Lab 8: FLUENT: Turbulent Boundary Layer Flow with Convection

Objective:

The objective of this laboratory is to use FLUENT to solve for the total drag and heat transfer

rate for external, turbulent boundary layer flow. In particular, we will investigate the flow of

water over a flat plate with constant surface temperature. This flow has been investigated by

many researchers [1-5]. Concepts introduced in this lab will include domain requirements for

external flows, external flow boundary conditions, and the use of wall functions for modeling

turbulent flows and the corresponding grid requirements.

Background:

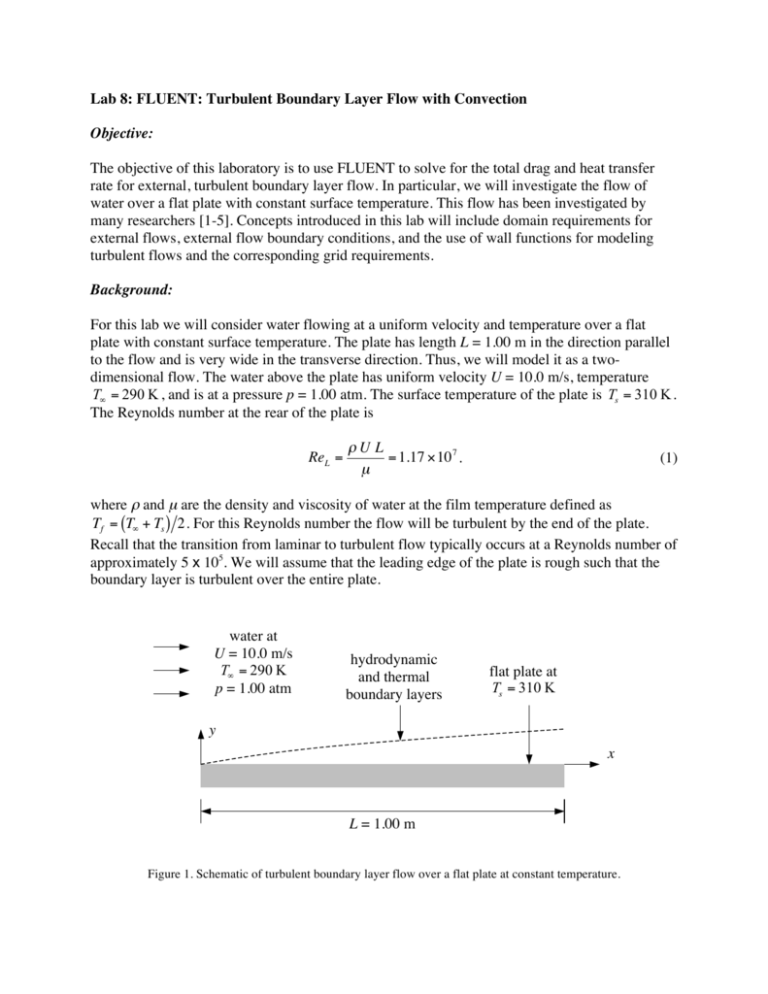

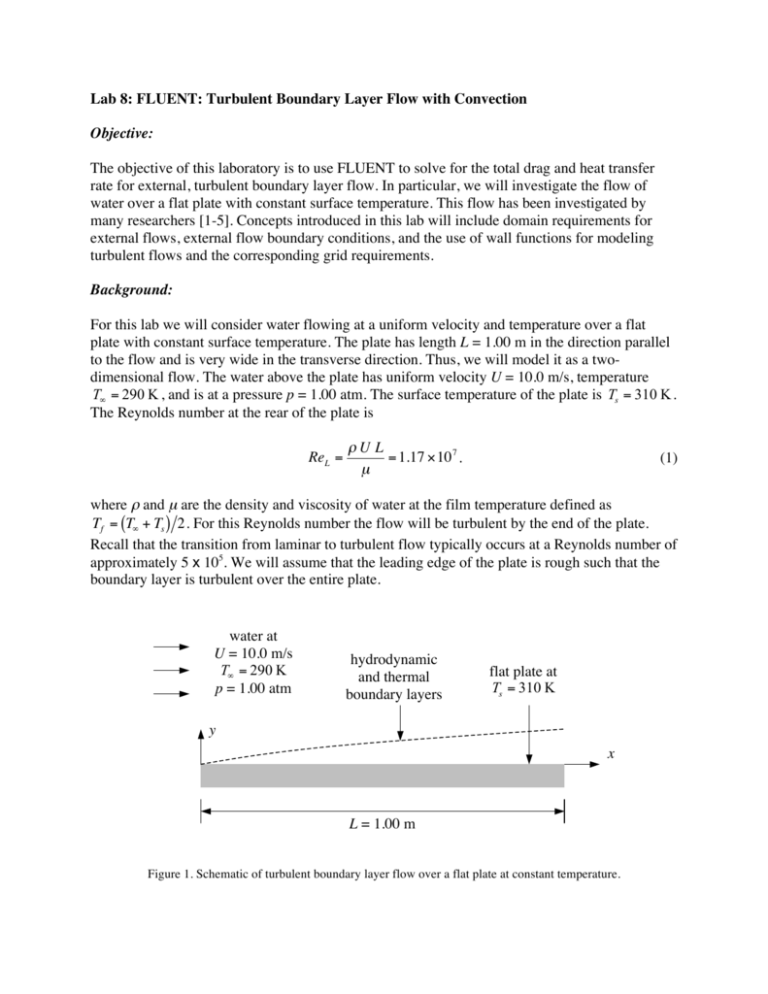

For this lab we will consider water flowing at a uniform velocity and temperature over a flat

plate with constant surface temperature. The plate has length L = 1.00 m in the direction parallel

to the flow and is very wide in the transverse direction. Thus, we will model it as a twodimensional flow. The water above the plate has uniform velocity U = 10.0 m/s, temperature

T∞ = 290 K , and is at a pressure p = 1.00 atm. The surface temperature of the plate is Ts = 310 K .

The Reynolds number at the rear of the plate is

ReL =

€

€

ρU L

= 1.17 ×10 7 .

µ

(1)

€

where ρ and µ are the density and viscosity of water at the film temperature defined as

Tf = (T∞ + Ts ) 2 . For this Reynolds number the flow will be turbulent by the end of the plate.

€

Recall that the transition from laminar to turbulent flow typically occurs at a Reynolds number of

approximately 5 x 105. We will assume that the leading edge of the plate is rough such that the

boundary layer is turbulent over the entire plate.

water at

U = 10.0 m/s

T∞ = 290 K

p = 1.00 atm

€

hydrodynamic

and thermal

boundary layers

flat plate at

Ts = 310 K

y

€

x

L = 1.00 m

Figure 1. Schematic of turbulent boundary layer flow over a flat plate at constant temperature.

