PDF Download

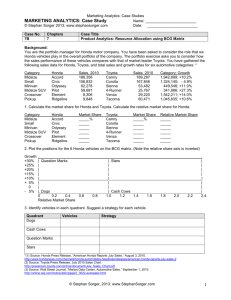

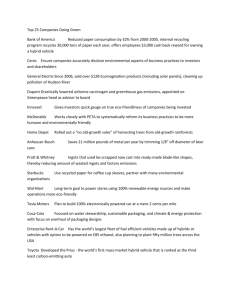

advertisement