01000 GENERAL

1. The structure reflected on the drawings is structurally sound in its completed condition only. The design of any and all temporary shoring and bracing

prior to the completed condition shall be the contractor's responsibility. The Structural Engineer of Record (EOR) shall not be responsible for the means,

methods, techniques, sequences, procedures nor safety programs which are empolyed by the contractor to build the completed structure. Any deviations

from the completed structure represented in the drawings must be submitted to the EOR for approval in writing.

2. The Contractor shall verify all conditions including exsisting structures (above and below grade) and shall notify of the EOR of any discrepancies. The

Contractor shall perform all required field measurements.

3. The Sections and Details shown shall be considered to be typical for all similar conditions. The Contractor shall submit written Requests for Information

for areas in question.

4. The Contractor shall submit shop drawings for each of the structural components shown on the drawings. Four copies of the shop drawings shall be

submitted to the Architect for distribution.

D

03000 FOUNDATIONS:

1. The Contractor shall notify the Structural Engineer of Record (EOR) of any below grade structure which may affect the foundation performance.

2. Foundations shall bear on residual soils or engineered fill capable of supporting an allowable pressure of 2000 psf. Soils shall be stable, and any expansive,

compressible, or shifting material shall be removed to ensure a stable moisture content. Slabs on grade are designed for a modulus of subgrade reaction of

100 pci using a K = 30. Consult with a Testing Agency for fill placement and compaction requirements required to obtain these design parameters.

03300 CAST-IN-PLACE CONCRETE:

1. All concrete work and materials shall be in accordance with ACI 318 2008 and ACI 301.

2. Minimum Material Specifications:

a. Portland Cement:

ASTM C150, Type 1

b.

Fly Ash:

ASTM C 618, Type F (limit to 20% of cementitious content)

c. Maximum water/cementitious material ratio: 0.5.

d. No water may be added at the site without consent of the engineer.

3. Foundations:

a. Foundations shall have a 28 day compressive strength of 3000 psi.

4. Slabs-on-grade:

a. Slabs-on-grade shall have a 28 day compressive strength of 3000 psi.

b. Interior slabs to receive a hard steel trowel finish with overall Ff =35 and FL=25, and minimum local values of Ff = 24 and Fl = 17.

c. Exterior slabs shall be per the Civil Drawings and Specifications.

d. Vapor barrier under interior slabs shall meet permeability requirements of the floor finishes. As a minimum, a 15 mil vapor barrier is required, lapping

and sealing all seams.

e. Provide sawcut control joints or construction joints at 12’-0” (maximum) square pattern (see slab plan for other requirements). Cut 1” joints as

soon as possible after finishing (within 12 hours of placement).

f. Provide isolation joints at column boxouts, walls, and penetrations.

g. Reinforce at all re-entrant corners with no control joints with (2) #3 x 4’-0” long centered on the corner, located in the top of the slab. Reinforce

around all pipe or box penetrations greater than 3” with (4) #3 in diamond pattern.

h. Concrete splatter on walls or adjacent slabs shall be removed.

5. Reinforcing Steel:

a. All detailing, fabrication, and placing shall be in accordance with ACI 315.

b. Reinforcing steel shall be new billet bars conforming to ASTM A615, grade 60.

c. Provide 3” concrete cover for all concrete cast against earth.

6. Post-Installed Anchors

a. Expansion Anchors to be Hilti Kwik Bolt 3, ITW Redhead Trubolt, or approved equal. Sleeve anchors to be Hilti HLC Sleeve Anchor or ITW Redhead

Dynabolt.

b. Epoxy or chemical adhesive shall be Ramset Epcon A7 or C6; Hilti HY 150; or Simpson SET Epoxy-TIE.

c. Anchors labeled as LDT anchors are to be hot-dip galvanized anchors with cutting threads such as Ramset/Redhead LDT; Simpson Titen HD; or

Powers Wedge.

C

04300 MASONRY:

1. Masonry work and materials shall comply with ACI 530 02. All CMU shall conform to ASTM C90, ASA A79.1 for light weight block. Mortar shall conform

with ASTM C270, Type S. Masonry cement and Type N mortar are not allowed for CMU work.

2. The minimum compressive strength of the system, f’m, shall be 1,500 psi.

3. CMU to be laid in running bond.

4. Provide 9 gage ladder type joint reinforcing at 8" o.c. below grade.

5. As a minimum, provide (1) #5 vertical bar at 24” o.c. and 9 gage ladder type joint reinforcing at 16” o.c. Joint reinforcing to have prefabricated tees and

corners. Fill all cells containing reinforcing with 3000 psi reinforced masonry grout meeting ASTM C476. Grout lifts are not to exceed 56”. Provide joint

reinforcing at 8” o.c. in all CMU below grade. Fill all cells below grade. Fill cells at elevator guide rail inserts anchors.

6. Provide masonry lintels or steel lintels at all openings. Galvanize steel lintels with G60 finish.

05120

Z:\AA\Projects\CGD- Craig Gaulden Davis\15-CGD-97_FPC Greer\15-CDG-97 STRUCT R2016.rvt

9/18/2015 11:07:04 AM

B

06100 ROUGH CARPENTRY

1. Structural framing lumber shall conform to the minimum material properties listed in the National Design Specification for Wood Construction (2001)

for the sizes, species, and grades listed on the drawings.

