Learning Curves

advertisement

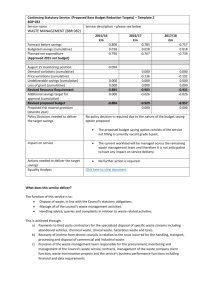

BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Learning Curves – Some Alternative Approaches Alan R Jones, BAE Systems “O! This Learning, what a thing it is.” William Shakespeare (c.1594, The Taming of The Shrew) The material presented here is based on a case study presented in the following publication: Jones, A.R. ‘Case Study - Applying Learning Curves in Aircraft Production - Procedures and Experiences’ in Zandin, K (editor) Maynards Industrial Engineering Handbook, 5th Edition, McGraw-Hill, New York, 2001 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Learning Curves – An Alternative Approach Learning Curves – Definition and Basic Properties – Unit Learning Curve Formula Constituent Elements of Production Learning – Segmentation Theory Applications – Effect of Output Rate Constraint – “End of Line” Effect – Assessing Loss of Learning Cumulative and Cumulative Average Data – Formulae – Examples BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 The Basics Learning Curves – Definition and Basic Properties BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Learning Curve: Definition The Learning Curve expresses the empirical relationship between experience and efficiency - hence their alternative name of “experience curve”. The Learning Curve Effect states that the more times a task is performed, the less time will be required on each subsequent iteration. The phenomenon was first quantified in the USA by T.P.Wright* in 1936 in relation to Aircraft Production. Equation of a Unit Learning Curve: TA = T1 Aε where ε is the learning exponent: ε = log(p)/log(2) with p = the learning percentage expressed as a decimal and TA is the time at Unit A * Source: T. P. Wright, (1936) Learning Curve, Journal of the Aeronautical Sciences, Feb 1936 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Simple Learning Curve: Basic Property Equation of a Unit Learning Curve: TA = T1 Aε where ε is the learning exponent: ε = log(p)/log(2) with p = the learning percentage expressed as a decimal and TA is the time at Unit A This is often expressed by saying that whenever the number of units produced doubles, the time to produce a unit reduces to p% of the earlier time. But the more general property is that for any constant multiplier, k say, the time taken reduces by a fixed percentage TkA = T1 (kA)ε = T1 kε Aε = kε T1 Aε = kε TA BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Learning based on any multiplier - Example Unit Manhours 1 100.00 2 80.00 3 70.20 4 64.00 5 59.56 6 56.17 7 53.45 8 51.20 9 49.29 10 47.65 11 46.21 12 44.93 Multiple of 2 Multiple of 3 Multiple of 4 80% of 100.00 70.2% of 100.00 80% of 80.00 80% of 70.20 64% of 100.00 70.2% of 80.00 80% of 64.00 64% of 80.00 70.2% of 70.20 80% of 59.56 80% of 56.17 70.2% of 64.00 64% of 70.20 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Man-hours Unit Learning and Batch Learning are “Equivalent” Σ Σ If you have batch totals only, do a Best Fit Regression on the last points in each batch only – not all the points – that gives a different result! Σ Σ Σ 1 10 Cumulative Units Unit Average Values 100 Cumulative Batch Values 1000 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Background to the Approach Constituent Elements of Production Learning BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Constituent Elements of Production Learning Tooling Improvements 34% Manufacturing Cost Improvements Quality Control 23% 4% 6% 22% 11% Manufacturing Control Operator Learning Engineering Changes to Assist Production Source: P Jefferson, ‘Productivity Comparisons with the USA – where do we differ?’ Aeronautical Journal, Vol 85 No.844 May 1981, p.179 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Segmenting the Learning Curve: Mathematical Model Consider 4 cost driver components with values α, β, γ, and δ where α + β + γ + δ = 1 (or 100%) Equation of a Unit Learning Curve: TA = T1 Aε where ε is the learning exponent: ε = log(p)/log(2) with p = the learning percentage expressed as a decimal and TA is the time at Unit A Expand the exponent: TA = T1 A(α + β + γ + δ) ε TA = T1 Aαε Aβε Aγε Aδε In order to model data with breakpoints, re-define the variable A: TA = T1 A1αε A2βε A3γε A4δε For the primary learning (where all cost drivers are “active”), the values of A1 A2 A3 and A4 are all equal BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Segmenting the Learning Curve: Mathematical Model Example based on a production run of 60 units Impact of design freeze truncates relative learning for this cost driver All cost drivers active. Relative learning points are all equal Build No Design Operator Tooling Logistics A A1 A2 A3 A4 1 1 1 1 1 2 2 2 2 2 3 3 3 3 3 4 4 4 4 4 5 5 5 5 5 10 5 10 10 10 45 5 10 45 45 60 5 10 45 45 Impact of constant output rate truncates relative learning for this cost driver “End of Line” truncates relative learning for these cost drivers BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Learning Curve Segmentation: Points to Consider Benefits of Approach: • • • Allows discontinuities to be modelled easily (using an on/off switch approach) Allows scenarios to be modelled which assume learning rates greater than or less than the “norm” for a particular process or product type Allows multiple linear regression techniques to be applied in cost data analysis Words of Caution: • • As with all modelling techniques, the approach requires calibration for the specific environment in which it is to be applied There should be a logical model or explanation of why particular