Student Notes: Green Nitration of L-Tyrosine

advertisement

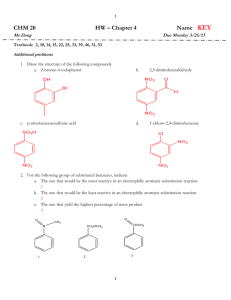

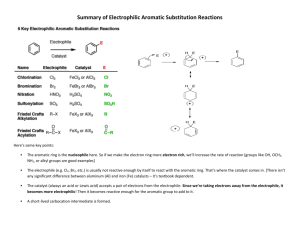

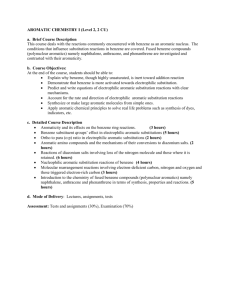

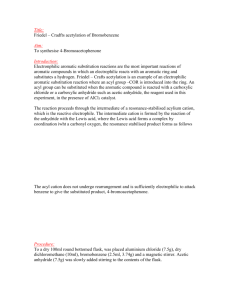

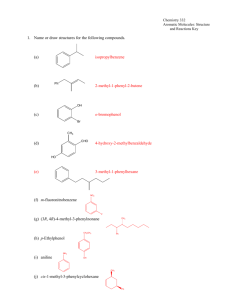

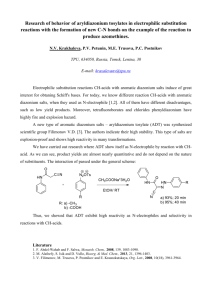

Hiram College, Chem. 320: Spring 2010 Student Notes: Green Nitration of L-Tyrosine “An Electrophilic Aromatic Substitution (EAS)” (ref: Jones-Wilson, T.M.; Burtch, E.A. JCE., 2005, 84, 616-617) In this experiment you will: Successfully perform an electrophilic aromatic substitution reaction on an organic substrate and characterize the product. Techniques: refluxing, suction filtration, and recrystallization Characterization: melting point, 1H NMR Spectroscopy, and UV-Vis Spectroscopy Chemicals Used: L-Tyrosine, concentrated nitric acid, concentrated sulfuric acid, ethyl acetate, and D2O (NMR solvent). (All of these should be in table of reagents including the overall product) Pre-Lab Assignments Notebook After table of reagents include: overall reaction (draw the structures) convert all amounts to moles label the limiting reagent calculate the theoretical yield Questions (on a separate sheet of paper, turn in at the beginning of lab) 1. Show the reaction for the electrophilic nitration of tyrosine 2. Provide a list of at least 5 strong ortho, para directing substituents and 5 strong meta directing substituents in EAS reactions. What type of substituents are on the starting material? 3. Describe the expected results from UV-Vis analysis and 1H NMR (i.e. absorbance wavelength and important chemical shifts). 4. Using 0.05 g of product (3-nitrotyrosine), show the calculation for a 1 x 10-4M solution in water. You will be given two 20 ml volumetric flasks, you will need to carry out 2 dilutions. Waste Disposal: Aqueous waste can be disposed of in the sink with water. Ethyl acetate and all solid wastes should be collected in the proper waste containers in the hood. Electrophilic Aromatic Substitution Electrophilic aromatic substitution is the most significant reaction type experienced by aromatic compounds and is fundamental to the study of organic chemistry. Thousands of substituted aromatic compounds can be prepared by means of this reaction. In electrophilic aromatic substitution, the nucleophilic aromatic ring reacts with a strong electrophile and addition occurs. A hydrogen atom is then eliminated and aromaticity is restored to the substituted ring. Hiram College, Chem. 320: Spring 2010 All aromatic compounds, including benzene and substituted benzene rings, are capable of undergoing electrophilic aromatic substitution. Conjugated systems contain a substantial amount of electron density, thus allowing them to act as efficient nucleophiles. The driving force behind the electrophilic aromatic substitutive process is the extreme stability of the aromatic ring. In general, alkenes react with strong electrophiles by means of addition. In the first step, the nucleophilic aromatic ring attacks a strong electrophile. This process is identical to that of addition and is the rate-limiting step for the aromatic substitution. A nonaromatic carbocation intermediate is produced. This intermediate is doubly allylic and can be resonance stabilized. Nevertheless, this first step is endothermic and requires significant activation energy due to the loss of aromaticity experienced by the ring. As a result, addition to the carbocation intermediate does not occur. Instead, elimination of hydrogen occurs and a neutral, aromatic compound is produced. The stabilization energy of the aromatic ring is restored and the net reaction is exothermic. Substituents already on the aromatic ring affect both the reactivity of the substrate as well as the orientation of the reaction. Functional groups that are capable of donating electron density generally serve to activate the ring and are ortho/para directors. Electron withdrawing substituents are most often deactivators and direct further substitution onto the meta position. Reactions of activated aromatic rings proceed more quickly than those of deactivated substrates because electron donating groups are capable of stabilizing the carbocation intermediate formed. This lowers the activation energy of the addition step. Deactivating groups, however, destabilize this intermediate and so the rate of formation is decreased. The position of substitution can also be explained by considering resonance and inductive effects. Ortho and para substitution occurs because the carbocation intermediate is most stabilized in these configurations when electron donating groups are present. On the other hand, with the presence of electron withdrawing groups, the carbocation is most stabilized when meta addition occurs. Common electrophilic aromatic substitution reactions are employed to halogenate, nitrate, sulfonate, alkylate, and acylate aromatic compounds. Electrophilic aromatic substitution reactions differ drastically from nucleophilic substitution reactions in that no leaving group is expelled. As a result, the primary environmental consideration for electrophilic substitution reactions involves the nature of the aromatic substance. Unfortunately, though, many