View/Open - Research Archive

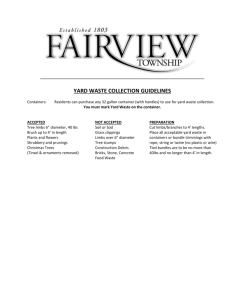

advertisement