© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

INSIDE: Profile of a Protective Glazing Fabricator

METAL & GLAZING

®

THE MAGAZINE OF RECORD FOR ARCHITECTURAL GLASS INDUSTRY LEADERS VOLUME 44, ISSUE 6 JUNE 2009

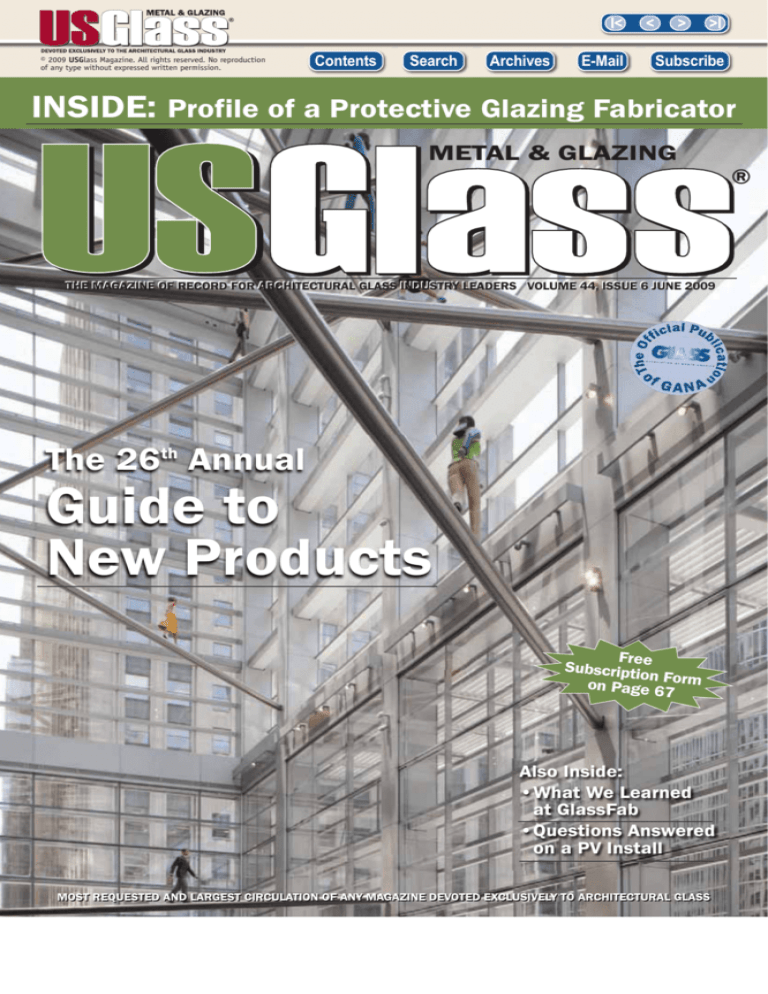

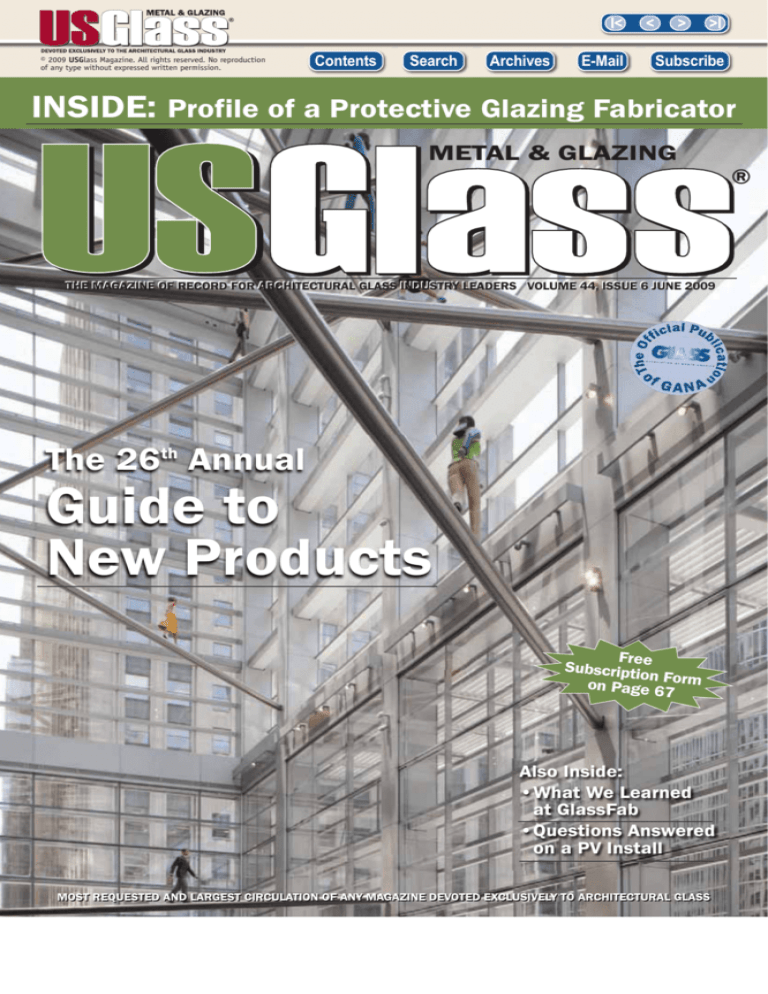

The 26th Annual

Guide to

New Products

Fre

Subscriptioe

n

on Page 6Form

7

Also Inside:

•What We Learned

at GlassFab

•Questions Answered

on a PV Install

MOST

MOST REQUESTED

REQUESTED AND

AND LARGEST

LARGEST CIRCULATION

CIRCULATION OF

OF ANY

ANY MAGAZINE

MAGAZINE DEVOTED

DEVOTED EXCLUSIVELY

EXCLUSIVELY TO

TO ARCHITECTURAL

ARCHITECTURAL GLASS

GLASS

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

Subscribe

When the pressure is on and there's no time to waste waiting for delivery, depend on

Mayflower to act immediately! We stock Floor Closers including the BTS 75V and the

BTS 80; Overhead Closers including the RTS 88; Surface Closers including the 7400, 8600

and 8900 series and Exit Devices including the 9100 and 9300. For further information

plus your copy of our extensive catalog, call 1-800-221-2052.(in NYC 718-622-8785).

MAYFLOWER SALES CO INC, 614 BERGEN ST, BROOKLYN NY 11238 FAX: 718-789-8346 E-MAIL: PILGRIM @MFSALES.COM

FREE TECHNICAL SUPPORT.

CALL, EMAIL, WRITE OR FAX

US AND WE'LL HELP!

>I

tag

P

VISORY GROU

TECHNICAL AD

M AY F L

OWER

www.mfsales.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

And a better place to live.

The right glass can create

a better place to work.

Cut cooling costs, equipment costs,

and carbon emissions with a name you trust.

When you need to deliver impossibly impressive results, count on your local PPG Certified Fabricator

and Solarban Low-E glass. A third-party energy analysis shows that our leading Solarban glass can

eliminate 21,000 tons of CO2 emissions and save more than $400,000 in up-front equipment costs

– results today’s architects and building owners are looking for. And with over a billion square feet sold,

you know your local PPG Certified Fabricator will come through every time. To find yours, or for a copy

of the energy analysis, call 1-888-PPG-IDEA.

Solarban, IdeaScapes, PPG and the PPG logo are trademarks owned by PPG Industries, Inc. | Cradle to Cradle CertifiedCM is a certification mark of MBDC.

PPG Industries, Inc., Glass Business & Discovery Center, 400 Guys Run Road, Pittsburgh, PA 15024 www.ppgideascapes.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

<

E-Mail

>

>I

Subscribe

[june 2009]

columns

features

26 The 26th Annual Guide

to New Products

If you’re looking to make a smart

investment in a new product line or a more

efficient piece of equipment, don’t do so

before checking out our annual listing of

the latest new products.

54

54 Packing a

Protective Punch

Dlubak Corp. has steadily built a

reputation for itself as a provider of a

range of protective glass products.