2. Bolts shall conform to ASTM A307. Steel connection plates shall conform to ASTM A36.

3. Nail shank sizes and lengths are as specified for the penny weights on the drawings:

a. 6d 0.113” diameter, 2” long

b. 8d 0.131” diameter, 2.5” long

c. 10d

0.148” diameter, 3” long

d. 16d

0162” diameter, 3.5” long

4. ROOF CONSTRUCTION

a. Roof to be sheathed with 5/8” 24/48 rated sheathing, grade C-D, Exposure 1 nailed to rafters or trusses with 10d ring shank nails at 6” o.c. at panel

edges and 12” o.c. elsewhere. Provide plywood clips at each rafter or truss space.

b. Rafters to be Yellow Pine #2 or better.

c. Provide blocking between rafters or between trusses at all valleys and ridges. Nail sheathing to blocking at 6” o.c.

d. At hipped ends where trusses are dropped 1-9/16” for 2x4 purlins, the purlins must be attached to the top chord of the dropped trusses with Simpson

H2.5 anchors.

e. Attachment of Piggy back trusses to base trusses must be clearly shown on truss erection drawings.

f. Metal Plate Connected Wood Trusses

i.

Design by fabricator shall be in accordance with the applicable provisions of the latest edition of the American Forest & Paper Association's

(AF&PA’s) National Design Specification® (NDS®) for Wood Construction, ANSI/TPI 1, and all applicable legal requirements. Truss

Manufacturer shall furnish Truss Design Drawings and a Truss Placement Plan. See the roof framing plan and design criteria for design loads.

Deflection criteria of L/360 (LL) and L/240 (total) shall be calculated with pin/roller support conditions and one end moving laterally 1” max.

ii.

If needed, trusses shall be supplied with bearing enhancing hardware to distribute support reactions to supporting wall plates such that bearing

pressure does not exceed 425 psi.

iii.

The design and placement drawings shall include as a minimum:

1. Slope, span, and spacing

2. Location of joints

3. Required bearing widths

4. Design loads (top and bottom chord live and dead loads, wind uplift forces at bearing)

5. End Reactions and directions

6. Lumber grades, sizes, and species

7. Truss to truss girder, truss ply to ply, and field assembly connections (manufacturer to design and supply)

8. Deflections (horizontal and vertical)

9. Size, connections, and anchorage of the permanent continuous lateral bracing required for axial force buckling resistance.

iv.

Lumber shall be Yellow Pine #2 or better for chords and webs. Lumber shall have moisture content of no less than 7% at time of manufacturing.

Adjustment factors shall be in accordance with NDS. Minimum

v. Metal connector plates shall be manufactured by a Wood Truss Council of America (“WTCA”) member plate manufacturer and shall not be less

than 0.036 inches in thickness (20 gauge) and shall meet or exceed ASTM A653/A653M grade 33, and galvanized coating shall meet or exceed

ASTM A924/924M, coating designation G60. Working stresses in steel are to be applied to effectiveness ratios for plates as determined by test

and in accordance with ANSI/TPI 1.

vi.

Trusses shall be handled during manufacturing, delivery and by the Contractor at the job site so as not to be subjected to excessive bending.

Unload trusses in a manner to minimize lateral strain.

vii.

Contractor shall be responsible for the handling, installation, and temporary bracing of the Trusses in a good workmanlike manner and in

accordance with the recommendations set forth in WTCA/TPI’s Building Component Safety Information BCSI 1-03: Guide to Good Practice For

Handling, Installing & Bracing of Metal Plate Connected Wood Trusses; 2013 edition.

1. Bracing/Shoring plans if required by the Building Official shall be submitted by the contractor, prepared by a Professional Engineer.

viii.

Cutting and altering of Trusses is not permitted. If any Truss should become broken, damaged, or altered, written concurrence and approval by a

licensed design professional is required.

ix.

Trusses shall be permanently braced in a manner consistent with good building practices and in accordance with sections in the drawings. Trusses

shall furthermore be anchored or restrained to prevent out-of-plane movement so as to keep all Truss members from simultaneously buckling together

in the same direction. Such permanent lateral bracing shall be accomplished by: (a) anchorage to solid end walls; (b) permanent diagonal bracing

in the plane of the web members; or (c) other suitable means. Materials for temporary and permanent bracing shall be by the contractor.

x. Full depth blocking or x-bridging is required over all exterior walls where heel height exceed 10”. Nail blocking to top plates and top chord of truss.

xi.

All specified uplift connection hardware capacities shall be reviewed by the contractor using the final truss shop drawings and calculations. The uplift

capacity shall exceed the uplift given on the shop drawings.

5. FLOOR CONSTRUCTION

a. Subfloor to be ¾” (nominal) tongue and groove 48/24 rated sheathing (APA Rated Sturd-I-Floor); exposure 1. Glue and nail to supports with 10d ring shank

nails at 6” o.c. at edges and 12” o.c elsewhere.

b. Floor joists and blocking to be Yellow Pine #2 or better.

