Fastening Devices

advertisement

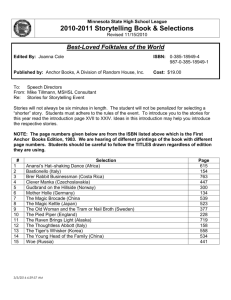

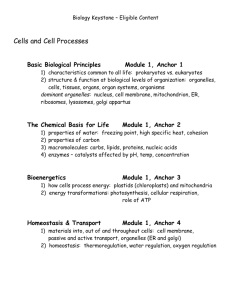

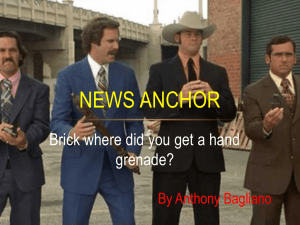

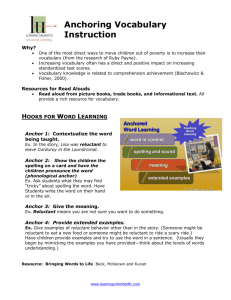

Excerpts from Fastening Devices Hilti, Inc. 1 ©NJATC Fastening Technology–General Information 2.3 Base Materials 2.1.1 BASE MATERIALS FOR FASTENING The hardness of concrete aggregate can also affect the load capacity of power actuated fasteners and anchors. Driven nails or studs can generally penetrate “soft” aggregates (shale or limestone), but hard aggregates (like granite) near the surface of the concrete can adversely affect the penetration of a nail or stud and reduce its capacity. The effect of aggregate mechanical properties on anchor performance are less well understood, although in general harder/denser aggregates such as granite tend to result in higher concrete cone breakout loads, whereas lightweight aggregates produce lower tension and shear capacities. The design of modern buildings requires fastenings to be made in a wide variety of base materials. To meet this challenge fastener manufacturers have developed many products specifically targeted to certain types of base materials. There is hardly a base material in which a fastening cannot be made with a Hilti product. The user must carefully match the type of fastener with the base material to obtain the desired results. The properties of the base material play a decisive role in the suitability and performance of a fastener. Values for the ultimate strength of fasteners in concrete are traditionally given in relation to the 28-day uniaxial compressive strength of the concrete (actual, not specified). Concrete which has cured for less than 28 days is referred to as green concrete. Aggregate type, cement replacements such as fly ash, and admixtures can have a significant effect on the capacity of some fasteners, and this may not be reflected in the concrete strength as measured in a uniaxial compression test. Generally, Hilti data reflects testing with common aggregates and cement types in plain, unreinforced concrete. In questionable cases, consult with your Hilti field engineer. 2.1.2 CONCRETE Concrete is a mineral building material which is made from three basic ingredients; cement, aggregate and water. Special additives are also used to influence or change certain properties. Concrete has a relatively high compressive strength compared to its tensile strength. Thus, steel reinforcing bars are cast in concrete to carry the tensile forces, and this combination is referred to as reinforced concrete. Cement is the binding agent which combines with water and aggregate and hardens through the process of hydration to form concrete. Portland cement is the most common cement and is available in several different types, as outlined in ASTM Specification C-150, to meet specific design requirements. In view of the significantly lower strength of green concrete (less than a 28-day cure), it is recommended that anchors and power actuated fastenings not be made in concrete which has cured for less than 7 days, unless site testing is performed to verify the fastening capacity. If an anchor is installed in green concrete and loaded (or torqued) immediately, its capacity should be based on the actual concrete strength at the time of installation. If an anchor is installed in green concrete, but not loaded until the concrete has achieved full cure, in most cases the capacity of the anchor can be based on the strength of the concrete at the time of loading. Power actuated fastening capacity should be based on the concrete strength at the time of installation. The aggregates used in concrete consist of both fine aggregate (usually sand) and coarse aggregate graded by particle size. Different types of aggregates can be used to create concrete with specific characteristics. Normal weight concrete is generally made from crushed stone or gravel. Lightweight concrete is used when it is desirable to reduce the dead load on a structure or to achieve a superior fire rating for a floor structure. Lightweight aggregates are made from expanded clay, shale, slate or blastfurnace slag. Lightweight insulating concrete is used when thermal insulating properties are a prime consideration. Lightweight insulating aggregates are manufactured from perlite, vermiculite, blast-furnace slag, clay or shale. Sand lightweight concrete is made from lightweight aggregate and natural sand. All concrete with a unit weight between 85 and 115 pcf is considered to be structural lightweight concrete. The ASTM specification and unit weight for each of these concretes is summarized as follows: ASTM Aggregate Grading Specification Concrete Unit Weight pcf Normal Weight ASTM C-33 145-155 Sand Lightweight ASTM C-330 105-115 All Lightweight ASTM C-330 85-110 Lightweight Insulating Concrete ASTM C-332 15-90 Concrete Type Cutting through concrete reinforcement when drilling holes for anchors should be avoided. If this is not possible, the responsible design engineer should be consulted first. 2.1.3 MASONRY MATERIALS Masonry is a heterogeneous building material consisting of brick, block or clay tile bonded together using joint mortar. The primary application for masonry is the construction of walls which are made by placing masonry components in horizontal rows (coarse) and vertical rows (wythe). Masonry components are manufactured in a wide variety of shapes, sizes, materials and both hollow and solid configurations. These variations require that the selection of an anchoring or fastening system be carefully matched to the application and type of masonry material being used. As a base material, masonry generally has a much lower strength than concrete. The behavior of the masonry components, as well as the geometry of their cavities and webs, have a considerable influence on the ultimate loads of the fastening. When drilling holes for anchors in masonry with hollow cavities, care must be taken to avoid spalling on the inside of the face shell. This could greatly affect the performance of “toggle” type mechanical anchors whose length must be matched to the face shell thickness. To reduce the potential for spalling, holes should be drilled using rotation only (i.e. hammering action of the drill turned off). The type and mechanical properties of concrete aggregate have a major influence on the behavior of drill bits used to drill anchor holes. The harder aggregates cause higher bit wear and reduced drilling performance. 2 ©NJATC Fastening Technology–General Information Base Materials 2.1 2.1.3.1 CONCRETE BLOCK 2.1.3.2 BRICK Concrete block is the term which is commonly used to refer to concrete masonry units (CMU) made from Portland cement, water and mineral aggregates. CMU’s are manufactured in a variety of shapes and sizes using normal weight or lightweight aggregates. Both hollow and solid load bearing CMU’s are produced in accordance with ASTM specification C-90. Nominal Width of Unit in. (mm) 3 (76) 6 8 10 (152) (203) (254) 12 (305) Minimum face-shell Thickness ** in. (mm) 3/4 4 1 11/4 13/8 11/4 11/2 11/4 (19) (102) (25) (32) (35) (32)†† (38) (32)†† Bricks (unburned clay masonry units) are prismatic masonry units made from a suitable mixture of soil, clay and a stabilizing agent (emulsified asphalt). They are shaped by moulding, pressing or extruding and are fired at elevated temperature to meet the strength and durability requirements of ASTM C-62 for solid brick and C652 for hollow brick. Minimum web Thickness ** in. (mm) 3/4 (19) 1 1 11/8 (25) (25) (29) 11/8 (29) Depending upon the grade, brick (solid clay masonry) can have a compressive strength ranging from 4,000 to over 12" Brick 14,000 psi. Grouted multiwythe masonry Bearing Walls construction typically consists of two wythes, each one unit masonry in thickness, separated by a space 2 to 4-1/2 inches in width, which is filled with grout. The wythes are connected with wall ties. This space may also be reinforced with vertical reinforcing bars. Solid brick masonry consists of abutting wythes interlaced with header courses. In general, chemical anchors are recommended for use in brick. In older unreinforced construction (URM), or where the condition of the masonry is unknown, it is advisable to use a screen tube to prevent unrestricted flow of the bonding material into voids. Adapted from ASTM C90 ** Average of measurements on three units taken at the thinnest point. This face-shell thickness is applicable where the allowable design load is reduced in proportion to the reduction in thickness from the basic face-shell thickness shown. †† CMU sizes generally refer to the nominal width of the unit (6", 8", 10" etc.). Actual dimensions are nominal dimensions reduced by the thickness of the mortar joint. 