Comparison of Traditional Worksheet and Linear Programming

advertisement

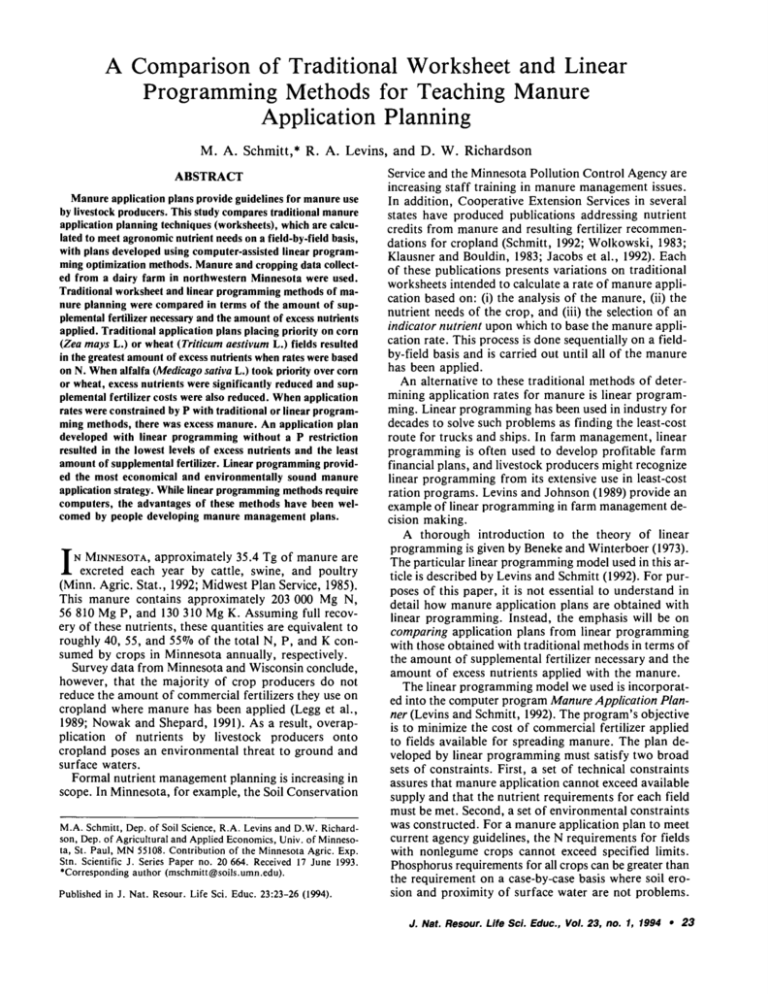

A Comparison of Traditional Worksheet and Linear Programming Methods for Teaching Manure Application Planning M. A. Schmitt,* R. A. Levins, ABSTRACT Manure applicationplansprovideguidelinesfor manure use by livestock producers.Thisstudycompares traditional manure applicationplanningtechniques(worksheets),whichare calculated to meetagronomic nutrientneedson a field-by-fieldbasis, with plans developedusing computer-assisted linear programmingoptimizationmethods.Manure andcroppingdatacollected froma dairy farmin northwesternMinnesotawere used. Traditionalworksheetandlinear programming methodsof manureplanningwere compared in termsof the amountof supplemental fertilizer necessary andthe amount of excessnutrients applied.Traditionalapplicationplansplacingpriority on corn (ZeamaysL.) or wheat(TriticumaestivurnL.) fields resulted in the greatestamount of excessnutrientswhenrates werebased on N. When alfalfa (Medicago sativa L.) tookpriority overcorn or wheat,excess nutrientsweresignificantly reducedandsupplementalfertilizer costs werealso reduced.When application rates wereconstrainedby P withtraditionalor linear programmingmethods,there wasexcess manure.Anapplication plan developedwith linear programming withouta P restriction resultedin the lowestlevels of excessnutrientsandthe least amount of supplemental fertilizer. Linearprogramming provided the most economicaland environmentallysound manure applicationstrategy. Whilelinear programming methods require computers,the advantagesof these methodshavebeen welcomedby people developing manuremanagement plans. IN MINNESOTA, approximately 35.4 Tg of manure are excreted each year by cattle, swine, and poultry (Minn. Agric. Stat., 1992; MidwestPlan Service, 1985). This manure contains approximately 203 000 Mg N, 56 810 MgP, and 130 310 MgK. Assuming full recovery of these nutrients, these quantities are equivalent to roughly 40, 55, and 55%of the total N, P, and K consumed by crops in Minnesota annually, respectively. Survey data from Minnesota and Wisconsin conclude, however, that the majority of crop producers do not reduce the amountof commercial fertilizers they use on cropland where manure has been applied (Legg et al., 1989; Nowakand Shepard, 1991). As a result, overapplication of nutrients by livestock producers onto cropland poses an environmental threat to ground and surface waters. Formal nutrient managementplanning is increasing in scope. In Minnesota, for example, the Soil Conservation M.A. Schmitt, Dep. of Soil Science, R.A. Levins and D.W. Richardson, Dep. of Agricultural and Applied Economics, Univ. of Minnesota, St. Paul, MN55108. Contribution of the Minnesota Agric. Exp. Stn. Scientific J. Series Paper no. 20 664. Received 17 June 1993. *Corresponding author (mschmitt@soils.umn.edu). Published in J. Nat. Resour. Life Sci. Educ. 23:23-26 (1994). and D. W. Richardson Service and the Minnesota Pollution Control Agencyare increasing staff training in manuremanagementissues. In addition, Cooperative Extension Services in several states have produced publications addressing nutrient credits from manureand resulting fertilizer recommendations for cropland (Schmitt, 1992; Wolkowski, 1983; Klausner and Bouldin, 1983; Jacobs et al., 1992). Each of these publications presents variations on traditional worksheets intended to calculate a rate of manureapplication based on: (i) the analysis of the manure, (ii) nutrient needs of the crop, and (iii) the selection of indicator nutrient upon which to base the manureapplication rate. This process is done sequentially on a fieldby-field