ISyE 3104: Introduction to Supply Chain Modeling: Manufacturing

advertisement

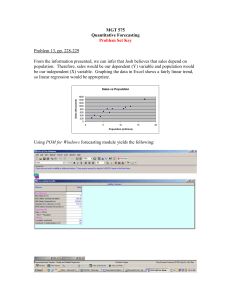

ISyE 3104: Introduction to Supply Chain Modeling: Manufacturing and Warehousing Instructor: Spyros Reveliotis Summer 2002 Homework #2 Due Date: Wednesday, 6/12/02 Problem set: 1. Chapter 4: Discussion Questions: 1,3,4,9,16 2. Chapter 5: Discussion Questions: 2,4,6,10,12 Problem 5.13 and 5.14 Case Study 2 on Regal Marine Extra Credit (40%) Use your background on linear regression from your statistics class, to address the case study on Southwestern University at the end of Chapter 4 in your textbook. Chapter 4 Forecasting DISCUSSION QUESTIONS 1. The steps that should be used to develop a forecasting system are: (a) Determine the purpose and use of the forecast (b) Select the item or quantities that are to be forecasted (c) Determine the time horizon of the forecast (d) Select the type of forecasting model to be used (e) Gather the necessary data (f) Validate the forecasting model (g) Make the forecast (h) Implement the results (i) Evaluate the accuracy of results, and if necessary revise the model (in case of repetitive use) C.f. also the corresponding slide in the class presentation on forecasting. 3. A time series model uses only historical values of the quantity of interest to predict future values of that quantity. The associative model, on the other hand, attempts to identify underlying causes or factors that control the variation of the quantity of interest, predict future values of these factors, and use these predictions in a model to predict future values of the specific quantity of interest. 4. Qualitative models incorporate subjective factors into the forecasting model. Qualitative models are useful when subjective factors are important and/or in case that more quantitative data is difficult to obtain. In general, in Operations Management, longer term forecasts tend to be based more on qualitative rather than quantitative models. 9. MAD (Mean Absolute Deviation) is the method for determining the accuracy of a forecast by taking the average of the absolute deviations between the forecasted values and actual/observed values. MAD is an important method because it provides a measure of forecast accuracy that can be easily calculated. Furthermore, in most practical cases, a good estimate of the standard deviation of the forecast error, eeethat characterizes the variability in the observed quantity, can be obtained from MAD through the equation: eee MAD. 16. Any functional relationship y = f(x) defines a causal relationship between variables x and y, in the sense that knowledge of the value of x, allows the determination of the value of y. Hence, x is characterized as the independent variable and y is characterized as the dependent variable). Chapter 5 Design of Goods and Services DISCUSSION QUESTIONS 2. Explicit documentation accomplishes two things: (a) it provides the information necessary to produce the product in the appropriate fashion. (b) if the product we produce does not perform as we anticipated, the documentation provides the basis for finding and correcting the problems in a logical manner. 4. Configuration management is a system by which a product’s planned and changing configurations are managed. Such a system is of particular value where the product is rapidly and continually evolving or where safety is a particular issue. Examples of industries that practice configuration management include those who manufacture airplanes or microcomputers. 6. Group technology is basically a manufacturing practice that encourages similar components to be produced by the same process in the same work area. Successful implementation leads to: (a) improved product design (b) reduced raw material and parts purchases (c) simplified production and planning (d) improved routing and machine loading (e) reduced tooling setup time, work-in-process inventory, and production time (f) a systematic way to reduce component proliferation by reviewing existing component designs to ascertain if an existing component can be used in a new design. 10. Product selection and design is plays a crucial role for the quality image projected by any given company, because one of the basic ways to define quality is through the intended product functionality and the way/degree in which the actual product supports this functionality (i.e., product functional specifications and conformance to these specifications). Apparently, both of these issues are strongly determined at the product design stage. 12. Configuration management is used by every automobile manufacturer to track all of the changes between and during a model year. Notice that when ordering a spare part, companies use the car model and the year it was produced, but also, quite often, they will use the VIN (vehicle identification number). This information allows the manufacturer to trace the particular lot in which the car was produced, and therefore, ship out the exact type of the required spare part that fits this particular version of the model. PROBLEMS CASE STUDY 2 PRODUCT DESIGN AT REGAL MARINE 1. The concept of product life applies to Regal Marine because Regal is constantly under pressure to introduce new products – and those products have life cycles of relatively few years. As it is suggested in the text material, it is a matter of typically less than five years before a boat is out of style and its life cycle terminated. 2. Regal Marine uses a strategy of product differentiation, which constantly introduces new products with new innovations and new styling to stay competitive in the luxury performance boat market. Some of these new designs are enhancements or migrations of older ones. 3. The cost and time saving at Regal Marine through use of CAD is typical of the use of CAD everywhere. It allows a variety of designs and styles to be tested very fast and economically. The ratio of savings of engineering talent is about four to one. Hence,, it allows them to be creative, both, economically and rapidly. 4. The payoff from CAD is not only evident in efficiency, creative designs, and styling but by production of the control code – i.e., software - necessary for the numerical machines, used in the production operations of Regal Marine. CAD also provides, as a by-product, very effective and comprehensive documentation of design variables. Extra Credit (40%) CASE STUDY: SOUTHWESTERN UNIVERSITY 1. Develop a forecasting model using linear regression to project attendance through 2002. Since the attendance of the different games presents strong systematic fluctuation from game to game – i.e., seasonalities – a different prediction model must be built for each particular game in the season, if the used approach is linear regression (there are other more sophisticated approaches, like Winter’s method, that account for the seasonality effects in a single model). Below we show the detailed calculation for the homecoming game (game 2) only: Year (Xi) 1995 1996 1997 1998 1999 2000 Sum Average Sxx = Sxy = Xi 1 2 3 4 5 6 21 3.5 Attendance (Yi) 39800 40200 46500 46100 48200 50100 270900 45150 91-(21^2)/6 = 985700-21*270900/6 = Xi^2 1 4 9 16 25 36 91 Xi*Yi 39800 80400 139500 184400 241000 300600 985700 17.5 37550 Sxy/Sxx = 37550/17.5 = 2145.714 E[Y]- *E[X] = 45150 - 2145.714*(3.5) = Simple linear regression model: Regression line: 37640 y i o 1 xi i Y = 37640 + 2145.7*X Regression on Number of Attendance 60000 50000 40000 30000 20000 10000 0 y = 2145.7x + 37640 R2 = 0.8987 Year (Xi) 1995 1996 The summary of all forecasts are as follow: 1997 1998 1999 2000 Game 1 2 3 4 5 Total Model y = 30,713 + 2,534x y = 37,640 + 2,146x y = 36,940 + 1,560x y = 22,567 + 2,143x y = 30,440 + 3,146x Forecasts 2001 2002 48,453 50,988 52,660 54,806 47,860 49,420 37,567 39,710 52,460 55,606 239,000 250,530 R2 0.92 0.9 0.91 0.88 0.93 2. What revenues are to be expected in 2001 and 2002? Revenue in 2001 = (239,000)($20/ticket) = $4,780,000 Revenue in 2002 = (250,530)($21/ticket) = $5,261,130 3. Discuss the school’s options. Since the forecast of the 2002 attendance for games 2 and 5 exceeds stadium capacity, the school should seriously consider the expansion of the stadium capacity.