7⁵⁄₈" 8" 8" 16" Nominal Size (usually fictitious) 7⁵⁄₈" 2.1.3.3 CLAY TILE Structural Clay load-bearing wall tile is made from clay or shale and heat treated (fired) at an elevated temperature to develop the strength and durability required by ASTM Specification C-34. These units are manufactured in a variety of shapes and sizes with one or more cavities and develop a compressive strength of 500 to 1000 PSI depending upon the grade and type. These units typically have a 3/4" face shell thickness and 1/2" interior web thickness. 15⁵⁄₈" Modular Size (actual) Concrete block construction can be reinforced, whereby reinforcing bars are placed vertically in the cells and those cells are filled with grout to create a composite section analagous to reinforced concrete. If all cells, both unreinforced and reinforced, are filled with grout, the construction is referred to as fully grouted. If only the reinforced cells are grouted, the construction is referred to as partially grouted. Horizontal reinforcing may be placed in the wall via a bond beam, which is always grouted. Ladder reinforcement may also be placed in the mortar bed between courses. Grout typically conforms to ASTM C-476 and has a compressive strength of at least 2,000 psi. Concrete masonry units have a compressive strength which may range from 1,250 to over 4,800 psi, although the maximum specified compressive strength of the assembled masonry will generally not exceed 3,000 psi. In general, both chemical and mechanical anchors may be used in grouted CMU. If voids are present or suspected, mechanical anchors should not be used, and chemical anchors should only be installed in conjunction with a screen tube to prevent uncontrolled flow of the bonding material. In ungrouted CMU, anchor strength is generally assumed to be derived from the face shell thickness, which can be variable. Clay tile as a base material is somewhat more difficult to anchor to due to the thin face shell and low compressive strength. Adhesive anchors such as the Hilti HIT HY20 with a wire screen are usually recommended because they spread the load over a larger area and do not produce expansion forces. 3 ©NJATC Fastening Technology–General Information 2.1 Base Materials 2.1.3.4 MORTAR Mortar is the product which is used in the construction of reinforced and non-reinforced unit masonry structures. Mortar consists of a mixture of cemetitious material, aggregate and water combined in accordance with ASTM specification C270. Either a cement/lime mortar or a masonry mortar, each in four types, can be used under this specification. A summary of properties and guide for selection according to ASTM specification are shown in the tables. Mortar Cement-Lime Masonry Cement Type M S N O M S N O Average Compressive Strength at 28 Days, Min. psi (MPa) 2500 1800 750 350 2500 1800 750 350 (17.2) (12.4) (5.2) (2.4) (17.2) (12.4) (5.2) (2.4) 2.1.4 GYPSUM WALLBOARD joist in residential and commercial buildings to form the base for the finished wall or ceiling treatment. Gypsum wallboard consists of an incombustible core, essentially gypsum, surfaced with paper firmly bonded to the core. It is typically made in flat sheets four feet by eight feet or larger, and from 1/4" to 5/8" thick in accordance with ASTM specification C36. Gypsum wallboard does not have the capacity to accept high loads. Hilti offers several small anchors designed strictly for use in wallboard. Gypsum wallboard is attached to the wall studs and ceiling 2.1.5 AUTOCLAVE AERATED CONCRETE Precast autoclaved aerated concrete (AAC) is a lightweight, precast building material of a uniform porous structure. AAC is made by combining sand, lime, cement, water and an expansion agent, which forms a porous microstructure in the concrete. After mixing, the slurry is poured into a mold and allowed to “rise”. During this expansion process, millions of small, finely dispersed air pockets are formed in the AAC. The product is removed from its mold after a few hours and fed through a cutting machine, which sections the AAC into predetermined sizes. Reinforcing is achieved with corrosion protected steel. These AAC products are then placed into an autoclave and steam cured for 10 to 12 hours. Autoclaving initiates a second chemical reaction that transforms the material into a hard calcium silicate. AAC was developed in Europe and is currently being manufactured in the United States by licensed facilities. Average Comprssive Strength, psi (N/mm2) Average Density lb/ft3 (kg/dm) AAC 2.5 (G2) 360 (2.5) 32 (0.5) AAC 5.0 (G4) 725 (5.0) 38 (0.6) AAC 7.5 (G6) 1090 (7.5) 44 (0.7) Strength Class Due to the low compressive strength of AAC, anchors that spread the load over the entire embedded section are preferred (eg. HUD, HRD, adhesives). 2.1.6 STEEL The grade of steel is very important when selecting a power actuated fastener. The grade and thickness determine the resistance that must be overcome when setting the fastener. The power required to drive a fastener must be greater than the resistance. If the power and resistance are too high, the fastener could be damaged during the setting process. This is referred to as exceeding the application range for the fastener. For a given fastener, the application range is determined by its length, diameter, material strength and hardness. Structural steel is a critical building component which serves as the main structural support in many structures. Iron ore is processed and combined with other elements to produce different types of steel. The types of structural steel are covered by an ASTM standard. Reference to a particular type of steel is usually made by giving its ASTM standard. For example, ASTM A36 is the specification for what is usually referred to as A36 steel. Steel is hot-rolled into structural shapes that are available in different grades, with the grade corresponding to the yield strength. The most common grade is ASTM A36, which has a yield strength of 36 ksi. Another common grade of structural steel is ASTM A572, which is available in grades 42, 45, 50, 55, 60 and 65. 4 ©NJATC Fastening Technology–General Information Corrosion 2.3 2.3.1. THE CORROSION PROCESS In broad terms corrosion has been defined as the destructive alteration of a substance (usually a metal) because of a reaction with its environment. The corrosion process is very complex and has many aspects, all of which lead to the same destructive result. In the design of anchors and fasteners the most common types of corrosion are direct chemical attack and electrochemical reaction. 