60 Everything I

Learned About Glass

Each year, GANA’s Glass Fabrication and

Glazing Educational Conference educates

many of the newest members of our

industry. Learn what tips and techniques

you should be passing on.

Special Sections

Architects’ Guide to Glass

64 A Review of the

AIA Convention

Solar Glazing

20 Solar Insights

22 Solar Watch

6

Issue at Hand

8

GANA Perspectives

10

From the Fabricator

80

The Business

departments

4

Only Online

12

Dear USGlass

14

Company News

16

Contract Glazing

18

Hardware Focus

68

Newsmakers

70

Reviews & Previews

71

Up & Coming

72

Supplier’s Guide

77

Classifieds

79

Advertising Index

•••

on the cover

The Comcast Center in

Philadelphia features PPG’s

Solarban 60 Starphire and

Solarban 60 clear.

Architect: Robert A.M. Stern

Architects LLP

Glass Fabricator:

JE Berkowitz LP

Glazing Contractor: Enclos Corp.

Photo by Tom Kessler. Courtesy of PPG

Industries.

USGlass, Metal and Glazing (ISSN 0041-7661), Reg. U.S. Patent Office is published 12 times per year by Key Communications, Inc., P.O. Box 569, Garrisonville, VA 22463; 540/720-5584; Fax 540/720-5687. Subscriptions: $80 per year. Advertising offices listed on page 6. Unsolicited manuscripts and other materials will not be returned unless accompanied by a self-addressed, stamped envelope. All contents are ©2009

by Key Communications, Inc. Neither publisher nor its representatives nor its subcontractors assume liability for errors in text, charts, advertisements, etc. and suggest appropriate companies be contacted before

specification or use of products advertised or included in editorial materials. Views and opinions expressed by authors are not necessarily those of the publisher. For permission to reprint, contact editorial offices.

Printed in the U.S. Periodicals postage paid at Stafford, VA, and additional post offices. Postmaster: send change of address to USGlass, P.O. Box 569, Garrisonville, VA 22463. ©2009 by Key Communications, Inc.

All rights reserved. No reproduction permitted without expressed written permission. Send subscription inquiries to Key Communications Inc., P.O. Box 569, Garrisonville, VA 22463.

2

USGlass, Metal & Glazing | June 2009

www.usglassmag.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

I<

Archives

E-Mail

<

>

>I

Subscribe

3

Good Reasons

The Bohle Group, leading manufacturer and supplier of tools, machines and accessories for glass processing and finishing, has been

represented in North America with their own subsidiary since 2008. We offer a long history of manufacturing and innovation since

1923, with our own products made in Germany, now available directly - bringing quality and affordability together.

01 High Quality - Made in Germany

Bohle is a leading manufacturer and supplier of tools, machines and accessories for glass

processing and finishing. The company looks back on more than 85 years of know-how and

tradition, through innovation and consistent quality.

Long service life

New technologies

02 The Best from 14 Product Fields

All product fields fulfill the highest quality demands and provide a broad range for the

industry. Product fields like: Glass Cutting, UV Bonding, Measuring Tools, Vacuum Cups,

Sealants & Glazing Tools...

We have all the supplies you need

Free support from master glaziers

03 Expanding Online-Shop

Visit us and find our monthly specials in the NEW

Online-Shop for America. Your item is just a click away!

Find out more at: www.bohle-america.com

ly low

Incredib

Monthly specials

shippin

g rates

g

shippin

le, free

p

m

a

x

e

For

$500

rs over

all orde

for

Growing product range

Bohle America, Inc. · 13850 Ballantyne Corporate Place · Suite 500 · Charlotte, NC 28277 · T +1 866 939 0053 (toll free) · www@bohle-america.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

<

E-Mail

>

>I

Subscribe

USGlassElectronic

Only on USGlassmag.com

Features Online

•

Packing a Protective Punch – EXTENDED

Get more behind-the-scenes information on innovative protective

glass fabricator Dlubak Corp.

•

Everything I Learned About Glass – EXTENDED

Gather more tips from this year’s Glass Fabrication and Glazing

Educational Conference.

Departments Online

•

Company News: Read more about what’s happening in the glass

industry, and how companies are being recognized for a number of

achievements.

Go to www.usglassmag.com

Online Survey

Speak out and tell us what you think with our online reader poll.

Read the articles inside the issue and then cast your votes online.

This month’s question:

Dlubak Corp. provides sophisticated “disaster glass products,” but has

focused in recent years on federal and military demand for laminated

glass. Owner Frank Dlubak notes that this focus may change during the

next four years of a new administration. “We listen to some of our

customers that there’s a reduction in military applications,” he says. “But

who knows …” (see full article on page 54). What do you see as the

biggest demand for laminated glass in the next four years?

❏ Expansion of hurricane resistance code requirements

❏ Federal and/or military investment in laminated glass

❏ Home and building owner demand for sound dampening

❏ New decorative options ranging from fabric interlayers to LEDs

WeBlogs

Read weekly updates via www.USGNN.com.

Monday - Let's Be Clear

Megan Headley

Editor,

USGlass Magazine

Tuesday - USGlass & Paul

Paul Bieber

Online editor,

www.usgnn.com

Wednesday The Entrepreneur’s Corner

Pete Chojnacki

President, FabTech LLC

Thursday - From the Fabricator

Max Perilstein

Vice president of

marketing, Arch

Aluminum & Glass

Friday Off the Press, On My Mind

Ellen Rogers

Online editor,

www.usgnn.com

May Survey Results

What changes are you making to get your company through this

economic downturn?

You answered:

Diversifying product offerings......20%

Better promotion of

advantages over competitors ......20%

Finding ways to cut

operating costs.............................40%

Waiting out the downturn ............20%

4

USGlass, Metal & Glazing | June 2009

20%

40%

On Occasion - deBLOG

Debra Levy

Publisher,

USGlass Magazine

20%

20%

Visit our online discussion boards at

www.usglassmag.com/phpBB2

to ask questions and share

experiences about business

and life in the glass industry.

www.usglassmag.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

Introducing Ti-AC 23 Low-E Glass.

Keeps the heat out while letting the best of nature in.

™

New Ti-AC 23 Low-E glass from AGC has the lowest solar heat gain coefficient of any

high-performance coating on clear-based glass. It offers an incredibly neutral look

with excellent glare control, as well as an aesthetically pleasing blue-grey hue.

Nothing gets you closer to nature more comfortably.

Call 1-800-251-0441 or visit www.ti-ac23.com to learn more.

©2009 AGC Flat Glass North America. All rights reserved.

BEY O ND GLASS

formerly

™

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

I<

Archives

E-Mail

Publisher

Editor

Managing Editor

<

>

>I

Subscribe

Debra A. Levy

Extension 111 • deb@glass.com

Megan Headley

Extension 114 • mheadley@glass.com

Erin Harris

Extension 130 • eharris@glass.com

Contributing Tara Taffera, vice president

Editors Extension 113 • ttaffera@glass.com

Charles Cumpston

Extension 0 • ccumpston@glass.com

Penny Stacey

Extension 148 • pstacey@glass.com

Ellen Rogers

Extension 118 • erogers@glass.com

Circulation Thomas Cory

Director circulation@glass.com

Art Chris Bunn

Directors Extension 132 • cbunn@glass.com

Dawn Campbell

Extension 150 • dcampbell@glass.com

Advertising/Exhibits Tina Czar

Manager Extension 115 • tczar@glass.com

Marketing Holly Biller, vice president

Director Extension 123 • hbiller@glass.com

Marketing Patrick Smith

Manager Extension 133 • psmith@glass.com

Customer Janeen Mulligan

Relations Mgr. Extension 112 • jmulligan@glass.com

Web Bryan Hovey

Developer Extension 125 • bhovey@glass.com

Video Drew Vass

Producer Extension 124 • dvass@glass.com

Customer Katie Hodge

Service Assistant Extension 0 • khodge@glass.com

Published by Key

Communications Inc.

P.O. Box 569

Garrisonville, VA 22463 USA

540/720-5584; fax 540/720-5687

Monthly Newscast

Let our team show what your industry is doing.

