Qualification and Routine Environmental Monitoring of Critical

advertisement

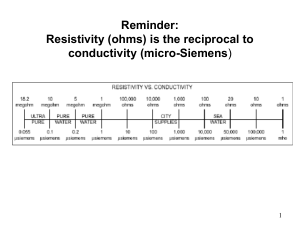

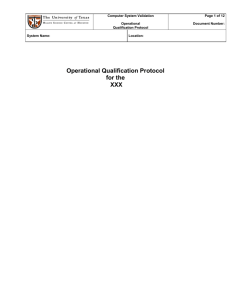

Qualification and Routine Environmental Monitoring of Critical Utility Systems 21th Annual Validation Week Day Three, Session 10:30am – 12:00 pm Qualification and Routine Environmental Monitoring of Critical Utility Systems 1 CONTACT INFORMATION for Course Leader Ed Winnett/VP Operations Validation Technologies, Inc. San Diego, CA Office: 800-930-9222 Fax: 858-676-3677 Email: edw@validation.org Website: http://www.validation.org 2 PRESENTATION OVERVIEW SUPPORT DOCUMENTATION CONSTRUCTION QUALIFCATION QUALIFICATION OF CRITICAL SYSTEMS ESTABLISHING A ROUTINE ENVIRONMENTAL PROGRAM TRENDING AND DATA SUMMARY “PROBLEM AREAS” - UTILITY SYSTEMS REVALIDATION 3 Part 1 Documents to Support Equipment Qualification DQ IQ PQ OQ PV IQ OQ IQ/OQ Documentation PQ VC CQ 4 Support Documents • • • • • • • • • • • The User Requirements Specification (URS) Design Specifications Functional Specifications Purchases Requisitions Turn-Over- Packages Vendor Manuals P&IDs Manuals Commissioning FAT/SAT Change Management 5 Part 2 Critical Utility Project Strategy Plan the Work and Work the Plan 6 PROGRAMS REQUIRED FOR FACILITY & CRITICAL UTILITIES QUALIFICATIONS • • • • • • • • • • • PROJECT DESIGN SPECIFICATION VALIDATION MASTER PLAN PROJECT SCHEDULE CONSTRUCTION QUALIFICATION PACKAGES INSTALLATION QUALIFICATION PROTOCOLS FACILITY STARTUP/COMMISSIONING STANDARD OPERATING PROCEDURES CALIBRATION PROGRAM OPERATIONAL QUALIFICATION PROTOCOLS ANALYTICAL METHODS VALIDATED PERFORMANCE QUALIFICATION 7 PROJECT SCHEDULE • DEFINED CRITICAL PATHS • CONSTRUCTION ACTIVITIES • COLLECTION OF CONSTURCTION QUALIFCATION CQ DATA • DEVELOPMENT OF PROTOCOL FORMAT • WRITE IQ & OQ PROTOCOLS • EQUIPMENT INSTALLATION ACTIVITIES • EXECUTION OF IQ PROTOCOLS • COMMISSION OF SYSTEM • EXECUTION OF OQ PROTOCOLS • ANALYTICAL METHODS VALIDATED • WRITE & EXECUTE PERFORMANCE QUALIFICATIONS 8 PROJECT SPECIFICATION • • • • • • • • EQUIPMENT DATA SHEETS SPARE PARTS LIST VENDOR CERTIFICATION FACTORY ACCEPTANCE TEST REPORT MATERIALS OF CONSTRUCTION ON SITE TESTS CLEANING REQUIREMENTS COMPONENTS SELECTION 9 VALIDATION MASTER PLAN • • • • • • VALIDATION PROJECT ROAD MAP FACILITY & PROCESS DESCRIPTION VALIDATION PROGRAM EQUIPMENT & UTILITY LIST PROJECT RESPONSIBILITIES VALIDATION PROJECT DESCRIPTION 10 Part 3 Commissioning and Construction Program 11 Good Engineering Practice (GEP) • “Established Engineering methods and standards that are applied throughout the project lifecycle to deliver appropriate cost-effective solutions” 12 Good Engineering Practice (GEP) • GEP project scope – – – – – – – – Documentation Organization and Communication Requirements Phase Design Phase Construction Phase Project Controls Commissioning and Qualification Project Closeout and Turnover 13 Commissioning Plan • Commissioning Plan should contain the following deliverables: (Direct Impact Systems) – – – – – – – – – – Commissioning Plan Commissioning Schedule Commissioning Budget Overall Test Plan Factory Acceptance Test/Report Site Acceptance Test/Report Inspection Plan/Report Functional Test/Report System Test Summary Reports Commissioning Summary Reports 14 Scope of the Commissioning and Qualification Guide Engineering Change Management Impact Assessment QA Change Control Design Development Enhanced Design Review commissioning PQ Process Validation IQ & OQ Design for Impact Scope of Guide GEP Contribution Of Interest to the Regulatory 15 System Impact and Component Criticality • • • • Indirect Impact or No Impact system are comprised of non-critical components only Direct Impact system have both critical and non-critical components. (Components deemed non-critical may be managed within Good Engineering Practices (GEP) alone) Design for Impact reduces the scope of the system and components to Qualification Practices allowing appropriate focus on the components presenting a risk to product quality Should an Indirect Impact or No Impact system incorporate one or more critical components, either the system has been mis-classified or the component was wrongly assessed. 