2.3.2 DIRECT CHEMICAL ATTACK Corrosion by direct chemical attack occurs when the base material is soluble in the corroding medium. One solution for this type of corrosion is to select an anchor or fastener material which is not susceptible to attack by the corroding chemical. Many books present compatibility tables which provide a guide for selecting the proper materials. When selecting a base metal which is compatible with the corroding medium is not possible or economical, another solution is to provide a coating which is resistant to the corroding medium. These might include metallic coatings such as zinc or cadmium or organic coatings such as epoxies or fluorocarbons. Galvanic Series of Metals and Alloys 2.3.3 ELECTRO-CHEMICAL CORROSION All metals have an electrical potential relative to each other and have been ranked, accordingly, to form the “electromotive force series” or “galvanic series” of metals. When metals of different potential contact in the presence of an electrolyte, the more active metal (more negative potential) becomes the anode and corrodes, while the other metal becomes the cathode and is galvanically protected. The severity and rate of attack will be influenced by the relative position of the contacting metals in the galvanic series, the relative area of the contacting metals, and the conductivity of the electrolyte. For anchoring and fastening applications, galvanic corrosion can be reduced by: 1. Using similar metals or metals close together in the electromotive force series 2. Separating dissimilar metals with non-conductive gaskets, plastic washers or paint 3. Selecting materials so that the anchor or fastener is the cathode 4. Providing drainage to prevent entrapment of the electrolyte 2.3.4 CORROSION PROTECTION The most common type of corrosion protection for carbon steel fasteners and anchors is zinc. Zinc coatings can be uniformly applied by a variety of methods to achieve a wide range of coating thicknesses. As a rule, thicker coatings provide a higher level of protection. Based on research by ASTM and other organizations the estimated mean corrosion rate for zinc coatings in various atmospheres is shown in the table. These values are for reference only, due to the large variances in the research findings and specific site conditions. Zinc coatings can be applied to anchors and fasteners by different methods. Applicable ASTM specifications are as follows: ASTM B633 ASTM B695 ASTM A153 This specification covers electrodeposited (electroplated) zinc coatings applied to iron or steel products. This specification covers mechanically deposited zinc coatings applied to iron or steel products. This specification covers zinc coatings applied by the hot-dip process on iron and steel products. 5 Corroded End (anodic, or least noble) Magnesium Magnesium alloys Zinc Aluminum 1100 Cadmium Aluminum 2024-T4 Steel or Iron Cast Iron Chromium-iron (active) Ni-Resist cast iron Type 304 Stainless (active) Type 316 Stainless (active) Lead tin solders Lead Tin Nickel (active) Inconel nickel-chromium alloy (active) Hastelloy Alloy C (active) Brasses Bronzes Monel nickel-copper alloy Copper Copper-nickel alloys Silver solder Nickel (passive) Inconel nickel-chromium alloy (passive) Chromium-iron (passive) Type 304 Stainless (passive) Type 316 Stainless (passive) Hastelloy Alloy C (passive) Silver Titanium Platinum Graphite Gold Protected End (cathodic, or most noble) Atmosphere Industrial Urban Non-Industrial or Marine Suburban Rural Indoors Mean Corrosion Rate 5.6 µm/year 1.5 µm/year 1.3 µm/year 0.8 µm/year Considerably less than 0.5 µm/year ©NJATC Anchoring Systems 4.1.1 Anchor Terminology = Tensile stress area s = Actual spacing c = Actual edge distance scr = Minimum spacing to obtain maximum ccr = Minimum edge distance to obtain maximum As fastener capacity smin = Minimum fastener spacing to preclude failure fastener capacity during setting or torquing of the anchor cmin = Minimum fastener edge distance to preclude failure t during setting or torquing of the anchor = Thickness of material being fastened d = Shank diameter Tinst = Recommended installation torque dbit = Nominal bit diameter Tmax = Maximum tightening torque dh = Diameter of clearance hole in plate; expansion sleeve V = Shear load Vall = Allowable shear load from load tables dnom = Nominal fastener diameter Vd = Design shear load do = Outside fastener diameter Vrec = Recommended shear load (allowable load x dw = Washer diameter F = Load fA = Load adjustment factor for anchor spacing fAN = Tension load adjustment factor for anchor spacing fAV = Shear load adjustment factor for anchor spacing fc = Actual concrete strength f'c = Specified concrete strength fR = Load adjustment factor for edge distance fRN = Tension load adjustment factor for edge distance fRV = Shear load adjustment factor for edge distance h = Thickness of base material hef = Actual depth of embedment clearance hole influence factors) hmin = Minimum depth of embedment hn = Thickness of nut and washer hnom = Standard depth of embedment ho = Hole depth of full cross section h1 = Hole depth to deepest point = Anchor length th = Useable thread length M = Bending moment N = Tensile load Nall = Allowable tensile load from load tables Nd = Design tensile load Nrec = Recommended tensile load (allowable load x influence factors) 6 ©NJATC Anchoring Systems Anchor Principles/Design Considerations 4.1.2.1 ANCHOR WORKING PRINCIPLES 4.1.3.2 ANCHOR FASTENING DESIGN AND INFLUENCING FACTORS There are three basic working principles by which an anchor develops its “holding” power in concrete: friction, keying, and bonding. Friction: The tensile load, N, is transferred to the base material by friction, Ffr. An expansion force Fexp is necessary for this to take place. It is produced, for example, by driving an expansion plug into an HDI anchor. Keying: The tensile load, N, is in equilibrium with the bearing forces, Fb, acting on the base material, such as with the HDA undercut anchor. 4.1.2 / 4.1.3 The primary factors that directly affect the load-carrying capacity of anchors are embedment depth, edge distance, spacing between anchors and concrete strength. Testing is performed in different concrete strengths and embedments to develop tables of ultimate and allowable load capacities for most common installation conditions. They are presented in this Product Technical Guide. Intermediate load values for other concrete strengths and embedments can be calculated by linear interpolation. Edge distance and spacing influences are given as load reduction factors for use in obtaining recommended load capacities using Eq. 4.1.3.1. N Fb N Frec = Fall • fR • fA Fb = the resulting recommended load after influencing factors have been applied to the allowable load Fall = the allowable tension or shear load value from the product data tables fR = the edge distance influencing factor from the appropriate table or calculated from the related equations fA = the spacing influencing factor from the appropriate table or calculated from the related equations Where: Frec Bonding: A synthetic resin fills the annular space around the anchor N and provides adhesive bonding to the anchor rod and the wall of the drilled hole. Transfer of the tensile load, N, takes place through shear stresses, , into the concrete. Combination of Working Principles: Anchors may derive their holding power through a combination of these working principles. In an expansion anchor, for example, an expansion force is exerted by an anchor against the wall of the hole as a result of the displacement of a cone relative to a sleeve. This causes the longitudinal force to be transmitted from the anchor to the concrete by friction. At the same time, the expansion