HEAR THE LATEST

HEADLINES

SEE NEVER BEFORE

SHOWN FOOTAGE

ENJOY THE NEWS

IN A WHOLE

NEW FORMAT

Midwest

Advertising Offices:

Lisa Naugle

Associate Publisher

lnaugle@glass.com

Phone 312/850-0899 Fax 312/277-2912

Northeast & Rocco Zegalia

Eastern Canada rzegalia@glass.com

Phone 540/720-5584 x194 • 267/626-8405

Southeast

Scott Rickles

srickles@glass.com

Phone 770/664-4567 Fax 770/740-1399

West Coast & Ed Mitchell

Western Canada emitchell@glass.com

Phone 805/445-4805 Fax 805/445-4806

Europe

Patrick Connolly

patco@glass.com

99 Kings Road, Westcliff on Sea

Essex SS0 8PH ENGLAND

Phone (44) 1-702-477341 Fax (44) 1-702-477559

China & Asia

Sean Xiao

sxiao@glass.com

Rm.403, Block 17,Wuyimingzhu, No.6 Jinshan Road,

Fuzhou, Fujian, 350001, China.

Phone (86) 591 83863000

Visit www.usgnn.com and look for the video icon

Or sign up for the daily

newsletter and receive the Special Alert when the newscast is first delivered.

6

USGlass, Metal & Glazing | June 2009

All Others Contact Publisher Directly

MEMBER,

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

E-Mail

Two City Place Lobby, Fort Worth, TX | Gideon Toal Architects

WE CREATE PRODUCTS

THAT CREATE IDEA S.

Limitless choice and unmatched quality, that’s what you deserve for every project. As part of our Classic

Line™ Architectural Products, Envision™ Glass Systems provide you with an impressive range of design

solutions, all backed by a commitment to superior service and expertise. From all-glass doors to structural

glass walls to handrails and more, our products afford you answers for virtually every project application

need. Now you can embrace your creativity, knowing that your vision is indeed possible.

ENVISION™ ALL- GL ASS DOORS | ENVISION™ CL AD DOORS

ENVISION™ SLIDING & STACKING DOORS | ENVISION™ GL ASS WALLS

ENVISION™ HANDRAILS | ENVISION™ SHOWER ENCLOSURES

ENVISION THE POSSIBILITIES.™

W W W.VITROAMERICA .COM | 800.238.6057

I<

<

>

>I

Subscribe

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

GANAPerspectives

Learn More About Lamination

GANA Offers Updated Laminated Glazing Manual

by Brian Pitman

eaded by the competent leadership of Solutia Inc.’s Julie

Schimmelpenningh, a Glass Association of North America (GANA)

task group has completed its review

and update of the GANA Laminated

Glazing Reference Manual, a document

that has helped many professionals in

the construction industry for almost a

decade. The new 2009 edition is the

third update of the Manual since it was

first released in 2000, and the first since

April 2006.

H

formation about laminating interlayers, as

well as in-depth discussions on the numerous

applications of laminated architectural glass

including safety, solar

control, ultraviolet radiation, sound control, security, sloped glazing

and skylights, wind

storms and hurricane

and earthquake resist-

With completion of these revisions

and inclusion of newly developed

information, the 2009 edition of the

Manual was released earlier this month.

As one of the most successful publications offered by GANA, the Manual

contains information that covers a

broad range of considerations for the

application and specification of laminated glass in building construction. It

has sold more than 8,000 copies since

its initial release. With the changes in

trends and further information development in the three years since the release of the 2006 edition, an update was

needed. The task group worked for two

years to compile and verify the most

current information. With completion

of these revisions and inclusion of

newly developed information, the 2009

edition of the Manual was released earlier this month.

The current Manual presents general

useful information, technical details,

performance data and the installation

guidelines for laminated glass products.

The 2009 edition includes the latest in-

8

USGlass, Metal & Glazing | June 2009

ance. Updates on laminated glass

strength, cutting, handling and installation also are highlighted throughout

the Manual. There also is a very useful

quick reference section on standards as

developed by various organizations that

apply to laminated glass.

The Manual can be used effectively

by anyone in the glazing industry but is

intended for use specifically by architects, designers, engineers, component

manufacturers and installers of laminated glazing materials in buildings.

Several GANA members also have purchased previous editions of the Manual

in bulk to give to clients as a useful reference tool. Bulk pricing is

available by calling GANA Headquarters at 785/271-0208 and

speaking with Carol Land.

Pricing for the new Manual has

been set at $35 each for GANA

members and $70 each for non-

members. It is available

in both hardcopy document or in electronic format on CD. The GANA

Laminated Glazing Reference Manual also may

be purchased on the

GANA website, along

with the various other

GANA resources, at

www.glasswebsite.com.

SPECIAL THANKS

The 2009 edition of

the Manual could not have been revised

without the help of the task group

members. These industry experts include Schimmelpenningh, Peter Anderson of Viracon Inc., Michael Burriss of

CYTEC Industries Inc., John Bush of

Oldcastle Glass Inc., Michael L. Griffin

of Huntsman Polyurethanes, Jeff

Haberer of Cardinal IG, Bernie Herron

of Cardinal Glass Industries, James

Touchette of MJR Enterprises Corp. and

Rick Wright of Oldcastle Glass Inc.

The task group strives to make this

the most up-to-date laminating reference document available. As such, they

welcome the suggestion of new topics,

comments and clarifications from anyone in the industry. If you or someone

within your company is interested in

participating on the Manual task group,

please contact the GANA office at

785/271-0208. ■

B r i a n P i t m a n is GANA’s

director of marketing and

communications. Mr. Pitman’s

opinions are solely his own

and not necessarily those of

this magazine.

www.usglassmag.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

Make your window and curtain wall systems – and your buildings – rise above the ordinary. With Technoform’s TGI® warm

edge IG spacers and Bautec structural insulating struts for aluminum frames, it’s possible. You see for over 30 years, we’ve

been helping architects, designers and fabricators create some of the most striking, high-performing window and curtain wall

systems in the world. Our spacers and struts deliver unsurpassed design capabilities, energy efficiency, durability and structural

strength. And our people bring you unrivaled expertise. Which means when you work with Technoform, you can take your

designs to a whole new level.

www.technoform.us | 330-487-6600

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

FromtheFabricator

One-on-One

An Interview With, and By, the Author

by Max Perilstein

n this great magazine there have

been tremendous interviews over

the years and, I must say, I am jealous. Even though I have a blog and a

column, I have always wanted to be interviewed. But I know I am not in a position to ever get that honor—so I

decided I would interview myself. The

best part is, if I say something wrong I

can blame the interviewer for misquoting me.

From the Fabricator: How do you

see the health of the industry especially

with the economy struggling?

Max Perilstein: I am surprised that

no one has gone out of business yet, if

that’s what you mean. I think many

people “in the know” expected some

players to fall by the wayside and that

has not happened. And this is at every

level. Glaziers thought their competition would start to reduce, as did fabricators, and there were even rumblings

of the same at the primary level. But it

has not happened anywhere … yet.

FtF: Is there anything more frustrating than the .30/.30?

MP: Heck, there’s tons of things more

frustrating, but right now nothing

should infuriate you more than the government passing a provision like the

.30/.30 that was slipped in at 3 a.m. and

with no idea of how it would work or

who it would effect. The whole thing is

pretty sad and its effects will be felt for

years. I crack up when people say this

item “saved” the window industry. All it

did was make more money for test labs

and consultants. A smart reinforcement

of a good program like ENERGY STAR

would’ve made much more sense.

FtF: How do you see the “green” building world? It seems to be as strong as

ever.

I

10

USGlass, Metal & Glazing | June 2009

MP: No, because, as far as I know, if

MP: It is, but it has its issues too. I get

just as many e-mails asking me to rant they read my blog they wouldn’t be

on the U.S. Green Building Council and able to understand it; it’s beyond a

its LEED program as I do the National third-grade reading level. But seriFenestration Rating Council. There are ously, I don’t because unfortunately

some serious holes in the LEED process certain people in D.C. only choose to

and too many designers will skip good listen to a select group of people and

building materials or techniques be- they rarely if ever open themselves up

cause they are in search of credits— to reality. When the Department of

and let’s not forget the whole Energy can have a meeting and call it

“greenwashing” issue too. Despite that, a “Building Envelope Executive

it seems like every decent job starts out Forum” and not have groups such as

wanting to be LEED-certified so it’s the Glass Association of North America, the Insulating Glass Manufacturhard to bash that.