16 Impact Assessment • “Direct Impact” Systems are expected to have an impact on product quality • Indirect Impact systems are not expect to have an impact on product. – – Both types of systems will require commissioning; however, the “Direct Impact” system will be subject to qualification practices to meet additional regulatory requirements of the FDA and other regulatory authorities System Impact Assessment Form Direct HVAC System Template Part 1.doc 17 System Impact Assessment Process Overview Identify System Develop System Boundaries Yes Does the system have a direct impact on product quality No Is the system linked to Direct Impact System Yes “Indirect Impact” system “Direct Impact” system No “No Impact System” Develop Supporting Rationale 18 Qualification Risk Based Assessment • • • “Direct Impact” Systems are expected to have an impact on product quality therefore the level of validation or qualification must be determine by using Qualification Risk Based Asessment Qualification Level Analysis Form Direct HVAC Template Part 2.doc Qualification Level Analysis Results Form Direct HVAC Template Part 3.doc 19 Component Criticality Assessment Process • • The components within “Direct Impact”, Indirect Impact” and in some cases “No Impact” systems should be assessed for criticality. Must have updated Piping and Instrument Drawings (P&IDs) 20 Component Criticality Assessment Process • Applicability of any of the following criteria to a given component will provide an indication that component is critical: 1. 2. 3. The component is used to demonstrate compliance with the registered process. The normal operation or control of the component has a direct effect on the product quality. Failure or alarm of the component will have direct effect on the product quality. 21 Component Criticality Assessment Process (Continued) • Applicability of any of the following criteria to a given component will provide an indication that component is critical: 4. 5. 6. 7. Information from the component is recorded as part of the batch record, lot release data or other GXP related documentation. The component has direct contact with product or product components The component controls critical process elements that may affect product quality, without independent verification of the control system performance. The component is used to create or preserve a critical status of a system. 22 System Impact and Component Criticality • • • • • Indirect Impact or No Impact system are comprised of non-critical components only Direct Impact system have both critical and noncritical components. (Components deemed noncritical may be managed within Good Engineering Practices (GEP) alone) Design for Impact reduces the scope of the system and components to Qualification Practices allowing appropriate focus on the components presenting a risk to product quality Should an Indirect Impact or No Impact system incorporate one or more critical components, either the system has been misclassified or the component was wrongly assessed. Critical Component Analysis Form Direct HVAC Template 4.doc 23 Part 4 Qualification of Critical Utilities Systems Design, Construct, Commission then Qualify 24 Critical Utility Qualification • Construction Qualification – During construction, document procurement and verification of construction activities, are critical components of a successful Installation Qualification (IQ). Must have Engineering Turnover Packages (ETOP) • • • • • • • • • • • • Design/Functional Specifications Test Reports Material Certifications Purchase Specification & Orders State and Local Code Compliance ASME, ANSI and other Certifications Pipe Specifications Cleaning and Passivation Reports Stainless Steel Weld Documentation Vendor/Manufacturer's Submittals Manufacturer's Mechanical Specifications Instrumentation Specifications 25 Commissioning Phase: Leverage Support Document • FAT/SAT can be leverage to support IQs and OQs • Some of the test and information collected during the commission