The turbulent hydrodynamic boundary layer that forms at the leading edge of the plate grows

thicker downstream along the surface of the plate. Recall that a boundary layer is a thin region at

the surface where the flow velocity goes from zero (due to the no-slip condition at the surface) to

the free stream velocity. The turbulent boundary layer velocity distribution can be approximated

by the following power-law profile developed from a curve fit to experimental data

⎛ y ⎞1/ 7

u(y) = U ⎜ ⎟

⎝ δ ⎠

(2)

where y is the vertical coordinate measured upwards from the plate surface and δ is the boundary

layer thickness. A correlation for δ for a smooth plate is

€

δ 0.382

= 1/ 5 for 5 ×10 5 ≤ Rex ≤ 10 8

x Rex

(3)

where x is the horizontal distance along the plate measured from the leading edge of the plate

€ x as the length scale. For the same Reynolds number

and the Reynolds number is defined using

€ the skin friction coefficient on the plate has been developed

range, a correlation for

C f ( x) =

τ w ( x ) 0.0594

=

for 5 ×10 5 ≤ Rex ≤ 10 8

2

1/ 5

1

Rex

2 ρU

(4)

where τw is the shear stress at the wall and ρ is the fluid density. Note that the skin friction

€

coefficient and the wall shear stress are theoretically

infinite at the leading edge where the

€

boundary layer is very thin and then decreases along the plate. Equation (4) can be integrated

over the entire plate to calculate the total drag coefficient

1

CD = L

∫

1

2

L

x= 0

τ w dx

ρU

2

=

0.0743

Re1/L 5

(5)

which is used to calculate the total drag force

€

FD = 12 ρ U 2 A CD

(6)

where A is the total surface area of the plate in contact with the fluid.

€

In addition to the turbulent hydrodynamic

boundary layer, a thermal boundary layer also forms at

the leading edge of the plate and grows thicker along the surface of the plate. Due to the

significant turbulent mixing in the boundary layer region the growth rate of the hydrodynamic

and thermal boundary layers will be the same. Thus, Equation (3) can also be used to determine

the thickness of the thermal boundary layer. The local Nusselt number for the turbulent boundary

layer is given by the following correlation developed by Reynolds et al. [2]

2

⎛ ⎞−0.4

hx x

4 /5

0.6 T s

Nux =

= 0.0296 Rex Pr ⎜ ⎟

kf

⎝ T∞ ⎠

(7)

where hx is the local convection coefficient, kf is the thermal conductivity of the fluid, and Pr is

the Prandtl number. This correlation is valid for 5 ×10 5 ≤ Rex ≤ 10 8 and 0.6 ≤ Pr ≤ 60 .

€

Equation (7) can be integrated over the length of the plate to obtain the average Nusselt number

⎛ s ⎞−0.4

h€

L

4 /5

0.6 T€

Nu L =

= 0.037 Rex Pr ⎜ ⎟

kf

⎝ T∞ ⎠

(8)

which can be used to calculate the average heat transfer coefficient, h , and the total heat transfer

from the plate using

€

q = h A (Ts − T∞ ) .

€

(9)

Note that all of the above correlations were developed for turbulent flows over a wide range of

conditions such as free stream turbulence and actual plate roughness. Thus, they are only an

€ considered to be accurate to only about ±15% for any

approximation and are typically

particular flow condition.

Laboratory:

ICEM CFD

To create the mesh for our flow field, we will consider what is necessary to model the “real

flow” correctly. In particular, because this is an external flow we have to decide how large to

make the overall extent of the domain and how to handle the boundary conditions far away from

the flat plate.

From Equation (3) we can estimate the thickness of the boundary layer at the end of the plate to

be approximately 1.5 cm. However, as the boundary layer grows along the plate the fluid has to

move upward in the y-direction to satisfy conservation of mass. To allow the boundary layer to

grow unconstrained like it would for a real external flow we must make sure there is sufficient

area above the plate well beyond the width of the boundary layer to allow for this growth. The

best way to test if the extent of the domain is sufficient is to run your simulations on a series of

meshes of increasing extent from the solid surfaces until the solution no longer depends on this

parameter. For flat plate simulations a domain height equal to the length of the plate will

generally be sufficient. Also, the domain should begin before the plate (about 10% of the length

of the plate) to correctly simulate the flow at the leading edge.

For external simulations of blunt bodies (such as a car) a general recommendation is that the

domain be at least 3 body lengths in front of the body and 5 body lengths behind. Also, the body

should not be more than about 1.5% of the total cross-sectional area of the domain.

3

For the boundary condition at the top of the domain, where the velocity should be about the same

as the free stream velocity, there are three choices that will work: (1) fixed velocity of U,

(2) pressure outlet, or (3) symmetry. Again, if the extent of the domain is sufficient it should not

matter which one is used. Generally, the symmetry boundary condition will work the best

insuring that the boundary layer is unconstrained for a given domain size.

Finally, as with the pipe flow case that we considered in Lab 6 it is desirable to concentrate the

mesh in the boundary layer region where the gradients in velocity and temperature are the

highest. In fact, due to the strong interaction of the mean flow and turbulence, the numerical

results for turbulent flows tend to be more susceptible to grid dependency than those for laminar

flows. Thus, we need to carefully control the number of cells in the boundary layer and their

location relative to the wall. We do this in terms of a dimensionless variable called the wall unit

defined as

y+ =

ρ uτ y

µ

(10)

where uτ is the friction velocity defined as

€

uτ =

€

τw

ρ

(11)

In particular, we need to make sure that the y+ value for the centroid of the cell closest to the flat

plate is in the right range for the turbulence model we choose. We will discuss this further when

we select turbulence models in the€FLUENT section. We can estimate the size of the element

along the plate that corresponds to a particular y+ value using Equation (4) for the skin friction

coefficient to estimate the friction velocity. The results are shown in Figure 2.

100

y=δ

y

y (mm)

10

1

y+ = 300

y+ = 30

y+ = 5

0.1

0.01

0.001

0.0

0.2

0.4

0.6

0.8

1.0

xx (m)

Figure 2. Estimate of y-coordinate versus axial location and y+ value.

4

The range from 0 < y + < 5 is called the viscous sublayer because the effects of molecular

viscosity dominate in this region. The velocity in this region is simply

u+ =

€

u

= y+

uτ

(12)

The range from 5 < y + < 30 is called the buffer layer. There is no simple model to describe the

velocity in this range. Next is the log-law layer (or logarithmic overlap layer) where shear

€

stresses due to both molecular viscosity and turbulent mixing are both important. This layer

extends from y + > 30 up to approximately y + ≈ 300 where the actual y + magnitude is dependent

€

on the details of the flow. The velocity distribution in this region is given by

+

€ u =

€

u

= 2.5 ln( y + ) + 5.0

€

uτ

(13)

Finally, at higher y + values is the outer turbulent layer where turbulent shear dominates.

€

To begin we will create a mesh where 30 < y + < 300 for the centroid of the wall adjacent cell

which is in the log-law layer. Using Figure (2) as a guide, we will select a mesh size of 0.2 mm

€ adjacent to the wall for our initial mesh. After we have completed our simulations we

for the cell

will calculate our observed y+ values along the flat plate to determine if they are in the estimated

€ we have at least a few cells in the boundary layer region and that

range. Also, we will insure that

we do not use excessive stretching in the direction normal to the wall. We are now ready to

create a mesh for the external flow over the flat plate by following the sequence of commands

listed below. Your mesh will be a two-dimensional slice of the domain as shown in the Figure 3.

y

symmetry

plane

velocity

inlet

pressure

outlet

symmetry

plane

H = 1.0 m

flat plate

x

L0 = 0.1 m

L = 1.0 m

Figure 3. Schematic of computational domain.

