Fractional Distillation & Gas Chromatography Lab

advertisement

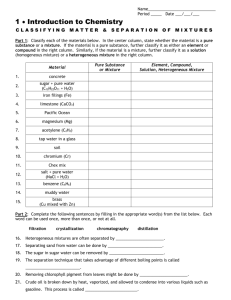

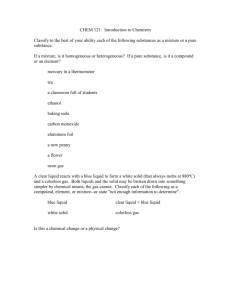

Fractional Distillation and Gas Chromatography Background Distillation The previous lab used distillation to separate a mixture of hexane and toluene based on a difference in boiling points. Hexane boils at 69 °C and toluene boils at 110 °C. In an idealized situation, you could imagine heating a mixture of hexane and toluene to 69 °C and all of the hexane would start boiling, leaving the toluene behind. You could then collect the vapor, condense it, and obtain pure hexane. Unfortunately the real situation is not so simple. Just as with melting points, when you start mixing solvents together, the mixed solution has a boiling point that is different from the pure components. Figure 4.1 shows an approximate boiling curve, showing that a mixture of hexane and toluene boils somewhere between pure hexane and pure toluene. Figure 4.1 – Boiling points for mixtures of hexane and toluene 110 °C temperature 69 °C pure hexane 50:50 mixture mixture composition fysiske egenskaber af zink sulfat pure toluene When a mixture of hexane and toluene begins to boil, hexane is not the only component to go into the gas phase. Some toluene molecules will also go into the gas phase. However, since hexane is more volatile, more molecules of hexane will go into the gas phase. So if a 50:50 mixture of hexane and toluene boils, the gas coming off will not be pure hexane, but it will also not be a 50:50 mixture. In figure 4.2, the red curve shows the boiling points for different mixtures of hexane and toluene. The blue curve shows the composition of vapor at any given temperature. That is, if you follow the vertical dotted line up for the 50:50 solvent mixture, you will find the boiling point for that mixture on the red curve. Then follow the horizontal dotted line to the left, the point that it intersects the blue curve gives the composition of the gas phase mixture at that temperature. That is, the composition of the gas vapor boiling off will not be pure hexane, but it will be “enriched” in hexane—having more hexane than the initial liquid mixture. Figure 4.2 – Composition of the gas phase mixture at various temperatures 110 °C temperature 69 °C pure hexane 50:50 mixture mixture composition pure toluene In a simple distillation, you condense the vapor that boils off and collect it as a liquid. However, given the discussion above, this will not be pure hexane, but will instead be a mixture of hexane and toluene with somewhere between 50% and 100% hexane (Figure 4.3). Figure 4.3 – Simple distillation 110 °C condense temperature boil 69 °C collect pure hexane initial mixture 50:50 mixture pure toluene mixture composition If you collected this enriched mixture of hexane and toluene and re-boiled it, you would again get a gas phase mixture that had more hexane than you started with. Collection of the condensate would provide a liquid that was even more enriched in hexane (Figure 4.4). Figure 4.4 – A second simple distillation 110 °C temperature 69 °C collect pure hexane start 50:50 mixture pure toluene mixture composition If this process were repeated several times, every time you would collect a liquid that was closer and closer to pure hexane. Eventually you would have one pure solvent. However, this would be an extremely tedious process. The solution to this problem is instead to perform a fractional distillation. In a fractional distillation setup (Figure 4.5), the vapor that comes from the boiling mixture is not immediately collected, as it was in a simple distillation. Instead there is a long fractionating column between the boiling liquid and the condenser. Figure 4.5 – Fractional distillation setup As the vapor from the boiling solution rises up the fractionating column, it will begin to cool and collect as a very thin film of liquid on the inside of the fractionating column. This thin film will be enriched in hexane, as this is essentially the first simple distillation described in Figure 4.3. There is enough heat energy present, though, to boil this thin film of liquid, and it will re-enter the gas phase and continue to rise up the fractionating column. Again it will cool and condense on the sides, forming a liquid that is even more enriched in hexane. This is essentially the second simple distillation described in Figure 4.4. By the time the vapor reaches the top of the column it will have condensed and boiled many times. As shown in Figure 4.6, as you go back and forth from the liquid to the gas phase, you become more and more enriched in hexane, and the result of this fractional distillation will be a pure sample of hexane. Figure 4.6 – Fractional distillation resulting in pure hexane 110 °C temperature 69 °C pure hexane 50:50 mixture pure toluene mixture composition The number of times a solvent boils and condenses by the time it reaches the top is called the number of “theoretical plates” of the column. The number of theoretical plates can be increased if the column is longer, or if it has a greater surface area for the vapor to condense onto. A greater surface area can be achieved with different columns with bumpy inner surfaces, or by packing the column with something like glass beads. Greater numbers of theoretical plates lead to more efficient distillations resulting in extremely pure solvents. Gas Chromatography Like thin layer chromatography (TLC), gas chromatography (GC) involves organic compounds carried through a stationary phase, pushed along by a mobile phase. In TLC the stationary phase was silica gel powder coated onto a solid surface and the mobile phase was an organic solvent that soaked up the TLC plate through the powder. In