Alliance,

the

American

FtF: What do you see being the hottest ers

Architectural Manufacturers Associproduct of the next 10 years?

MP: Building integrated photo- ation and the Aluminum Extruders

voltaics (BIPV). Hands down. BIPV Council attend, there’s a problem—

today is like low-E was in 1991; people especially when they prefer to have

are starting to grasp it but are ques- consultants attend instead of those

tioning its abilities. Eventually it will groups or instead of true commercial

breakthrough and become a major industry players such as Kawneer,

force in our industry. With the energy Viracon, Oldcastle or Arch, just to

push, having the glass working for name a few. So backlash does not

you will become more and more worry me, their uninformed ignorant

decisions do.

important.

FtF: And you wonder why you don’t

FtF: Any other product lines you see

get interviewed?

doing well?

MP: Yep, I deserve that. Hey, I am

MP: Well, I still think low-E glasses

and their advancements will be para- what I am. This industry gets stepped

mount. And I love the electrochromic on daily. I choose to have my voice

and thermoreflective glass (and the heard and I hope people can respect

whole range of “smart” glass to come). that. Something tells me I won’t be inWhat the people who take pot shots at terviewed again for a long time … ■

our industry don’t realize is that

we are making tremendous

strides every day in manufacturM a x P e r i l s t e i n serves

ing and fabricating these types of

as the vice president of

materials. Unfortunately, we need

marketing for Arch Aluminum

to do a better job of promoting

and Glass. Mr. Perilstein’s

opinions are solely his own

ourselves.

and do not necessarily reflect

FtF: Do you ever fear a backlash

the views of this magazine. His column

from the Washington, D.C. folks

appears bi-monthly.

you take on in your blog posts?

www.usglassmag.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

DearUSG

Shame and Blame

Dear USGlass:

I read your article in the April 2009 issue concerning the

whining over the Freedom Tower glass buy-out (see April

2009 USGlass, page 30) and offer the following comments.

With regard to the persons and companies that committed their research and development cost to the project, one word comes to mind: “suckers.”

There is no point in trying to assist architects and public

agencies in solving their budget and constructability issues

on projects that ultimately will be awarded based on low

price.Were these people born yesterday? Even if they were paid

for their services, it does not solve the dilemma. Our investment of key resources is only benefited when we can manufacture a product in the end. Any company in the USA that has

a factory surely can identify with this.

As far as outsourcing to foreign companies go, we have

the power to change this, but greed continually prohibits

this from happening. There always is a glazing contractor

or erector willing to offer savings back to an owner while

taking on a risk they don’t even understand in order to

sell some contract work.

Glazing contractors that offer installation of foreign

products are the problem here. Public agencies such as

the Port Authority are not to blame for their low-bid procurement practices. Everyone out there that offers foreign

products on a building is either giving the savings back to

the owner or pocketing some portion (if they’re even

smart enough) but still are not recognizing the risk they’re

accepting that the owner is not taking on.

Stop offering foreign products and there will be no

more crying over it. Hear that, Zetian?

John D’Amario

Vice President - Sales

Architectural Glass & Aluminum Co.

Don’t Stop Pursuing

Dear USGlass:

In your article regarding the Freedom Tower (see April

2009 USGlass, page 30), the real issues are the underhanded dealings between the Authority and the Chinese.

This, in my opinion, is what needs to be exposed … along

with the larger issue of to what testing the Chinese must

submit their products before it is ever installed in a building. A very good example of “ooops, it’s too late now,” is

the horrible Chinese drywall debacle in Florida. This country has got to stop permitting untested products from

China to be shipped into the United States … period.

Please don’t stop pursuing the issue. It has wide future

ramifications for every citizen in the United States.

Bob Lang ■

Billco Manufacturing ■

12

USGlass, Metal & Glazing | June 2009

www.usglassmag.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

Contents

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

CompanyNews

Glaston Merges Business Areas;

Closes New Jersey Location

s part of a company-wide restructuring, Finland-based Glaston Corp.’s pre-processing and

heat treatment business areas have been

merged into one new business area, Machines BA. The company also has announced that it will close a machine

manufacturing plant in Cinnaminson, N.J.

Glaston estimates the targeted annual cost savings from the merger and

A

improved productivity to be $4.5 million USD (3.5 million EUR) globally.

The merger will generate one-off costs

estimated at approximately $4.8 million

USD, recognized mainly in the second

quarter of 2009. Possible redundancies

will be analyzed and faced in compliance with local legislation.

Regarding the facility closure, the manufacturing of U.S. tempering lines will be

Kawneer Plant Closing to Result

in the Loss of 250 Jobs

K

awneer Co. Inc., an Alcoa company headquartered in Norcross, Ga., is

closing its Hernando, Miss., manufacturing facility at the end of this

month. As a result of the closing 250 employees will lose their jobs.

“The consolidation of our operations will ultimately result in a business that

is more responsive to market cyclicality and is more capable of servicing our

customers,” says Kevin Lowery, Alcoa’s director of corporate affairs. “We are

committed to maintaining high levels of service and will do everything possible to make the transition seamless. We will not do anything to impact customer service. We are contacting customers to discuss the transition so there

is no disruption in their service.”

The facility has an annual payroll of $12 million and has been in Hernando

for 41 years, making it one of the oldest industries in DeSoto County.

“Decreasing demand and increasing competition both inside and outside

of Kawneer are the primary contributors for the need to realign production to

other plants,” says plant manager Derek Wilson. “Our employees have worked

very hard at reducing costs, increasing productivity and driving to be competitive in a global market. I sincerely appreciate the hard work that everyone has

put forward, which has gotten us this far. However, the current economic downturn has forced us to this position.”

Wilson said they will work with state and Hernando officials to help employees. “As for the facility itself, we will transfer or properly dispose of any major

assets and eventually sell the property,” Wilson adds.

Earlier this year Alcoa announced it would cut 13,500 jobs, or 13 percent,

of its workforce, and curb production to reduce costs in the face of the economic downturn (see February 2009 USGlass, page 12).

Cuts are expected to be completed by the end of this year.

❙❙➤ www.kawneer.com

14

USGlass, Metal & Glazing | June 2009

transferred to Finland and China. However, a company representative notes that

Glaston will maintain its North American

offices in Cinnaminson. In addition, it has

decided to expand its services with the

formation of a service delivery center in

the existing New Jersey office.

According to a company news release, overall equipment efficiency can

be achieved by focusing on preventive

service check-ups and documented

service history, training and process

consultation, spare part inventories and

annual replenishment of spare parts.

The Service Delivery Center will aim to

respond to these needs with solutions

to improve equipment performance.

❙❙➤ www.glaston.net

Bohle America

Doubles Space

Bohle America Inc. has more than

doubled its office facilities at its Charlotte,

N.C., headquarters. The company has

added 176,500 square feet of warehouse

space to accommodate its new product

lines, and also has more than doubled its

office space in the last two months.

“We are rapidly developing our U.S.

operation and we need to grow both our

team and our facilities,” comments Gary

Dean, chief executive officer. “We recognized from the beginning that we would

be able to expand once we gave ourselves

some time to listen to our customers and

understand the market needs. Hence we

decided from the outset to engage flexible warehouse and office arrangements,

which would facilitate our growth.”

Dean adds,“These arrangements will

provide further opportunities for significant expansion of product lines and

sales support teams without the need

to relocate.”

❙❙➤ www.bohle-america.com ■

www.usglassmag.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

THE ORIGINAL CUSTOM BATH ENCLOSURE

Sapa Fabricated Products is home to

Alumax Bath Enclosures, the brand most

chosen by the professional installer. Ease

of installation, safety, leak prevention and

overall durability are just some of the key

features value-engineered into each of our

products.