5

To run ICEM CFD, click on the ICEM CFD icon on the desktop. In the Main Menu, from the

Settings pull down menu select Product. In the DEZ verify under Product Setup that ANSYS

Solvers - CFD Version is selected. If it is not, do so, click OK, exit the program, and then

restart ICEM CFD.

Step 1. Select Working Directory and Create New Project

Main Menu - Create a folder for your project. Do not use a name with spaces, including all the

directories in the path. From File pull down menu, select Change Working Directory using

LMB. In Browse for Folder dialog box select the folder you just created and click OK. Verify

that the new working directory has been set in the Message Window.

Main Menu - From File pull down menu, select New Project using LMB. In New Project dialog

box create a new project. Again, do not use a name with spaces. Verify that your new project has

been created in the Message Window.

Step 2. Start Recording Replay Script

Because we will create several meshes, we will use a replay script (written in the scripting

language Tcl/Tk) to generate meshes for a range of domain heights automatically.

Main Menu - From File pull down menu, select Reply Scripts -> Replay Control using LMB.

Organize the ICEM CFD window and Replay Control window so you can see both and ensure

that Record (after current) is selected in the Replay Control window. While creating the

geometry and mesh in the steps below note that script lines (or instructions) will be automatically

recorded in the Replay Control window under Operations in script.

Step 3. Create Points for Geometry

Function Tab - From Geometry select Create Point

using LMB.

DEZ - For Create Point enter the following:

deselect Inherit Part (NOTE, this is only needed for Windows OS),

in Part text edit box click LMB and enter PNT (replacing GEOM),

select Explicit Coordinates

using LMB,

under Explicit Locations ensure Create 1 point is selected from pull down menu,

in X, Y, and Z text edit boxes ensure 0 is entered in each for point at (0, 0, 0),

click Apply using LMB and verify the Message Done: points pnt.00,

repeat this process for all of the points listed in Table 1, and

click Dismiss using LMB.

Utilities - Select Fit Window

using LMB to verify that nine points have been created.

DCT - Expand Geometry and Parts menus by using LMB to change + to - for each.

6

Under Model\Geometry use RMB to click on Points and select Show Point Names using

LMB. Verify that nine points have been created.

Table 1. Coordinates for points with part name PNT.

Name

x (mm)

y (mm)

z (mm)

pnt.00

0

0

0

pnt.01

-100

0

0

pnt.02

1000

0

0

pnt.03

1000

50

0

pnt.04

0

50

0

pnt.05

-100

50

0

pnt.06

-100

1000

0

pnt.07

0

1000

0

pnt.08

1000

1000

0

In the Replay Control Window click Clean and Renumber using LMB. Note that lines that

mark the beginning and ending of an undo group are deleted.

Step 4. Create Curves for Geometry

Function Tab - From Geometry select Create/Modify Curve

using LMB.

DEZ - For Create/Modify Curve enter the following:

deselect Inherit Part (NOTE, this is only needed for Windows OS),

in Part text edit box click LMB and enter WALL (replacing PNT),

select From Points

using LMB,

select Select location(s) using LMB (if not already selected),

select pnt.00 and pnt.02 using LMB and then click MMB to create flat plate,

verify the Message Done: curves crv.00,

in Part text edit box click LMB and enter INLET,

select pnt.01 and pnt.05 using LMB and then click MMB to create lower inlet,

verify the Message Done: curves crv.01,

select pnt.05 and pnt.06 using LMB and then click MMB to create upper inlet,

verify the Message Done: curves crv.02,

in Part text edit box click LMB and enter OUTLET,

select pnt.02 and pnt.03 using LMB and then click MMB to create lower outlet,

verify the Message Done: curves crv.03,

select pnt.03 and pnt.08 using LMB and then click MMB to create upper outlet,

verify the Message Done: curves crv.04,

7

in Part text edit box click LMB and enter SYMMETRY,

select pnt.01 and pnt.00 using LMB and then click MMB to create boundary before plate,

verify the Message Done: curves crv.05,

select pnt.06 and pnt.07 using LMB and then click MMB to create left upper boundary,

verify the Message Done: curves crv.06,

select pnt.07 and pnt.08 using LMB and then click MMB to create right upper boundary,

verify the Message Done: curves crv.07,

in Part text edit box click LMB and enter INTERIOR,

select pnt.04 and pnt.00 using LMB and then click MMB,

verify the Message Done: curves crv.08,

select pnt.04 and pnt.07 using LMB and then click MMB,

verify the Message Done: curves crv.09,

select pnt.04 and pnt.05 using LMB and then click MMB,

verify the Message Done: curves crv.10,

select pnt.04 and pnt.03 using LMB and then click MMB,

verify the Message Done: curves crv.11,

click DISMISS using LMB.

DCT - Under Model\Geometry use RMB to click on Points and unselect Show Point Names

using LMB. Under Model\Geometry use RMB to click on Curves and select Show Curve

Names using LMB. Verify that twelve curves have been created.

In the Replay Control Window click Clean and Renumber using LMB. Note that lines that

mark the beginning and ending of an undo group are deleted.

Step 5. Create Surfaces for Fluid Flow

Function Tab - From Geometry select Create/Modify Surface

using LMB.

DEZ - For Create/Modify Surface enter the following:

ensure Inherit Part is NOT selected,

in Part text edit box click LMB and enter FLUID (replacing INTERIOR),

select Simple Surface

using LMB,

under Surf Simple Method ensure From 2-4 Curves is selected from pull down menu,

select Select curve(s) using LMB,

select crv.00, crv.03, crv.08, and crv.11 using LMB and then click MMB,

select crv.01, crv.05, crv.08, and crv.10 using LMB and then click MMB,

select crv.02, crv.06, crv.09, and crv.10 using LMB and then click MMB,

select crv.04, crv.07, crv.09, and crv.11 using LMB and then click MMB, and

click DISMISS using LMB.

NOTE: This step is not necessary for creating our mesh because the required surfaces are also

created during the blocking step below.

8

Step 6. Create Blocking

To create the meshes in Labs 6 and 7 we used 2-D surface (or shell) meshing. For this lab to

create the mesh we will use blocking, a useful tool for creating 2-D and 3-D structured grids for

complicated geometries. Step 1 is to create a block (or rectangle for 2-D) around the entire

geometry, consisting of edges and vertexes, which can be split up into sub-blocks (some of

which can be deleted) depending on the requirements of the geometry. Step 2 associates the

block vertexes and edges with the actual geometry points and curves, respectively. Step 3

specifies the distribution of nodes along each edge from which a structured mesh is generated for

each block and then mapped to the actual geometry.

