One-pot Synthesis of Benzil Derivatives from Aromatic Aldehydes

advertisement

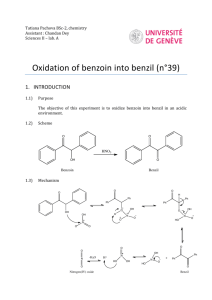

Org. Chem. J. 2014, 3(1), 28-33 One-pot Synthesis of benzoin derivetives One-pot Synthesis of Benzil Derivatives from Aromatic Aldehydes Mohsen Mousavi* and Hasan Seyfi Department of Chemistry, Saveh branch, Islamic Azad University, Saveh, Iran E-mail: drmousavi@hotmail.com Abstract One-pot benzoin condensation and air oxidation of some aromatic aldehydes were investigated. All the reactions were carried out by catalytic effect of cyanide ion in alcoholic solvents under atmospheric O2. Under these conditions, 4-methoxybenzaldehyde, 4-bromobenzaldehyde, 3-nitrobenzaldehyde and 2furylcarbaldehyde transformed to their relative benzil derivatives, directly. But the procedure was not successful with 4-methylbenzaldehyde, 4-chlorobenzaldehyde, 2-pyridinecarbaldehyde and 4pyridinecarbaldehyde. The later compounds were converted to their relative benzoin or pyridoin derivatives. The so-formed benzoins were then oxidized to their corresponding benzil derivatives using a mixture of ammonium nitrate and cupric acetate in 80% aqueous solution of acetic acid. However, pyridoines converted to blue complexes in the same reaction conditions. Keywords: Aromatic aldehydes, Benzil, Benzoin, Cyanide, Oxidation 1. Introduction Benzil derivatives are interested for their photoluminescence properties,1,2 photochemical reactions,3 antioxidant activity4,5 and potential application as inhibitors of acid corrosion of mild steel and photosensitive agents in photocurable coating.6 Moreover, these compounds constitute useful intermediates in organic synthesis as precursor of various homo- and heterocyclic compounds7-15 as well as multi-dentate ligands utilizable in coordination chemistry.16-18 Oxidation of benzoin is a traditional approach for the preparation of benzil.19,20 Benzoin itslf, is usually prepared from cyanide catalyzed condensation of benzaldehyde. This classic route is 28 Mousavi et al. Org. Chem. J. 2014, 3(1),28-33 extendable to the preparation of benzoin drivetives. In spite of developing various new methods for preparation of symmetric or asymmetric α-diketons and α-hydroxyketons, 6,21 benzoin condensation is a very simple and efficient method which uses a group of simply accessible starting materials. Having these advantageous, yet the process requires a second oxidation step to convert benzoin to benzil. In continuation of our previous work in preparation of benzoin derivatives, 22 herein we report the one-pot synthesis of some benzil derivatives via benzoin condensation and air oxidation of aromatic aldehydes. 2. Results and Discussion Cyanide catalyzed condensation of some aromatic aldehydes, including 4-methoxybenzaldehyde, 4bromobenzaldehyde, 3-nitrobenzaldehyde and 2-furylcarbaldehyde was performed in alcoholic solvents under atmospheric O2. All above mentioned aldehydes converted to their relative α-diketon derivatives. The structures of products were identified from their IR and 1H NMR spectra. The products were obtained with moderate to good yields. The time of reactions varied from 1.5 to 15 hours as shown in Table 1. It should be mentioned that in our previous work, the reaction of 2-furylcarbaldehyde under the same conditions led to the formation of its relative α-hydroxyketon, after 1.5 hours reflux. In the present work, by increasing the reaction time to 6 hours, a α-diketon derivative was obtained. So, the formation of α-diketon may be attributed to the oxidation