Architecture

Planning

Interiors

19 Washington Park

Greenville, SC 29601

Phone 864.242.0761

Fax

864.501.9945

E-mail cgd@cgdarch.com

COPYRIGHT © 2015 CRAIG GAULDEN & DAVIS,

INC. ALL RIGHTS RESERVED

THIS COPYRIGHTED DOCUMENT AND ALL

INFORMATION CONTAINED HEREIN IS AN

INSTRUMENT OF SERVICE AND SHALL NOT BE

REPRODUCED, ALTERED, OR REUSED IN PART

OR IN WHOLE WITHOUT PRIOR WRITTEN

PERMISSION FROM THE ARCHITECT. THIS

DRAWING IS THE EXCLUSIVE PROPERTY OF THE

ARCHITECT AND MUST BE RETURNED UPON

REQUEST.

arrowood

arrowood

Arrowood & Arrowood, PC

412-B Pettigru Street

Greenville, SC 29607

864.233.9383 (t)

864.232.7855 (f)

A&A PROJECT #15-CGD-97

FIRST

PRESBYTERIAN

CHURCH

GREER

STRUCTURAL STEEL:

1. Design, fabrication and erection of all structural steel shall be in accordance with the AISC Manual of Steel Construction, ASD,

Thirteenth Edition.

2. Minimum material specifications:

a.

W-Structural Steel Shapes:

ASTM A992

b.

Rolled Steel Floor Plates:

ASTM A786 Commercial Grade

c.

Steel Pipe:

ASTM A53 gr. B

d.

Hollow Structural Sections:

ASTM A500 gr. B

e.

M, S, C, MC, HP Shapes:

ASTM A36

f.

Plates:

ASTM A36

g.

Angles:

ASTM A36

h.

Anchor Rods:

ASTM F1554 gr. 36

i.

Bolts:

ASTM A325N

j.

Weld Electrodes:

AWS E70xx

k.

Shear Connectors

ASTM A108, grades 1015 through 1020, headed stud type

l.

Non-shrink grout:

ASTM C 1107, non metallic – 5000 psi

3. Product Submittals:

a. Typical shop fabrication and field erection drawings.

4. Provide 2 mils DFT of rust inhibitive primer after power tool cleaning. Provide asphaltic coating for columns or any other steel below slab.

5. Field connections shall be bolted unless shown otherwise on the drawings. Bolted connections shall be made with A325N bolts.

Connections shall be designed for half of the uniform load shown in the AISC Beam Tables.

6. Post-Installed Anchors

a. Expansion Anchors to be Hilti Kwik Bolt 3, ITW Redhead Trubolt, or approved equal. Sleeve anchors to be Hilti HLC Sleeve

Anchor or ITW Redhead Dynabolt.

b. Epoxy or chemical adhesive shall be Ramset Epcon A7 or C6; Hilti HY 150; or Simpson SET Epoxy-TIE.

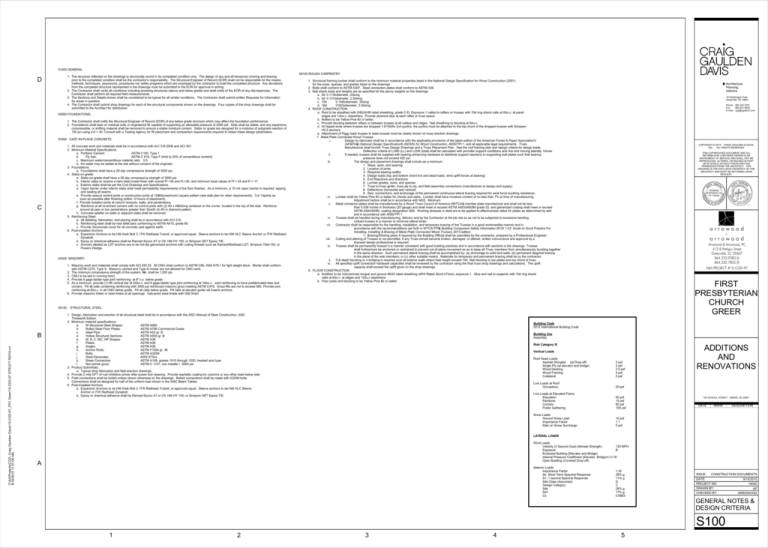

Building Code

2012 International Building Code

Building Use

Assembly

Risk Category III

Vertical Loads

Roof Dead Loads

Asphalt Shingles (at Drop-off)

Single Ply (at elevator and bridge)

Wood Decking

Wood Framing

Collateral

3 psf

2 psf

2.5 psf

4 psf

5 psf

Live Loads at Roof

Occupancy

20 psf

Live Loads at Elevated Floors

Education

Partitions

Corridor

Public Gathering

50 psf

15 psf

80 psf

100 psf

Snow Loads

Ground Snow Load

Importance Factor

Rain on Snow Surcharge

10 psf

1.1

5 psf

ADDITIONS

AND

RENOVATIONS

100 SCHOOL STREET, GREER, SC 29651

DATE

MARK

DESCRIPTION

LATERAL LOADS

Wind Loads

Velocity (3 Second Gust-Ultimate Strength)