Figure 4 shows an example for a simple pipe flow. For step 1, an initial single block is split twice

vertically and once horizontally. Then, the bottom left and right blocks are deleted leaving four

sub-blocks as shown on the left. For step 2, the vertexes and edges of the block are associated

with the actual pipe geometry on the right such that the bottom sub-block corresponds to the

small pipe and the three top blocks corresponded to the large pipe. For step 3, node distributions

on each edge of the sub-blocks are specified, structured meshes are created on each sub-block,

and then mapped to the actual pipe flow as shown.

!

Figure 4. Example of a block mesh mapped onto a curved geometry.

For this lab, the blocking is very simple and our block and actual geometry overlap as shown in

Figure 5 allowing us to use auto association. Blocking is still useful for this lab because it allows

us to easily modify the domain extent without changing the boundary layer mesh.

9

crv.06

y

Blockingcrv.07

Blocking

pnt.06

pnt.07

pnt.08

Figure: 3D Blocking

Figure: Blocking Menu

crv.02

crv.09

crv.04

H

pnt.05

crv.10

pnt.04

crv.11

pnt.03

The Blocking tab contains the following options to create blocking over any ge

crv.03

h

Create Block

crv.01

crv.08

crv.05

crv.00

Split Block

x

Merge

Vertices

pnt.01

pnt.00

pnt.02

Edit Block

Associate

L0

L

Move Vertex

Transform Blocks

Figure 5. Schematic

of blocking

strategy for flat plate.

Figure:

Blocking

Edit Edge2D

Pre-Mesh Params

Pre-Mesh Quality

DCT - Under Model\Geometry usePre-Mesh

RMB toSmooth

click on Curves and unselect Show Curve Names

using LMB, use RMB to click on Surfaces

and select Show Surface Names using LMB and

Block Checks

verify that four surfaces have been Delete

created,

and

Block then unselect Curves and Surface to hide them.

Create

Function Tab - From Blocking select

CreateBlock

Block

using LMB.

Create Block Options

DEZ - For Create Block enter theFigure:

following:

under Part select FLUID from pull down menu,

under Initialize Blocks Type select 2D Planar from pull down menu, and

click Apply and Dismiss using LMB.

Split

Function Tab - From Blocking select

SplitBlock

Block

using LMB.

DEZ - For Split Block enter the following:

under Split Method select Prescribed point from pull down menu,

select Select edge(s) using LMB,

The following options are available for creating blocks:

select left edge using LMB,

Initialize Block

select point on left edge at ( -100, 50, 0) using LMB to create horizontal split,

From Vertices/Faces

select bottom edge using LMB,

Extrude Face

select point on bottom edge2D

at to

(0,3D

0, Blocks

0) using LMB to create vertical split,

click Dismiss using LMB. 3D to 2D

The following options are available for splitting blocks:

NOTE: For the block, boundary edges

are

colored black and interior edges are light blue.

Split

Block

Ogrid Block

Extend Split

Split Face

Split Vertices

10

Split Free Face

Imprint Free Face

ANSYS ICEM CFD 13.0 - © SAS IP, Inc. All rights reserved. - Contains proprietary and confide

formation of ANSYS, Inc. and its subsidiaries and affiliates.

The Unsplit groups

Edge option

allows

you tocurves.

remove splits from edges. For the Single m

only the

selected

of the split edge to remove. For the All method, select the edge to remove all the

All tangential

groups all curves that are tangential to the selected curves.

Link Edge

Part by Part

groups all the curves in each part into composite curves.

The Link Edge option allows you to set the shape of edges. Select the target edg

Ungroup

Curves

Function Tab - From Blocking select

Associate

using LMB.

theAssociate

source

of the

shape.

allows you to select the composite curve to ungroup.

Figure:

Selected

DEZ - For Blocking Associations

enter theBlocking

following:Associations Options

Block

Mesh

Factor of Two

sets Figure:

the shape

of only

the Scaled

selectedby

edge.

Auto

under Edit AssociationsIn

select

AutoAssociate

Association

using LMB,

dimension

under Auto Association ensure

Snap

Project

Vertices

is

selected,

and edges. Select the source edge f

sets the shape automatically for

all connected

The

Auto

Associate

option

allows

you

to associate edges to curves. Auto As

click Apply and Dismiss using

the LMB.

Source index or vertex, and the Target index or vertex.

of the surfaces and the topology of the blocking and attempts to link the ed

in relation

the topology

the geometry.

NOTE: All the block edge colors should

turn to to

green

to indicateofthey

have been associated with

a curve. Using auto association is

only possible

Unlink

Edgebecause of the very simple geometry. In Lab 9

we will need to manually associate each vertex and edge.

Move Vertex

The Unlink Edge option allows you to unset the shapes of edges linked by the L

Step 7. Mesh Blocks and Surface

Figure:

Move

Vertices

Options

The

following

options

are available

for blocking associations.

Pre-Mesh

Params

Associate

Vertex

Function Tab - From Blocking select Pre-Mesh Params

using LMB.

Associate Edge to Curve

Associate

Edge toParameters

Surface

Figure:

Pre-Mesh

Options

DEZ - For Pre-Mesh Params enter

the following:

Associate Face to Surface

Edge

from

Geometry using LMB,

under Meshing ParametersDisassociate

select

EdgeParams

Params

Update

Associations

scroll down and select Copy Parameters using LMB

The

Edge Params

allows

youmenu,

to modify the mesh parameters in a

Reset

Associations

under Copy Method select To

All

Parallel

Edges option

from pull

down

various

bunching

laws

and

the

node

spacing along any particular edge. Ea

Snap Project

Vertices

scroll up and select Select Edges(s)

using

LMB,

that determine

the spacing of the mesh along the edge: number of nodes

Group/Ungroup

select bottom edge on left (corresponding

toCurves

before

the flat plate) using LMB,

the beginning/end of the edge, the expansion of the mesh from the be

Autoat

Associate

under Mesh law select Uniform from pull down menu,

andoptions

the maximum

element

the edge.

Theinterior,

following

are available

for length

movingalong

vertices:

under Nodes enter 11,

Move Vertex

TheAssociate

following

options

are available

for up

Pre-Mesh

parameters:

The Edge

Params

icon brings

a window

with all the mesh parameters

Vertex

Set

Location

NOTE: The edge meshing will automatically

be

applied,

recorded

in

the

replay

script,

and shown

Updatethe

Sizes

mesh parameters for that edge will be displayed.

All parameter values

Align

Vertices

as soon as you enter or change theScale

number

of

nodes

so

you

do

not

need

to

click

Apply.

Edge ID and

theoption

Edge Length,

which

are pre-defined.

The Sizes

Associate

Vertex

allows you

to associate

vertices and project the ve

Align

Vertices

In-line

Edge

Params

curves,

and

surfaces.

Select the vertex and the entity to project it onto.

Set

Edge

Length

select Select Edges(s) using

LMB,

Match Edges

Move Face Vertices

select bottom edge on right

(corresponding

to flat plate) using LMB,

Refinement

Associate

Edge

Curve

under Mesh law select Uniform

from pull

downto

menu,

under Nodes enter 101

ANSYS ICEM CFD 13.0 - © SAS IP, Inc. All rights reserved. - Contains proprietary an

Move

Vertex

The

Associate

Edge to Curve option allows

youofto

associate

edges

block

Update

Sizes

formation

ANSYS,

Inc. and its the

subsidiaries

andof

affiliates.

end of the edges are also associated to the same curve unless they were pre

select Select Edges(s) usingthe

LMB,

The

Move

Vertex

option

allows

you

to modify

the

location

of ausing

vertex.

