attempt to address the country’s problems with product safety.28 China is one of the world’s fastest growing economies with an economic growth rate of more than ten percent a year on average since 197829 and a population of more than 1.3 billion people. This economy with a GDP of $US2765.4 billion has opened up to foreign investors since China’s accession to the WTO (World Trade Organisation) in 2001 and the government is expected to pursue further policies aimed at the liberalisation of trade. This is an incredible achievement, considering that the People’s Republic of China is only around fifty years old and that most business laws have only been enacted during the last twenty years. A plentiful supply of low cost skilled and semi skilled labour together with a very favourable foreign exchange rate and liberal tax rates help to make this market extremely attractive to foreign investors. The Economist ‘Big Mac’ Index30 suggested that the Chinese Yuan may be undervalued against the US Dollar by as much as 56 percent – the most undervalued currency, making this market even more attractive for foreign manufacturers with global or international customers. There are many rewards but also many dangers for western business people wishing to start doing business in China. Quite apart from the long distance to market and the inherently long lead times, there are very sharp cultural differences between China and the EU and North America, for example. These differences can have a major impact upon how business is conducted in China. In his book Cross-Cultural Business Behaviour (1999), Richard Gesteland makes the point that ‘face’ is very important in negotiating with Chinese business people and that you can cause serious loss of face by “expressing sharp disagreement, embarrassing them, criticizing them in public or by showing disrespect” (p155) and he further goes on to say that causing loss of face can disrupt promising business negotiations. A mistake may be repaired by saving your face with a ‘humble apology’ and allowing the other party to save face by allowing a ‘graceful exit from a difficult negotiating position’. In contrast Americans tend to be more verbally direct and to ‘tell it like it is’ placing more emphasis on frank and straightforward exchanges and can often be “suspicious of negotiators who prefer indirect, oblique, ambiguous communication.” (ibid) Thomas Debrowski, Mattel Exec. Vice President of Worldwide Operations, quoted in Daily Telegraph September 22nd 2007, ‘Mattel takes blame in China toy recall apology’. 27 Downloaded on15.09.07 from; http://www.cpsc.gov/cpscpub/prerel/prhtml07/07212.html 28 Royal Society of Chemistry, downloaded on 02.10.07 from; http://www.rsc.org/chemistryworld/News/2007/August/ 21080701.asp 29 China’s economy, How fit is the panda? Sep 27th 2007 | BEIJING. From The Economist print edition 30 The Economist Big Mac Index 2007, Downloaded on 02.10.07 from; http://www.economist.com/markets/indicators/ displaystory.cfm?story_id=8649005 26 Page 10 of 16 PD3 Exam Exemplar Questions July 2013 Social and cultural differences such as these can make it very difficult for foreign businesses wishing to enter a foreign market. One effective way of doing so is to form a partnership in the form of a joint venture or strategic alliance with a local organisation. In fact until relatively recently the only way a foreign owned company could invest directly in China was by forming a joint venture with a Chinese partner. This, of course, can be very beneficial to a foreign organisation especially if the partner or collaborator or agent has good ‘guangxi’ or connections and relationships with important and powerful people who are in positions to help businesses to cut through bureaucracy and to obtain favourable business deals. Taking time to establish a good relationship with the right partner is essential for businesses wishing to establish themselves successfully in this market. Foreign multinationals, in particular, need to understand how the political system works in a country that is moving rapidly from a planned, socialist economy to an entrepreneurial market economy while maintaining stable one-party rule. Performance evaluations for officials are based mainly upon GDP growth in areas or regions under their jurisdiction and they also gain by benefiting financially from that growth through investment in or holding positions for themselves or family members in key firms. Such incentives “encourage local officials to protect their enterprises from meaningful implementation of environmental laws and regulations that might constrain economic expansion. Indeed, officials often require that enterprises in their jurisdiction ignore such laws and regulations in their quest for GDP growth.” 31 It can therefore be a challenging process for multinationals to ensure that their supply chains meet international or even Chinese standards (ibid) without closely monitoring their contractors and subcontractors. The risks of not doing so, however, should be fairly obvious. Regulating and Controlling the Toy Industry (UK) The British Toy and Hobby Association (BTHA) has been operating to improve safety standards in children’s toys since it was founded in 1944. Members of the BTHA are responsible for over 95 percent of the British market for toys and games32 and currently hold the position of chair and secretary of the ICTI (International Council of Toy Industries). In 1961 in collaboration with the BSI (British Standards Institute) the BTHA published the world’s first toy safety standards and launched its own ‘Lion Mark’ in 1989. This mark indicates that toys are made to the current British and European Standards and that they are following the BTHA code of