of initially formed α-hydroxyketon on exposure to atmospheric O2. Despite lacking high yields, the procedure benefits from omitting the oxidation step from two steps classic route for synthesis of benzil derivatives from aromatic aldehydes. However, by using the same procedure, 4-methylbenzaldehyde, 4-chlorobenzaldehyde, 4pyridinecarbaldehyde and 2-pyridinecarbaldehyde formed their relative α-hydroxyketon derivatives, even after 15 hours reflux under air. We are unable to establish a good relation between the speed of air oxidation and the electronic or steric effects in the structure of aromatic aldehydes. To obtain other benzil derivatives, the separated α -hydroxyketons were subjected to catalytic oxidation in the presence of cupric acetate and ammonium nitrate in 80% aqueous acetic acid.19 4Methylbenzaldehyde and 4-chlorobenzaldehyde converted to their relative α-diketons with relatively high yields, as shown in Table2. However, 2- pyridincarbaldehyde and 4-pyridincarbaldehyde formed blue complexes of Cu(II), which were not structurally identified. This behavior is not surprising for pyridine derivatives, because of their known coordination tendency. 29 Org. Chem. J. 2014, 3(1), 28-33 One-pot Synthesis of benzoin derivetives Table 1. Summary of result in one-pot synthesis of benzil derivatives Entry Aromatic aldehyde Solvent Product 4-methoxybenzalehyde 2-butanol (%) 12 89 15 70 1.5 58 6 56 15b 82 15b 90 15b 75 15b 94 Br O 4-bromobenzaldehyde (h) O MeO 2 Yielda OMe O 1 Time Ethanol O Br O 3 3-nitrobnzaldhyde Methanol O2N NO2 O O 4 2-furylcarbaldehyde O Ethanol O O Me OH 5 4-methylbenzaldehyde 2-butanol O Me Cl OH 6 4-chlorobenzaldehyde Ethanol O Cl OH 7 4-pyridylcarbaldehyde N Ethanol N O OH 8 2-pyridylcarbaldehyde Ethanol N N OH a The yields refer to isolated products b The same product was previously obtained in much shorter time.22 30 Mousavi et al. Org. Chem. J. 2014, 3(1),28-33 Table 2. Catalytic oxidation of benzoin derivatives Entry Substrate OH Product Me Time (h) Yield (%) 1.5 93 3 87 Me O 1 Me O OH O Me Cl Cl O 2 Cl O Cl O 3. Experimental 3.1. Material and measurements All chemicals are commercially available and used as received. Melting points were determined on a Bransted Electrothermal apparatus and are uncorrected. FTIR spectra were measured on a PerkinElmer Spectrum RX1 spectrometer. 13 C NMR and 1H NMR spectra were recorded on a Bruker Avance-300 MHz spectrometer employing tetramethylsilane as an internal reference. 3.2. Typical procedure for preparation of α-diketones A solution of potassium cyanide (1 mmol, 0.65 g) in H2O (2 ml), was added to a stirred solution of benzaldehyde derivative (10 mmol) in appropriate solvent (10 ml) (Table 1). The mixture was then refluxed. The reaction progress was monitored by TLC using hexane/ethyl acetate (80:20) as eluent. After completion of reaction, the solvent was removed by evaporation under reduced pressure. The residue was washed with water and diethylether. 3.2.1. 1,2- Bis(4-methoxyphenyl)ethanedione Yellow crystals, Yield: 89%, mp: 129-131 ̊C; FT-IR (KBr, Cm-1): 1655 (C=O), 1159 (O-CH3); 1H NMR (DMSO-d6, ppm): δ 3.85 (s, 6H, OCH3), 7.12 (d, 4H, Ph), 7.84 (d, 4H, Ph). 3.2.2. 1,2-Bis(4-bromophenyl)ethane-1,2-dione Yellow crystals, Yield: 70%, mp: 229-232 ̊C; FT-IR (KBr, Cm-1): 1662 (C=O); 1H NMR (DMSO-d6, ppm): δ 7.14 (d, 4H, Ph), 7.76 (d, 4H, Ph). 3.2.3. 1,2-Bis(3-nitrophenyl)ethane-1,2-dione Pale yellow crystals, Yield: 58%, mp: 254-257 ̊C; FT-IR (KBr, Cm-1): 1667 (C=O), 1348 (NO2); 1H NMR (DMSO-d6, ppm): δ 7.66 (t, 2H, Ph), 8.28 (d, 4H, Ph), 8.6 (t, 2H, Ph). 