Selec

curve

or

point.

Edge

segments

can to

be update

individually

associated

after

edge

sp

Update

Sizes

allows

sizes

in the

pre-mesh.

The followin

select left edge on bottomThe

(corresponding

tooption

flow

inlet

onyou

bottom)

using

LMB,

button,

accept

the

selection

by

pressing

the

middle

mouse

button,

and

use t

associated

with multiple

curves, but all the curves will be grouped into a single

for

updating

sizes

in

the

pre-mesh:

under Mesh law select Geometric

from

pull down

menu,

cancel1the

selection.

After

fixing the constraints, select the vertex to move.

under Spacing 1 enter 0.2

for

the

spacing

for

the

first

nodes

from the surface,

Update All

Note

Single

Method

under Nodes enter 22 (for Ratio

1 of 1.20816

andnode

Spacing

2 ofbased

8.78027

as indicated),

computes

the edge

spacing

on constraint

equations with the def

allows

to select

a singleofvertex

moved.

law. You

canyou

adjust

the number

nodestoonbeeach

edge based on the Global S

Associating edges to curves also results in the creation of line elements alo

select Select Edges(s) using Size

LMB,

and by

default each edge will follow the BiGeometric geometry law.

Multiple

Method

2D planar blocking, it is essential that all the perimeter edges be associated

select left edge on top (corresponding

flowtoinlet

onmultiple

top) using

LMB,for movement.

allowstoyou

select

vertices

because

many

solvers

use the perimeter

line elements as boundaries.

under Mesh law select Uniform from pull down menu,

Movement Constraints

ANSYS ICEM

CFDof

13.0

SAS IP, Inc. All rights reserved. - Contains proprietary and confidenti

under Nodes enter 96 (corresponding

to an element

size

10- ©mm),

374Project

allows

you to constrain a vertex

moving

initsany

direction.

formationto

of ANSYS,

Inc. and

subsidiaries

and affiliates.

vertices

click Dismiss using LMB.

If enabled, the vertices will automatically be projected to the corresponding

ANSYS ICEM CFD 13.0 - © SAS IP, Inc. All rights reserved. - Contains proprietary and co

formation of ANSYS, Inc. and its subsidiaries and affiliates.

Project to surface intersection

If enabled, the surface-surface intersection will be captured correctly. This is f

where the intersection curve may not match with the intersection of the sur

edge with11a curve using this option, the edge will be colored purple. The edg

ANSYS ICEM CFD 13.0 - © SAS IP, Inc. All rights reserved. - Contains proprietary and confiden

DCT - Expand Blocking menu by using LMB to change + to - . Under Model\Blocking select

Pre-Mesh. In the Mesh Dialog Box select Yes to compute the mesh.

NOTE: You should produce a structured mesh with nodes concentrated near the wall.

Step 8. Save Files and Export Initial Mesh

In Replay Control window unselect Record (after current) to stop recording your script. Click

Save and use the Save Script File Dialog Box to save a copy of your script file.

Main Menu - From File pull down menu, select Blocking -> Save Unstructured Mesh using

LMB. Use the Save Mesh as Dialog Box to save the unstructured mesh.

Function Tab - From Output select Output To Fluent V6 using LMB.

In Family boundary conditions dialog box:

expand Edges menu by using LMB to change + to -,

expand INLET menu by using LMB to change + to -,

click Create new to open the Selection dialog box,

under Boundary Conditions select velocity-inlet using the LMB,

click Okay using LMB to close the Selection dialog box,

expand INTERIOR menu by using LMB to change + to -,

click Create new to open the Selection dialog box,

under Boundary Conditions select interior using the LMB,

click Okay using LMB to close the Selection dialog box,

expand OUTLET menu by using LMB to change + to -,

click Create new to open the Selection dialog box,

under Boundary Conditions select pressure-outlet using the LMB,

click Okay using LMB to close the Selection dialog box,

expand SYMMETRY menu by using LMB to change + to -,

click Create new to open the Selection dialog box,

under Boundary Conditions select symmetry using the LMB,

click Okay using LMB to close the Selection dialog box,

expand WALL menu by using LMB to change + to -,

click Create new to open the Selection dialog box,

under Boundary Conditions select wall using the LMB,

click Okay using LMB to close the Selection dialog box,

click Accept using LMB.

In Save dialog box click Yes using LMB to Save current project first.

In Open dialog box click Open to select unstructured mesh with current project name.

In Fluent V6 dialog box enter the following:

in Grid dimension select 2D using LMB,

in Scaling ensure No is selected,

12

in Write binary file ensure No is selected,

in Ignore couplings ensure No is selected,

in Boco file retain the default file name,

in Output file change the file from fluent to a new name for your first mesh,

and click Done using LMB.

Step 9. Create and Save Meshes with Different Boundary Layer Node Spacings

Return to Steps 7 and 8, modify the edge parameters using the settings for Cases 2 through 5

shown in Table 2 (you have already done Case 1), and save your new project and meshes to

separate files. To recreate the mesh each time in the DCT under Model and Blocking deselect

and then reselect Pre-Mesh.

Table 2. Mesh settings for different boundary layer element spacing. All meshes have a total height of 1.0 m.

Case

1

2

3

4

5

Spacing 1

(mm)

0.2

0.002

0.2

0.2

0.2

Nodes

22

40

35

17

14

Growth

Factor

1.20816

1.25139

1.10082

1.31472

1.43545

Spacing 2

(mm)

8.78027

10.0462

4.75106

12.1213

15.3071

Step 10. Create and Save Meshes with Different Domain Heights

You will create 3 new meshes with new domain heights as shown in Table 2 where the bottom

two blocks are kept the same (Case 1 in Table 1) and only change the top two blocks are

changed. You will automate this process by using an edited replay script. You could use your

own replay script, but instead use the one named lab_8.rpl available from my web page and in

Appendix A. It is similar to the one you created, except that all unnecessary lines have been

removed, comment lines have been added, geometry parameters are defined to make it easier to

change the height, and lines to set the boundary conditions are included at the end.

Table 2. Mesh settings for different heights.

Case

6

7

8

Height

(mm)

500

250

100

13

Nodes

46

21

6

Complete the following steps to test the original replay script and then to change the height and

number of nodes to the values shown in Table 2 to generate your new meshes:

Main Menu - From File pull down menu, select Close Project using LMB. Use the Save Dialog

Box to save the current project if necessary.

In Replay Control window click Load using LMB to open text editor. Under Operations in

Script highlight the first line and click Do all using LMB. In DCT under Model expand

Blocking and select Pre-Mesh using LMB to display mesh. Verify that your Case 1 mesh has

been recreated.

Main Menu - From File pull down menu, select Close Project using LMB. Use the Save Dialog

Box to not save the current project (you already have your own).

