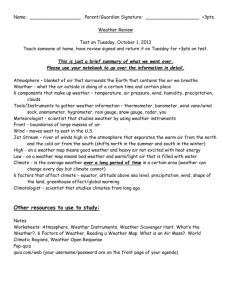

Process Measurement Instrumentation

advertisement