Practical Prestress Detailing

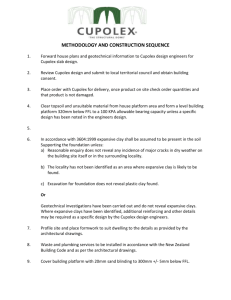

advertisement

Practical Prestress Detailing Disclaimer: "This presentation is for guidance only & is not to be taken as specific advice applicable to a particular project." This presentation will only cover bonded post-tensioning, because Structural Systems do not claim to be knowledgeable about pre-tensioning nor about unbonded systems (as used in Europe & North America). Topics: 1. Selection of slab system or multistrand, strand size & grade, number of strands / tendon. 2. Cover & selection of tendon drapes. 3. Concrete thicknesses for pans, anchorages & couplers. 4. Anti-burst reinforcement & transfer strength. 5. Co-ordination with reinforcement. 6. Miscellaneous. 7. Tendons at joints. -----0----- page 1 of 21 pages 1. • • • Selection of: slab system or multistrand, strand size & grade, number of strands / tendon. ‘Multi-strand’ = all strands in a tendon generally stressed simultaneously; round duct & square anchorages. ‘Slab system’ or ‘Mono-strand’ = strands stressed individually, flat / oval duct & rectangular anchorages. (refer Structural Systems Prestressing Technology brochure) We use "slab post-tensioning" in preference to "mono-strand", but they mean the same thing. Slab post-tensioning systems are very similar amongst all the companies in the post-tensioning industry. "Multi-strand" is usually only necessary for bridges, silos, tanks, off-shore structures & larger transfer beams in tall buildings. We often find projects where multi-strand is specified, but slab system is more suitable, because: • generally a greater drape & lever arm can be achieved; &/or • jacks are smaller, likely to avoid the need for stressing recesses or blockouts; &/or • jacks are hand weight, not requiring cranage; &/or • stage stressing can be achieved by fully stressing selected tendons instead of partially stressing all tendons; &/or • smaller individual live & dead anchorages; &/or • simpler anti-burst reo; whilst still achieving the required stressing force & lever arms (for flexure). How many strands can be fitted into a band beam without using multistrand ? Methods of fitting in more force as slab system: • use 6x12.7 or 5x15.2 tendons • stacking live & dead ends, divert tendons in plan to reach low & high points: centrelines of live ends 300 mm cl to cl horizontal centrelines of live ends 100 mm cl to cl vertical spacing of 5x12.7 (70 mm) duct 150 mm cl to cl in plan, 100 mm cl to cl vertically spacing of 5x15.2 (90 mm) duct 175 mm cl to cl in plan, 125 mm cl to cl vertically • locate ~half of the live ends at each end (for single live tendons); Refer examples, Figures. 1, 2 & 3. Use double live ends only where necessary. Maximum tendon lengths (limited by force losses): • band beam tendons about 30 m single live, • slab tendons about 40 m single live, • distribution & slab on grade tendons about 50 - 55 m single live. Double live can generally go twice the above, but pour sizes usually control. Minimum tendon lengths usually about 6 m (otherwise draw-in losses excessive). Underside stressing is where the live end is accessed from below concrete. Only applicable to slab system, because multistrand jacks require suspension. To be avoided, as it requires formwork to be built to allow access without stripping. Initial stressing is usually impractical for underside stressed tendons. Underside live end anchorages must be min. 80 mm clear below soffit behind live end, & be stripped before 1st stressing to allow sufficient access. Underside stressing on either or both ends of a double live cable is NOT acceptable. This is for safety, as with double live no part of strand is bonded into concrete, & stressors are more likely to be closer to strand. Where possible, always use pans instead of undersides. Distribution tendons in 1 way structures: multiple 2 or 3 strand tendons can often be replaced with one 5 strand. Minimise number of tendons by maximising spacing (usually 10xD), consistent with the maximum number of strands per slab system tendon. page 2 of 21 pages (Maximum tendon spacings were stated in AS1480. No specific limits stated in AS3600, it is a matter for design.) Sizes & grades of strand available: • 12.7 super • 15.2 super • 15.2 EHT: • not always available, & • likely at a cost premium, & • cost premium is usually more than the extra 4.4% strand force. Generally 15.2 strand is the same cost / Tonne as 12.7. BS5896 / Euronorm / 12.9 mm / 15.7 mm strand not usually available in Australia (included in Structural Systems Prestressing Technology brochure for use in UK). Use only 1 strand diameter & only 1 strand grade in a project, because: • market pricing will be more competitive; • multiple strand sizes provide another potential avenue for error on design & shop drawings; • multiple strand sizes can congest site with more coils & provide another avenue for error. 