The Heartbeat of the Factory

The Heartbeat of the Factory:

Understanding the Dynamics of Agile Manufacturing Enterprises1

Van Parunak (vparunak@erim.org)

ERIM

Abstract

Manufacturing engineers often characterize the behavior of a manufacturing system with averages over time. This

approach is appropriate for a system that spends most of its time in a steady state. Manufacturing systems that face a

constantly changing demand for a changing array of products may never reach a stable equilibrium. Like a surfer

balanced on a wave, they must continually adjust themselves in a state of constant transition.

Averages and variances are not enough to understand such an adaptive system. The study of naturally occurring

adaptive systems (such as ecosystems, market economies, and various physical and chemical processes) is yielding a

new breed of analytical tools that can characterize the dynamics, or quantifiable time-varying behavior, of these

systems. Agile manufacturing requires the adaptation and application of these tools to manufacturing systems, first to

measure the baseline behavior of current systems, then to model the patterns we observe so that we can test our

understanding of how the systems operate, and finally to manage systems for greatest competitive advantage.

The paper has three parts. Section 1 develops the problem of unstable manufacturing systems in more detail, and

describes why we need to direct attention to their dynamic analysis. Section 2 illustrates the approach by presenting a

simple analysis of data from an actual automotive-like manufacturing plant, using the “time-delay plot,” one of the

tools of dynamic analysis. Section 3 outlines the broader questions that must be addressed to deliver the promise of

this approach.

1. The Problem

Manufacturing engineers often characterize the behavior of a manufacturing system with averages over time. Typical

measures include, “How many parts of which types did we make last month? What utilization did we achieve on the

various machines on the floor? What was our WIP level?” At the level of a supply chain, trading partners are

interested in such measures as aggregate release rates and expected flows of payment.

Averages over time are useful ways to characterize a system that is in a steady state, but they are less helpful if the

system is moving between states. For example, when a manufacturing system is shifting from one product to another,

it may show erratic transients that are not present once the new product is flowing at capacity. Traditionally,

engineers have been more concerned with the steady-state behavior of the system than with its transient behavior as it

changes state, under the assumption that the transition is short compared with the steady-state production run.

These assumptions may be appropriate for a manufacturing system that provides a single product to supply a

constant demand. Such systems are becoming scarce. Competitive pressures are reducing product life times and thus

the length of production runs, forcing systems to change frequently. Mass customization (as of fighter aircraft in the

JAST program or of missiles in the AM3 program) requires systems to assemble products in batches approaching

single items, and generates a highly variable demand for the components of these products. In such an environment

of continual, unexpected change, a manufacturing system may never reach a steady state, but must balance on the

crest of a constantly breaking wave.2 Like a fly-by-wire fighter, its inherent instability permits it to react rapidly to

change, but requires that it leave the comfort of a stable steady state for a world of constant transition.

One way to understand the dynamics of such a complex system is to reason analytically from its detailed internal

structure. This approach has limits when applied to manufacturing systems. First, important components of the

system involve human decision-making and thus cannot (at the current state of the art) be modeled in detail. Second,

analytic solutions are unavailable for systems beyond even a very modest level of complexity (for example, the

equations of motion for three masses under gravitational forces).

1

The latest version of this paper is available on-line at http://www.erim.org/~vparunak/heartbt.pdf .

2

[Preiss 95] offers a useful discussion of the difference between static and dynamic manufacturing systems.

7/17/00 12:14 PM

Copyright © 1995, Industrial Technology Institute

All Rights Reserved

Page 1

The Heartbeat of the Factory

Level of

Understanding

New Perspective

Data Collection

Generalizations and

Patterns

Predictive Rules that

enable Control

Mechanisms

Table 1: Levels of Understanding

Example from Physics

Manufacturing Systems Parallel

Copernicus: Shift focus from earth-ascenter to sun-as-center

Brahe: Detailed measurements

Kepler: Solar “radius” sweeps out equal

areas in equal time

Newton: F = Gm1m2/r2

Shift focus from steady-state to dynamics

Existing shop-floor and supply-chain data; other

data to be gathered

Results of applying dynamic systems techniques to

manufacturing data

???