basis and is carried out until all of the manure has been applied. An alternative to these traditional methodsof determining application rates for manure is linear programming. Linear programminghas been used in industry for decades to solve such problems as finding the least-cost route for trucks and ships. In farm management,linear programming is often used to develop profitable farm financial plans, and livestock producers might recognize linear programmingfrom its extensive use in least-cost ration programs. Levins and Johnson (1989) provide example of linear programming in farm managementdecision making. A thorough introduction to the theory of linear programmingis given by Beneke and Winterboer (1973). The particular linear programmingmodelused in this article is described by Levins and Schmitt (1992). For purposes of this paper, it is not essential to understand in detail how manure application plans are obtained with linear programming. Instead, the emphasis will be on comparing application plans from linear programming with those obtained with traditional methodsin terms of the amountof supplemental fertilizer necessary and the amount of excess nutrients applied with the manure. The linear programmingmodel we used is incorporated into the computer program Manure Application Planner (Levins and Schmitt, 1992). The program’s objective is to minimizethe cost of commercialfertilizer applied to fields available for spreading manure. The plan developed by linear programming must satisfy two broad sets of constraints. First, a set of technical constraints assures that manureapplication cannot exceed available supply and that the nutrient requirements for each field must be met. Second, a set of environmental constraints was constructed. For a manure application plan to meet current agency guidelines, the N requirements for fields with nonlegume crops cannot exceed specified limits. Phosphorusrequirements for all crops can be greater than the requirement on a case-by-case basis where soil erosion and proximity of surface water are not problems. J. Nat. Resour. Life Sci. Educ., Vol. 23, no. 1, 1994 ¯ 23 As environmental stewardship mandates that manure management plans he implemented by all livestock producers, determining manureapplication plans that effectively address both the economic and environmental concerns of the farmer is of paramount importance. Agricultural professionals working with livestock producers--current and soon-to-be (college students)need to be familiar with calculation techniques that are available. The objective of this study is to comparetraditional manureapplication planning techniques, which are calculated to meet agronomic nutrient needs on a fieldby-field basis, with manure application plans developed using linear programming methods. MATERIALS AND METHODS Manure and cropping data collected from an active dairy farm in northwestern Minnesota were used to compare manureapplication plans calculated by the traditional and linear programmingmethods. This case farm was a Holstein (Bos taurus) dairy operation with 121.5 ha of tillable cropland. The crops were wheat (62.8 ha), corn (16.2 ha), and alfalfa (42.5 ha). There were 40 milking cows with 30 other livestock comprising the replacement stock. Manure from the lactating cows was handled as a liquid in an earthern storage structure. There were 767.3 m3 produced/yr, and the analysis of this manure per 0.378 m3 was 15-10.1-15.8 (kg of N-P-K). Manure from the dry cows and other animals totaled 288 Mg/yr and was stored as a solid pack, the analysis of which was 6-3.1-10.8 kg N-P-K/t. Storage facilities were such that manurewas spread in the fall and spring. All