common aromatic compounds are toxic. Nitration of Tyrosine Amino acids are green reagents because they are nontoxic. They contain a variety of functional groups useful for the illustration of common organic reactions. An alternative to the traditional starting materials employed to demonstrate electrophilic aromatic substitution makes use of the aromatic moiety on the amino acid tyrosine. Concentrated sulfuric acid and nitric acid can be used to generate a nitronium electrophile. The aromatic ring on tyrosine can then react with the nitronium ion via electrophilic aromatic substitution to produce 3-nitrotyrosine. Although both the hydroxyl group and the alkyl substituent serve to activate the aromatic ring, the hydroxyl is a stronger electron donating group. Therefore, substitution occurs at the ortho position to produce 3-nitrotyrosine. The deactivating effect of the nitro substituent restricts any additional nitration from occurring. Hiram College, Chem. 320: Spring 2010 Procedure Reaction Synthesis of 3-nitrotyrosine 1. Weigh 5.0 g L-tyrosine in a 100-mL round-bottomed flask attached to a Claisen adapter. 2. Add a stir bar and fit with a reflux condenser. Fit the open neck of the claisen adapter with a lightly greased stopper. Correctly attach the reflux condenser to the water supply (in the bottom and out the top!) 3. Add 20 mL of DI water to create a suspension. Stir and turn on the water supply. 4. Cool a second 50-ml round-bottomed-flask in an ice water bath. See the Hazards section for additional cautions. Add 3.6 mL of concentrated H2SO4 and 4.7 mL of concentrated HNO3 carefully via the flask neck using a disposable glass pipette, swirling the flask occasionally. The addition should be dropwise and at a rate to minimize the effects of the highly exothermic reaction. 5. When the acid mixture has cooled move the ice water bath to the 100 mL flask. See the Hazards section for additional cautions. Add the acid mixture dropwise to the tyrosine suspension under water reflux and with gentle stirring. Cooling in an ice water bath should be maintained throughout the addition. Make sure your condenser is operational throughout the reaction. 6. After the addition is completed, leave the reaction in the ice water bath with stirring for 15 minutes (if a stir plate is not available gently swirl the flask in the ice water bath). In the meantime prepare a 40°C water bath for the next step. 7. Remove the ice water bath and allow the reaction to warm to room temperature while stirring. Place the reaction mixture in the 40°C water bath for 30 minutes. Continue stirring. Product Isolation and Purification 1. Transfer the reaction solution quickly to an Erlenmeyer flask. Cool the Erlenmeyer flask in an ice water bath until crystallization occurs. 2. Filter using a Buchner funnel and collect the crude product. 3. Rinse the product cake with a 10-mL aliquot of ethyl acetate. 4. Recrystallize in the minimal volume of deionized water. 5. If crystallization does not occur see your instructor. Check with your instructor about which methods you will be using to characterize your product. 6. Obtain the melting point of your dry product. 7. Prepare a 10-4 M solution of your product in deionized water and obtain a UV spectrum. Scan from 240nm-400nm. 8. Prepare a 10% solution of your product in D2O and obtain an 1H NMR. Hiram College, Chem. 320: Spring 2010 Hazards In part of this experiment you will handle concentrated acids. ACIDS BURN! Take care when handling the sulfuric and nitric acids. Wear gloves and safety goggles and make sure you carefully follow the procedure. Additions of acids are HIGHLY exothermic. Add acids SLOWLY and COOL and stir as directed. If you spill any of the acid on yourself immediately notify your instructor and rinse with large quantities of water. Reactivity Hazard Mixtures of concentrated sulfuric and nitric acids violently oxidize acetone. All glassware containing the acids should be thoroughly cleaned and rinsed with water before drying with acetone. Any paper used to wipe up nitric acid spills should be thoroughly rinsed to avoid fire hazard. As always: wear your safety goggles! LAB REPORTS (20 points) -You must have in order: 1) Title (in bold and centered) 2) Objectives-1 pt 3) Procedure -a few sentences, reference where the entire procedure can be found -1 pt 4) Results -must include the overall reaction, equation for percent yield, one sample calculation for percent yield, a table with all obtained percent yields (if only one product was obtained no table is needed for percent yield), a table for melting points with both experimental and literature values and reference where it was found, a table with important chemical shifts from 1H NMR-labeling each shift with it’s characteristic bond, and a table including the wavelength max from UV-Vis spectroscopy including both the experimental and literature values- 6 pt 5) Discussion-discuss the results from the percent yields, melting points, NMR, and UV-Vis. Compare and contrast your results to what is known in the literature and reference where you obtained that information. -9 pt 6) Conclusion- be brief, restate results, include error, and provide enhancements for future experiments-3 pt