12.7 strand is by far the most commonly used, especially in NSW. We find 12.7 is the better choice for most structures, allows designer to more economically select tendon size to match design requirements. For a heavily loaded structure or heavily stressed structure where 15.2 strand will reduce the total number of tendons, 15.2 is usually the best choice. page 3 of 21 pages 2. Cover & selection of tendon drapes. Cover to tendons: • often cover to perpendicular reinforcement (e.g. top bars, beam ligs or distribution bars) will govern • obviously governed by AS3600 requirements for durability & FRL • for 12.7 strand in slab system tendons at high & low points, it is usual to take 5 mm of this cover being the duct & grout (ducts are galvanised are beneficial to corrosion protection) • similar is considered reasonable for 15.2 strand • minimum 25 mm chairs at low points (to avoid concrete popping off during grouting) • minimum 20 mm cover to duct at high points (for same reason) Drapes generally Chair & anchor heights to be co-ordinated with all reinforcement, including distribution bars. Refer Figure 4. Live ends in edge beams to be co-ordinated by the designer with reo, such that void former (refer SSL brochure) fits under the corner bar, taking into account concrete cover, links, slab reo layering, corner bar diameter, tolerances & real bar sizes. If distribution or other bars clash with tendons, re-layer or label them to be installed after post-tensioning. Drapes specific to one-way (banded & transfer) structures Refer Figure 5. Slab tendons to drape to edge of beams, only exception is sometimes for edge beams. If band has tapered edges, best results (deflection & bending moment resistance) if slab direction tendons are draped to thin end of taper. It might seem obvious, but in banded structures the slab tendons must clear the band tendons. E.g. slab system tendon ducts are 20 mm high, so slab span tendons must be 20 mm higher than band tendons (assuming band tendons are also slab system). The only exception is if slab span tendons are kept clear of band tendon high points, & checked for clashes. Drapes are generally parabolic, except for point loads (e.g. transfer columns) where generally low point is under transferred column, unless this is inconsistent with minimum tendon bend radii. Drapes specific to two-way (flat plate or flat slab) structures Refer Figure 6. Generally, for perpendicular directions using slab system: • High points in column strip are 20 mm different. • Low points in middle strip are 20 mm different. • (Low points in column strip & high points in middle strip do not clash.) Tendon profiles cannot be same in both directions. Tendon low points to be co-ordinated with bottom reo in both directions. Refer Figure 7. At both high & low points, we layer reinforcement such that the tendons in same layer are parallel. This implies a maximum bar size of N20, but this is rarely a problem. page 4 of 21 pages 3. Concrete thicknesses for pans, anchorages & couplers. Pans are to be avoided, because of: • effect on completed concrete structure o filled pans unsightly if exposed; & o bonding filling is difficult if exposed to wheeled traffic; & o not generally compatible with slabs in a watertight structure; & • increase in reinforcement to complete structural continuity;& • concrete at pan anchorages more likely to fail, because anchorage is closer to surface. For pan dimensions refer to Structural Systems brochure. Suggested min. slab depth 150 for pans (for depth under pan). The pan effectively creates a penetration, which must be considered in design & detailing. Pan centreline is 80 mm down from top of slab (no flexibility in this, because pans are limited in depth & we must get concrete over anchorage). Minimum concrete thicknesses for live end & dead end anchorages: • 3x12.7 140 mm • 4x12.7 150 mm • 5x12.7 160 mm • 6x12.7 170 mm • 4x15.2: 160 mm • 5x15.2: 170 mm All these are subject to co-ordination with anti-burst