120 MPH

Exposure

B

Enclosed Building (Elevator and Bridge)

Internal Pressure Coefficient (Elevator, Bridge)+/-0.18

Open Building (Covered Drop-off)

A

Seismic Loads

Importance Factor

Ss, Short Term Spectral Response

S1, 1 second Spectral Response

Site Class (Assumed)

Design Category

Sds

Sd1

Cs

1.25

28% g

11% g

D

C

28% g

17% g

0.0683

ISSUE:

CONSTRUCTION DOCUMENTS

DATE:

PROJECT NO:

DRAWN BY:

CHECKED BY:

9/15/2015

14045

AP

ARROWOOD

GENERAL NOTES &

DESIGN CRITERIA

S100

1

2

3

4

5

D

Architecture

Planning

Interiors

19 Washington Park

Greenville, SC 29601

Phone 864.242.0761

Fax

864.501.9945

E-mail cgd@cgdarch.com

COPYRIGHT © 2015 CRAIG GAULDEN & DAVIS,

INC. ALL RIGHTS RESERVED

THIS COPYRIGHTED DOCUMENT AND ALL

INFORMATION CONTAINED HEREIN IS AN

INSTRUMENT OF SERVICE AND SHALL NOT BE

REPRODUCED, ALTERED, OR REUSED IN PART

OR IN WHOLE WITHOUT PRIOR WRITTEN

PERMISSION FROM THE ARCHITECT. THIS

DRAWING IS THE EXCLUSIVE PROPERTY OF THE

ARCHITECT AND MUST BE RETURNED UPON

REQUEST.

C

arrowood

1

S104

arrowood

Arrowood & Arrowood, PC

412-B Pettigru Street

Greenville, SC 29607

864.233.9383 (t)

864.232.7855 (f)

A&A PROJECT #15-CGD-97

FIRST

PRESBYTERIAN

CHURCH

GREER

DN

1

S105

Z:\AA\Projects\CGD- Craig Gaulden Davis\15-CGD-97_FPC Greer\15-CDG-97 STRUCT R2016.rvt

9/16/2015 4:59:36 PM

B

ADDITIONS

AND

RENOVATIONS

100 SCHOOL STREET, GREER, SC 29651

DATE

MARK

DESCRIPTION

A

ISSUE:

CONSTRUCTION DOCUMENTS

DATE:

PROJECT NO:

DRAWN BY:

CHECKED BY:

FLOOR PLAN - MAIN

LEVEL

1

S103

S101

1

2

9/15/2015

14045

AP

ARROWOOD

3

4

5

D

Architecture

Planning

Interiors

19 Washington Park

Greenville, SC 29601

Phone 864.242.0761

Fax

864.501.9945

E-mail cgd@cgdarch.com

COPYRIGHT © 2015 CRAIG GAULDEN & DAVIS,

INC. ALL RIGHTS RESERVED

THIS COPYRIGHTED DOCUMENT AND ALL

INFORMATION CONTAINED HEREIN IS AN

INSTRUMENT OF SERVICE AND SHALL NOT BE

REPRODUCED, ALTERED, OR REUSED IN PART

OR IN WHOLE WITHOUT PRIOR WRITTEN

PERMISSION FROM THE ARCHITECT. THIS

DRAWING IS THE EXCLUSIVE PROPERTY OF THE

ARCHITECT AND MUST BE RETURNED UPON

REQUEST.

C

arrowood

2

S104

arrowood

Arrowood & Arrowood, PC

412-B Pettigru Street

Greenville, SC 29607

864.233.9383 (t)

864.232.7855 (f)

A&A PROJECT #15-CGD-97

FIRST

PRESBYTERIAN

CHURCH

GREER

2

S105

DN

DN

ADDITIONS

AND

RENOVATIONS

2

S103

100 SCHOOL STREET, GREER, SC 29651

DATE

DESCRIPTION

PO

ST

(4

)2

x6

N

EW

PO

ST

(4

)2

x6

REFERENCE B/EXISTING 2x6

CEILING JOIST = 9'-4"

B/ROOF DECK @ POST = 12'-0"

MARK

N

EW

Z:\AA\Projects\CGD- Craig Gaulden Davis\15-CGD-97_FPC Greer\15-CDG-97 STRUCT R2016.rvt

9/16/2015 4:59:38 PM

B

A

(3) 2x10*

ARROWOOD & ARROWOOD TO REVIEW AREA

DURING DEMOLITION AND WILL PROVIDE A

DETAIL OF FRAMING CONNECTIONS

1

S102

ISSUE:

CONSTRUCTION DOCUMENTS

DATE:

PROJECT NO:

DRAWN BY:

CHECKED BY:

FLOOR PLAN UPPER LEVEL

UPPER FLOOR

1/8" = 1'-0"

S102

1

9/15/2015

14045

AP

ARROWOOD

2

3

4

5

1

L-SHAPED PLATE 1/2"x5"

BLOCKING

3/8" CAP PLATE

SIMPSON H2.5a

8"

W14

HSS COLUMN

CANOPY TRUSS BEARING

10' - 4"

D

A

B

D

E

F

I

L

N

(2) 2x6 w/ (2) 5/8" THREADED

STUDS @ 32" O.C.