force causes a permanent local deformation of the concrete. This allows a keying of the sleeve into the base material, giving a second method of holding power. Eq. 4.1.3.1 If there is more than one influencing factor, a reduction factor is applied for each influencing condition, that is, fR1 • fR2 • . . . fA1 • fA2 • . . . • fAn. 4.1.3.2.1 INFLUENCE OF EDGE DISTANCE For adhesive anchors, there is, in addition to the bonding, a local keying as the adhesive infiltrates into any pores of the base material. If anchors are installed near a building component edge, there may be a reduced volume of concrete to resist the anchor load. The closest point near an edge at which there is no influence or reduction on the anchor capacity is called the critical edge distance, ccr. For edge distances less than the critical edge distance, reduction factors are to be applied to obtain the reduced structural resistance. The minimum edge distance, cmin, is defined as the minimum edge distance at which an anchor can be properly installed and the specified torque applied without a concrete edge failure. Reductions for edge distances between ccr and cmin are calculated using linear interpolation. The anchor technical data gives the edge distance adjustment factors by table, by equation and by graph. The adjustment factors for shear, fRV, and tension, fRN, are given separately where they are different. Once the type of loading, embedment depth and edge distance are known, the appropriate influencing factor can be determined from either the tables, equations or graphs for the type of anchor under consideration. The graphs are determined from the equations given under the tables. 4.1.3.1 ANCHOR BEHAVIOR—FAILURE MODES The weakest aspect of the anchoring system determines the failure mode. The failure mode depends on the type of anchor, concrete strength, depth of embedment, type of loading, loading direction, edge distance and spacing between anchors. For mechanical anchors the failure modes under tension loading are steel breakage, concrete cone failure, concrete splitting, edge breakout or pullout (including any expansion sleeve), or pullthrough (whereby the anchor shaft pulls through the expansion mechanism). For adhesive-bonded anchors the failure mode is bond failure along the concrete/adhesive interface or along the adhesive/anchor rod bond line. Many times a shallow concrete cone accompanies the bond failure, but this secondary failure mode and is not controlling. For shallow embedments, adhesive anchors may fail with a concrete cone breakout. In shear for both mechanical and adhesive anchors, the failure modes are steel breakage, back pryout of the anchor or group of anchors (usually with smaller embedments) or edge breakout. Where there is more than one edge influencing the anchor, each edge will contribute an adjustment factor, and they are multiplied together. For example, for three edges, fR = fR1 • fR2 • fR3 . See section 4.1.3.4 for an example using reduction factors. 7 ©NJATC Anchoring Systems 4.1.3 Anchor Design Considerations 4.1.3.2.2 INFLUENCE OF MULTIPLE ANCHORS (Nd/Nrec)n + (Vd/Vrec)n ≤ 1.0 If two or more anchors are in close proximity, then a spacing adjustment factor is to be taken into account. Critical spacing, scr, is defined as the minimum centerline-to centerline anchor spacing at which there is no influence on load capacity. Minimum spacing, smin, is defined as the smallest spacing at which an anchor can be installed and torqued to the specified torque without causing a failure. For anchors with spacing between the critical spacing and minimum spacing, adjustment factors are calculated using linear interpolation. The adjustment factors are given in the anchor technical data. The data is presented by table, by equation and by graph. Once the spacing to each influencing anchor is known, the influencing factor for each anchor can be determined. The graphs are determined from the equations given under the tables. n = 1 straight line Where an anchor is being influenced by more than one anchor, each influencing anchor will contribute an adjustment factor, and they are multiplied together. For example, for an anchor influenced by three other anchors, fA = fA1 • fA2 • fA3 . See section 4.1.3.4 for an example using reduction factors. 4.1.3.3 ANCHOR LOADING The type of anchor loads and their position play an important role in the selection of the proper anchor for an application. Both shear and tension values for various concrete strengths are provided in this manual. These must be carefully matched to the design requirements to develop a safe and serviceable connection. n = 5/3 parabolic A straight line assumption is nearly always conservative. Use of parabolic relationships should be supported by testing with oblique loading. 0.8 Tension Ratio, Nd Nrec where: 1.0 Parabolic 0.6 0.4 Straight Line 0.2 0 0.2 4.1.3.3.2 BENDING MOMENT 0.4 0.6 0.8 Shear Ratio, Vd Vrec 1.0 Anchors subjected to ultimate shear loads will cause the base material (concrete, masonry) near the surface to crush or spall. This loss of bearing support in turn increases the secondary bending moment in the anchor body. In the absence of other guidance, the resultant reduced shear capacity of the anchor may be evaluated as follows: Vred = M · M/L ≤ Vrec Nd = Design tension load Vd = Design shear load Nrec = Recommended tension load Vrec = Recommended shear load 4.1.3.3.1 COMBINED LOADING A wide variety of interaction equations have been developed to represent the capacity of anchors loaded simultaneously in tension and shear. Where the capacity of the steel parts (threaded rod, bolts, etc.) controls, the usual interaction relationships used in the design of steel structures are valid, with due account given to secondary bending effects (see Sect. 4.1.3.3.2). Test data for obliquely loaded anchors will typically include a mix of steel and concrete failures. As such, predictive relationships for interaction are typically based on a fairly wide data scatter. Two of the more common relationships in use, straight line and parabolic, take the form shown below: Where: M = factor to account for rotational restraint, take as 1.0 for free cantilever M = anchor moment capacity = (0.6 S fy)(1-Nd/Nrec) L = bending lever arm = z + (n · danchor); n = 1 (Static) n = 3 (dynamic) S = elastic section modulus of stressed anchor section 4.1.3.3.3 INCREASE IN CAPACITY FOR SHORT TERM LOADING Some building codes have allowed a capacity increase of 1/3 when used in conjunction with short-term loading, such as wind and seismic. The origin of the 1/3 increase is unclear, but is generally assumed to cover two loading conditions: 1) consideration of strain-rate effects, whereby the capacity of a material is able to resist higher transitory stresses and 2) the lower probability of permanent and transitory loads acting simultaneously. While Hilti does not include any 1/3 increase in published capacities for anchors in concrete, there is nothing inherently improper with using a 1/3 increase. It is the responsibility of the responsible designer to determine the appropriateness of such a capacity increase under the applicable code. For power-driven fasteners, Hilti does not recommend the use of a 1/3 capacity increase. For decking applications the 1/3 increase is not appropriate for decking methodologies utilizing wind as the primary loading. 