phase can be used to support I/OQ protocol execution • Most of the information contain in the FAT such as material of construction can used to support the IQ document. • Some of tests performed in the SAT are duplicated during the execution of the OQ therefore it only make sense to leverage of SAT to support some of the tests in the OQ protocol 26 Utility Qualifications • Basic checklist is used for IQ • Defined Direct/In-Direct/Non-Impact System • Manufacturer information: contact info., specs, P.O., manuals, etc. • Equipment description (make, model, serial number, etc.) • Instrumentation • Spare Parts • Control Panels • Safety • PM • Calibration • Support Utilities 27 IQ : IS IT INSTALLED CORRECTLY? • • • • • • • • • • • • • • Full description of equipment capabilities, design features and company's specific intended use in manufacture. Vendor, equipment ID, serial number, etc. Location of installation Process Equipment Listing Drawings or Flow Diagrams Operator’s Manual Maintenance Procedures and Schedule; Cleaning Schedule Calibration Procedure and Schedule Spare Parts List Configuration of Components, Drawings Materials of construction, Interface with other equipment (peripherals); Interface with utilities, facility Safety Appropriate Environmental Conditions 28 Critical Utility Qualification • Installation Qualification - is a documented plan for the performance of inspections and the collection of documentation to verify static attributes of a system. – – – – System Location System Description Major Components Identification Summary Field Inspection Report- Comparison of Actual to Specified – Instrumentation List – Spare Parts List – Documentation/Drawings List 29 Utility Qualifications • Operational Qualification - Does the equipment function as intended? • Challenge the process (equipment) parameters under worst case testing. This is where you determine the degree of “robustness” with the equipment. • Objective, Scope, Description, etc. • Operational testing • Acceptance criteria • Deviations (Excursions, etc.) • Approvals 30 Critical Utility Qualification • Operational Qualification (OQ) - is a documented plan for the performance of inspections and tests to verify specified dynamic attributes of a system. – SOP Review – Calibration Review – Test of Alarms – Test of Controls – Test of Interlocks – Start Up/Shutdown Sequence Verifications – Normal Run Mode Verification - Monitoring Applicable Indications: • • • • • • Pressure Temperature Time Resistivity/Conductivity Flow pH 31 PERFORMANCE QUALIFICATION PROTOCOL FOR CRITICAL UTILITIES • • • • • • • • • • • OBJECTIVE IDENTIFICATION SYSTEM PERFORMANCE DESCRIPTION REFERENCES RESPONSIBILITIES PROCEDURE ACCEPTANCE CRITERIA PERFORMANCE QUALIFICATION TEST COMMENTS DEVIATION/EXCEPTIONAL CONDITION ATTACHMENTS 32 Utility Qualifications • Performance Qualification • Objective, scope, description, equipment testing, approvals, etc. • Documented verification that the equipment operates the way it is purported to do. This operation must be reliable and reproducible within a specified, predetermined set of parameters under nominal or normal production conditions. 33 Critical Utility Qualification • Performance Qualification (PQ) - is a documented plan for the execution of tests to demonstrate the effectiveness and reproducibility of a system/process as a fully integrated functional entity. – All installed critical instruments shall be calibrated prior to execution of the protocol. – All test instruments used to execute the protocol shall be calibrated and certified prior to use. – Test methods, analytical procedures and sampling techniques, when not defined in a protocol, shall be written and approved as SOPs. – The system can consistently meet its predetermined acceptance criteria. 