Synthetic pathways and processes in green chemistry. Introductory

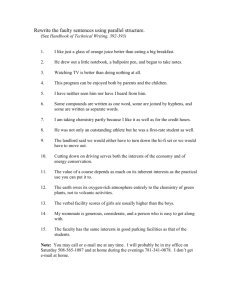

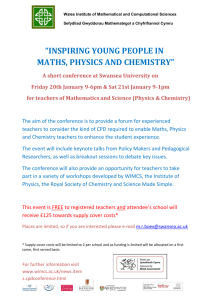

advertisement