Our clients appreciate the fact that all of our

products are available in both standard and

custom configurations, and that our product

features include a complete selection of

color options and glass patterns.

PERFORMANCE AND DURABILITY

Every Alumax Bath Enclosure is engineered to exacting standards and mechanically tested to ensure a long-lasting,

maintenance free product. To prevent any type of discoloration or performance issues, only the finest stainless steel

GBTUFOFSTBSFVTFEUPTFDVSFPVSQSPEVDUT0VSQSPEVDUTBSFFOWJSPONFOUBMMZGSJFOEMZBOESFDZDMBCMF

w w w.sapafabricatedproducts.com

Sapa Fabricated Products

/8BTIJOHUPO.BHOPMJB"3

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

ContractGlazing

Permasteelisa Streamlines

Curtainwall Processes via Autodesk

ermasteelisa S.p.A. will combine the use of Autodesk

Inc.’s architectural and manufacturing 3D design software and services throughout its curtainwall creation

process to improve its ability to react to customer demand, as

well as focus on increased quality of product and service.

The new Permasteelisa Moving Forward (PMF) system is

expected to accelerate the company’s ability to react to customers from initial inquiry to final installation. The PMF system is a custom suite developed together with Autodesk using

Autodesk software, including the Revit platform for building

information modeling (BIM). This new design platform will

serve 5,000 users in 50 global locations and enable users at

up to five sites to work simultaneously on the same project.

As an example of how the initiative will work, Permasteelisa

P

InterClad Announces

New Location

G

lazing contractor InterClad, an Egan Co. based

in Plymouth, Minn., has moved to a new

location.

“After almost 11 years in business, we have purchased

our own building and will be moving across the freeway,”

says Bill John, president of InterClad and executive vice

president of Egan Company. “For my valued business

partners and friends, I would like to thank all of you for

making this possible and helping to make InterClad a

success over the past decade.”

❙❙➤ www.eganco.com

16

USGlass, Metal & Glazing | June 2009

can design a new curtainwall based on 3D models created in

Revit and then transfer the data to other teams working on materials and manufacturing to create a single 3D digital model in

Autodesk Inventor and AutoCAD Mechanical software.

Increases in Surety Bond Guarantees

Could Help Spur Construction Growth

In years past, many contract glaziers found it challenging to

gain surety bonding. In the early 2000s sureties incurred numerous losses and tightened up on underwriting and pricing, closing off opportunities for some small contract glaziers.

Then, just a couple of years ago, the industry loosened up and

bonding requirements became less stringent, making it a bit easier for small contract glaziers to gain bonding (see October 2007

USGlass, page 32). Now, even with the country in the midst of

an economic and financial crisis, some contract glaziers still are

able to bond their jobs with relative ease. Danny Davis, vice president and chief operating officer of Arrow Glass and Mirror in

Austin, Texas, says his company has had no trouble bonding jobs.

“Some commercial general contractors have made it their

policy that [contract glaziers] must have the capacity to obtain bonding,” says Davis. “We think that is good and look at

it as a competitive advantage.”

And help may even be on the way for those small business

contract glaziers that may have struggled to gain bonding in

the past. As part of the Recovery Act, those companies can now

qualify for U.S. Small Business Administration (SBA)-backed

surety bonds of up to $5 million, more than double the previous amount of $2 million. Through its Surety Bond Guarantee

program, the SBA, in partnership with the surety industry, will

guarantee bid, payment and performance bonds. The SBA will

provide a guarantee to a participating surety company of between 70 and 90 percent of the bond amount.

“Small businesses are the backbone of our nation’s economy and we want to get them up and growing again, as that

will help everyone,” says Frank Lalumiere, director of the

SBA’s Office of Surety Guarantees. “The country is in a tough

way right now and a lot is being done to turn that around.”

Lalumiere says that while construction may be slow, with

the Recovery Act money that is going toward it he expects to

see it turn around soon. And for those companies that will

be looking to take advantage of the SBA’s surety program, Lalumiere has a few tips they should keep in mind.

“They need to be sure that they have a current business

plan in place, that they have their financial statements in

www.usglassmag.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

<

E-Mail

>

>I

Subscribe

Introducing Q-railing,

Just Some Of Our Top

Quality Railing Systems

You've Been Waiting For!

Handrail bracket

1.5" top rail,

stainless steel

AISI 304 satined

$ 13.50 Each

order and they need to be prepared to talk about cash flow

requirements,” says Lalumiere.

❙❙➤ www.sba.gov

Ironworkers and Glaziers Favor

the Use of Project Labor Agreements

Many curtainwall installers and glazing subcontractors are

already familiar with project labor agreements (PLAs) but

now, with stimulus funds dedicated to federal construction

projects, installers can likely expect to see them even more.

Earlier this year President Obama signed an executive order

requiring the use of PLAs on all federal construction projects,

stating: “Large-scale construction projects pose special challenges to efficient and timely procurement by the Federal Government. Construction employers typically do not have a

permanent workforce, which makes it difficult for them to predict labor costs when bidding on contracts and to ensure a

steady supply of labor on contracts being performed. Challenges also arise due to the fact that construction projects typically involve multiple employers at a single location.”

But PLAs are not just for federal jobs; some say they have

also proven beneficial on many other types of jobs—especially

large-scale, complex installations. Several union organizations

with focuses on curtainwall construction say they are in full

support of the use of PLAs as they serve as effective construction management tools for quality construction.

Eric Dean, general vice president of the International Association of Bridge, Structural, Ornamental and Reinforcing

Iron Workers, heads up the association’s ornamental architectural and miscellaneous metals efforts, which includes

curtainwall construction.

“PLAs provide criteria for every contractor, builder, owner

that assures the consistency of the project and it ensures uniformity to build the project on time and without labor disputes,” Dean says. “It’s a blueprint document on how labor

contracts can help on these projects.”

The International Union of Painters and Allied Trades

(IUPAT) also is in favor of PLAs.

“We feel the PLAs increase the efficiencies of projects and

that they do not increase costs,” says George Galis, IUPAT’s

general secretary-treasurer.“Our contractors report to us all

the time that on hard-dollar bid projects, especially major

curtainwall jobs, they are able to beat out non-union workers.” Galis adds, “PLAs are not going to cost the end-user or

the taxpayer any more money.” ■

www.usglassmag.com

Toprail

for 1.5", length 16.7'

stainless steel

AISI 304 satined

$ 87.50 Each

Glass clamp, model 20,

for glass 5/16",

stainless steel

AISI 304 satined

$ 14.40 Each

Get Your

Discount

Today!

Glass standoff

for glass 1/4" – 5/8",

stainless steel

AISI 304 satined

$ 11.20 Each

Experience a new level of excellence in quality, functionality

and design, from Europe's #1 railing systems supplier.

Call now for your

free catalog and Discount

714-259-1372

The new quality in railingsystems

Q-railing USA Co.

1382 Valencia Avenue

Unit N

Tustin, CA 92780

T: 714-259-1372

F: 714-259-1720

sales@q-railingusa.com

www.q-railingusa.com

united states of america

June 2009 | USGlass, Metal & Glazing

17

Contents

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Search

Archives

I<

<

E-Mail

>

>I

Subscribe

HardwareFocus

company news

Ingersoll Rand Offers New

Web Course on Door Closers

ngersoll Rand Security Technologies

is offering a free web-based course

that covers the basic role the door

closer plays in controlling the

door. With the e-learning course, security directors, maintenance personnel,

facility managers, locksmiths, distributors and security dealers can learn

about door control according to their

own schedule and from wherever they

have access to the Internet.

The online, self-paced format covers the five critical needs of an opening, including durability, ADA, safety,

security and design. The online

course provides interactive learning

of the features and benefits of heavyduty (institutional) and mediumduty (commercial) products. Students

learn about effective LCN door closer

applications, installations, adjustments and servicing.