34 Critical Utility Qualification • Performance Qualification (PQ) - Standard Testing Intervals – Water For Injection Systems - 30 to 45 Days (30 - 40 days Standard @ Shut Down Recover Test) – Purified Water Systems - 30 Days – Clean Steam Systems - 30 Days – Gases/Clean Dry Air Systems - 7 to 14 Days or three lots – HVAC System (Controlled Environment)- 1 Baseline (Before cleaning), 3 Static States, 3 Dynamic (20 -30 days) 35 Part 5 Validation of Purified Water Systems Purified Water is used in Aspect of GMP Manufacturing Operations 36 Water Usage in Pharmaceutical Production • Water Requirements – Potable - EPA – USP Purified – USP Water For Injection 37 Validation of Critical Water Systems • FDA Requirements: Phase 1 • All water systems should have documentation containing a system description and accurate drawing. • The drawing needs to show all equipment in the systems from water input to points of use. It should also show all sampling points and their designations. 38 Validation of Critical Water Systems • FDA Requirements: Phase 1 • After all the equipment and piping has been verified as installed correctly and working as specified, the initial phase of the water system validation can begin. 39 Validation of Critical Water Systems • FDA Requirements: Phase 1 • During the initial phase the operational parameters and cleaning/sanitation procedures and frequencies will be developed. Sampling should be daily after each step in the purification process and at each point of use for two to four weeks. 40 Validation of Critical Water Systems • FDA Requirements: Phase 1 – The sampling procedures for point of use should reflect how they are taken, e.g. use of hose, and time for flushing. At the end of the two (2) or four (4) weeks the firm should have developed its SOPs for operation and maintenance of the water system. 41 Validation of Critical Water Systems • FDA Requirements: Phase 2 • The second phase of the water system validation is to demonstrate that the system will consistently produce the desired water quality when operated in conformance with SOPs. 42 Validation of Critical Water Systems • FDA Requirements: Phase 2 • The sampling is performed as in the initial phase and for the same period . At the end of this phase the data should demonstrate that the system will consistently produce the desired quality of water. 43 Validation of Critical Water Systems • FDA Requirements: Phase 3 • The third phase of validation is designed to demonstrate that when the water system is operated, in accordance with the SOPs, over a long period of time it will consistently produce water of desired quality. 44 Validation of Critical Water Systems • FDA Requirements: Phase 3 • Any variations in quality of the feedwater, that could affect the operation and ultimately the water quality, will be noticed during this phase of the validation. 45 Validation of Critical Water Systems • FDA Requirements: Phase 3 • Sampling is performed according to routine procedures and frequencies. • For Water for Injection systems samples should be taken daily from a minimum of one point of use, with all points of use tested weekly. 46 Validation of Critical Water Systems • FDA Requirements: Phase 3 • The validation of the water system is completed when the firm has collected data for a full year. • The FDA states that “while the above validation scheme is not the only way a system can be validated, it contains the necessary elements for validation of a water system.” 47 Validation of Critical Water Systems • FDA Requirements: Phase 3 • First, there must be data to support the SOPs. • Second, there must be data demonstrating that the SOPs are valid and that the system is capable of consistently producing water that meets the desired specifications. 48 Validation of Critical Water Systems • FDA Requirements: Phase 3 • Finally, there must be data to demonstrate that seasonal variations in the feedwater do not adversely affect the operation of the system or the water quality. This last part of the validation is the compilation of the data, with any conclusions into the final report. 