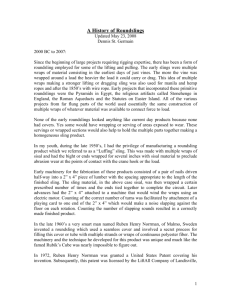

Welded Master Links

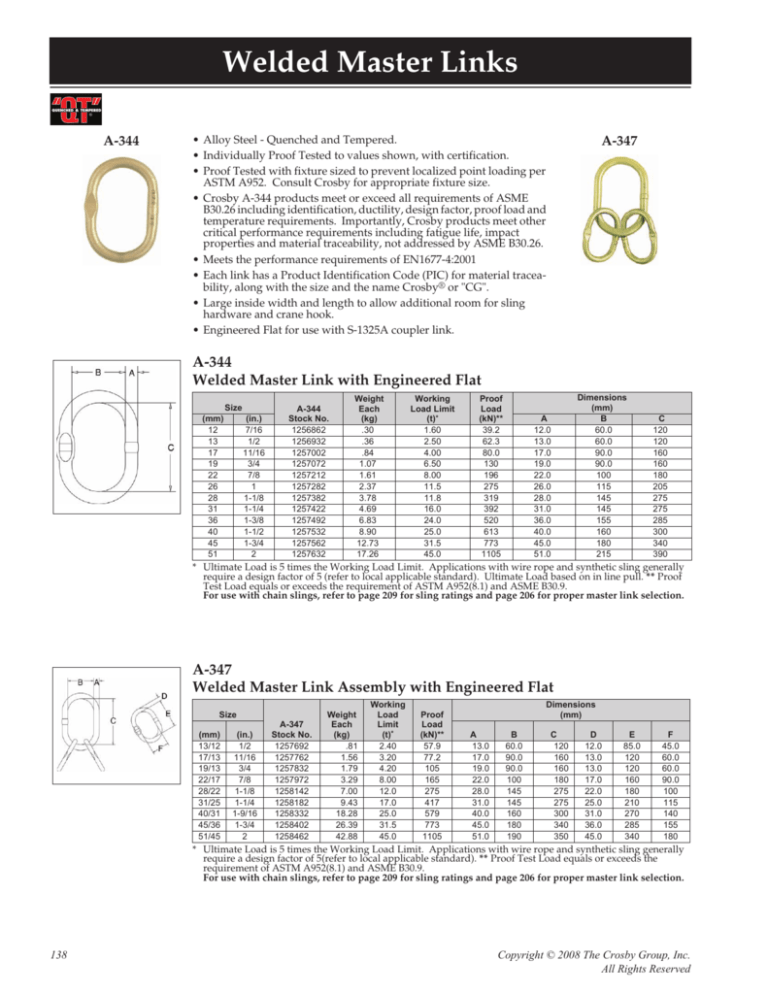

A-344

A-347

• Alloy Steel - Quenched and Tempered.

• Individually Proof Tested to values shown, with certification.

• Proof Tested with fixture sized to prevent localized point loading per

ASTM A952. Consult Crosby for appropriate fixture size.

• Crosby A-344 products meet or exceed all requirements of ASME

B30.26 including identification, ductility, design factor, proof load and

temperature requirements. Importantly, Crosby products meet other

critical performance requirements including fatigue life, impact

properties and material traceability, not addressed by ASME B30.26.

• Meets the performance requirements of EN1677-4:2001

• Each link has a Product Identification Code (PIC) for material traceability, along with the size and the name Crosby® or "CG".

• Large inside width and length to allow additional room for sling

hardware and crane hook.

• Engineered Flat for use with S-1325A coupler link.

s k n i L

r e t s a M

d e d l e W

A-344

Welded Master Link with Engineered Flat

A-34

Size

(mm)

12

13

17

19

22

26

28

31

36

40

45

51

(in.)

7/16

1/2

11/16

3/4

7/8

1

1-1/8

1-1/4

1-3/8

1-1/2

1-3/4

2

A-344

Stock No.

1256862

1256932

1257002

1257072

1257212

1257282

1257382

1257422

1257492

1257532

1257562

1257632

Weight

Each

(kg)

.30

.36

.84

1.07

1.61

2.37

3.78

4.69

6.83

8.90

12.73

17.26

Working

Load Limit

(t)*

1.60

2.50

4.00

6.50

8.00

11.5

11.8

16.0

24.0

25.0

31.5

45.0

Proof

Load

(kN)**

39.2

62.3

80.0

130

196

275

319

392

520

613

773

1105

A

12.0

13.0

17.0

19.0

22.0

26.0

28.0

31.0

36.0

40.0

45.0

51.0

Dimensions

(mm)

B

60.0

60.0

90.0

90.0

100

115

145

145

155

160

180

215

C

120

120

160

160

180

205

275

275

285

300

340

390

* Ultimate Load is 5 times the Working Load Limit. Applications with wire rope and synthetic sling generally

require a design factor of 5 (refer to local applicable standard). Ultimate Load based on in line pull. ** Proof

Test Load equals or exceeds the requirement of ASTM A952(8.1) and ASME B30.9.