31 Org. Chem. J. 2014, 3(1), 28-33 3.2.4. One-pot Synthesis of benzoin derivetives 1,2-Bis(furan-2-yl)ethane-1,2-dione Yellow crystals, Yield: 91%, mp: 159-161 ̊C; FT-IR (KBr, Cm-1): 1665 (C=O), 1287 (C-O); 1H NMR (DMSO-d6, ppm): δ 6.84 (m, 2H, furyl), 7.66 (d, 2H ,furyl), 8.24 (d, 2H, furyl). 3.3. Typical procedure for oxidation of benzoin derivatives In a glass beaker, benzoin derivative (20 mmol) was dissolved in aqueous acetic acid (80%, 10 ml). Then cupric acetate (4 mmol) and ammonium nitrate (10 mmol) was added to the solution. The mixture was stirred at 70°C, until nitrogen release stopped, and then refluxed. After cooling, the precipitate was filtered off, washed with water and cold ethanol. 3.3.1. 1,2-Bis(4-methylphenyl)ethane-1,2-dione Pale yellow crystals, Yield: 93%; mp: 101-103 ̊C; FT-IR (KBr, Cm-1): 1673 (C=O); 1H NMR (DMSOd6, ppm): δ 2.4 (s, 6H, CH3), 7.41(d, 4H, ph), 7.76 (d, 4H, ph). 3.3.2. 1,2-Bis(4-chlorophenyl)ethane-1,2-dione Pale yellow crystals, Yield: 87%, mp: 197-199 ̊C; FT-IR (KBr, Cm-1): 1662 (C=O); 1H NMR (DMSOd6, ppm): δ 7.4(d, 4H, Ph), 7.89 (d, 4H, Ph). 4. Conclusion In summary, we have prepared some benzil derivatives directly from their corresponding aromatic aldehydes. The procedure is advantageous, because it omits the oxidation step from the classic route for synthesis of benzil and its derivatives. In fact, by increasing the reflux time in classic benzoin condensation, an air oxidation of benzoin to benzil takes place. However, the procedure lacks from good generality and high yields. Acknowledgement Financial support from Islamic Azad University, Saveh branch is gratefully acknowledged. References and Notes 1. Ma, B-Q.; Ferreira, L. F. V.; Coppens, P. Org. Lett. 2004, 6, 1087. 2. Zheng, S-L.; Coppens, P. Cryst. Eng. Comm. 2005, 7, 289. 3. Prasad, G.; Giri, B. P.; Mehrotra, K. N. J. Org. Chem. 1982, 47, 2353. 4. Hatanaka, M.; Nishizawa, C.; Kakinoki, T.; Takahashi, K. Bioinorg. Med. Chem. Lett. 2008, 18, 5290. 5. Hatanaka, M.; Takahashi, K.; Nakamura, S.; Mashino, T. Bioinorg. Med. Chem. 2005, 13, 6763. 6. Giraud, A.; Provot, O. Peyrat, J-F.; Alami, M. Brion, J-D. Tetrahedron 2006, 62, 7667. 32 Mousavi et al. Org. Chem. J. 2014, 3(1),28-33 7. Ogata, H.; Kawasaki, A.; Sugiura, F. J. Org. Chem. 1969, 34, 3981. 8. Prasad, G.; Giri, B. P.; Mehrotra, K. N. J. Org. Chem. 1982, 47, 2353. 9. Marjani, K.; Asgarian, J.; Mousavi, M. J. Chem. Res. 2007, 548. 10. Marjani, K.; Sharifi Moghadam, M.; Arazi, O.; Mousavi, M. Acta Crystallogr. 2007, E63, o3519. 11. Marjani, K.; Mousavi, M.; Ashouri, A.; Arazi, O.; Bourghani, S.; Asgari, M. J. Chem. Res. 2008, 398. 12. Marjani, K.; Mousavi, M.; Arazi, O.; Ashouri, A.; Bourghani, S.; Rajabi, M. Monatsh. Chem. 2008, 140,1331. 13. Sannicolo, F. J. Org. Chem. 1983, 48, 2924. 14. Coan, S. B.; Trucker, D. E.; Becker, E. I. J. Am. Chem. Soc. 1955, 77, 60. 15. Maly, K. E.; Gagnon, E.; Maris, T.; Wuest, J. D. J. Am. Chem. Soc. 2007, 129, 4306. 16. Arquero, A.; Canadas, M.; Martinez-Ripoll, M.; Mendiola, M. A.; Rodriguez, A. Tetrahedron 1998, 54, 11271. 17. Jones, L. A.; Hancock, C. K.; Seligman R. B. J. Org. Chem. 1961, 26, 228. 18. Raman, N.; Ravichandran, S.; Thangaraja C. J. Chem. Sci. 2004, 116, 215. 19. Mousavi, M.; Gouya, M. R. Organic Chemistry Journal 2010, 1, 20. 20. Yasuike, S.; Kishi, Y.; Kawara, S.; Kurita J. Chem. Pharm. Bull. 2005, 53, 425. 21. Enders, D.; Kallfass, U. Angew, Chem. Int. Ed. 2002, 41, 1743. 22. Mousavi, M.; Seyfi, H. Organic Chemistry Journal, 2011, 2, 17. 33