I

❙❙➤ www.lcn.ingersollrand.com/

education

product news

Kaba Locks

Continue to Learn

The E-Plex 3700 Series narrow stile PIN/PROX lock is the

latest addition to WinstonSalem, N.C.-based Kaba Access

Control’s E-Plex line. The electronic PIN and/or PROX lock for

narrow stile aluminum glass

doors works with HID®’s PROX

credentials (cards, fobs, etc.).

PROX credentials

can be quickly

enrolled at the

lock or with optional software.

This series, along with the EPlex PROX-based E5700 series

electronic locks and E5770 series standalone access con-

18

USGlass, Metal & Glazing | June 2009

Ingersoll Rand’s new web-based course teaches students about door closer

applications, installations, adjustments and servicing.

SDC Offers More

Mechanical Mortise Locks

SDC in Westlake Village, Calif., has introduced a complete new line of UL-listed,

ANSI grade 1 and ADA-compliant mechanical cylindrical locksets. The new M7800

grade 1 mortise locksets are designed for

commercial, industrial and institutional use.

An internal clutch provides vandal resistance

by permitting lever rotation without retracting

the latch when locked. Independent heavy-duty

springs provide effective lever return and support. A variety of

functions and lever styles are available.

❙❙➤ www.SDCsecurity.com

troller, all have gained a new feature:

LearnLok™. LearnLok™ simplifies programming of up to 300 user credentials

(HID PROX cards, fobs, etc.) per door

by “learning” them right at the lock’s

reader without the use of software and

related lock programming

devices. The locks can be upgraded

with optional software to accommodate

up to 3,000 users/30,000 audit events

per door.

❙❙➤ www.kabaaccess.com ■

www.usglassmag.com

Contents

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Search

I<

Archives

E-Mail

<

>

Subscribe

SARGENT

in stock and ready to ship.

®

SARGENT

“Copyright ©2009 Midwest Wholesale Hardware. All rights reserved.”

®

midwestwholesale.com

800 821 8527

800 659 8527

888 707 8527

>I

800 821 8527 or 800 659 8527

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

SolarInsights

Going Solar

YKK’s Tom Minnon Shares His PV Experience

ith all the talk in the glass in- our state initiative and utility initiatives,

dustry these days about solar the system is literally going to cost me

energy and photovoltaics almost nothing …

Q: And how long have

(PV), it’s no surprise that

you had the system?

members of the glass industry

A: It went in … right after

are turning to solar energy to

the first of the year. The timing

power their own homes. Tom

was just right, as the new fedMinnon, CSI, CCPR, LEED AP,

eral tax credits had just come

YKK AP America Inc.’s reout so everything worked out

gional sales manager, installed

well from that standpoint.

a 2KW system on his home in

Q: Now you had menDerry, N.H., in January. After a

tioned you studied solar enfew months’ payback on the

ergy in school. Can you

system, Minnon shared with Tom Minnon

elaborate on that?

USGlass his research into PV

A: It was kind of an experimental

and where he sees the glass industry fitthing. We installed some solar hot water

ting into solar energy.

Q: What led you to install PV in panels in buildings; typically back then

[solar] was used for heating buildings.

your home?

A: It’s been 35 years in the making. There was a grant and two students

When I was in college back in 1974 I ac- were picked to work on the project, I was

tually worked on a solar energy project one of the two. I had always been interat the school that I was at in New Hamp- ested in things like that anyway. I was

shire. … When I got out of school in ’75 going to school in mechanical engiI went to work with Powerwall Corp. and neering, which is what my degree is in.

Obviously it was cutting-edge back in

they were opening a company called

Solar Components Corp., which is still the mid-70s. We had the energy crisis,

around today … Obviously in the last there was the OPEC oil embargo, peo30-some-odd years huge strides have ple were waiting in line for gasoline.

been made in PV as far as the efficiency There was this huge awareness in the

public of ‘Gee, we need to wean ourand manufacturing and all that.

Now, with all the incentives and the selves off foreign oil.’ Sound familiar?

Q: Certainly does. And it begs the

rebates and the tax credits that are

available, it just didn’t make sense not question: do you expect interest to

to do it. Between the federal initiative, wan in solar energy this time around?

A: I see a difference this time around.

Tom Minnon’s PV Savings There are so many people that are involved now; you’ve got the whole green

PV Costs

building movement, which has such

Installed cost

$17,000

momentum. We tried to go through that

State of NH rebate

-$6,000

back in the 1970s and tried to tell peoElectric utility rebate

-$3,500

ple about intelligent building design

Federal tax credit

-$5,100

and passive solar design, not to mention solar collectors and things like that.

$2,400

Net cost

W

20

USGlass, Metal & Glazing | June 2009

And there was some interest but it just

kind of went away. People forgot about

the oil embargo and the energy crisis

and changing political climates just did

not focus on or keep people’s awareness

on what we were doing. Next thing you

know we’re back to where we were and

we’re importing oil and here we are.

Q: Can you offer some specifics

about your latest project?

A: There were a couple companies involved. The company that installed it

was a local company here in New

Hampshire called SolTerra. They did a

very nice job. The solar panels were

made by a company called EverGreen

in Massachusetts, which is local. Part of

sustainable design is trying to buy

things that are made locally to cut down

on transportation costs. The fact that

the panels were made in the adjoining

state here was a benefit to me.

Q: Did you observe the installation?

A: I was here that morning … There

had to be an electrician involved and we

did have to get an electrical permit. We

didn’t need a building permit but we did

need an electrical permit because the

power from the solar panel comes down

and it gets fed into what’s called an inverter. The power that comes from the

solar panel is 12 volt DC. The inverter

takes that and converts it into 120 volt

AC, which is obviously what we all use

in our homes. It then gets fed back to my

circuit breaker panel. Then what happens is what’s called net metering. When

I’m generating more solar energy than

I’m using—so on any typical day when

my wife and I aren’t home and the sun is

out—then we actually spin the meter

backwards. On a good sunny day you

can actually watch the meter go backwards. That’s just a neat thing.

www.usglassmag.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

We’re getting paid back in the fact

that whatever we don’t use in the

house is getting fed back into the grid.

I guess, in essence, my neighbor is

buying my electricity …

Q: So it only took the morning to

do? That’s pretty quick.

A: It was done in that same day …

There’s a racking system that goes up

on the roof, the solar panels get attached to the rack. And then there’s

wiring from the roof down to the basement where the inverter is. They were

in and out in that same day.

Q: Now do you think solar energy is

an area likely to become profitable for

the glass industry?

A: Where glass companies are going

to get involved is in building integrated

photovoltaics (BIPV), where they are

glazing the panel into, let’s say, the

storefront or the wall or sloped glazing

system. You’re glazing in a PV panel instead of glass so it becomes the building envelope. Instead of having a roof

where they’re putting solar panels on

the roof, solar panels are the roof. We’re

saving money there by not having duplicity of a fenestration system.

Let’s say we take a system where

there’s a curtainwall elevation and the

architect has designed in some PV. The

glass company needs to look at that and

figure out how they’re going to coordinate their work with the electrician who

is going to be coming in behind them

and wire these things together.

I would just caution when a glass

company is looking at something like

this—and I haven’t personally been involved with any—but companies that

have been involved that I’ve talked with

say the coordination of trades is very

important. You’re installing the curtainwww.usglassmag.com

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

EverGreen produced these rooftop PV panels which were installed by SolTerra.

wall but you, the glazing contractor,

probably are not installing the PV. It’s

probably a PV company you’re working

with or coordinating with in order to

get those panels glazed into the curtainwall and then wired up.

Q: I know there are projects YKK AP

has been involved in with PV in Japan

(the SBIC East Building is reportedly

Japan’s first case of total introduction

of BIPV in the building design, and

YKK AP Inc. produced the PV). Is this

a market segment that you see YKK

AP America becoming involved in?

A: I would say so, within the next

five years. With the interest growing as

it is—and we’re so involved in sustainability and green design around

the world—that I certainly see us getting involved within that timeframe. It

may even be sooner, I don’t have a

timeframe on it nor have we discussed

it. We’re certainly aware of the interest

and we have some experience obviously in having done it overseas on

several projects.

Q: Would you have any advice to

give to other building or homeowners

before going to PV?