practice. Toys with the Lion Mark are manufactured to BS EN 71, the highest British and European safety standard. The Lion Mark is in two parts; the first is the graphic symbol and the second is a message telling the buyer that the toys conform to BS EN 71. European Standard EN 71 consists of six parts including mechanical and physical properties of toys and specifications for the migration of certain elements (toxicity). Toys for sale within the European Union must also bear, or be accompanied by, the CE marking in a visible, easily legible and indelible form. It may be on the toys themselves or their packaging (regulation 10(1)). Affixing the CE marking represents a declaration, which only the manufacturer or his authorised representative in the Community can make, and results in a presumption – which is rebuttable – that the requirements of the regulations have been complied with. The Toy Safety Regulations 1995 (SI 1995 No.204) require, among other things, that toys or their packaging must bear the CE mark as a positive declaration by the manufacturer or his authorised representative that the toys satisfy the essential safety requirements of the Toys Safety Directive (regulations 10(2) (a) and 10(2) (b)) and that compliance has been verified by the use of the appropriate test/assessment procedures and that these have been correctly applied by the person entitled to do so.33 Economy E & Lieberthal K. (2007), Scorched Earth; will environmental risks in China overwhelm its opportunities?, Harvard Business Review, June 2007, p5. 32 Playsafe, Downloaded on 03.10.07 from; http://www.btha.co.uk/pdfs/PlaysafeToySafety.pdf?PHPSESSID=6b33f8aa1209146c9f 3d07168b1fa99d 33 DTI, Toy Safety Quick Facts Downloaded on 16.09.07 from; http://www.dti.gov.uk/consumers/fact-sheets/page38560.html 31 Page 11 of 16 PD3 Exam Exemplar Questions July 2013 Guidance from the BTHA to members concerning legislation on the chemical based legislation affecting toy safety standards is that demonstrating compliance by product testing is complicated, time-consuming and costly and is, in any case, not the most effective way of showing compliance. This is recognised by the regulatory authorities as the principal of “verification and assurance of conformity”, which the BTHA argues is a reasonable approach to apply to toys with regard to restricted chemicals, such as lead, for example. In order to obtain the CE mark a toy manufacturer will have to make a ‘declaration of conformity’ which is a recognised legal document. The BTHA recommend that in order “to maintain continuous compliance and ensure that restricted chemicals do not end up in finished products, the manufacturer needs to have in place systems and processes to manage the purchase of raw materials. A chemical management system would ensure that raw materials and components do not fail the requirements at source.”34 The BTHA goes on to say that “a chemical management system may include detailed purchase specifications, material supplier management systems, raw material and due diligence testing. Such systems may require an audit to validate them”. (ibid) Conclusion There are many criticisms levelled at multinational organisations for choosing to relocate their manufacturing operations from domestic markets in developed countries to developing countries many thousands of miles away. Suspicion is often focussed on cheap labour and possibly lower or less enforced health, safety and environmental legislation all contributing to lower production costs. Pressure groups concerned at the loss of manufacturing jobs and expertise, and politicians subject to pressure from lobby groups are often ready to make sweeping criticisms of an entire country rather than focus on the specifics. Ultimately, it is the responsibility of the manufacturer to ensure that its products are produced to the highest safety standards, that its workers are not exploited and that health and safety and environmental standards not compromised in the search for lower prices. In this case the stakes are very high since the safety of all our children is at stake as well as the acceptance of the ‘Made in China’ designation in world markets. British Toy and Hobby Association, Chemical Compliance the Bill of Material Approach, The British Toy and Hobbies Association, Toy Safety, Downloaded on 16.09.07 from; http://www.btha.co.uk 34 Page 12 of 16 PD3 Exam Exemplar Questions July 2013 QUESTIONS These questions relate to the case study and should be answered in the context of the information provided. You are advised to spend 45 minutes on each question. QUESTIONS Q1 (a) Explain a systematic process that Mattel could apply to analyse its supply chain environment. (10 marks) (b) Discuss, using examples, FIVE of the major STEEPLE factors that Mattel should consider when analysing its strategic supply chain. (15 marks) Q2 Evaluate the drivers for change for globalisation in Mattel’s supply chains that it should include in creating its supply chain plan. (25 marks) Q3 Mattel, based on the case study materials, has adopted an approach in managing its supply chain a strategy of focussing on lean production and supply, producing large quantities in low labour cost locations on long lead times at very low cost. Explain TWO benefits and TWO problems for Mattel of adopting “lean production and supply” as an approach to managing its supply chains. (25 marks) Q4 Discuss the potential benefits and problems with the use of outsourcing as a part of a supply chain strategy as used by Mattel. (25 marks) Page 13 of 16 PD3 Exam Exemplar Questions July 2013 Page 14 of 16 PD3 Exam Exemplar Questions July 2013 Page 15 of 16 PD3 Exam Exemplar Questions July 2013 Page 16 of 16 PD3 Exam Exemplar Questions July 2013