Thesis - MPG.PuRe

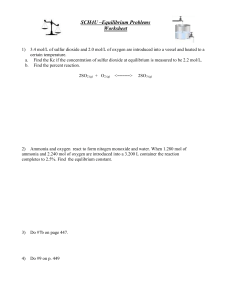

advertisement