GC the stationary phase is a viscous liquid that coats the interior surface of a very long thin tube (the “column”). The mobile phase is an inert gas such as helium that is pressurized and pushed through the column. A gas chromatograph is shown in Figure 4.7 (reference: http://elchem.kaist.ac.kr/vt/chem-ed/sep/gc/gc.htm). Figure 4.7 – Typical GC In GC, the sample is in the gas phase, which means that it must be kept hot enough so it does not condense into a liquid. To accomplish this, the column is kept in an oven that maintains a set temperature. Figure 4.8 shows a schematic for a typical GC. On the left hand side is a cylinder filled with the carrier gas. This is under pressure so it runs through the coiled column and out through the detector. When a sample is injected, it is carried along through the column (stationary phase) by the carrier gas (mobile phase). Due to interactions between the organic compounds in the sample and the stationary phase, different compounds move through the column at different rates. As they reach the detector they are measured and a signal is recorded as a series of peaks, called a chromatogram. Figure 4.8 – GC schematic inject sample here recorder flow x detector He gas oven Compounds are characterized by their retention time—the length of time between the injection of the sample and the detection of the individual component. This is similar to the Rf values in TLC. Compounds with lower boiling points move through the column more quickly, and so have shorter retention times. Compounds with higher boiling points have longer retention times. In a chromatogram, the different signals correspond to different organic compounds. Figure 4.9 shows a gas chromatogram of a car exhaust (reference: http://www.mindfully.org/Air/2002/VOCs-New-Auto-Smell23dec99.htm). Each of the different peaks represents a separate organic component. This is an example of how GC can be used to monitor environmental pollutants. For example, peak 7 is toluene. Figure 4.9 – Organic components of automobile exhaust Figure 4.10 shows a medical application of GC (reference: http://www.clinchem.org/cgi/content/full/43/6/1003). Part a) shows a portion of the chromatogram of a urine sample. Part b) shows the same sample with ethanol (the intoxicant in alcoholic drinks) added. The peak marked with an arrow represents the ethanol. Note that in part a) there is no peak at the retention time marked with an arrow, meaning that there was no ethanol in the urine. Part c) shows a urine sample taken a few hours after the patient drank a glass of wine. The signal marked with an arrow shows that ethanol can be found in the urine. You could easily imagine how such tests might be used for legal or medical reasons. Figure 4.10 – Ethanol in urine samples In addition to acting as a qualitative tool, telling what different components are present, GC can also act as a quantitative tool, telling how much of each component is present. The relative sizes of the peaks, measured as the area under each peak, corresponds to their relative concentrations in the sample. To measure the relative sizes of the peaks, we treat the signals as if they were triangles. Figure 4.11 a) shows a typical signal in black and a triangle in red. If we can measure the area of the red triangle, the area of the peak is about the same. The area of a triangle is calculated as one half of the height times the width at the base. Figure 4.11 a), though, shows that at the bottom of the peak, the chromatogram signal deviates from the red triangle quite a bit, so measuring the width of the base is difficult. In Figure 4.11 b), though, it is shown that the area of a triangle can also be defined as the height times the width of the triangle half-way up. In 4.11 a), about half-way up the red triangle and the black peak signal match very closely, and this used to measure the area of the peak. Figure 4.11 – Areas of peaks and areas of triangles a) b) height height width at half the height base To measure the area of the peak, follow the procedure shown in Figure 4.12. For a given signal, use a ruler to draw a straight line connecting the baseline on the left side to the baseline on the right side (shown in green). Then draw a vertical line from this baseline to the top of the peak (shown in blue). Using your ruler, find the midpoint of this vertical line and draw a horizontal line from one side of the peak to the other (shown in red). Measure the lengths of the blue and red lines and multiply these. This is the height times the width at half the height, or the area of the peak. Do this for each of the signals. Add these all up to get the total area, and divide each peak by the whole and multiply by 100 to get the percent areas. Figure 4.12 – Approximating peak area For example, in Figure 4.12, I get the following measurements (your measurements will vary depending on how large you print this file, but the percent areas should end up roughly the same). For the left-hand peak, the height is 67 mm and the width at the halfway point is 49 mm. This gives an area of 3283 square mm. For the right-hand peak, the height is 57 mm and the width at half the height is 16 mm, for a peak area of 912 square mm. The total area of the two peaks is 3283 + 912 = 4195. The percent area of the left-hand peak = (3283 / 4195) x 100 = 78%. The percent area of the right-hand peak = (912 / 4195) x 100 = 22%. Note that the percent areas should always add up to 100%. Using GC, you can identify the components in a mixture by their retention times and calculate the relative amounts of each component using the peak areas. This analytical technique has a wide variety of applications in the laboratory, in medicine, in environmental science, and many other fields.