8 ©NJATC Anchoring Systems HSL Heavy Duty Sleeve Anchor 4.3.2 4.3.2.3 TECHNICAL DATA HSL Specification Table HSL Anchor Thread Diameter (mm) Details 8 8 10 10 12 12 16 16 20 20 24 24 dbit: nominal bit dia.1 mm 12 15 18 24 28 32 h1: mm (in.) 75 (3) 85 (33/8) 100 (4) 125 (5) 150 (6) 175 (7) hnom: min. depth of embedment mm (in.) 65 (29/16) 75 (3) 80 (33/16) 105 (41/8) 130 (51/8) 155 (61/8) t: max. thickness fastened mm 20 40 20 40 25 (in.) (3/4) (11/2) (3/4) (11/2) (1) : anchor length mm 95 115 107 127 120 145 148 173 183 213 205 235 (in.) (33/4) (41/2) (41/4) (5) (43/4) (53/4) (53/4) (63/4) (71/4) (83/8) (8) (91/4) hole depth hn: head height + washer 50 (2) 25 (1) 50 30 60 30 60 (2) (11/8) (21/4) (11/8) (21/4) mm (in.) 7.5 (5/16) 10 (3/8) 11 (7/16) 14 (9/16) 17 (11/16) 19 (3/4) Tmax: max. tightening torque Nm (ft lb) 25 (20) 55 (40) 80 (60) 200 (150) 400 (300) 710 (525) max. gap2 mm (in.) 4 (3/16) 5 (3/16) 8 (5/16) 9 (3/8) 12 (1/2) 16 (5/8) 36 wrench HSL/HSLG 13 17 19 24 30 HSLB — — 24 30 36 41 size (mm) dh: clearance hole mm (in.) 14-15 (9/16) 17-18 (11/16) 20-21 (13/16) 26-28 (11/8) 31-33 (15/16) 35-37 (17/16) dw: washer dia. mm (in.) 20 (3/4) 25 (1) 30 (13/16) 40 (19/16) 45 (13/4) 50 (115/16) h: mm (in.) 120 (43/4) 140 (51/2) 160 (61/4) 180 (7) 220 (83/4) 270 (103/4) min. base material thickness 1. For Hilti matched tolerance carbide tipped drill bits, see section 10.4.1. 2. For pull-down of parts to be fastened. Combined Shear and Tension Loading ≤ 1.0 (Ref. Section 4.1.3) Dynamic Loading The HSL anchor has been tested under shock, seismic and fatigue (2 x 106 cycles) loading conditions. Contact your Hilti Field Engineer for additional information. Metric Ruler Inches 0 0 1 10 20 2 30 40 50 3 60 70 4 80 90 100 5 110 120 130 6 140 150 7 160 170 180 Millimeters 9 ©NJATC Anchoring Systems HSL Heavy Duty Sleeve Anchor 4.3.2 4.3.2.4 INSTALLATION INSTRUCTIONS 1. Drill a hole with the prescribed Hilti metric bit. Note: the HSL can be installed in a bottomless hole. 2. Clean the hole using compressed air. SETTING INSTRUCTIONS FOR THE HSL-I M12 1. Drill an 18mm hole to an embedment depth of 90mm (3 1/2") with a Hilti metric bit (Item #28002 TE-C+ 18/22 BIT) or Hilti Matched Tolerance diamond core bit (Item #239908) with BI connector for DD100. 2. Clean the hole using a Hilti Blow Out Pump (Item #60579) or compressed air with a nozzle (Item #63964) to reach the bottom of the hole. 3. Using a hammer, tap the preassembled anchor through the object being anchored and into the hole. The anchor should be seated firmly against the base plate. Note: Do not expand the anchor by hand before tapping it into the hole. 5. Tighten bolt or nut to the specified torque, using a torque wrench. Note: When using an HSLB anchor, no torque wrench is required. The torque cap shears off at the appropriate torque value. 3. Use a hammer to tap the anchor flush with the concrete (do not install the threaded rod). Insert the blade of the red handle setting tool into the anchor and engage the blade into the slot of the anchor. Tap the setting tool with a hammer until flush with the concrete. (If there is no setting tool available, a standard punch can be used. Use the punch and hammer to tap the anchor into the hole until the top of the anchor is 6mm (1/4") below the surface of the concrete.) 4. Turn the setting tool clockwise until snug. (A screwdriver can be used if a setting tool is unavailable.) 5. A. Installations with equipment or base plates: Install equipment or base plate over the anchor. Insert the thread ed rod through the base plate or equipment into the anchor a minimum of four full threads. Place washer and torque nut on the threaded rod and hand tighten. Use a box end or socket wrench to tighten the torque nut until the torque nut shears off. Caution - The torque nut shears off suddenly - Gloves are recommended. The torque nut shears off at approximately 60 ft-lbs. B. Installations with stand-off connections such as raised computer floors: Insert the threaded rod into the set anchor a minimum of four full threads. Place washer and torque nut on the threaded rod and hand tighten against the concrete. Use a box end wrench to tighten the torque nut until the torque nut shears off. Caution-The torque nut shears off suddenly-Gloves are recommended. The torque nut shears off at approximately 60 ft-lbs. Complete the stand-off connection using two metric 12mm nuts and washers to clamp the apparatus at the correct stand-off height. 4.3.2.5 ORDERING INFORMATION HSL Bolt Version HSLB Torque Cap Version Description Item No. Box Quantity HSL M 8/20 HSL M 8/40 HSL M 10/20 HSL M 10/40 HSL M 12/25 HSL M 12/50 HSL M 16/25 HSL M 16/50 HSL M 20/30 HSL M 20/60 HSL M 24/30 HSL M 24/60 00066573 00066575 00066576 00066578 00066592 00066593 00066594 00066595 00066596 00066597 00260383 00260384 40 40 20 20 20 20 10 10 6 6 4 4 HSLG-N Stud Anchor Version Description Item No. Box Quantity HSLG-N M 8/20 HSLG-N M 10/20 HSLG-N M 12/25 HSLG-N M 12/50 HSLG-N M 16/25 HSLG-N M 16/50 HSLG-N M 20/30 HSLG-N M 20/60 00068411 00068425 00068439 00068440 00068452 00068453 00068465 00068467 40 20 20 20 10 10 6 6 Description Item No. Box Quantity HSLB M 12/6 HSLB M 12/25 HSLB M 12/50 HSLB M 16/6 HSLB M 16/25 HSLB M 16/50 HSLB M 20/30 HSLB M 20/30 HSLB M 24/30 HSLB M 24/60 00045706 00067400 00067401 00045707 00067402 00067403 00067404 00067405 00260385 00260386 20 20 20 10 10 10 6 6 4 4 HSLG-R Stainless Steel Anchor Material: Stainless Steel AISI 316 Description Item No. Box Quantity HSLG-R M 10/20 HSLG-R M 12/25 HSLG-R M 16/25 HSLG-R M 20/30 00067922 00067924 00067926 00067928 20 20 10 6 HSL-I Internally Threaded Version Description Item No. Box Quantity HSL-I M 12/40 00217174 20 10 ©NJATC Anchoring Systems Kwik Bolt II Expansion Anchor 4.3.3.1 PRODUCT DESCRIPTION 4.3.3 Nut Washer Collar Wedge Dimple Wedges Expansion Cone The Kwik Bolt II is a stud type expansion anchor with a single piece wedge that performs as three independent wedges if necessary to provide consistent performance in a wide variety of medium-duty applications. Applicable base materials include concrete, lightweight concrete and grout-filled block. Impact Section (Dog Point) Product Features Anchor Body • Mechanical expansion allows immediate load application • Can be installed in bottomless hole, which allows the anchor to be driven flush with the surface after use. Eliminates cutting bolt heads. • Can be installed through the fixture, improving productivity • Comprehensive product offering includes many head styles, sizes, carbon steel and stainless steel materials for a variety of applications • Impact section (Dog Point) prevents thread damage during installation • Independent 3-piece wedge with dimples help prevent anchor from spinning during installation • Length identification code facilitates quality control & inspection after installation • Anchor size is same as drill bit size for easy installation • Comprehensive performance testing to provide high & consistent performance in concrete, light-weight concrete & grout filled block base materials Guide Specifications Expansion Anchors Expansion anchors shall be stud type with a single piece three section wedge and zinc plated in accordance with ASTM B633. The anchors must meet the description in Federal Specification FF-S-325, Group II, Type 4, Class I for concrete expansion anchors. Anchors shall be Hilti Kwik Bolt II as supplied by Hilti, Inc., P.O. Box 21148, Tulsa, OK 74121. Installation Anchors to be installed in holes drilled with Hilti carbide tipped drill bits or matched tolerance diamond core bits. Anchors shall be installed per manufacturer’s recommendations. Listings/Approvals • • • • • • • • Underwriters Laboratory No. 203 “Pipe Hangers” (3/8"-3/4" diameters) International Conference of Building Officials (ICBO ES): Evaluation Report No. 4627, KB II International Conference of Building Officials (ICBO ES): Evaluation Report No. 5224, HCKB Southern Building Code Congress (SBCCI): Report No. 9930 City of Los