Architecture

Planning

Interiors

W14

L8x4x3/8x7 1/2

19 Washington Park

Greenville, SC 29601

TYPICAL BOLTED SHEAR TAB

Phone 864.242.0761

Fax

864.501.9945

E-mail cgd@cgdarch.com

5/16"

10

MOMENT CONNECTION

A

S103

3

S103

1" = 1'-0"

SECTION

1" = 1'-0"

ALUMINUM CANOPY

COLUMN (TYPICAL)

9

COPYRIGHT © 2015 CRAIG GAULDEN & DAVIS,

INC. ALL RIGHTS RESERVED

9

ALUMINUM CANOPY COLUMN

WITH BASE CONFIGURATION

BY CANOPY DESIGNER

GROUT POCKET PER

CANOPY DESIGNER'S

DIRECTION

#5x3'-0" IN DIAMOND

PATTERN AROUND CANOPY

COLUMN

#5x2'-0" ON EACH

SIDE OF COLUMN

THIS COPYRIGHTED DOCUMENT AND ALL

INFORMATION CONTAINED HEREIN IS AN

INSTRUMENT OF SERVICE AND SHALL NOT BE

REPRODUCED, ALTERED, OR REUSED IN PART

OR IN WHOLE WITHOUT PRIOR WRITTEN

PERMISSION FROM THE ARCHITECT. THIS

DRAWING IS THE EXCLUSIVE PROPERTY OF THE

ARCHITECT AND MUST BE RETURNED UPON

REQUEST.

4

S103

PER CANOPY DESIGN

8

(3) #5 EACH WAY

10" MIN.

C

7

arrowood

arrowood

PER CANOPY DESIGN

Arrowood & Arrowood, PC

412-B Pettigru Street

Greenville, SC 29607

864.233.9383 (t)

864.232.7855 (f)

SECTION

4

S103

1" = 1'-0"

E

C

F

6

G

A&A PROJECT #15-CGD-97

5/8" WOOD SHEATHING ON PREFABRICATED WOOD TRUSSES @ 24" O.C.

TRUSSES TO CLIP TO DOUBLE 2x6 NAILERS

w/ SIMPSON H2.5a. DOUBLE H2.5a @

GIRDERS AND HIP GIRDERS. DOUBLE 2x6

NAILERS TO BOLT TO BEAMS w/ (2) 5/8"

THREADED STUDS @ 32" O.C.

27' - 0"

C1

F6

5

5

W14X34

4

4

H

B

3

ADDITIONS

AND

RENOVATIONS

23' - 0"

W14X34

3

GIRDER TRUSS

S103

GIRDER TRUSS

Sim

W14X34

3

Z:\AA\Projects\CGD- Craig Gaulden Davis\15-CGD-97_FPC Greer\15-CDG-97 STRUCT R2016.rvt

9/16/2015 4:59:40 PM

FIRST

PRESBYTERIAN

CHURCH

GREER

C1

F6

ALUMINUM CANOPY

COLUMN (TYPICAL)

2

C1

F6

2

C1

F6

100 SCHOOL STREET, GREER, SC 29651

DATE

W14X34

1

MARK

DESCRIPTION

1

BRICK OVER 24" SQUARE

CMU PIER FILLED SOLID

3

C

S103

G

H

J

K

M

A

ISSUE:

2

S103

CANOPY FRAMING PLAN

1

S103

1/4" = 1'-0"

NOTES:

1) TRUSS BEARING = 10'-7"

1/4" = 1'-0"

DATE:

PROJECT NO:

DRAWN BY:

CHECKED BY:

NOTES:

CANOPY PLANS

CANOPY - FOUNDATION / SLAB PLAN

1) TOP OF FOOTING TO BE A MINIMUM OF 1'-0" BELOW GRADE. ELEVATION SHALL BE FIELD DETERMINED BY CONTRACTOR.

= MOMENT CONNECTION. SEE DETAIL A/S-103.

1

CONSTRUCTION DOCUMENTS

S103

C1 = HSS8x8x1/4 w/ BASE PLATE 3/4x1'-4"x1'-4" AND 3/4" Ø THREADED RODS SET 10" INTO CHEMICAL ADHESIVE.

F6 = 6'-0" x 6'-0" x 1'-4" FOOTING w/ (7) #6 EACH WAY; TOP & BOTTOM

2

3

4

5

9/15/2015

14045

AP

ARROWOOD

+0'-0"

3B

BASE PLATE 3/4x1'-2" SQ w/ (4) 3/4"

THREADED ROD SET 8" INTO

CHEMICAL ADHESIVE (6 PLACES)

F3

(2) 14" LVL

2x8 @ 16" O.C.