of the manure was surface-broadcast; therefore, incorporation within a couple days was possible for that land planted to wheat and corn. Fertilizer recommendationsfor the three fields were based on soil tests, crop rotation, yield goals, and soil characteristics. The alfalfa, corn, and wheat recommendations were 0+24.9+125.3, 50+29.3+64.7, and 67 ÷ 14.9+28.2 kg/ha N, P, and K, respectively (Rehmet al., 1993a,b, c). A soil N test to measureresidual nitrateN was used because the location of the farm was in the more arid region of Minnesota. The farm had no significant slopes in its landscape and was not near surface water bodies, so no P restrictions were mandatedby Minnesoo ta’s Pollution Control Agency. Any needed supplemental fertilizer was surface-applied and incorporated into the soil. Fertilizer nutrients were valued at $0.29, $1.01, and $0.29 per kg of N, P, and K, respectively. Traditional manure application plans were calculated based on the nutrient requirement of the field and the nutrient content of the manure. Nitrogen availability indices were 0.40 for when the manure was applied to the wheat and corn and 0.20 when applied to the alfalfa, the difference due to incorporation (Schmitt, 1992). It was assumedthat a field could be partitioned into smaller portions. This allowed manureto be applied at the appropriate rate until the manure supply was gone. With traditional methods, the choice of which source of manure(liquid or solid) to use first, the order in which the fields were treated with manure, and the nutrient upon which applications were based was left to the judgment 24 ¯ J. Nat. Resour. Life Sci. Educ., Vol. 23, no. 1, 1994 Table 1. Seven manure application managementstrategies determined by selection of manure source, crop, and nutrient constraint priorities. Sequential solution order~ Strategy designation A B C D E F G H Manure 1st 2nd L S L S S L L S L S L S Simultaneous Simultaneous Crop 1st 2nd 3rd C C C W A A W W W C C C Simultaneous Simultaneous A A A A W W Nutrient constraint N P N N N~ P N P Abbreviations usedare:L = liquid, S = solid, C = corn,W = wheat, andA = alfalfa. Phosphorus isusedas constraining nutrient whenrates foralfalfa fields arebeing calculated. of the person using the method. To show how different solution strategies affected the plan developed, the traditional method was used in six different ways in which starting manure source, crop ordering, and indicator nutrient were varied (Table 1). The linear programming method was to calculate two plans--one with N and one with P as the indicator nutrient. For each solution, the total nutrients applied in excess of crop requirements and the cost of supplemental fertilizer were calculated. Because linear programmingconsiders all fields (crops) and manure sources simultaneously, the order of the fields or manure sources was irrelevant. RESULTS AND DISCUSSION The manure application plans developed for the case farm using different strategies are shownin Table 2. The first six plans were developed using variations on the traditional method, and the last two were developed with linear programming. Liquid manure application rates ranged from 1.9 to 41.3 m3/ha, depending on the strategy used to calculate the rates. Solid manurerates ranged from 0.8 to 24.0 Mg/ha. Although traditional application plans calculated manureapplication rates using only one source of manure for a given hectare, the solution using linear programming(strategies G and H) could determine application rates for both sources of manurefor a given field. Supplemental commercial fertilizer was often recommendedusing traditional rate calculation methodson fields after the supply of