Angeles (COLA): Research Report No. 24946 Conforms to the description in Federal Specification FF-S-325, Group II, Type 4, Class 1 Factory Mutual (FM) KB II 3/8" x 2 1/4" w/Rod Coupler Metro-Dade County Approval 98-0901.13 4.3.3.2 MATERIAL SPECIFICATIONS Carbon Steel KB II studs conform to ASTM A510 with chemical composition of AISI 1038 except countersunk KB II, KB 3/4" x 12", KB II 1" x 6", KB II 1" x 9" and KB II 1" x 12" which conform to ASTM A108 with chemical composition of AISI 11L41 Wedges are manufactured from AISI 1010 carbon steel, except KB II 3/4" x 12", KB II 1" x 6", KB II 1" x 9" and KB II 1" x 12" wedges which conform to chemical composition of AISI 304 Nuts are carbon steel conforming to ASTM A563 Grade A and meet dimensional requirements of ANSI B18.2.2 Washers are carbon steel conforming to SAE 1005-1033 and meet dimensional requirements of ANSI 18.22.1 Type A Plain All carbon steel parts are zinc plated in accordance with ASTM B633, Type III Fe/Zn 5 Stainless Steel KB II studs conform to ASTM A276 or ASTM A493 with chemical composition of either AISI 304 or 316 1/4" thru 9/16" over 9/16" Stainless steel wedges are of the same material grade as bolts or superior. Nuts are stainless steel conforming to ASTM F594 with chemical composition of either AISI 304 or 316 and meeting dimensional requirements of ANSI B18.2.2 to conform with stud material Washers are AISI 304 or 316 stainless steel conforming to ASTM A240 to conform with stud material Note: Special Order KB II’s, nuts and washers may vary from standard materials. 11 MECHANICAL PROPERTIES fy min. fu ksi (MPa) ksi (MPa) 41 (282) 75 (517) 75 (517) 90 (620) N/A N/A N/A N/A N/A N/A N/A N/A 76 (524) 64 (441) 90 (620) 76 (524) ©NJATC Anchoring Systems Kwik Bolt II Expansion Anchor 4.3.3 Countersunk Kwik Bolt II Installation Instructions 1. Drill 2. Clean 6. Tighten 5. Tap-in again 4. Loosen screw 2 full turns 3. Thread Post Nut completely onto anchor. Tap into hole Kwik Bolt II Rod Coupling Installation Instructions 1. Drill 3. Tap-in 2. Clean 4. Tighten Hilti Ceiling Kwik Bolt (HCKB) Installation Instructions 1. Drill 3. Pry downward 2. Tap-in 12 4. Secure ©NJATC Anchoring Systems 4.3.3 Kwik Bolt II Expansion Anchor 4.3.3.5 ORDERING INFORMATION Stud Version Stud Version—Extra Thread Countersunk Version Rod Coupling HCKB Hilti Tamper Proof Nuts (HTN) Fits Bolt Size in. Embedment Item No. Box Quantity Use With 38 HTN Description 3/8 All 00071689 50 All 3/8" HKBII Torque ft-lb 23 12 HTN-M 1/2 ≥ hmin 00071690 50 1/2" HKBII 40 12 HTN-SD 1/2 ≥ hnom 00071691 50 1/2" HKBII 65 12 HTN-CSM 1/2 ≥ hmin 00248311 50 1/2" HKBII 65 58 HTN-SD 5/8 ≥ hnom 00071699 25 5/8" HKBII 110 HTN Removal Tool Description Item No. For HTN Size HTN Removal Tool 38 HTN Removal Tool 1258 00070973 00260212 1/2& 5/8 3/8 Standard 13 Conical ©NJATC Anchoring Systems HDI / HDI-L Drop-In Anchor 4.3.5 4.3.4.1 PRODUCT DESCRIPTION The Hilti HDI/HDI-L Drop-In anchor is an internally threaded, flush mounted expansion anchor for use in concrete. Product Features HDI • Anchor, setting tool & Hilti drill bit form a matched tolerance system to provide reliable fastenings • Below surface setting for easy patchwork • Allows for shallow embedment without sacrificing performance HDI-L • Lip provides flush installation, consistent anchor depth, and easy rod alignment • Lip allows accurate flush surface setting, independent of hole depth & ideal for repetitive fastenings with threaded rods of equal length • Intelligent expansion section adapts to the base material & reduces number of hammer blows up to 50% • Easy to read brand & size identification (red laser print) Guide Specifications Expansion Anchors: Expansion anchors shall be flush or shell type which meet the description in Federal Specification FF-S-325, Group VIII, Type 1, for expansion shield anchors. Anchors to be zinc plated in accordance with ASTM B633, Sc. 1, Type III. Anchors shall be Hilti HDI/HDI-L anchors as supplied by Hilti, Inc., P.O. Box 21148, Tulsa, OK 74121. Installation: Shell or flush type anchors to be installed in holes drilled with Hilti carbide tipped drill bits. Anchors shall be installed per manufacturer’s recommendations. Approvals/Listings • • • • • • City of Los Angeles (COLA): Research Report No. 23709 (HDI Only) Factory Mutual (FM): Serial No. 22765 “Sprinkler Hangar Components—Expansion Shields.” (HDI and HDI-L) Conforms to the description in Federal Specification FF-S-325, Group VIII, Type 1 for expansion shield anchors. (HDI and HDI-L) Underwriters Laboratory (UL), “Pipe Hangers” (3/8"–3/4" diameter) (HDI and HDI-L) MECHANICAL International Conference of Building Officials (ICBO ES): Evaluation Report No. 2895 (HDI Only) PROPERTIES Southern Building Code Congress (SBCCI): Report No. 9930 (HDI Only) fy min. fu ksi (MPa) ksi (MPa) 4.3.5.2 MATERIAL SPECIFICATIONS HDI/HDI-L Carbon Steel material meets the requirements of AISI 1010M for the 1/4", 3/8" & 1/2” HDI Carbon Steel material meets the requirements of AISI 12L14 for the 5/8” and 3/4” sizes HDI Stainless Steel material meets the requirements of AISI 303 Carbon Steel HDI/HDI-L plated with a dull zinc finish for corrosion protection in accordance with ASTM B633, Sc. 1, Type III 44 (303) 53 (365) 60 (415) 78 (540) 60 (414) 100 (689) 4.3.5.3 TECHNICAL DATA HDI/HDI-L Specification Table HDI/HDI-L HDI/HDI-L HDI/HDI-L Anchor Size Details dbit: bit diameter1 hnom: std. depth of embed. : anchor length h1: hole depth th: useable thread length Threads per in. h: min. base material thickness Tinst: max. tightening torque in. (mm) in. in. (mm) in. (mm) in. (mm) ft lb (Nm) /4 1 /8 3 /2 1 HDI /8 5 HDI /4 3 (6.4) 3 /8 1 (25) (9.5) 1 /2 19/16 (40) (12.7) 5 /8 2 (51) (15.9) 27 /32 29/16 (65) (19.1) 1 33/16 (81) /16 (11) 20 3 (76) 4 (5.4) /8 (15) 16 31/8 (79) 11 (14.9) /16 (17) 13 4 (102) 22 (29.8) /8 (22) 11 51/8 (130) 37 (50.2) 13/8 (34) 10 63/8 (162) 80 (108.5) 7 5 11 7 Combined Shear and Tension Loading ≤ 10 (Ref. Section 4.1.3) 1. For Hilti matched tolerance carbide tipped drill bits, see section 10.4.1. 14 ©NJATC Anchoring Systems 4.3.5 HDI / HDI-L Drop-In Anchor 4.3.5.4 INSTALLATION INSTRUCTIONS 1. Adjust depth gauge so that anchor will be flush with the concrete surface when installed. 2. Hammer drill hole. 3. Clean hole. 4. Install anchor using proper setting tool. Setting tool to be driven into anchor until setting tool shoulder meets top of anchor. 4.3.5.5 ORDERING INFORMATION HDI Products Anchor Thread Size 1/4” Carbon Steel Stainless Steel Quantity per Box Description HDI 1/4 Item No. 00045752 Description HDI-L 1/4 Item No. 247818 Description HDI (SS 303) 1/4 Item No. 00045787 3/8” HDI 3/8 00045753 HDI-L 3/8 247817 HDI (SS 303) 3/8 00045788 50 1/2” HDI 1/2 00045754 HDI-L 1/2 247816 HDI (SS 303) 1/2 00045789 50 5/8” HDI 5/8 00045755 - - HDI (SS 303) 5/8 00045790 25 3/4” HDI 3/4 00045756 - - HDI (SS 303) 3/4 00045791 25 100 Setting Tools for HDI / HDI-L Anchors Anchor Thread Size 1/4” Hand Setting Tools Description HST HST 3/8 Setting Tool 00032978 00032979 Description — HSD-MM 3/8” (TE-C-24SD10 3/8” Setting tool) 1/2” HST 1/2 Setting Tool 00032980 HSD-MM 1/2” (TE-C-24SD12 1/2” Setting tool) 5/8” HST 5/8 Setting Tool 00032981 — 3/4” HST 3/4 Setting Tool 00032982 — 1. Use automatic setting tools with TE-5, TE-5A, TE-15, TE-18, and TE-25 rotary hammer drills. 