49 Microbiological/Chemical Limits Tests pH TOC Conductivity Bacteria Endotoxins Potable Water Purified Water Water for Injection N/A N/A N/A 500 cfu/mL N/A 5.0 - 7.0 500 ppb 4.7 to 5.8 S/cm 100 cfu/mL Not Specified 5.0 - 7.0 500 ppb USP Specifications 10 cfu/100mL 0.25 EU/mL cfu = Colony Forming Units 50 Critical Utility Qualification • Performance Qualification (PQ) Standard Testing Intervals – Water For Injection Systems - 30 to 60 Days (20 - 40 days Standard @ Shut Down Recover Test) – Purified Water Systems - 30 Days WFI –PW Systems reduce sampling (3 Phases 1st 15 days, 2nd Phase 15 days, if results are acceptable system be have interim release for GMP use) 3rd Phase 350 days (52 weeks or 1 yrs) systems can be considered fully validated, historical data can be trended to set true alert and action levels 51 ESTABLISHING ENVIRONMENTAL MONITORING PROGRAM • When establishing a routine environmental monitoring program, the PQ study data should be the starting point for determining the sampling sites and testing frequencies. 52 HIGH PURITY WATER SYSTEMS ENVIRONMENTAL MONITORING PROGRAM • Sample Site and Frequencies Determination – For Water for Injection systems samples should be taken daily from all point of use. – For Purified Water systems samples should be taken daily from a minimum of one point of use, with all points of use tested within a week. 53 HIGH PURITY WATER SYSTEMS ENVIRONMENTAL MONITORING PROGRAM • Sample Site and Frequencies Determination – For Water for Injection systems samples should be taken daily from all point of use. – For Purified Water systems samples should be taken daily from a minimum of one point of use, with all points of use tested within a week. 54 HIGH PURITY WATER SYSTEMS ENVIRONMENTAL MONITORING PROGRAM Water Type WFI RO/DI Potable Water Sample Description USP/EU Conductivity/ TOC Tests USP/EU USP/EU/CP Microbial/ Endotoxin Chemistry (Heavy Metals/Nitrates) / Appearance pH / Ion Testing Coliform Steam Quality Testing Beginning of , Post Circulation Pump and WFI still outlet Daily read/ Weekly data collection Weekly No Routine Sampling Not Required Monthly (information Only) Quarterly Point of Use Ports Weekly or Use Data from inline device Monthly Weekly Not Required Not Required Not Required End of Loop Sample Daily/Compare to inline device Daily Daily Weekly Not Required Not Required RO Before EDI (DI System) Supply Inlet to WFI Still Weekly Weekly + Coliform No Routine Sampling Weekly Weekly Not Required DI Supply Inlet to WFI Still Sample Weekly Weekly + Coliform No Routine Sampling Weekly Weekly Not Required Infeed water to RO/DI System2 Grab Sample Weekly Weekly + Coliform No Routine Sampling Weekly Weekly Not Required 55 Part 5 Validation of Clean System Systems Clean Steam is used in certain aspects of GMP Manufacturing Operations 56 Clean Steam Usage in Pharmaceutical Production • Clean Steam Requirements – Steam-In-Place (SIP) – Sterilization Process – SIP Water For Injection 57 Validation of Critical Water Systems • FDA Requirements: Phase 1& 3 • Same requirements as WFI system Qualification. 58 Validation of Critical Water Systems • FDA Requirements: Phase 3 • The validation of the clean steam system is completed when the firm has collected data for a full year. 59 CLEAN STEAM SYSTEM ENVIRONMENTAL MONITORING PROGRAM • Sample Site and Frequencies Determination – For Clean Steam systems samples should be before manufacturing process i.e. SIP, autoclave, etc. and from a minimum of one point of use, with all points of use tested weekly. 60 CLEAN STEAM SPECIFICATIONS Table: Microbiological/Chemical Limits Tests pH TOC Conductivity Bacteria Endotoxins Clean Steam 5.0 - 7.0 500 ppb Current USP Specifications/ method 10 cfu/100mL (Information Only – None Routine) 0.25 EU/mL cfu = Colony Forming Units 61 CLEAN STEAM SYSTEM MONITORING PROGRAM Type Pure (Clean) Steam Sample Description USP/EU USP/EU/CP Microbial/ Endotoxin Chemistry (Heavy Metals/Nitrates) / Appearance Endotoxin Weekly Grab Sample Monthly Monthly USP/EU Conductivity/ TOC Tests Steam Generator pH / Ion Testing Coliform Steam Quality Testing Weekly Not Required Not Required Quarterly Endotoxin Monthly Monthly Not Required Not Required Not Required Monthly Quarterly No Routine Sampling No Routine Sampling Annually Weekly Point of Use (SIP) Autoclave Point of 62 Part 5 Validation of Compress Gas Systems There are many different types of gases used in a GMP