Supply Chain Management Regal Marine

advertisement

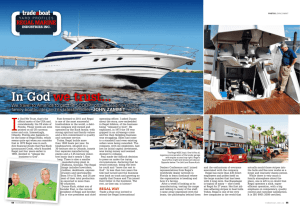

Supply Chain Management. As firms become increasingly focused and specialized, the supply chain performance grows in importance. Money spent with suppliers represents a huge portion of most firms' revenues. This is the case at Regal Marine where suppliers are relied upon not only for quality components delivered on time, but for up-to-date technology and innovation. Regal expects members of its supply chain to be full partners. Suppliers are expected to join Regal in providing the customer not just quality and on time delivery, but performance and image. Luxury performance boats require no less. At the same time, Regal expects value. Vendors meet with Regal’s designers to discuss changes to be incorporated into new product designs. Regal’s strategy of differentiating itself by building luxury performance boats means that suppliers must participate in this ongoing effort. The characteristics expected of suppliers when the strategy is one of differentiation include: • • • • • • Share market research; jointly develop products and options. Select primarily for product development skills. Use modular processes that lend themselves to mass customization. Minimize inventory in the chain to avoid obsolescence. Invest aggressively to reduce development lead time. Use modular design to postpone product differentiation for as long as possible. These characteristics are high on the list of issues between Regal and its suppliers and lead to the concept of ‘partnering’. ‘Partnering’ extends from jointly developing components, to modular designs at suppliers and at Regal, to rapid delivery and low inventories. These techniques allow innovative products to be rapidly and economically included in Regal’s boats. Regal has also developed special arrangements with suppliers who maintain shop floor components for Regal. In some instances title transfers when the item is used, and in other cases title transfers when items are delivered to the property. Both approaches help Regal reduce total inventory and the related costs. Additionally, Regal’s membership in the American Boat Builders Association allows it to participate in lower costs because of the combined purchase strength of the association. Finally, Regal works with an Orlando personnel agency to outsource part of the recruiting and screening process for employees. In all of these cases, Regal is demonstrating creative approaches to supply chain management that help Regal and the end user. Discussion Questions 1. What other techniques might be used by Regal to improve supply chain management? Apparently the most appropriate technique for Regal Marine is the few suppliers strategy, having quality vendors and partnering. Other possible techniques would not be suitable for Regal Marine: for example a vertical integration strategy would require a very high investment, and would be unsuitable for the boat manufacturing rapidly improving technology. Also, a many suppliers strategy results in sporadic deliveries of high quantities, which would clearly increase required inventory and eliminate the “just in time” advantage which Regal has. 2. What kind of response might members of the supply chain expect from Regal in response to their "partnering" in the supply chain? They can expect loyalty from Regal, and the suppliers can gain prestige by representing the high-quality products which Royal Marine produces, which can result in profit margins. Suppliers can also largely benefit from economies of scale and learning curves, reducing the production cost. The “friendship” and loyalty which arise from partnership gives confidence and stability to the business 3. Why is supply chain management important to Regal? Firstly Regal needs the highest possible quality. It cannot possibly achieve highest quality on every single component which boats use by itself. It’s far better to do partnership with suppliers for each item, so that each producer can focus on a particular item, resulting in the best product, innovative and using the newest technology. Secondly, a very important cost reduction which Regal Marine uses is the lack of stock or inventory, eliminating the costs and time associated to them. This can only possibly be achieved through partnering: producers provide on a regular basis directly to the production line, in the quantities needed, just in time.