Einstein: mass warps the space-time

???

continuum

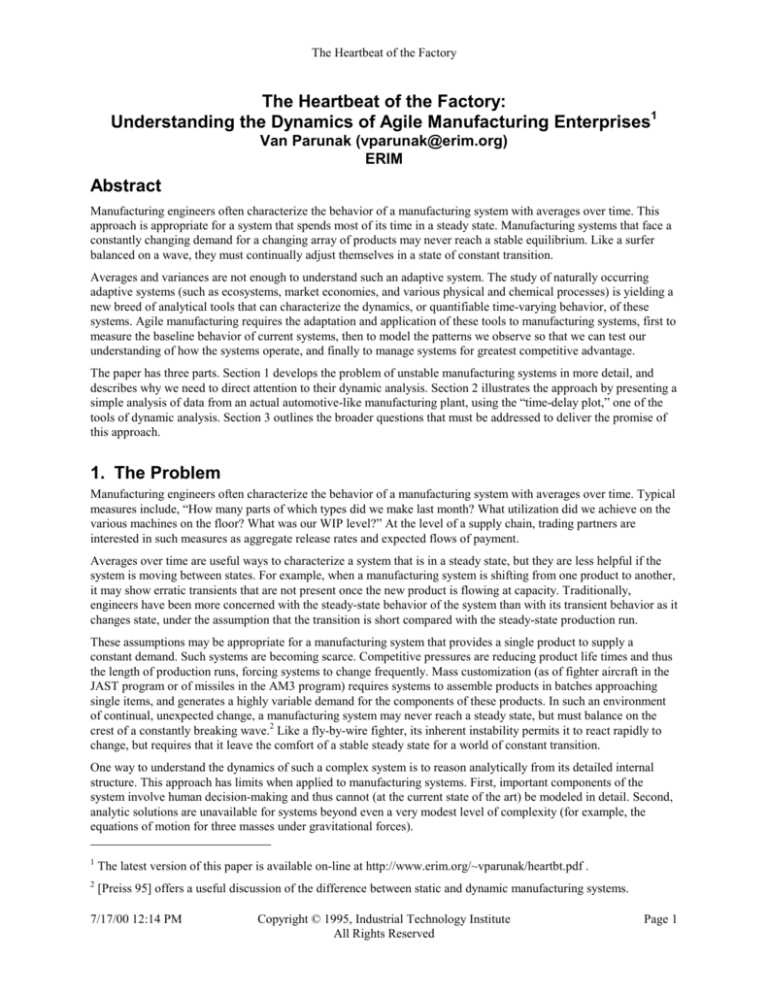

An alternative approach is to begin by studying actual operating systems and attempting to generalize from their

behavior. As an example of this approach, consider the development of Newtonian physics (Table 1). Starting with

the Copernican model of planets orbiting the sun, Brahe gathered detailed observational data on the motion of

planets from which Kepler was able to develop important generalizations. These generalizations in turn led to

Newton’s laws. As manufacturing engineers, we need the manufacturing equivalent of Newton’s laws. The vision of

manufacturing systems that can thrive on change plays the role of the Copernican model. This new perspective tells

us, like Brahe, what kind of data we need to gather (in our case, data that has not had the time variation averaged out

of it). In turn, we may form generalizations at the level of Kepler’s laws that ultimately will permit us to understand

the physics of manufacturing in a manner comparable with Newton’s achievement.

Even before we reach the ultimate abstractions, this approach can yield important commercial benefit. In medicine,

physicians learn to recognize particular patterns of EKG’s or brain wave recordings and the underlying conditions

that they reflect without understanding in detail the mechanisms by which these signals are generated. [Kempf &

Beaumariage 94] have derived some tantalizing patterns from a simplified simulation of a semiconductor fab. Our

vision here is to build a body of understanding that will permit us to use easily gathered data for diagnostic and

descriptive purposes. We can reasonably expect in less than five years to develop a crude tool that can give us the

EKG of a factory or a set of trading partners. Such a tool in turn will refine our understanding of manufacturing

systems.

