Advance section BS 5950 version.

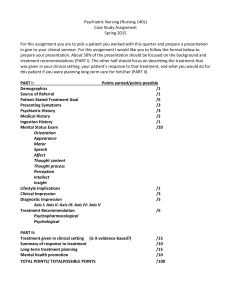

advertisement