cost drivers have been “switched in or out” BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Application Example Effect of Output Rate Constraint on Learning BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Effect of Output Rate Constraint on Learning Average Contents Number of Operators x Average Hours Worked in Time Period = Constant “Constant” Every operator performs same task on every unit Constrained by working hour practices (basic working week & sustainable overtime (For Optimum Learning) (Effective Upper & Lower Limits) Average Hours spent per Unit in Time Period Reducing (Learning Curve) x Number of Units produced in Time Period Increasing (Rate Ramp-up) The “Reduced Cost : Increased Output” is in part a natural response of increased product familiarity, and in part a response to market expectations of affordability etc BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Effect of Output Rate Constraint on Learning Average Contents Number of Operators x Average Hours Worked in Time Period = Average Hours spent per Unit in Time Period Reducing x Number of Units produced in Time Period Reducing “Constant” Constant (Effective Upper & Lower Limits) (Learning Curve) (Fixed Output Rate) Reducing the number of operators violates the premise for optimum learning Constrained by working hour practices (basic working week & sustainable overtime A response to market expectations of affordability etc to drive down costs Customer contractual limitation or constraint BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Example 1: Cumulative Deliveries of Product A 350 Delivery Rate Build-up Constant Rate Deliveries 300 Cumulative Units 250 200 9.75 per month 150 117 100 50 0 Years BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Example 2: Assembly Learning for Product A Delivery Rate Build-up Constant Rate Deliveries Man-hours 80.4% Learning after the breakpoint 75.7% Learning up to the breakpoint Swingometer 22% Breakpoint @ 117 1 10 Actual Regression Cumulative Units 5% Confidence Level 100 78% 1000 95% Confidence Level BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Example 2: Cumulative Deliveries of Product B 250 Delivery Rate Build-up Constant Rate Deliveries Cumulative Units 200 150 4 per month 100 60 50 0 Years BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Example 2: Assembly Learning for Product B Constant Rate Deliveries Man-hours Delivery Rate Build-up 87.8% Learning after the breakpoint Swingometer 72.1% Learning up to the breakpoint 40% 60% Breakpoint @ 60 1 10 Actual Regression Cumulative Units 5% Confidence Level 100 1000 95% Confidence Level BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Effect of Output Rate Constraint on Learning Other factors affecting the analysis: • • • • • • The examples emanate from different factories with little different management styles and cultural heritage One product was essentially for a single customer variant/mark initially followed by small batch export orders The other product was a multiple variant/mark international collaboration The level of continued investment was geared around the known and perceived market opportunities The level and timing of engineering change required to introduce export variants and support customer modifications has to be considered The underlying manufacturing technology used on the two products was similar but not identical BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Application Example “End of Line” Effect on Learning Curves BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 “End of Line” Effect on Learning Curves Premise: To enable ongoing learning curve reduction once a constant rate of output is achieved requires investment in new or improved technology, process or logistics etc Reduced quantity remaining over which investment can be recovered 100 Cumulative Return on Investment 90 Reduced saving per unit 80 70 60 50 40 30 1 2 3 4 5 6 7 8 9 10 11 12 Diminishing Return on Investment BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 “End of Line” Effect on Learning Curves Factor (Cumulative Return on Investment) 1000 Learning Rate 75% 80% 85% 90% 100 Diminishing Cumulative Return on Investment = (Unit Learning Curve Reduction) x (Units Remaining) It would seem that there is a case that a 75% learning curve will truncate naturally 80% 85% somewhere between the 60% to 80% point 90% of the total envisaged production quantity, regardless of the learning curve rate? 10 1 ¾ Quantity 0.1 0.01 ¾ Quantity 0.001 1 10 Cumulative Units 100 1000 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 “End of Line” Effect on Learning Curves Factor (Cumulative Return on Investment) 100000 The empirical relationship of the “End of Line” Effect on a learning curve can be attributed to the “Law of Diminishing Returns”. It is not unreasonable to expect that a learning curve will truncate naturally somewhere between the 60% to 80% point of the total envisaged production quantity. 10000 ¾ Quantity Example: • Constant rate of output at unit 50 • 400 units planned in total • 75% Learning Curve 1000 1 10 Breakpoint @ Constant Rate Cumulative Units 100 1000 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Application Example Assessing Loss of Learning BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Assessing Loss of Learning: Anderlohr Method Consider a Break in Production of 12 months after 50 units Man-hours 3. 4. 1. 2. 