F3

Architecture

Planning

Interiors

NOTE:

T/JOIST, LVL = 22'-8 1/4"

19 Washington Park

Greenville, SC 29601

Phone 864.242.0761

Fax

864.501.9945

E-mail cgd@cgdarch.com

5/8" WOOD ROOF SHEATHING

10' - 5"

SOLID MASONRY UP TO

1'-0" ABOVE FINISH GRADE

C2

2' - 0" 1' - 6"

1' - 6" 1' - 6" 1' - 4"

2' - 10"

1' - 6"

2' - 0"

BEARING

PLATE B

C2

F4

(2) 11 1/4" LVL

2B

8

S104

BEARING

PLATE A

(2) 14" LVL

BEARING

PLATE C

(2) 14" LVL

COPYRIGHT © 2015 CRAIG GAULDEN & DAVIS,

INC. ALL RIGHTS RESERVED

THIS COPYRIGHTED DOCUMENT AND ALL

INFORMATION CONTAINED HEREIN IS AN

INSTRUMENT OF SERVICE AND SHALL NOT BE

REPRODUCED, ALTERED, OR REUSED IN PART

OR IN WHOLE WITHOUT PRIOR WRITTEN

PERMISSION FROM THE ARCHITECT. THIS

DRAWING IS THE EXCLUSIVE PROPERTY OF THE

ARCHITECT AND MUST BE RETURNED UPON

REQUEST.

3' - 6"

C2

F43

+0'-10"

8' - 3"

BASE PLATE 3/4x7"x1'-4" SQ w/ (4)

3/4" THREADED ROD SET 8" INTO

CHEMICAL ADHESIVE (5 PLACES)

C2

F43

SIMPSON HANGER

(TYPICAL)

BEARING

PLATE B

DN

C2

F43

(2) 11 1/4" LVL

2B

C2

F4

(2) 14" LVL

2' - 0"

C2

F4

8' - 3"

BEARING

PLATE C

C2

F43

20' - 1"

D

C2

F43

BEARING

PLATE C

(3) 14" LVL

9' - 8"

3B

(2) 14" LVL

2x8 @ 16" O.C.

BEARING

PLATE C

1B

BEARING

PLATE C

1B

(3) 14" LVL

9' - 4"

3' - 9"

BEARING

PLATE A

6"

+2'-1"

9' - 7"

(3) 14" LVL

11' - 4"

C

AB

1

S104

BB

CB

DB

EB

AB

BRIDGE - FOUNDATION / SLAB PLAN

CB

S104

EB

arrowood

arrowood

1/4" = 1'-0"

NOTES:

SEE ARCH.

DRAWINGS

1) TOP OF FOOTING TO BE A MINIMUM OF 1'-0" BELOW GRADE. ELEVATION SHALL BE FIELD DETERMINED BY CONTRACTOR.

AB

Brick Lintel Schedule

3/4" T&G SUB-FLOOR

LINTEL

ANGLE

MINIMUM

BEARING

UP TO 4'-8"

L4x4x1/4

6"

4'-8" TO 7'-4"

L6x4x5/16

8"

8'-8"

L7x4x3/8

8"

14" LVL

14" LVL

4"

3/4"Ø THROUGH BOLT

2x8 @ 16" O.C.

PLATE 3/8

SIMPSON TOP FLANGE HANGER

1. LINTELS TO BE HOT-DIP GALVANIZED.

10' - 10"

3B

A&A PROJECT #15-CGD-97

6"

8"

OPENING

WIDTH

BB

G.C. TO FIELD CONFIRM

6"

(2) 5/8" THREADED STUDS @ 32" O.C.

HSS5x5x3/8

3'-0" x 3'-0" x 1'-0" FOOTING w/(4) #4 EACH WAY

4'-0" x 4'-0" x 1'-0" FOOTING w/ (5) #5 EACH WAY; TOP & BOTTOM

4'-0" x 3'-0" x 1'-4" FOOTING w/ #6 @ 9" SET IN CHEMICAL ADHESIVE 6" IN EXISTING FOOTING (TOP & BOTTOM) (4) #5 IN OTHER DIRCTION

2. LINTELS TO SUPPORT RUNNING BOND MASONRY ONLY.

BEAM (SEE PLAN)

W10X22

4

(10'-7 3/4")

S104

SECTION

7

S104

1" = 1'-0"

Arrowood & Arrowood, PC

412-B Pettigru Street

Greenville, SC 29607

864.233.9383 (t)

864.232.7855 (f)

PLATE 1/4 (NS, FS)

4"

C2 =

F3 =

F4 =

F43 =

DB

BRIDGE ROOF FRAMING PLAN

3

1/4" = 1'-0"

BB

FIRST

PRESBYTERIAN

CHURCH

GREER

SECTION

1" = 1'-0"

5

LINTEL

BELOW

L8x4x3/8x3

1/4"

1/4"

S104

HSS5x5x1/4

5/16"

5/16"

PLATE 3/8x1'-7" H.D.G.

(BEAR 6" AT JAMBS)

HSS COLUMN

W12X22

RAMP DOWN

(10'-7 3/4")

W12

2x8 @ 16" O.C.

W12X22 (10'-7 3/4")

S104

PLATE 3/8x4" w/

L4x4x1/4 SPACE

PLATE @ 24" O.C.

DWGS.

TYPICAL LINTEL @ LOWER LEVEL (8 PLACES)

PLATE 3/8"x3" w/

(3) 3/4" Ø BOLTS

OVERBUILD RAMPS & UPPER LANDING

L8x4x3/8x5

5

S104

SECTION AT LINTEL

PLATE 3/8x1'-7" H.D.G.