manufacturing operation 63 Compress Gases Usage in Pharmaceutical Production • Compress Gases Requirements – Preserve the Status of Product – Drying after Cleaning – Assist Cell Growth – Instrument Actuation – Move Fluid 64 Compress Gases Usage in Pharmaceutical Production • Types Of Gases – Clean Dry Air – Nitrogen – Carbon Dioxide – Helium – Oxygen – Argon 65 COMPRESSED GAS MAJOR COMPONENTS • • • • • • • • • Cylinders Dryer Manifold Automatic/Manual Switchover System Valves Pressure Gauges Filters Control System (Low Gases, Low Oxygen) Distribution System (SS or Type L copper) 66 COMPRESS GAS SYSTEMS ENVIRONMENTAL MONITORING PROGRAM • Sample Site and Frequencies Determination – For compress gas systems samples should be taken daily from all point of use for one week. 67 COMPRESS GAS SPECIFICATIONS Table: Microbiological/Chemical Limits Tests Compress Gas Dew Point Hydrocarbon as Oil Mist Gas Content < -10 oC < 1 ppm Current USP Specifications/ method for Purity < 0.1 CFU/ft3 Room Classification Bacteria Non-Viable Particulate: cfu = Colony Forming Units 68 COMPRESS GAS MONITORING PROGRAM Sample Location Dew Point Hydrocarbon as Oil Mist Bacteria Non-Viable Particulate Quarterly Monthly Monthly Not Required Weekly (day of filling process) Weekly (day of filling process) With each new lot Monthly Monthly Not Required Not Required Weekly Weekly Monthly Monthly Annually With each new lot or Quarterly Not Required Not Required Weekly Weekly Type Gas Content Source Clean Compressed Air USP/EU Monthly Annually Point of Use Grab Sample Monthly Source Monthly Not Required Annually Carbon Dioxide (CO2) Point of Use Grab Sample Monthly Source Monthly Nitrogen Point of Use Grab Sample Monthly 69 Part 6 Validation of HVAC Systems HVAC is used in Aspect of GMP Manufacturing Operations 70 Clean Room Standards • This ISO committee will produce 10 new standards documents that relate to cleanrooms or clean zones (described below). The first two standards have been published: ISO 14644-1 and -2. – The first document, ISO 14644-1, Cleanrooms and associated controlled environments Part 1: Classification of airborne particulates has been released as a final document. – The second document, ISO 14644-2, Cleanrooms and associated controlled environments Part 2: Testing and monitoring to prove continued compliance with ISO 14644-1; has been released as a final document. 71 Clean Room Standards • The cleanliness classification levels defined by FS209E and ISO 14644-1 are approximately equal, except the new ISO standard uses new class designations, a metric measure of air volume and adds three additional classes - two cleaner than Class 10 and one beyond than Class 100,000. • The second new ISO standard, ISO 14644-2, gives requirements for monitoring a cleanroom or clean zone to provide evidence of its continued compliance with ISO 14644-1. 72 Clean Room Certification • Clean Room Certification Testing – – – – – – – – – – – Differential Air Flow Humidity/Temperature Supply Air Volume/Room Air Change Rate Room Differential Pressures DOP Test of HEPA Filters Room Non-Viable Particulate Counts Light Levels Noise Levels Recovery Time Unidirectional and Parallelism Enclosure Induction 73 Monitoring Program • Controls/Alarms – reports verification and review (procedure) – Weekly reports – Alert vs Action Limits – Failure investigations • Laboratory testing – viable and nonviable counts – Analysis of Trends (Quarterly) – Alert Limits • Refer to ISO-14644-2 and 14644-3 for frequency guidelines and test equipment recommendations 74 HVAC SYSTEMS ENVIRONMENTAL MONITORING PROGRAM • Sample Site and Frequencies Determination – Would the act of sampling at a given site disturb the environment sufficiently to cause erroneous data or possibly cause the product to be contaminated? – At which site would the potential of microbial contamination most likely affect product quality adversely? – During the PQ study which sites were highest in microbial contaminates. – What sites would be the most difficult to clean? – Should site selection involve statistical design or should it be based on