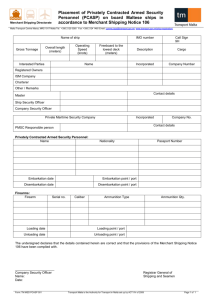

Ammunition Procedures

advertisement