A: Like anything, find a company

that has some experience, that you

feel comfortable with, get some references like you would for any sizeable

home improvement project. Check the

efficiencies of the panels.

Beyond that—nothing went wrong

so I can’t say here’s something you

need to watch out for … I can’t say

that I would have done anything differently. The system went in well. They

obviously had to make some penetrations in the roof to pass wiring down,

but nothing leaked. The power works

really well as far as powering everything that connects it.

… I’m looking at approximately a fiveyear payback. I look at it as return on investment (ROI). How many people can get

their money back in five years on anything? So I think that’s a pretty good ROI,

number 1; number 2, I have a $17,000 system on my house. It’s good equity should

I ever sell the house. And we aren’t stopping there. I just ordered a solar hot water

system that I’m going to install and just

this morning we had these same people,

SolTerra, out and I’m going to have geothermal for heating and cooling installed.

We haven’t stopped at the solar! ■

Learn about your state and local

and utility tax credits and rebates

by visiting the Database of State

Incentives for Renewables and

Efficiency at www.dsireusa.org.

June 2009 | USGlass, Metal & Glazing

21

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

<

E-Mail

>

>I

Subscribe

SolarWatch

company news

Schott Solar Inaugurates Flagship

Manufacturing Facility in New Mexico

chott Solar inaugurated its Albuquerque, N.M., manufacturing facility for products used to

generate solar power on May 11, one

year after breaking ground on the project’s first phase. The 200,000-squarefoot facility represents an initial

investment of more than $100 million.

Schott has created 350 jobs at the new

facility, which will continue to ramp up

production throughout the summer.

Federal, New Mexico and Albuquerque dignitaries and government

officials joined Schott Solar executives

to dedicate the facility.

S

Gov. Richardson and Dr. Ungeheuer

sign the first PV panel produced at

Schott Solar’s new plant.

The new site is designed to support

expansion of both Schott’s photovoltaic

(PV) module and solar thermal receiver

lines. Long-term plans call for the buildings to expand to 800,000 square feet

with employment reaching 1,500 people, representing a total investment of

approximately $500 million.

For the first phase, the Albuquerque

facility will have an annual capacity of

up to 85 megawatts (MW) of PV 225

watt polycrystalline modules, sold under

the name Schott Solar Poly 225. In addicontinued on page 24

New Giroux Glass Facility Uses Solar Power

L

os Angeles-based glazing contractor Giroux Glass has opened

a new fabrication facility in San

Bernardino, Calif., and has decided to

go green through solar power.

At the end of last year the company

purchased a 40,000-square-foot warehouse in San Bernardino to use as the

new fabrication center for the company’s custom and unitized curtainwall

and storefront projects coming out of

the Los Angeles headquarters, approximately 60 miles away. The facility also

will assist in fabrication for some projects based out of the Las Vegas office.

With the purchase of a great deal of

new fabrication equipment, the building has been retrofitted so that the

equipment runs off of solar energy.

“I was signing some checks here for

our utilities here at our facility in Los Angeles and was surprised at how high

those bills have been,” recalls vice president Robert Burkhammer. “I knew out

22

USGlass, Metal & Glazing | June 2009

So far 15 people have been hired for Giroux Glass’ new, solar-powered facility,

with plans to grow further.

in San Bernardino, with our new machines, the price of energy was going to

go up so I talked about it [with colleagues] and said why don’t we look at

using solar cells?”

Burkhammer already says, “It was a

good move.”

Solar Integrated Technologies in Los

Angeles provided the facility with its

building integrated photovoltaic (PV)

roofing product. With this addition,

Burkhammer notes, “We’re the very

first commercial building to have solar

power in San Bernardino City.”

In addition to the PV system, the

company is going green in a number

of other ways, including a recycling

program for cardboard and aluminum

waste. The company also has invested

in three Smart Cars during the past

few months to assist in conserving

fuel use. Through the facility’s location

within an enterprise zone, and with

the assistance of union local #636,

monetary incentives are offered to

employees that choose to carpool or

bike to work.

❙❙➤ www.girouxglass.com

www.usglassmag.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

THE AA®3200 ISOWEB® SLIDING DOOR is the perfect choice for your

next high-end project. It’s the combination of form and function that

makes this sliding door stand up to the elements, whether it’s

rain, wind or hurricane conditions. To learn more about our AA®3200

ISOWEB® Sliding Door, visit Kawneer.com.

© 2008 Kawneer Company, Inc.

Architectural Aluminum Systems

Entrances + Framing

Curtain Walls

Windows

>I

Subscribe

STANDS UP TO THE ELEMENTS.

STANDS OUT IN THE INDUSTRY.

kawneer.com

>

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

SolarWatch

continued

tion to manufacturing PV, the Albuquerque facility is the first in the U.S. to

produce receivers used in parabolic

trough, utility-scale, concentrated solar

power (CSP) plants. Initially, the two production lines will produce enough receivers to meet the demands of up to 400

MW CSP power plants per year.

Prototypes of next generation receivers were unveiled during the inauguration ceremony. The new receivers

offer new dimensions and can accommodate alternative heat transfer fluids.

❙❙➤ www.schottsolar.com

INTRODUCING THE ALL NEW

ELITE SHOWER DOOR

HEADER SYSTEM

5 ((+3/ "+. &1/0)!*0 +" %*#! "0!. */0((0%+*

5 + .%((%*# !-1%.! 0+ +1*0 %*#! 0+ ! !.

5 !/%#*! "+. * * )) (//

5 0* . %*%/$!/ 2%((!

5 +.'/ 3%0$ .#+* !2!(! +.

.!/0%#! -1.! 04(! %*#!/

%*#!/ +( !,.0!(4

USH10

FRAMELESS SHOWER DOOR

HARDWARE AND SUPPLY CATALOG

%!3 +. +3*(+ %0 0+ 4 +*(%*!

0 ushorizon.com

Toll Free Phone: (877) 728-3874 • Toll Free Fax: (888) 440-9567

24

USGlass, Metal & Glazing | June 2009

products

Arch and Konarka

Develop BIPV Products

Architectural glass fabricator Arch

Aluminum and Glass in Tamarac, Fla.,

and Konarka Technologies Inc., a solar

plastic film producer based in New

Bedford, Mass., have entered into a joint

development agreement under which

the companies will explore development of a complete line of semi-transparent, glass building integrated

photovoltaic (BIPV) products called

Active Solar Glass® (ASG).

Using Konarka’s semi-transparent

Power Plastic®, ASG will come in a

range of colors that will give architects

and designers the ability to make every

glass surface in a building a solar power

plant. ASG will also incorporate other

passive solar technologies, such as lowE coatings, that will result in the industry’s most energy-efficient line of

window, skylights and curtainwalls.

“Until today, aesthetic and performance concerns limited the ability of architects to use BIPV technology in their

designs,” says Leon Silverstein, chief executive officer of Arch. “[This] announcement is about the creation of a

new product category, one that had

been unavailable until now. It is energyefficient and transparent, with superior

vertical performance and a subtle red,

blue or green aesthetic. With these features, BIPV will no longer need to be

confined to spandrel or overhead applications. An entire building can be put

to use, producing its own power, and

looking good doing so.”

With the ability to collect energy at up

to 70 percent off-axis, ASG can harvest

energy from nearly sunrise to sunset,

and can even be used on vertical surfaces. The Konarka film is also bifacial,

so ASG can harness energy from both

indoor and outdoor light.

Konarka’s Power Plastic® was designed using a proprietary polymerbased, organic PV technology that is

free of hazardous materials.

❙❙➤ www.archaluminum.com ■

www.usglassmag.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

Loå3-366® > XL Edge® > Neat®> Preserve®

The “Universal” solution.