In Replay Control window click Edit using LMB to open text editor. Note that lines 5 through

10 are used to set parameter values for the geometry. Change the height, H, to 500 for Case 6

above. Notice that in line 65 of the replay script, the number of nodes necessary to keep the mesh

spacing the same (dx = 10 mm) is calculated. Save and exit the replay script. Under Operations

in Script highlight the first line and click Do all using LMB. In DCT under Model expand

Blocking and select Pre-Mesh using LMB to display mesh. A new mesh with the new height but

the same element sizes on the upper portion should be created.

Main Menu - From File pull down menu, select Blocking and Save Unstructured Mesh using

LMB. Use the Save Mesh As Dialog Box to save the current unstructured mesh.

Main Menu - From File pull down menu, select Save Project using LMB. Use the Save Project

Dialog Box to save the current project.

Function Tab - From Output select Output To Fluent V6 using LMB.

In Save dialog box click Yes using LMB to Save current project first.

In Open dialog box click Open to select unstructured mesh with current project name.

In Fluent V6 dialog box enter the following:

in Grid dimension select 2D using LMB,

in Scaling ensure No is selected,

in Write binary file ensure No is selected,

in Ignore couplings ensure No is selected,

in Boco file retain the default file name,

in Output file change the file from fluent to a new name for your first mesh,

and click Done using LMB.

Repeat these steps for the other 2 heights and node spacings.

Main Menu - From File pull down menu, select Exit using LMB.

14

FLUENT

Similar to the mesh, turbulence models must be carefully selected that are capable of correctly

modeling wall interactions so that quantities like wall shear stresses (used to calculate drag) and

temperature gradients (used to calculate heat transfer rates) can be accurately predicted. For this

class will use the k-ε turbulence model which is an older, but still very popular model for CFD

simulations. However, this model in its simplest form is primarily valid for the turbulent core

region away from walls. Therefore, the simplest version of the k-ε model must be modified to

model the near-wall region. The following are two common approaches used:

(1) Wall Function Method: The viscous sublayer and buffer layer are not resolved. Instead, semiempirical formulas called “wall functions” (Equations (12) and (13) for the velocity) are used to

bridge the viscosity-affected regions between the wall and the log-law layer. The use of wall

functions eliminates the need to modify the turbulence models to account for the presence of the

wall. The wall function method is in general economical, robust, and reasonably accurate. The

wall function method is further divided into “standard” and “non-equilibrium” versions. The

non-equilibrium version more accurately accounts for the effects of pressure gradients and

departures from equilibrium and is recommended for flows with high pressure gradients and

separation. The following mesh requirements should be used for this method:

•

The wall-adjacent cell’s centroid should be located between 30 < y + < 300 which is

in the log-law layer. A y + value close to the lower bound ( y + ≈ 30 ) is most desirable.

•

Excessive stretching in the direction normal to the wall should be avoided.

€

There should €

be at least about 3-5 cells inside the€boundary layer.

•

(2) Near-Wall Modeling: The turbulence models are modified to enable the viscosity-affected

region to be resolved with a mesh all the way to the wall, including the viscous sublayer.

Because the resulting equations are more complicated and the mesh needs to be more refined

near the wall this method is computationally more expensive. However, in situations where the

details of the boundary layer need to be resolved or they do not follow the standard relations

given by the wall functions this method will be much more accurate. The following mesh

requirements should be used for this method:

•

The wall-adjacent cell’s centroid should be located between 0 < y + < 5 which is in the

viscous sublayer. A y + value close to 1 is most desirable.

•

Excessive stretching in the direction normal to the wall should be avoided.

€

€ be at least 10 cells inside the viscosity-affected near-wall region.

There should

•

Note that for both of these methods it is very important that the wall adjacent cell’s

centroid not lie in the buffer region ( 5 < y + < 30 ).

€

15

For our case of turbulent flow over a flat plate where there are no strong pressure gradients and

no flow separation, any of these models will perform reasonably well. We will demonstrate this

by running each of these near-wall modeling approaches and show that we can get reasonable

results for each as long as we follow the recommended guidelines for the mesh. Begin by

completing the following steps:

Step 1. Read In Mesh

Import your first mesh created using ICEM CFD into FLUENT. Check to make sure the mesh

imported correctly and that you scale it correctly from mm to m.

Step 2. Problem Setup for Initial Simulation

In the Navigation Pane under Problem Setup use the following steps to setup your simulation:

General, Solver

• Type: Pressure-Based

• Time: Steady

• Velocity Formulation: Absolute

• 2D Space: Planar

Models (remaining models off)

• Energy: On

• Viscous (use defaults for coefficients and remaining options)

o Model: k-epsilon

o k-epsilon Model: Realizable

o Near-Wall Treatment: Standard Wall Functions

Materials, Fluid, water (change the properties for water to those at 300 K)

• Density: 997 .kg/m3

• Specific Heat: 4179 J/kg•K

• Thermal Conductivity: 0.613 W/m•K

• Viscosity: 8.55e-04 kg/m•s

Cell Zone Conditions

• Zone: water-flow

o Type: fluid

o Material Name: water

• Operating Conditions

o Operating pressure: 101,325 Pa

o Gravity: NOT selected

Boundary Conditions

• Zone: inlet

o Type: velocity-inlet

o Edit: Momentum tab

16

•

•

•

• Velocity Specification Method: Magnitude, Normal to Boundary

• Velocity Magnitude: 10.0 m/s

• Turbulence, Specification Method: Intensity and Viscosity Ratio

• Turbulent Intensity: 1%

• Turbulent Viscosity Ratio: 1.0

o Edit: Thermal tab

• Temperature: 290 K

Zone: outlet

o Type: pressure-outlet

o Edit: Momentum tab

• Gage Pressure: 0 Pa,

• Turbulence, Specification Method: Intensity and Viscosity Ratio

• Turbulent Intensity: 1%

• Turbulent Viscosity Ratio: 1.0

o Edit: Thermal tab

• Temperature: 300 K

Zone: wall

o Type: wall

o Edit: Momentum tab

• Wall Motion: Stationary Wall

• Shear Condition: No-Slip

o Edit: Thermal tab

• Temperature: 310 K

Zone: symmetry

o Type: symmetry

Step 3: Solution Setup for Simulation

In the Navigation Pane under Solution use the following steps to setup your solution methods,

controls, monitors, and initialization:

Solution Methods

• Pressure-Velocity Coupling

o Scheme: SIMPLE

• Spatial Discretization

o Gradient: Least Squares Cell Based

o Pressure: Standard

o Momentum: QUICK

o Turbulent Kinetic Energy: QUICK

o Turbulent Dissipation Rate: QUICK

o Energy: QUICK

Solution Controls

• Under-Relaxation Factors: default values

17

Monitors, Residuals

• Options

o Print to Console: selected

o Plot: selected

• Equations, Residual

o Monitor: selected for all

o Check Convergence: selected for all

o Absolute Criteria: 1e-6 for all

Solution Initialization

• Compute from: inlet

Step 4. Run Calculation

Navigation Pane - Under Solution select Run Calculation.