For use with chain slings, refer to page 209 for sling ratings and page 206 for proper master link selection.

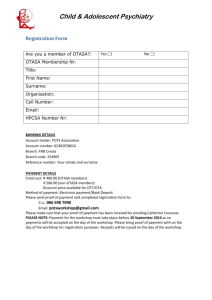

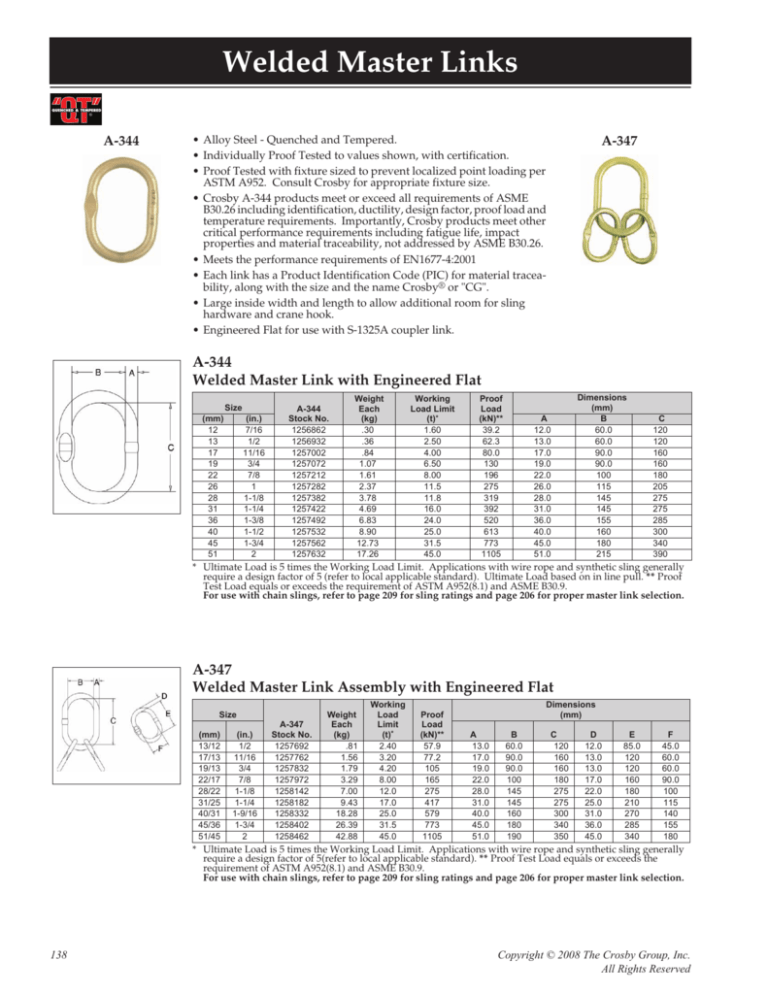

A-347

Welded Master Link Assembly with Engineered Flat

Size

(mm)

13/12

17/13

19/13

22/17

28/22

31/25

40/31

45/36

51/45

(in.)

1/2

11/16

3/4

7/8

1-1/8

1-1/4

1-9/16

1-3/4

2

A-347

A-347

Stock No.

1257692

1257762

1257832

1257972

1258142

1258182

1258332

1258402

1258462

Weight

Each

(kg)

.81

1.56

1.79

3.29

7.00

9.43

18.28

26.39

42.88

Working

Load

Limit

(t)*

2.40

3.20

4.20

8.00

12.0

17.0

25.0

31.5

45.0

Proof

Load

(kN)**

57.9

77.2

105

165

275

417

579

773

1105

Dimensions

(mm)

A

13.0

17.0

19.0

22.0

28.0

31.0

40.0

45.0

51.0

B

60.0

90.0

90.0

100

145

145

160

180

190

C

120

160

160

180

275

275

300

340

350

D

12.0

13.0

13.0

17.0

22.0

25.0

31.0

36.0

45.0

E

85.0

120

120

160

180

210

270

285

340

F

45.0

60.0

60.0

90.0

100

115

140

155

180

* Ultimate Load is 5 times the Working Load Limit. Applications with wire rope and synthetic sling generally

require a design factor of 5(refer to local applicable standard). ** Proof Test Load equals or exceeds the

requirement of ASTM A952(8.1) and ASME B30.9.

For use with chain slings, refer to page 209 for sling ratings and page 206 for proper master link selection.

138

Copyright © 2008 The Crosby Group, Inc.

All Rights Reserved