manurewas exhausted. Also, strategies that used P as the constraining nutrient generally required commercialN to be applied to the corn and wheatfields. All strategies required applications of supplemental K to the alfalfa crop. The excess nutrients and cost of supplemental fertilizer are shownin Table 3. None of the strategies allowed for excess N to be applied to any of the fields.. WhenP was the constraining nutrient (three of the eight strategies), no excess N was applied. Although N was recommended for alfalfa, the N was not considered excess. Based on the potential N amounts applied in a P-constraining calculation, research data have not found this N to be a high environmental risk due to the rapid disappearance of inorganic N (Schmitt et al., 1992). When Table 2. Application rates of liquid manure,solid manure, and commercialfertilizer for case farm’s crops as a function of selected strategy. Application rates Strategy A B C D E F G H Crop Wheat Alfalfa Corn Wheat Alfalfa Corn Wheat Alfalfa Corn Wheat Alfalfa Corn Wheat Alfalfa Corn Wheat Alfalfa Corn Wheat Alfalfa Corn Wheat Alfalfa Corn Liquidmanure Hectares m3/ha 41.3 Solidmanure Hectares N + P+ K Mg/ha 6.5 ........ 16.2 62.8 25.1 16.2 18.6 30.9 5.5 9.4 11.0 41.3 .... 41.3 24.0 12.2 67 + 14.9 + 28.2 0 24.9 125.3 ........ ..... 18.6 ....... .... 7.6 .... .... 58+ 0 + 5 0 + 0 + 64.7 32+0+ 19.9 67 + 14.9 + 28.2 0 + 24.9 + 125.3 17.4 17.9 12.5 16.2 23.1 ........ .... 9.4 30.9 5.5 9.4 11.0 6.8 1.9 15.9 7.5 3.8 7.5 42.5 12.2 33.6 42.5 16.2 62.8 42.5 16.2 62.8 42.5 16.2 Hectares kg/ha 24.0 .... 17.9 4.5 .... .... .... 6.7 .... 0.8 4.6 2.9 8.9 4.1 29.2 42.5 62.8 42.5 16.2 44.1 42.5 67 ÷ 14.9 ÷ 28.2 0 + 24.9 + 125.3 50 ÷ 29.3 + 64.7 67 + 14.9 + 28.2 0 + 0 + 87.2 62.8 42.5~" 16.2 44.1 42.5 -o 21.1 42.5 16.2 53.9 42.5 57+ 0 + 5 0 + 0 + 87.2 32+ 0 + 19.9 56+ 0 + 0 0 + 0 + 36.5 25 + 0 +0 57+ 0 + 0 0 + 0 + 54.8 30 + 0 + 0 62.85 42.5 16.2 62.8 42.5 16.2 62.8 42.5 16.2 Rates of Kwere 35.7 kg for 25.1 ha and 13.3 kg for 17.4 ha. Rates of N were 24 kg for 33.6 ha and 22 kg for 29.2 ha and the 1.7 kg of K was for only 336 ha. summedfor the entire case farm, excess nutrients ranged from 514 to 3059 kg for P and from 761 to 5452 kg for K. The cost of supplemental fertilizer varied from $1571 to $4494for the case farm. The fertilizer expense for the case farm if no manure were available would be $6303. The strategy selected had significant effects on application rates, excess nutrients, and the cost of supplemental fertilizer. Using traditional application planning methods,applying the solid or liquid manurefirst did not result in substantially different plans (Strategies A and C). These two strategies had comparable excess P and K nutrients and relatively high supplemental fertilizer COSt. The prioritization order given the three crops on this farm did have a noticeable effect when comparing the three strategies (A, D, and E). Similar results were achieved when either wheat or corn were the first two crops to receive manure (Table 3). However,whenalfalfa was given first priority for manure, the amounts of excess P and K were decreased by an average of 42 and 29%0,respectively. Averagesupplemental fertilizer costs decreased by 26%. Contrary to the perception that alfalfa should be the crop with the lowest priority for manure applications, the economic fertilizer replacement value of the P and K nutrients can be substantial, as this scenario illustrates. Basing manure application rates either on N or P had a noteworthy effect on the overall plans using traditional worksheetstrategies. Withstrategies that used P as the primary nutrient constraint (B and F), the case farm had excess manure(156 Mg) that