Task Page - Under Number of Iterations enter 1000 and click Calculate. The problem should

converge after about 500 iterations. However, later cases will not always reach 10-6 residuals.

Step 5. Make Contour Plots

Visualize your results by displaying a contour plot of temperature. You should see a VERY thin

layer of hot fluid near the surface of the plate. You will have to zoom in to see this.

Step 6. Make xy Plots of Variables

Make an x/y plot of the x-velocity profile at the exit of the flow using the following steps:

Navigation Pane - Under Results select Plots.

Task Page - Under Plots select XY Plot and Set Up to open Solution XY Plot Dialog Box.

In the Solution XY Plot Dialog Box do the following steps:

deselect Position on X Axis,

select Position on Y Axis,

under Plot Direction for X enter 0 and for Y enter 1,

under X Axis Function select Velocity and X Velocity,

under Surfaces select outlet

click Axes button and in the Axes - Solution XY Plot Dialog Box,

under Axis select Y,

under Options deselect Auto Range,

under Range set the Maximum to 0.05, and

click Apply and Close

click Plot to display the xy plot in the Display Window.

18

NOTE: Check that the velocity profile looks like a typical turbulent velocity profile and that the

thickness of the boundary layer is about 1.5 cm. Also, check how many nodes appear to be

within the boundary layer region and verify that it is at least 3-5. Write the data to a file.

Make an x/y plot of the temperature profile at the exit of the flow. To do this follow the

instructions above, but under X Axis Function select Temperature and Static Temperature.

NOTE: Check that the temperature profile looks like a typical turbulent temperature profile and

that the boundary layer thickness is also about 1.5 cm. Write the data to a file.

Make x/y plot of dimensionless wall unit, y+, for first cell along plate using the following steps:

In the Solution XY Plot Dialog Box do the following steps:

deselect Position on Y Axis,

select Position on X Axis,

under Plot Direction for X enter 1 and for Y enter 0,

under Y Axis Function select Turbulence and Wall Yplus,

under Surfaces deselect outlet and select wall,

click Axes button and in the Axes - Solution XY Plot Dialog Box

under Axis select Y,

under Options select Auto Range, and

click Apply and Close

click on Plot.

NOTE: Check that y+ values begin at about 65 near the leading edge and then decrease to about

40. This satisfies our mesh requirements for range for this value. Write the data to a file.

Step 7. Define Dimensionless Variables

First, set the reference values used to calculate the friction coefficient and heat transfer

coefficient to the flow conditions far above the plate and the properties set earlier for water using

the following steps:

Navigation Pane - Under Problem Setup select Reference Values.

Task Page - Under Reference Values select the following:

under Compute From select inlet and

under Reference Zone select fluid from the pull-down menus.

Define the local Reynolds number (use “re-x” for the name) and Nusselt number (use “nu-x” for

the name) using Define\Custom Field Functions from the Menu Bar. For both the Reynolds and

Nusselt numbers use the x-location for the length scale. To do this under Field Functions select

Mesh and X-Coordinate from the pull-down menus.

19

For the Reynolds number you can find ρ in the Field Functions under Density and µ in the

Field Functions under Properties and Molecular Viscosity where the definition will be given

as viscosity-lam. For the velocity use the constant free stream velocity of 10 m/s.

For the Nusselt number you can find hx in the Field Functions under Wall Fluxes and Surface

Heat Transfer Coefficient where the definition will be given as heat-transfer-coef. Also, you

can find kf in the Field Functions under Properties and Thermal Conductivity where the

definition will be given as thermal-conductivity-lam.

NOTE: FLUENT has a built in function that calculates the Nusselt number, but it uses a constant

length scale (defined in the reference values) instead of the distance along the plate which is

what we need to compare to correlations.

Step 8. Make xy plots of Dimensionless Variables

Make an x/y plot of the skin friction coefficient versus Reynolds number.

Navigation Pane - Under Results select Plots.

Task Page - Under Plots select XY Plot and Set Up to open Solution XY Plot Dialog Box.

In the Solution XY Plot Dialog Box do the following steps:

deselect Position on X Axis,

under Y Axis Function select Wall Fluxes and Skin Friction Coefficient,

under X Axis Function select Custom Field Functions and re-x,

under Surfaces select wall, and

click on Plot.

NOTE: The skin friction coefficient should be highest near the leading edge and decrease along

the plate. Write the data to a file.

Make an x/y plot of Nusselt number versus Reynolds number.

In Solution XY Plot Dialog Box do the following steps:

deselect Position on X Axis,

under Y Axis Function select Custom Field Functions and nu-x,

under X Axis Function select Custom Field Functions and re-x,

under Surfaces select wall, and

click on Plot.

NOTE: The Nusselt number should be 0 at the leading edge and increase to approximately

40,000. Write the data to a file.

Step 9. Calculate Total Drag Force and Heat Transfer Rate

Navigation Pane - Under Results select Reports.

20

Task Page - Select Forces and click Set Up to open the Force Reports Dialog Box.

In Force Reports Dialog Box under Wall Zones select wall and click Print to display

calculated forces in Console. The pressure force should be zero because the plate is parallel to

the flow. Record the magnitude of the viscous force. A width of 1.0 m set in the reference values

is used for this calculation.

Task Page - Select Fluxes and click Set Up to open the Flux Reports Dialog Box.

In Force Reports Dialog Box under Options select Total Heat Transfer Rate, under

Boundaries select wall, and click Compute to display calculated fluxes in Console. Record the

magnitude of the total heat transfer rate. A width of 1.0 m is also used for this calculation.

Step 10. Save Case and Data Files

Step 11. Test Near-Wall Treatments

Use the Viscous Model Dialog Box to change the turbulence model’s Near-Wall Treatment to

Non-Equilibrium Wall Functions and rerun the simulation on the current mesh by repeating

Steps 4 through 10 (using a different file name) for this case.

Use the Define\Model\Viscous menu to change the turbulence model’s Near-Wall Treatment

to Enhanced Wall Treatment and rerun the simulation on a revised mesh that has the

appropriate refinement in the viscous sublayer (Case 2 in Table 1). Rerun the simulation by

repeating Steps 4 through 10 (using a different file name) for this case. In particular verify that

the y+ values are again correct for this turbulence model’s wall treatment.

Step 12. Test Mesh Refinement

Use a series of meshes (Cases 1, 3, 4, and 5 in Table 1) to test the effect of refining the grid in

the boundary layer. Rerun the simulation by repeating Steps 4, 9, and 10 (using a different file

name) for each case. Make sure to correctly scale the mesh from mm to m each time. Note that

since all three near-wall region models perform about the same for this flow you will use the

simplest (k-ε turbulence model with standard wall functions) for the comparison.

Step 13. Test Domain Height

Use a series of meshes (Case 1 in Table 1 and Cases 6, 7, and 8 in Table 2) to test the effect of

domain height. Rerun the simulation by repeating Steps 4, 9, and 10 (using a different file name)

for each case. Again, make sure to correctly scale the mesh from mm to m each time. Again,

since all three near-wall region models perform about the same for this flow you will use the

simplest (k-ε turbulence model with standard wall functions) for the comparison.