(BEAR 6" AT JAMBS)

5A

S104

1" = 1'-0"

SECTION AT LINTEL (ALTERNATE)

1" = 1'-0"

DN

2x8 @ 16" O.C.

(11'-5 3/4")

RAMP DOWN

W12X22

(11'-5 3/4")

(11'-5 3/4")

DATE

MOMENT CONNECTION

A

S104

5 1/2" CLEAR (TYP.)

5 1/2" CLEAR (TYP.)

W12X22

W12X22

(11'-5 3/4")

(11'-5 3/4")

PROVIDE SPACER

@ DOUBLE LVL

PROVIDE SPACER

@ DOUBLE LVL

6 1/4"

14" LVL's (SEE PLAN)

1' - 0"

14" LVL's (SEE PLAN)

1' - 0"

3/4"Ø THROUGH BOLT

G.C. TO FIELD CONFIRM

PLATE 1/4

CB

DB

ISSUE:

EB

2

BRIDGE - UPPER FLOOR FRAMING PLAN

BEARING PLATE A

1/4" = 1'-0"

BEARING PLATE B

NOTES:

6

= MOMENT CONNECTION. SEE DETAIL A/S104.

1

S104

2

3/4"Ø THROUGH BOLT

6 1/4"

PLATE 1/4

5 1/2" CLEAR (TYP)

PROVIDE SPACER

@ DOUBLE LVL

S104

4

9/15/2015

14045

AP

ARROWOOD

BRIDGE PLANS

8

1" = 1'-0"

3

PLATE 1/4

BEARING PLATE C

SECTION

CONSTRUCTION DOCUMENTS

DATE:

PROJECT NO:

DRAWN BY:

CHECKED BY:

PLATE 3/8

3/4"Ø THROUGH BOLT

PLATE 3/8

S104

GROUND FLOOR

0"

14" LVL's (SEE PLAN)

PLATE 3/8

BB

DESCRIPTION

1" = 1'-0"

12' - 5"

AB

MARK

EB

1' - 0"

A

DN

100 SCHOOL STREET, GREER, SC 29651

W12X22

1' - 0"

1B

W12X22

(11'-5 3/4")

W12X22

W12X22 (11'-5 3/4")

2B

ADDITIONS

AND

RENOVATIONS

SEE ARCH.

1/4"

1/4"

W12X22 (11'-5 3/4")

Z:\AA\Projects\CGD- Craig Gaulden Davis\15-CGD-97_FPC Greer\15-CDG-97 STRUCT R2016.rvt

9/16/2015 4:59:41 PM

4

FIELD DETERMINE

PRIOR TO FABRICATION

B

Section 6

S104

1" = 1'-0"

5

1'-2" THICK ELEVATOR PIT BASE

w/ #5@12" EACH WAY; TOP & BOTTOM

SUMP

STEP FOOTING ELEVATION

(SEE A/S105)

NEW HEADER, BRICK

LINTEL IN EXISTING WALL

BEARING PLATE 3/8x5x8 w/ (2) 3/4"x6" H.S.

5/8" ROOF SHEATHING

(2) 11 1/4" LVL

(2) KINGS @ JAMBS

OF OPENINGS

F4 (-1'-4")

S105

(2) 11 1/4" LVL

F2 (-1'-4")

PATCH CONCRETE SLAB

Architecture

Planning

Interiors

4

2x8 @ 16" O.C.

5' - 10"

S105

2x8 @ 16" O.C.

8

W8x24

D

H

SS

4x

w

/

4x

3/ B

A

4

1/

(4 x S

4

1

)

AN 3 '- E

2

P

/

G C 4 " L

R H E SQ A

O O X

U R P. A TE

T S

N

D

BE . 2

D "

.

8" CMU ELEVATOR PIT WALLS

w/ #5 @ 16" O.C. AND 9GAGE

H.J.R. @ 8" O.C.

2x8

19 Washington Park

Greenville, SC 29601

SIMPSON LUS28

Phone 864.242.0761

Fax

864.501.9945

E-mail cgd@cgdarch.com

TREATED 2x8 w/ (2) 5/8"

SLEEVE ANCHOR @ 16" O.C.

BOND BEAM

4

S105

MICROPILE TO SUPPORT

EXISTING WALL /

FOUNDATIONS

SECTION

1" = 1'-0"

Brick Lintel Schedule

OPENING

WIDTH

COPYRIGHT © 2015 CRAIG GAULDEN & DAVIS,

INC. ALL RIGHTS RESERVED

LINTEL

ANGLE

MINIMUM

BEARING

UP TO 4'-8"

L4x4x1/4

6"

4'-8" TO 7'-4"

L6x4x5/16

8"

8'-8"

L7x4x3/8

8"

THIS COPYRIGHTED DOCUMENT AND ALL

INFORMATION CONTAINED HEREIN IS AN

INSTRUMENT OF SERVICE AND SHALL NOT BE

REPRODUCED, ALTERED, OR REUSED IN PART

OR IN WHOLE WITHOUT PRIOR WRITTEN

PERMISSION FROM THE ARCHITECT. THIS

DRAWING IS THE EXCLUSIVE PROPERTY OF THE

ARCHITECT AND MUST BE RETURNED UPON

REQUEST.