3/8” 1/4 Setting Tool Automatic Setting Tools 1 Item No. 15 Item No. — 00243751 00243752 — — ©NJATC Anchoring Systems HLC Sleeve Anchor 4.3.7 4.3.7.1 PRODUCT DESCRIPTION Hilti Sleeve Anchors are mechanical expansion bolts consisting of an externally threaded stud with a full length expanding sleeve for use in hollow and solid concrete and masonry base materials. Round Head Slotted (RS) Acorn Nut (AC) Bolt Head (H) 304SS Sleeve Anchors Flat Phillips Head (FPH) Rod Coupling (RC) Product Features • Stud bolt type anchor design allows easy through-type fastenings & can be set in bottomless hole • Pre-assembled anchor ensures easy & fast installation • Anchor size is same as drill bit size for easy installation • Variety of head styles, lengths & sizes allow for versatile applications • Comprehensive testing to provide high performance in block, masonry & concrete base materials Hex Nut (HX) • Bulged middle section with round & diamond shaped openings helps prevent the anchors from spinning in the hole or dropping out when setting it overhead Guide Specifications Expansion Anchors: Expansion anchors shall be flush or shell type which meet the description in Federal Specification FF-S-325, Group II, Type 3, Class 3 for expansion shield anchors. Anchors to be zinc plated in accordance with ASTM B633, Sc. 1, Type III. Anchors shall be Hilti sleeve anchors as supplied by Hilti, Inc., P.O. Box 21148, Tulsa, OK 74121. Installation: Sleeve type anchors to be installed in holes drilled with Hilti carbide tipped drill bits. Anchors shall be installed per manufacturer’s recommendations. Approvals/Listings Listings • Underwriters Laboratory, UL Standard No. 203 (1/2", 5/8", 3/4") 4.3.7.2 MATERIAL SPECIFICATIONS Carbon steel anchor studs meet the requirements for AISI 1010 or 1018 steel Carbon steel sleeves and spacers are manufactured from cold rolled steel Carbon steel anchors are zinc plated to minimum 5 µm thickness in accordance with ASTM B633, Sc. 1, Type III Stainless steel anchor material (stud, sleeve, nuts and washers) meet the requirements for AISI 304 stainless steel 4.3.7.3 TECHNICAL DATA Sleeve Anchor Specification Table Anchor Size, in. (mm) Details /4 1 (6.4) /16 5 (7.9) /8 3 (9.5) /2 1 (12.7) /8 5 (15.9) /4 3 (19.1) Combined Shear and Tension Loading d: shank diameter1, in. 3 dbit: bit diameter, in. 1 /4 Nd hmin: min. depth of embed., in. (mm) 1 (25) 1 (25) 11/4 (32) 11/2 (38) 2 (51) 2 (51) Nrec Tinst: Max. tightening ft lb HLC-HX, torque (Nm) 2.2 (3) 5 (6.8) 10 (13.6) 15 (20) 60 (81.4) 90 (122.1) - - HLC-H, ft lb (Nm) /16 1 /4 5 /4 5 /16 3 - /16 3 /8 1 /8 1 /2 5 12 18 35 (16) (24.4) (47.4) /2 5 /8 3 /8 + Vd Vrec ≤ 1.0 (Ref. Section 4.1.3) 1. For Hilti matched tolerance carbide tipped drill bits, see section 10.4.1. 16 ©NJATC Anchoring Systems 4.3.7 HLC Sleeve Anchor 4.3.7.4 INSTALLATION INSTRUCTIONS 1. Drill -Drill the hole. Clean hole with blow out bulb. 2. Insert -With the bolt flush to the top of the nut, drive the sleeve anchor into the hole. 3. Set-Tighten anchor to the recommended torque value. Over-torquing will reduce the pullout and shear loads. 4.3.7.5 ORDERING INFORMATION A Note: Definition of nomenclature Sleeve Anchor AC 1/4 x 13/8 Round Head Slotted (RS) Description Sleeve Anchor RS 1/4 x 11/4 Nut Configuration A: the overall length from bottom of washer Outside diameter of sleeve, see tables for threaded bolt diameter Item No. Bit Diameter1 in. Bolt Diameter in. 00336238 1/4 3/16 Minimum Embed. Depth in. (mm) 1 (25) Fastens Material Up To in. (mm) 1/4 (6.4) Quantity Per Box 100 1. For Hilti matched tolerance carbide tipped drill bits, see section 10.4.1. A Bolt Head (H) Item No. Bit Diameter1 in. Bolt Diameter in. Sleeve Anchor H 5/16 x 15/8 00336244 5/16 1/4 1 (25) 5/8 (16) 100 Sleeve Anchor H 5/16 x 25/8 Sleeve Anchor H 3/8 x 17/8 Sleeve Anchor H 3/8 x 3 Sleeve Anchor H 1/2 x 21/4 Sleeve Anchor H 1/2 x 3 Sleeve Anchor H 1/2 x 4 00336245 00336252 00336253 00336259 00336260 00336261 5/16 1/4 3/8 5/16 3/8 5/16 1/2 3/8 1/2 3/8 1/2 3/8 1 11/4 11/4 11/2 11/2 11/2 (25) (32) (32) (38) (38) (38) 15/8 5/8 13/4 3/4 11/2 21/2 (41) (16) (44) (20) (38) (64) 100 50 50 50 25 25 Description Minimum Embed. Depth in. (mm) Fastens Material Up To in. (mm) Quantity Per Box 1. For Hilti matched tolerance carbide tipped drill bits, see section 10.4.1. A Flat Phillips Head (FPH) Description Item No. Bit Diameter1 in. Bolt Diameter in. Minimum Embed. Depth in. (mm) Fastens Material Up To in. (mm) Sleeve Anchor FPH 1/4 x 11/2 00336234 1/4 3/16 1 (25) 1/2 ( 13) 100 Sleeve Anchor FPH 1/4 x 2 Sleeve Anchor FPH 1/4 x 3 Sleeve Anchor FPH 1/4 x 4 Sleeve Anchor FPH 3/8 x 23/4 Sleeve Anchor FPH 3/8 x 4 Sleeve Anchor FPH 3/8 x 5 Sleeve Anchor FPH 3/8 x 6 00336235 00336236 00336237 00336248 00336249 00336250 00336251 1/4 3/16 1/4 3/16 1/4 3/16 3/8 5/16 3/8 5/16 3/8 5/16 3/8 5/16 1 1 1 11/4 11/4 11/4 11/4 (25) (25) (25) (32) (32) (32) (32) 1 2 3 11/2 23/4 33/4 43/4 ( 25) ( 51) ( 76) ( 38) ( 70) ( 95) (120) 100 100 100 50 50 25 25 Quantity Per Box 1. For Hilti matched tolerance carbide tipped drill bits, see section 10.4.1. 17 ©NJATC Anchoring Systems HLD Kwik-Tog 4.3.11 4.3.11.1 PRODUCT DESCRIPTION The Hilti Kwik-Tog is a plastic anchor designed to accept No. 8 or No. 10 screws for light duty applications in hollow or solid base materials Product Features • Unique one piece design for easy setting • Three convenient sizes for use in a variety of hollow base materials from 1/4” drywall to block and concrete • Leg braces provide added support • Ribs on body help prevent anchor from spinning during installation • Remains mounted in the wall without screw for convenient handling, installation and reuse 4.3.11.2 MATERIAL SPECIFICATIONS Plastic; polypropylene for use in temperature range from -40°F to +140°F 4.3.11.3 TECHNICAL DATA HLD Kwik-TogTM 3 is specially designed for ⁵⁄₈" sheetrock Specification Table S = Thickness of material being fastened 5/18" L d HLD Kwik-TogTM 2 is specially designed for 1/2" sheetrock 5/32" L d - 1/2" 17/32" - 19/32" 3/8" 3/8" 11/4" + S 11/4" + S 19/16" + S #8 or 10 #8 or 10 #10 or 12 3/8" 3/8" 11/2" + S 11/2" + S 113/16" + S #8 or 10 #8 or 10 #10 or 12 11/8" - 11/4" greater than 2" 3/8" 3/8" 11/32" 17/8" + S 17/8" + S 2 3/16" + S #8 or 10 #8 or 10 #10 or 12 - 11/8" HLD Kwik-Tog Allowable Loads1 1/2" Drywall 2. Insert anchor through drilled hole. greater than 15/8" - 7/8" 3/8" 15/16" L d 4.3.11.4 INSTALLATION INSTRUCTIONS 1. Compress wings together. 3/4" HLD Kwik-TogTM 4 greater than 13/8"" 3/8" - 3/4" 3. Insert and tighten screw through fixture to expand wings. 5/8" Drywall Tension Tension Description lb (N) lb (N) HLD 2 20 (89) 25 (111) HLD 3 — 35 (156) HLD 4 — — 1. Based on using a safety factor of 5 Hollow Concrete Block, Tension lb (N) 40 (178) 50 (222) 70 (311) 4.3.11.5 ORDERING INFORMATION HLD Kwik-Tog Anchor Program Description Kwik-Tog 2 (HLD2) Kwik-Tog 3 (HLD3) Kwik-Tog 4 (HLD4) Item Number 00063581 00063582 00063583 Bit Diameter1 in. 3/8 3/8 3/8 Hollow Base Material Thickness 3/16" - 5/8" 5/8" - 7/8" 15/16" - 11/4" Allowable Load in 5/8" Drywall Tension, lb (kN) 25 (0.11) 35 (0.16) — Recommended Screw Size* Hollow Solid Base Mtl. Base Mtl. #8 or #10 #10 #8 or #10 #10 #8 or #10 #10 Quantity Per Box 100 50 50 * Screw not included 1. For Hilti matched tolerance carbide tipped drill bits, see section 10.4.1. 