A T E

I M

G L

A

S

U

S

L

T

O R

T H

E

F

N

CE

A

YE

From the cold north to the hot south, Loå3-366® (low-e cubed) glass delivers all-star performance. It’s the

one glass that can help you achieve compliance with the new ENERGY STAR guidelines, everywhere in the

country. With the lowest center of glass U-Factor in a double-pane unit (0.24 with argon fill), it offers the best

chance for your current window designs to meet northern zone insulation requirements. With a glass SHGC

of 0.27, Loå3-366® handles the hot south and the most stringent ENERGY STAR solar heat gain restrictions,

regardless of window size. Controlling heat loss in the winter and solar gain in the summer minimizes interior temperature swings, leaving homeowners more comfortable year around. Make every ENERGY STAR

zone a comfort zone – with Loå3-366®. For more information, visit www.cardinalcorp.com.

A

R

-

R

Cardinal CG Company / Superior glass products for residential windows and doors

A CARDINAL GLASS INDUSTRIES COMPANY

O

UN

D

O

P ERF

R

M

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

<

E-Mail

>

Subscribe

Know

What’s New?

The 26th Annual

We Do!

Guide

to New

Products

n times like these, savvy glass companies are investing in innovative and efficient new products to help them pull ahead of their competitors. New products

certainly continue to hit the market—from more efficient glass and windows to

time- and cost-effective material handling equipment and machinery—as evidenced by USGlass magazine’s 26th Annual Guide to New Products. Check out the

next 26 packed pages for information on the new products that just may help you

get more work for less.

I

glass

PPG Introduces Five Blue

Architectural Glass Tints

PPG Industries in Pittsburgh has introduced five blue glass tints, giving it

a broad palette of tints and performance options.

Tw o

new glass substrates are among

the new options. Pacifica glass has been

added to the Oceans of Color collection

of ocean-inspired tinted glass, which

now has Atlantica, Azuria, Caribia and

Solexia glasses. Solarblue glass joins Solargray, Solarbronze, Optigray 23 and

Graylite glasses in the collection of

Earth and Sky Tones.

Three additional tints can be specified

26

USGlass, Metal & Glazing | June 2009

by adding Solarcool reflective coatings to

Pacifica and Solarblue glasses, or by combining Pacifica glass with subtly-reflective, color-enriched Vistacool coating.

❙❙➤ www.ppg.com

Guardian Goes

Low Maintenance,

High Privacy and

Fabricator Friendly

The durability and low maintenance

of ShowerGuard has been combined

with the distinctive beauty of privacy

glass through the new acid-etched

product from Guardian Industries in

Auburn Hills, Mich.: ShowerGuard

SatinDeco.

ShowerGuard resists pitting and stain-

>I

ing as the result of a patented ion beam

sealing process. The addition of acidetching leads to a smooth, flat surface

that disperses light and transforms transparent float glass into translucent glass.

ShowerGuard SatinDeco is available in

10- and 12-mm on clear float glass and

in UltraWhite.

The company also is offering Neutral

70, a fabricator-friendly low-E glass that

the company says is higher performing

and more aesthetically pleasing than

pyrolytic low-E glass. Designed for both

light commercial and residential applications, Neutral 70 offers U-value ratings as low as 0.33 and solar heat gain

coefficient ratings as low as 0.40.

❙❙➤ www.guardian.com

AGC Introduces

Ti-Ac 23™ Low-E Glass

AGC Flat Glass North America in Alpharetta, Ga., has introduced the

newest member of its Comfort Ti™

family of low-E, energy-efficient glass

products. Ti-AC 23™ low-E glass has a

solar heat gain coefficient of 0.23—the

lowest level available in a high-performance product on a clear substrate.

Because it blocks the heat and glare

associated with high levels of sunlight,

while still allowing high levels of light

transmittance, the company says Ti-AC

23 is suitable for commercial projects

where energy efficiency and glare conwww.usglassmag.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Contents

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

The new VUE-50 insulating glass (IG) from Owatonna, Minn.-based Viracon

provides a balance of light, comfort, solar performance and sustainability.

VUE-50 features a visible light transmittance of 49 percent on clear glass and

more than 50 percent on low-iron substrates. It also provides low interior and

exterior reflectance and low UV light transmittance. In addition, it has a solar

heat gain coefficient of 0.26 and a light to solar gain ratio of 1.88, exceeding

the standard for sustainable design based on ASHRAE 90.1 requirements.

VUE-50 has a subtle blue-gray hue and, because the coating is applied after

heat-treating, its flatness is augmented compared to high performance coatings that are heat-treated after the coating application.

❙❙➤ www.viracon.com

trol are priorities, but aesthetics cannot

be compromised.

❙❙➤ www.ti-ac23.com

GLASS

GLASS

Viracon Introduces a New VUE

(From left) VRE1-46, VUE1-50, VE1-2M, VUE1-50, VNE1-63

SGP is nearly invisible. JEB representatives say SGP is the suitable choice for

glass canopy applications, with its excellent edge stability suited for exposed

edge applications found in canopies.

Photo courtesy of Mary Dey of Anco Inc.

❙❙➤ www.jeberkowitz.com

This Glass Looks Alive

JEB Offers

Invisiwall™ Units

JE Berkowitz LP (JEB) in Pedricktown, N.J., has expanded its Invisiwall™

point-supported insulating glass (IG)

wall product line to include point-supported applications. The fittings have

an articulating head, helping to minimize glass stress at the holes, and allow

for field installation of the attachment

bolts for an efficient package for jobsite

delivery. Invisiwall™ IGUs can be conwww.usglassmag.com

structed with tempered glass using

clear, low-iron, pyrolytic or laminated

glass.

Invisiwall also is offered for glass

canopies with SentryGlas® Plus (SGP), a

unique Ionoplast structural interlayer.

SGP is approximately five times stronger

and 100 times stiffer than traditional

PVB interlayer, allowing for thinner,

lighter laminates of equal or greater

strength and/or larger panel options.

When combined with low-iron glass,

LiveGlass, from LiveGlass International Inc. in San Francisco, is a proprietary laminated safety glass that is

composed of two or more lites permanently bonded together with multiple

independent layers of polymers. These

interlayers offer static and dynamic

control of the exterior climate for reductions in energy consumption. As an

example, the company says one layer

may warm the glass, one layer may reflect or absorb the heat of the sun, and

one layer may contain photovoltaics or

LEDs.

Company representatives say that

LiveGlass integrates seamlessly with

“smart” building controls. The monitoring of real-time energy performance

and automated controls deliver optimal

occupant comfort.

continued on page 28

June 2009 | USGlass, Metal & Glazing

27

Contents

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.

Search

Archives

I<

E-Mail

<

>

>I

Subscribe

Guide to New Products

continued from page 27

decorative glass

Walker Adds New Textures

Montreal-based Walker Glass Co. Ltd.

is expanding its Walker Textures™ Nuance Stock line of patterned acidetched glass and mirror with the

introduction of the 300 series. The

stock line of acid-etched patterns is

available in five distinctive designs with

the 100 and the new 300 series.

The 100 series is an acid-etched finish that combines Velour and Satin for a

true sense of privacy. The 300 series is

a satin finish on clear glass for increased visibility to the decor through

the glass. Both of these series feature a

relief effect that adds character to the

glass surface.

❙❙➤ www.walkerglass.com

Digital Images

Decorate Your Lifespace

LifespaceART Inc. in La Habra, Calif.,

puts art to glass with is digital images

printing process. The company uses its

LifespaceART technology to add vi-

continued on page 30

DECORATIVE GLASS GLASS

DECORATIVE

Silastial’s Glass Masquerades as Granite or Marble

After two years of development, Silastial Glass

Works in Sidney, British Columbia, is now able to

produce an all-glass countertop that it says has

similar fabrication and handling characteristics

to granite and marble. The light transfer glass

consists of a 4-milimeter shattered outer layer

on top and bottom, laminated to a float core

ranging from 10 to 19 milimeter in thickness.

28

This product can be produced from 100-percent recycled glass, miscuts from glass suppliers or new glass.

Because of the clear center core, the product produces spectacular visual results

when used in conjunction with LED lighting,

or Mylar graphics and some fabrics also can

be laminated into the glass.

❙❙➤ www.silastialglassworks.com

USGlass, Metal & Glazing | June 2009

www.usglassmag.com

© 2009 USGlass Magazine. All rights reserved. No reproduction

of any type without expressed written permission.