1. LINTELS TO BE HOT-DIP GALVANIZED.

HSS2x2x1/4 @ 12" O.C.

2. LINTELS TO SUPPORT RUNNING BOND MASONRY ONLY.

2x NAILERS

WOOD FLOORING

L6x4x3/8 WELDED

TO TUBES

FOUNDATION SCHEDULE

WIDTH x

LENGTH

TYPE

C

THICK.

EXISTING WOOD FRAMING

REINFORCING

F2

2'-0" x CONTINUOUS

12"

(2) #5 CONT.w/#5@32" SW *

F4

4'-0" x 4'-0"

12"

(5) #4 EACH WAY; TOP & BOTTOM

3/4" THREADED

RODS SET 8" INTO

CHEMICAL

ADHESIVE.

NOTES

arrowood

EXISTING BRICK

1. TOPS OF FOOTINGS TO BE x'-x" BELOW T/SLAB UNLESS NOTED.

1

S105

arrowood

ELEVATOR - FOUNDATION / SLAB PLAN

3

S105

1/4" = 1'-0"

ELEVATOR ROOF BEARING

5

S105

1/4" = 1'-0"

Arrowood & Arrowood, PC

412-B Pettigru Street

Greenville, SC 29607

864.233.9383 (t)

864.232.7855 (f)

SECTION

1" = 1'-0"

A&A PROJECT #15-CGD-97

FILLED CMU

2x10 BLOCKING

L-SHAPED BEARING

PLATE 3/8"x5" w/ 12"

LEGS AND (2) 3/4"x6"

H.S. PER LEG

+9'-8" (TO BE FIELD CONFIRMED)

NEW HEADER, BRICK

LINTEL IN EXISTING WALL

HSS8x4 w/ 5/8x1 1/2"

THREADED STUD @ 12" O.C.

TREATED 2x10

w/ (2) 3/4"Ø

ANCHORS @ 16" O.C.

8

5

2x10 w/ (2) 3/4"

SCREW ANCHORS

@ 16" O.C.

S105

TOP FLANGE HANGER

8" CMU w/ #5 @

CORNERS, AT

24" O.C., AND AT

DOOR JAMBS

GROUND FLOOR

0"

WALL BELOW

6" MIN.

HSS8x4x3/8

WELD HSS8x4x1/4 TO

HSS8x4x3/8

6

S105

BEARING PLATE 3/8x6x6 ON

EXISTING MASONRY

DOWEL #6x16" INTO EXISTING

BRICK WALL @ 16" O.C.

(VERTICALLY) 6" EMBEDMENT

1' - 2"

6

2x10 @ 16" O.C.

(2) 2x6 STUDS

S105

HSS2x2x1/4

EXISTING SLAB

L7x7x3/8 BRICK SUPPORT

(HOLD ELEVATION)

7

S105

S105

DEMOLISH EXISTING DOWN

2 1/4" BELOW WOOD

FLOORING

2x4

SIMPSON HANGER

HSS8x4x1/4. WELD ALL

AROUND TO HSS4 POST.

B

ADDITIONS

AND

RENOVATIONS

SECTION

1" = 1'-0"

EXISTING OPENING

TO BE ENLARGED

100 SCHOOL STREET, GREER, SC 29651

DATE

BEAR HSS8x4 ON PLATE 3/8x6x6

w/ (2) 3/4x4" H.S. IN FILLED

CELLS.SEE B/S105.

MARK

DESCRIPTION

MICROPILE OR HELICAL PIER

Z-BAR SIZE TO MATCH

LONGITUDINAL REINFORCING

IN FOOTING

S105

#5 @ 9" o.c.

( 4'-0" MAX. )

NEW WOOD FRAME RAMP & STAIRS

8

3"

SECTION

1/2" = 1'-0"

CONTRACTOR TO

FIELD DETERMINE

6"

3/4"Ø THROUGH

BOLT @ 16" O.C.

A

4 1/2"

Z:\AA\Projects\CGD- Craig Gaulden Davis\15-CGD-97_FPC Greer\15-CDG-97 STRUCT R2016.rvt

9/16/2015 4:59:43 PM

2x6 WALL

FIRST

PRESBYTERIAN

CHURCH

GREER

2

1

T/SUBFLOOR = 12'-5"

3/16

1' - 0"

2

S105

ISSUE:

L6x6x3/8 BEARING

8" AT JAMBS

ELEVATOR - UPPER FLOOR FRAMING

A

S105

1/4" = 1'-0"

DATE:

PROJECT NO:

DRAWN BY:

CHECKED BY:

PLATE 1/4"

3-12

SEE PLAN &

FOOTING SCHEDULE

STEP FOOTING DETAIL

B

S105

1" = 1'-0"

SECTION

7

S105

1" = 1'-0"

CONSTRUCTION DOCUMENTS

SECTION

1" = 1'-0"

ELEVATOR PLANS

AND SECTIONS

S105

1

2

3

4

5

9/15/2015

14045

AP

ARROWOOD