could not be spread on the available land. With this P constraint, excess nutrient amounts were considerably less than with comparable Table 3. The effect of selected strategy on excess nutrients and supplemental fertilizer for case farm. Excess nutrients Strategy N~ P K Supplemental fertilizer:~ A B C D E F G H 0 0 0 0 0 0 0 0 kg 2254 0 3059 2385 1353 0 514 0 5061 0 3512 5452 3746 761 0 0 $ 4494 2188 4494 4541 3360 2395 1571 1859 Nitrogen applied to alfalfa is not considered excess. This is the total cost of the case farm’s fertilizer accounting for the nutrient credit of the applied manure. strategies using an N constraint, and the commercialfertilizer costs were also less (Table 3). Whenthe linear programmingstrategy that was constraining for P was used (Strategy H), there were no excess nutrients applied, a relatively small increase in supplementalfertilizer costs, and an excess of 197.3 m3 of manure. The application plan that was N-based and used the linear programmingmethod (Strategy G) had the smallest supplemental fertilizer bill (Table 3). However,the low manureapplication rates suggested (Table 2) pose a concern to most producers, because applying these rates can be challenging with current equipment options. Although this logistical concernis pertinent to the strategies involving linear programming or whenapplication rates are constrained by P in this case study, traditional manure worksheet plans can also result in low application rates depending on manure nutrient content and the nutrient needs of a field. J. Nat. Resour. Life Sci. Educ., Vol. 23, no. 1, 1994 ¯ 25 SUMMARY Traditional application plans can result in a wide range of excess nutrients and supplemental fertilizer costs depending on the priority of the crops to be fertilized and the nutrient that is the basis for the application rate. For the case farm studied, priority given to corn or wheat fields resulted in the greatest amount of excess nutrients when rates were based on N. Prioritizing manure application rates for alfalfa before corn and wheat or limiting applications for all crops based on P resulted in relatively lower levels of excess nutrients. However, whenever P was used as the constraining nutrient, all of the manure could not be applied on the producer's fields. Application plans that used linear programming to determine application rates resulted in the lowest cost for supplemental fertilizer. Linear programming calculation provided the most economical manure application strategy, but the practicality of applying some of the low manure rates may limit widespread adoption of this type of manure management plan calculation. The teaching of manure application planning and rate calculation using linear programming has been well accepted in Minnesota. We have conducted educational programs for state agency and county extension personnel and have first used traditional worksheet methods to create awareness about the amounts of excess nutrient and supplemental fertilizer costs before introducing the linear programming option. Although using linear programming will always require computers, participants were generally comfortable with the software after the demonstrations and workshop sessions. The advantages of the linear programming strategies compared with traditional worksheet methods were clearly recognized. ACKNOWLEDGMENT The case farm used in this article was adapted from a case study project prepared by Rhonda Amundson, Minnesota Extension Service, and Wendy Lewis, form- 26 • J. Nat. Resour. Life Scl. Educ., Vol. 23, no. 1, 1994 erly a graduate research assistant with the Department of Agricultural and Applied Economics, University of Minnesota.