a grid profile? – How often is a particular area or process used? 75 Physical, Microbiological Testing Parameters •TABLE 1- Air Classification – – – – – a- All classifications based on data measured in the vicinity of exposed materials/articles during periods of activity. b- ISO 14644-1 designations provide uniform particle concentration values for cleanrooms in multiple industries. An ISO 5 particle concentration is equal to Class 100 and approximately equals EU Grade A. c- Values represent recommended levels of environmental quality. You may find it appropriate to establish alternate microbiological action levels due to the nature of the operation or method of analysis. d- The additional use of settling plates is optional. e- Samples from Class 100 (ISO 5) environments should normally yield no microbiological contaminants. 76 SURFACE MONITORING Table 2: USP’s 1116 microbial levels for Surface Monitoring Surface CFU/ 2 in2 3 (floor/except) Personnel CFU/ 2 in2 3 - gloves (5-mask/gown) Frequency of P Montoring M 5.5 5 (10 floor) 5-gloves (10-mask/gown) Each Shift1 2x/week2 M 6.5 20 (30-floor) 15-gloves (30-masks/gown) Weekly Classifications Zone Critical Area Class 100 M 3.5 Each Shift (ISO 5) Non-critical Class 10,000 ISO 7 Support Areas Class 100,000 ISP 8 1 2 Adjacent to Class 100 Support Areas - Product 77 CLEAN ROOM MONITORING PROGRAM Classification Sample Method Minimum Sampling Frequency1 Grade A ( ISO Class 5) Surface Viable Viable Particulates Total Airborne Particulates Weekly or when Filling process is being performed including during each shift Grade B (ISO class ISO-5.5 Or 6) Surface Viable Viable Particulates Total Airborne Particulates Weekly or when Filling process is being performed including each shift Grade C (ISO Class 7) Surface Viable Viable Particulates Total Airborne Particulates Weekly or when entering into Grade B and A area during filling operations. Grade D ( ISO Class 8) Viable Particulates Total Airborne Particulates Monthly or when entering into Grade C which leads into Grade B and A area during filling operations. Surface viable sampling should be performed every quarter. Restricted Areas With Monitoring Viable Particulates Total Airborne Particulates Monthly 78 Part 7 Maintenance Program for Critical Utility Systems Maintenance of Critical Utility Systems insure the life cycle approach to validation 79 CHANGE CONTROL PROGRAM • Change Control Program (CCP) Maintains Utility Systems Life Cycle Approach To Validations • Supports Revalidation Activities. • Should have established Change Control Program which includes critical review process when changes are made to any critical utility system. • CCP should include changes made and extent of validation required. 80 REVALIDATION PROGRAM • Annual review of change control forms for each critical utility system. • Annual review of the maintenance and cleaning logs associated with each critical utility system. • Annual review of routine environmental monitoring data. • Annual abbreviated PQ study may be required under certain conditions. 81 VALIDATION MAINTENANCE PROGRAM (CONT.) • Validation Maintenance Requirements: 1. System Specific Operation, Maintenance, Cleaning Procedures 2. System Specific Routine Monitoring Programs 3. Trend Analysis 4. Calibration Program 5. Preventive Maintenance Program 6. Change Control Program 7. QA Auditing 8. Deviation /Investigation Reporting 9. Revalidation Program 82 “PROBLEM AREAS” - UTILITY SYSTEMS • No diagrams provided, no narratives • Diagrams not detailed • Validation data summaries insufficient – – – – – – monitoring too infrequent sampling plan inadequate monitoring not performed during production inappropriate parameter tested validation period too short inadequate alert and action limits and specs 83 “PROBLEM AREAS” - UTILITY SYSTEMS • Validation data summaries insufficient – no SOP for corrective actions – no “historical data base” development • No discussion of system / equipment maintenance or calibration • inadequate proposal for routine monitoring program 84 Thank You Question and Answers Validation Technologies Inc. 85