reinforcement, and top & bottom cover. Minimum concrete thicknesses for slab system couplers - for durability & robustness: • 4x12.7: 170 mm, • 5x12.7: 200 mm, • 4 & 5x15.2: 200 mm, but also check for reo (called up, implicit or distribution) that may require more thickness. Coupler size usually dictates location at mid-depth of concrete in slabs, this constrains them close to quarter span of slab. Half of above dimensions are minimum distance from top / bottom of beam to centreline; but check coordination with reinforcement. page 5 of 21 pages 4. Anti-burst reinforcement & transfer strength. Slab system anti-burst reinforcement: Refer Figure 8. We consider slab system anti-burst design is 99% empirical, i.e. what works. We know that concrete, its compaction & strength development at time of final stressing are more important to slab system anchorages than anti-burst reinforcement. Multistrand anti-burst reinforcement: In accordance with AS3600. Check that hooks provide plenty of clearance from anchorage and ducting, for all small ties used overlapped ties instead of hooks. Suggested concrete strengths at transfer, for live ends, dead ends & coupler live ends: • final stress at 4 days minimum; & • 22 MPa minimum for F'c = 32 MPa concrete; • but 25 MPa minimum for F'c = 40 MPa concrete; & • 25 MPa minimum for 15.2 strand; & • 25 MPa minimum for multistrand; & whichever comes later. All based on test of cylinders stored & air-cured on site. (4 day requirement is to allow development of tensile & bond strengths, which develop more slowly than compressive strength.) Inadequate concrete strength at transfer cannot be compensated by additional anti-burst reinforcement. Draping through folds: Refer Figures 9 & 10. • sometimes tendon profile tends to cause local “popping” of concrete • if the curvature is considered sufficiently adverse, top hat &/or bottom hat (as applicable) reinforcement can be detailed to resist local popping. 5. Co-ordination with reinforcement. Standardise lig arrangements (as viewed in cross-section thru beam) to ease fitting of tendons In deep beams (>= 500 deep) pt chairs do not work, so a minimal reinforcement cage is necessary to support perpendicular slab tendons. This minimal cage in beam can N12-1000 central ligatures, about 300 wide, plus 2N12 bottom & 2N16 longitudinal top reo to support slab tendons. To allow installation of tendons in reasonable time, use open ligs in beams instead of closed ligatures. Use loose closers if necessary, & in any case sufficient to stop tall ligature tops wobbling. All reo, especially top reinforcement (including bar & mesh), to be chaired independently of post-tensioning, otherwise height of both is likely to be compromised, & extensions are likely to be poor. Reo that rests on ducts causes dents that can cause problems with tendon extensions. Both chairing & tying of top reinforcement must be adequate to support weight of concretors. page 6 of 21 pages 6. Miscellaneous. Stressing access space required: • slab system: 1000 mm. • multistrand: 3000 mm, but refer Structural Systems brochure. Also refer Structural Systems brochure for lateral clearances. Treatment of live ends for durability & appearance: • For stressing recesses exposed to B1 or B2, Structural Systems uses epoxy paint (either 'Galmet' epoxy spray can paint or 'Megapoxy MC') applied to the steel & iron in recesses, after strands are cut off & before parging. • Sand cement parge used to fill recess. Epoxy is NOT a suitable material for filling recesses. • Sometimes parge is left ~10 mm recessed to allow builder to render finish. Live ends at stair opening are not good for site safety. This must be considered by the designer. Minimum step-down dimension for stressing off: • 4x12.7: 125 mm, • 5x12.7: 130 mm, • 4x15.2: 130 mm, • 5x15.2: 135 mm. Alternatively, a pan can installed "partly submerged", & with a void former to allow cover to anchorage. Refer Figure 11. Note pans cannot be used at edge rebates, because there is no formwork soffit to support chairs for the 'thin end' of the pan. Without support a pan is unstable & unsafe. All of the above is dependent on suitable reo detailing & co-ordination by the designer. Swaged dead ends must be specifically noted as such on designer's drawings. In the absence of a specific note it is normal to assume a bonded 'onion' dead end. To changed an onion to a swaged end after installation requires a large amount of work & is likely to delay the pour. Stressing from service penetrations usually not a good idea, because it is almost universal practice for the builder to cast in mesh for safety reasons. This mesh clashes with the live end & stressing access. Slab system tendon curves in plan: Deviation of tendons around penetrations & openings: • commonly used, • maximum 70 angle as a guide. Continuing bends: • avoid, or at least make gentle (radius > ~50 m) • usually result in poor extensions, as strands on inside of bend are squeezed by outside strands • consider no initial stress, that way final stressing can proceed from inside of bend to outside • avoid reverse bends as no stressing sequence can avoid binding • strands pulling sideways against each other can tend to pop concrete off, especially at high points hard to repair • consider specifying top hat reinforcement to “pin down” tendon & strands at high points – this is located at bend points at junctions of short lengths of duct • consider double live, to assist in achieving reasonable extensions Refer Figures 12 & 13 for examples. Initial stressing: • very desirable for countering shrinkage cracking between 1 day and final stressing, especially for slabs with little or discontinuous conventional reinforcement • not usually necessary for beams with some longitudinal reinforcement full length, especially if floor not designed as watertight; • rarely required for multistrand. page 7 of 21 pages 7. Tendons at joints. Choice between post-tensioning couplers & reinforcement stitching at construction joints based on: • minimum slab thickness for coupler (especially 5x12.7 & any 15.2 coupler) may increase slab thickness; • couplers are near slab centroid, not much use for resisting bending moment; • there is always some conventional reo thru joint anyway, so couplers are unlikely to assist structure; • for suspended slabs, reo is more commonly used instead of couplers; • couplers useful for clamping construction joints in floors designed to be watertight; • for slabs on grade, couplers are used (but be careful in using construction joints in sog). At c.j.s & especially at pour strips, top bars to be <=N16, to allow bending for stressing access. Dummy cables: Refer Figure 14 for example. • Used to effectively allow BOTH pours at a construction joint to be stressed from that joint, whilst using the tendons to minimize conventional reinforcement stitching joint. • Dummy length is temporarily filled with short length strand to keep open during 1st pour. • Dummy length to be maximum 2 to 3 metres long (longer is very difficult or impossible to remove &/or repush new strand). -----0----References: Structural Systems Prestressing Technology brochure. AS3600 – Concrete Structures. Acknowledgements: Mr. Steven Edwards, Chief Design Draftsperson, Structural Systems (Northern) Pty Ltd. Mr. Roland Sommer, Senior Design Draftsperson (Contract), Structural Systems (Northern) Pty Ltd. Mr. Greg Gregory, Senior Design Draftsperson, Structural Systems (Northern) Pty Ltd. page 8 of 21 pages Figure 1 page 9 of 21 pages Figure 2 Comparison of slab system versus multistrand for band beam in Fig 1: Slab system Multistrand Tendons & strands 7 x 5 x 12.7 Super 2 x 12 x 12.7 + 1 x 11 x 12.7 Super Tendon MBL 6440 kN 6440 kN Maximum effective depth +ve flexure to centroid of tendons Maximum effective depth -ve flexure to centroid of tendons Maximum net drape, centroid to centroid, for an end span Comment Multistrand needs more space for jacks. 542 mm 506 mm ~ 7% less for multistrand 547 mm 511 mm ~ 7% less for multistrand (547-300)/2-58 = 365 mm (511+300)/2-94 =312 mm ~ 15% less for multistrand Basis: 1. 600 deep band beam. 2. At low points, 30 mm cover to N12 mm ligatures, rounded to next standard chair height of 45 mm. 3. At high points, 20 cover plus 20 mm slab system tendons for total cover from top of concrete to top beam tendons = 40 mm. 4. At end of end span, tendon anchorages assumed to all be at mid-depth of beam. -----0----- page 10 of 21 pages Figure 3 page 11 of 21 pages Figure 4 page 12 of 21 pages Figure 5 page 13 of 21 pages Figure 6 page 14 of 21 pages Figure 7 page 15 of 21 pages Figure 8 Refer document “Standard Slab System Helical Anchorage Reinforcement” available on PTIA website. page 16 of 21 pages Figure 9 Figure 10 page 17 of 21 pages Figure 11 page 18 of 21 pages Figure 12 page 19 of 21 pages Figure 13 page 20 of 21 pages Figure 14 page 21 of 21 pages