21

Assignment

Submit the following figures:

Figures 1 (a) and (b). Plots of Case 1 and Case 2 meshes zoomed in to show wall region.

Figures 2 (a), (b), and (c). Plots for y+ versus x for the 3 near-wall region turbulence models

(Case 1 with Standard Wall Functions, Case 1 with Non-Equilibrium Wall Functions, and Case 2

with Enhanced Wall Treatment).

For all 3 near-wall region turbulence models above on the same plot, hand in Figures 3-6:

Figure 3. Plot of x-velocity component versus y at outlet along with power law velocity

profile given by Equation (2). Note, Equation (2) is only valid for y = 0 to δ.

Figure 4. Plot of temperature versus y at outlet.

Figure 5. Plot of skin friction coefficient versus Reynolds number along with correlation for

skin friction coefficient given by Equation (4).

Figure 6. Plot of Nusselt number versus Reynolds number along with correlation for Nusselt

number given by Equation (7).

Figures 7 (a) and (b). Plots of drag force and heat transfer rate versus height of domain, H

(corresponding to Cases 1, 6, 7, and 8).

Figures 8 (a) and (b). Plots of drag force and heat transfer rate versus growth factor

(corresponding to Cases 1, 3, 4, and 5).

Submit the following tables:

Table 1. Total drag force for each near-wall region turbulence model along with drag force

computed using correlation given by Equations (5) and (6).

Table 2. Total heat transfer rate for each model along with heat transfer rate computed using

correlation given by Equations (8) and (9).

Submit answers to the following questions:

1. Comment on your ability to validate your results using the experimental correlations

developed for turbulent flow.

2. Comment on what is a reasonable height for the domain for an accurate solution.

3. Comment on what is a reasonable growth factor for an accurate solution.

Refer to each of the Figures and Tables produced above as part of your answer. Limit your

comments to 1 page of text.

22

References

[1] Edwards, A. and Furber, B. N., “The Influence of Free-Stream Turbulence on Heat Transfer

by Convection from an Isolated Region of a Plane Surface in Parallel Air Flow,” Proc. Inst. of

Mechanical Engineers, 170, 1956.

[2] Reynolds, W. C., Kays, W. M., Kline, S. J., “Heat Transfer in the Turbulent Incompressible

Boundary Layer,” NASA Memo 12-1-58W, December 1958.

[3] Rubesin, M., “The Effect of an Arbitrary Temperature Variation Along a Flat Plate on the

Convective Heat Transfer in an Incompressible Turbulent Boundary Layer,” NACA Technical

Note 2345, 1951.

[4] Seban, R. A. and Doughty, D. L., “Heat Transfer to Turbulent Boundary Layers with

Variable Freestream Velocity,” Journal of Heat Transfer, 78, 217, 1956.

[5] Wang, Q., “On the Prediction of Convective Heat Transfer Coefficients Using GeneralPurpose CFD Codes,” AIAA Meeting and Exhibit, AIAA 2001-0361, January 2001.

23

Appendix A. Replay Script

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

64.

65.

# Replay script for Lab #8

#

# define parameters

#

set L 1000

set L0 -100

set h 50

set H 1000

set dx 10

#

# define points

#

ic_geo_new_family PNT

ic_empty_tetin

ic_point {} PNT pnt.00 0,0,0

ic_point {} PNT pnt.01 $L0,0,0

ic_point {} PNT pnt.02 $L,0,0

ic_point {} PNT pnt.03 $L,$h,0

ic_point {} PNT pnt.04 0,$h,0

ic_point {} PNT pnt.05 $L0,$h,0

ic_point {} PNT pnt.06 $L0,$H,0

ic_point {} PNT pnt.07 0,$H,0

ic_point {} PNT pnt.08 $L,$H,0

#

# define curves with boundary names

#

ic_geo_new_family WALL

ic_curve point WALL crv.00 {pnt.00 pnt.02}

ic_geo_new_family INLET

ic_curve point INLET crv.01 {pnt.01 pnt.05}

ic_curve point INLET crv.02 {pnt.05 pnt.06}

ic_geo_new_family OUTLET

ic_curve point OUTLET crv.03 {pnt.02 pnt.03}

ic_curve point OUTLET crv.04 {pnt.03 pnt.08}

ic_geo_new_family SYMMETRY

ic_curve point SYMMETRY crv.05 {pnt.01 pnt.00}

ic_curve point SYMMETRY crv.06 {pnt.06 pnt.07}

ic_curve point SYMMETRY crv.07 {pnt.07 pnt.08}

ic_geo_new_family INTERIOR

ic_curve point INTERIOR crv.08 {pnt.04 pnt.00}

ic_curve point INTERIOR crv.09 {pnt.04 pnt.07}

ic_curve point INTERIOR crv.10 {pnt.04 pnt.05}

ic_curve point INTERIOR crv.11 {pnt.04 pnt.03}

#

# define surfaces with zone name

#

ic_geo_new_family FLUID

ic_surface 2-4crvs FLUID srf.00 {0.01 {crv.00 crv.03 crv.08 crv.11}}

ic_surface 2-4crvs FLUID srf.01 {0.01 {crv.01 crv.05 crv.08 crv.10}}

ic_surface 2-4crvs FLUID srf.02 {0.01 {crv.02 crv.06 crv.09 crv.10}}

ic_surface 2-4crvs FLUID srf.03 {0.01 {crv.04 crv.07 crv.09 crv.11}}

#

# create blocks and autoassociate to overlapping geometry

#

ic_hex_initialize_mesh 2d new_numbering new_blocking FLUID

ic_hex_split_grid 11 13 FLUID.19 m FLUID VORFN

ic_hex_split_grid 11 19 FLUID.14 m FLUID VORFN

ic_hex_auto_associate_geometry

#

# set parameters for mesh on block edges

#

ic_hex_set_mesh 11 37 n 11 h1rel 0.0 h2rel 0.0 r1 2 r2 2 lmax 0 uniform copy_to_parallel unlocked

ic_hex_set_mesh 37 19 n 101 h1rel 0.0 h2rel 0.0 r1 2 r2 2 lmax 0 uniform copy_to_parallel unlocked

ic_hex_set_mesh 11 33 n 22 h1rel 0.004 h2rel 0.0 r1 2 r2 2 lmax 0 geo1 copy_to_parallel unlocked

ic_hex_set_mesh 33 13 n [expr int(($H-$h)/$dx + 1)] h1rel 0.0 h2rel 0.0 r1 2 r2 2 lmax 0 uniform

copy_to_parallel unlocked

24

66.

67.

68.

69.

70.

71.

72.

73.

74.

75.

76.

77.

#

# create mesh for blocks

#

ic_hex_create_mesh FLUID proj 2 dim_to_mesh 3

#

# set boundary conditions

#

ic_boco_set INTERIOR {{1 INTER 0}}

ic_boco_set WALL

{{1 WALL 0}}

ic_boco_set INLET

{{1 VELI 0}}

ic_boco_set OUTLET

{{1 PRESO 0}}

ic_boco_set SYMMETRY {{1 SYM

0}}

25