Improving Global Market Competitiveness of the Textile

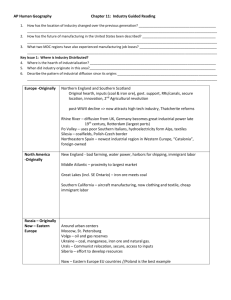

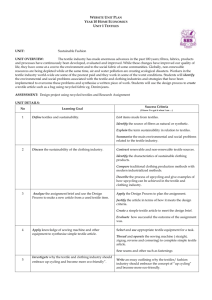

advertisement