1 This defines the re-start position for learning Repeat the learning process (offset by the number of units lost) Determine how many units have been produced in the previous 12 months Back track up the learning curve by this quantity 10 Cumulative Units 100 Source: Anderlohr, G., ‘What production breaks cost’, Journal of Industrial Engineering, September 1969, pp.34-36 1000 Basic Anderlohr BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Assessing Loss of Learning: Segmentation Method Consider a Break in Production of 12 months after 50 units Continued Component of Learning 3. le mp a Ex Man-hours 69% 4. 31% Component subject to Re-Learning 1. 2. After the break the continued learning component still applies Factor this by the re-learning component (offset by the number of units lost) Determine the proportion of learning that will continue by considering the cost drivers that might be affected This defines the re-start position for learning after the break 1 10 Basic Cumulative Units With Re-learning 100 Continued Learning 1000 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Assessing Loss of Learning: Comparison of Methods Man-hours Consider a Break in Production of 12 months after 50 units Anderlohr method always lags the segmentation method for the same re-start value 1 10 Basic Cumulative Units Anderlohr 100 Segmentation 1000 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Assessing Loss of Learning: Comparison of Methods Practical Considerations: • • • • Small breaks in production will be more difficult to detect further down the curve due to potential “noise” in the actual data The Anderlohr Method assumes that the rate of learning loss is equivalent to the rate of learning gain. This is not necessarily the case, but a modified approach which “backtracks” only a proportion of the “lost” learning could be adopted What happens when the break in production occurs during the latter stages of the production run (often the case)? The learning curve may have “bottomed out” by this stage Either approach could be applied to other cases of learning loss other than time breaks; for example, a physical relocation or new start-up. Consider the following example using the cost driver segmentation method BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Example 3: Cumulative Deliveries of Product C 3-Year Break In Production 1000 980 960 Cumulative Units 940 2 per month @ peak 2 per month @ end of line 920 900 880 860 840 820 800 Years BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Example 3: Assembly Learning for Product C Rate restricted learning Man-hours Re-learning Swingometer Swingometer 22% 29% 78% 700 71% Break in Production 750 800 850 Cumulative Units Actual Regression 900 950 1000 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Alternative Approaches Cumulative and Cumulative Average Data BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Cumulative Average Data Cumulative Average Model: • The formula for the Cumulative Average version of a Learning Curve is the same as that for a Unit Learning Curve: TA = T1 Aε where ε is the learning exponent: ε = log(p)/log(2) with p = the learning percentage expressed as a decimal and TA is the Cumulative Average Time at Unit A (Clearly T1 = T1) • The Cumulative Average version will be inherently “smoother” than its Unit counterpart, but the rate of learning indicated will be very similar for higher quantities (greater than 30 – depending on the accuracy required) BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Man-hours Cumulative Average Data Cumulative Average Curve runs parallel to the Unit Curve for larger quantities 1 10 Unit Cumulative Units Unit Cum Ave 100 Unit Regression 1000 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Cumulative Data Approximation Formulae Cumulative Data Approximations for a Unit Learning Curve: For a positive error1, CA ~ T1 [ (A + 0.5)ε+1 - 0.5ε+1 ] (ε + 1) For a negative error2, CA -> TA -> T1 Aε+1 (ε + 1) T1 Aε (ε + 1) CA ~ T1 (Aε+1 - 1) + T1 (Aε + 1) (ε + 1) 2 where ε is the learning exponent: ε = log(p)/log(2) with p = the learning percentage expressed as a decimal For large values of A Source: 1. Conway, R.W. and Schultz, A.Jr., ‘The Manufacturing Progress Function’, Journal of Industrial Engineering, Jan-Feb 1959, pp.39-54 2. Jones, A.R. ‘Case Study - Applying Learning Curves in Aircraft Production - Procedures and Experiences’ in Zandin, K (editor) Maynards Industrial Engineering Handbook, 5th Edition, McGraw-Hill, New York, 2001 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Cumulative Data Approximation Formulae Error 2.50% 2.00% 1.50% % Error Conway-Schultz Approximation 80% learning curve 1.00% 0.50% 0.00% -0.50% 75% learning curve -1.00% Jones Approximation -1.50% -2.00% -2.50% 0 10 20 30 40 50 60 70 80 90 100 Cumulative Units Source: Jones, A.R. ‘Case Study - Applying Learning Curves in Aircraft Production - Procedures and Experiences’ in Zandin, K (editor) Maynards Industrial Engineering Handbook, 5th Edition, McGraw-Hill, New York, 2001 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Cumulative Data: Equivalent Unit Completion Method 50 40 30 20 10 0 Calendar Time Cumulative Average Cumulative Average based on Equivalent Unit Completions Man-hours Cumulative Units 60 Unit Learning Curve • So, by using time-phased (EVM) data, you can test whether the target learning curve is being met much earlier in the programme • The method also provides an ‘early warning’ indicator of whether later units are going to ‘stick’ to the assumed learning curve 0.1 1 Cumulative Units 10 100 BAE Systems Proprietary Information Professional Development Learning Event, 27th March 2007 Learning Curves – Some Alternative Approaches Thank you for you for listening – any questions