18 ©NJATC Anchoring Systems 4.3.12 HSP/HFP Drywall Anchor 4.3.12.1 PRODUCT DESCRIPTION The Hilti HSP/HFP Drywall Anchor is a self-drilling anchor designed for fast and reliable fastenings in drywall. Product Features • • • • Shark tooth design for correct positioning and quick installation Cuts its own thread - no predrilling necessary One Hilti bit for anchor and screw setting Can be set with electric or standard screwdriver for quick and simple installation • Removability adds to the anchor’s versatility • Available in non-conductive nylon or zinc for a variety of applications • Available with and without screws for your convenience 4.3.12.2 MATERIAL SPECIFICATIONS Zinc Nylon 4.3.12.3 TECHNICAL DATA HSP/HFP Drywall Anchor Allowable Loads1 Gypsum Wall Board 1/2" HSP with Screw # 8 x 1 3/16 5/8" Tension lb (N) Shear lb (N) Tension lb (N) Shear lb (N) HFP with Screw 15 (70) 40 (180) 22 (100) 60 (270) #6x1 15 (70) 40 (180) 22 (100) 60 (270) 1. Based on using a safety factor of 5 4.3.12.4 INSTALLATION INSTRUCTIONS Push the teeth of the anchor into the drywall panel. Drive the anchor (clockwise rotation) until it lies flush with the wall. Drive and tighten the screw with the Hilti bit. 4.3.12.5 ORDERING INFORMATION HDS Drywall Anchor Program Item no. Description 00332682 00332683 00333557 00332686 00332687 00332688 00332689 HSP HSP-S HSP-1/4” THREAD HFP HFP-S D-B PH2 HSP/HFP D-B SQ HSP-G Anchor length ld (in.) Screw dia. Quantity 1 1/2 1 1/2 1 1/2 1 1/8 1 1/8 –– –– #8 #8 –– #8 #8 –– –– 100 100 100 100 100 5 5 19 Remarks Delivered with 100 screws, # 8 x 1 3/16˝ Delivered with one bit D-B SQ HSP-G (00332689) Delivered with 100 screws, # 8 x 1˝ ©NJATC Screw Fastening Systems Self-Drilling Screw Selection Guide 5.2.1 5.2.1.1 DRILL POINT SELECTION Top Material to be Drilled Bottom Material to be Drilled Total Thickness to be Drilled Top Material to be Drilled Void or Insulation Bottom Material to be Drilled Total Thickness to be Drilled Hole Diameter Larger than Screw Threads Top Material Void or Insulation Bottom Material to be Drilled Total Thickness to be Drilled Drill Flute Point Length Drilling Through Wood to Metal The length of the drill flute determines the metal thickness that can be drilled. The flute itself provides a channel Drill for chip removal during Flute drilling action. If it becomes completely imbedded in material, drill chips will be trapped in the flute and cutting action will cease. This will cause the point to burn up or break. The unthreaded section from the point to the first thread should be long enough to Point assure the drilling action is Length complete before the first thread engages the drilled metal. Screw threads advance at a rate of up to ten times faster than the drill flute can remove metal. All drilling therefore should be complete before threads begin to form. If your application calls for drilling through wood over 1/2" in thickness, a clearWinged ance hole is required. Select Reamer a fastener with breakaway wings for this type of job. The wings will ream a clearance hole and break-off when they contact metal surface (minimum metal thickness .090") to be drilled. Thickness of material to be drilled (inches) Drilling Capacity – MD-Applications (Steel to Steel) #2 Point #3 Point #5 Point #4 Point .500 .400 .300 .312 .312 .175 .175 .250 .210 .200 .100 .250 .175 .110 .100 .110 .110 .110 .035 0 Screw Diameter #8 #10 #10 #12 1/4" *#12 1/4"** #12 Note: The above chart covers the Hilti standard self-drilling screw program. For information on specialty fasteners (Kwik Seal, wing reamers, etc.), contact your Hilti representative. Shaded area represents optimal drilling range. * #12 #4 point winged reamer fasteners have a maximum drill capacity of .220". ** 1/4" #4 point winged reamer fasteners have a maximum drill capacity of .250". 20 ©NJATC Screw Fastening Systems 5.2.1 Self-Drilling Screw Selection Guide 5.2.1.1 DRILL POINT SELECTION (Continued) 5.2.1.2 THREAD SELECTION Conversion Tables Metal Gauge Fraction to Decimal Sheet Metal Number Aluminum of Gauge (Thickness in decimal parts of an inch) 000000 00000 0000 000 00 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 .5800 .5165 .4600 .4096 .3648 .3249 .2893 .2576 .2294 .2043 .1819 .1620 .1443 .1285 .1144 .1019 .0907 .0808 .0720 .0641 .0571 .0508 .0493 .0403 .0359 .0320 .0285 .0253 .0226 .0201 .0179 .0159 .0142 .0126 .0113 .0100 .0089 .0080 .0071 .0063 .0056 .0050 .0045 .0040 — — .4062 .375 .3437 .3125 .2812 .2656 .2391 .2242 .2092 .1943 .1793 .1644 .1495 .1345 .1196 .1046 .0897 .0747 .0673 .0598 .0538 .0478 .0418 .0359 .0329 .0299 .0269 .0239 .0209 .0179 .0164 .0149 .0135 .0120 .0105 .0097 .0090 .0082 .0075 .0067 .0064 .0060 Thread Length Fraction (in.) Decimal Equivalent (in.) 1/64 1/32 3/64 1/16 5/64 3/32 7/64 1/8 9/64 5/32 11/64 3/16 13/64 7/32 15/64 1/4 .015 .031 .046 .062 .078 .093 .109 .125 .140 .156 .171 .187 .203 .218 .234 .250 Always choose a fastener with sufficient threads to fully engage in the base metal. For example: If you are fastening into 1/4" steel, the fastener should have at least 1/4" of threads. It is helpful, but not critical, that the threads also engage in the material being fastened. The head of the fastener provides the holding power for the material being fastened, while the threads provide the holding power in the base material. Holding Material Being Fastened Base Material Holding Thread Pitch Screw Wire Gauge Number of Gauge Decimal Equivalent (in.) #6 #8 #10 #12 #14 .138 .164 .190 .216 .242 The thickness of material being fastened and diameter of the screw determine the type of thread pitch to be used. In general, the thinner the fastened materials, the fewer the number of threads. The thicker the material, the greater the number of threads. This principle is due to two primary methods of thread engagement/holding power: Clamping and Threading. In light gauge metal, the materials are actually being clamped together by the upper and lower threads. Clamping Holding Holding Therefore, the thinner the material, the coarser the thread pitch must be to assure proper clamping. The thicker the material, the finer the threads must be. In very thick metal (3/8" - 1/2" thick), a fine thread is adviseable. This will allow the thread to “tap” into the base material with less installation torque than a coarse thread. Thread Engagement 21 ©NJATC Screw Fastening Systems Self-Drilling Screw Selection Guide 5.2.1 5.2.1.3 HEAD STYLE SELECTION HWH PPH PFH PWH Hex Washer Head: Washer face provides a bearing surface for the driving sockets. Phillips Pan Head: Conventional head for general applications and provides low profile fastening. Phillips Flat Head: Used primarily in wood to countersink and seat flush without splintering the wood. Phillips Wafer Head: Large head provides the bearing surface necessary to seat flush in soft materials. 5.2.1.4 SEALING CRITERIA The Kwik-Seal™ sealing screws offer weatherproof fastenings where moisture or condensation is a factor. The integrated washer/head design seals the hole to prevent moisture from dripping into the fastener threads, reducing corrosive build-up. As added protection against corrosion, all Kwik-Seal™ sealing screws come standard with KwikCote® coating. The torque control and adjustment of the Kwik-Tapper electric screwdrivers help ensure that the optimal seal is applied. If you underdrive, the compression ring design results in a low torque seal. If you overdrive, the compression ring, outer skirt, and rugged washer prevents spinout and the one-piece head design completely eliminates the possibility of washer inversion. If you angle-drive, the design of the fastener head, outer skirt, and compression ring, along with the special washer, still helps provide a positive seal. 5.2.1.5 LENGTH SELECTION Length of the screw (L) Depending on the screwhead, there are two different ways of measuring the overall length of a screw. HWH, PPH screws overall length is measured from the bottom of the collar under the head to the point of the screw. MF L Maximum thickness fastened(MF) MF The maximum thickness fastened for all screws is the length of the threads reduced by the first three threads (embedement in the base material). See drawings above. L The maximum thickness fastened (MF) describes the maximum thickness of the attachments to be secured to the base material. • PWH, PFH screws overall length is measured from the top of the head to the point of the screw. 22 ©NJATC