2. A Real-World Example

This section illustrates the vision by applying a simple tool for analysis of dynamic systems (the time-delay plot) to

actual data from an operating manufacturing plant. It defines the manufacturing context, introduces the analytical

methodology, applies it to the data, and discusses the implications of the results. This exercise does not by any means

exhibit the breadth of the dynamical systems toolbox. We use a shop-floor example because we have that data

available, but the techniques should be applicable to interactions between firms as well. Our objective is to get a feel

for the kind of information that a dynamical perspective on manufacturing can yield. In particular, we will see how

fairly conventional data can distinguish between two different obstacles to the throughput of a plant: various degrees

of equipment shutdown, and dynamic congestion due to the real-time flow of material.

2.1 The Manufacturing Context

The data in this study come from an operating American factory that produces several different models of specialty

vehicles, and from a portion of that factory that is similar in its processes and structures to an automotive body and

paint shop. Parts are mounted on carriers, which in turn travel on a power-and-free conveyor system. Sensors placed

at critical points in the process record the time and identity of passing carriers.

Carriers pass sensors 12 and 17 in that order, and traffic jams sometimes form in the intervening segment of the

conveyor. We will examine the transit times for carriers moving between these sensors. That is, we calculate from

the raw data how long it takes each successive carrier to move from sensor 12 to sensor 17, and record these transit

times in the order in which the successive carriers reach sensor 17. Transit times are recorded in days. That is, a

7/17/00 12:14 PM

Copyright © 1995, Industrial Technology Institute

All Rights Reserved

Page 2

The Heartbeat of the Factory

transit time of 1.5 is one and a half days, or 36 hours. For convenient reference,

Table 2 gives the translation among fractional days, hours, and minutes.

Table 2: Translating Time

Units

Days

Hours Minutes

1.0000 24.000 1440.00

0.1000

2.400 144.00

1.000

0.0417

60.00

0.0100

0.240

14.40

0.0010

0.024

1.44

1.00

0.0007

0.017

0.0001

0.002

0.14

Figure 1 shows the overall series of 1685 successive transit times over a two-week

period. The vertical (logarithmic) axis indicates the transit time for a single carrier in

days, and the horizontal axis counts the successive transits included in the data.

Transit Time (Days

Summary statistics are not enough to understand this scenario, but they are a useful

starting point. Most of the transits are well below 0.1 days (about 2.5 hours), with

prominent peaks about every 200 readings. The largest peak, at index 1200, is

Thanksgiving weekend, and the second largest peak is the previous weekend. The

population on the segment between the two sensors ranges from 0 to 17, with an

average of 4; the average transit time is .066

10

(about an hour and a half); the median transit

time is .013 (about 20 minutes), and the

shortest .0065 (about ten minutes). These

1

numbers capture some basic information

about the shop, but the complex structure of

0.1

the plot shows that there is much more that

they do not capture. In the following sections,

we explore how one simple tool of dynamical

0.01

systems analysis can uncover some of this

information.

1601

1401

1201

1001

801

601

2.2 Analysis Method: Timedelay plots

401

1

201

0.001

Time Series Index

Figure 1: Basic Transit Time Data (Two-Week Period)

We want to learn how successive transit times

depend on one another. A useful tool for this

purpose is the time-delay plot, which plots each value of a time series (on the Y axis) against the

Table 3: Timeprevious value (on the X axis). The justification for this procedure lies in Takens’ theorem

Shifting a

[Takens 81], which shows that such plots capture the topology of the system’s underlying state

Time Series

space, to which we do not have direct access. For our purposes, the proof of the value of the

x=t(i-1) y=t(i)

technique will lie in the results we gain from it.

1

1

For example, consider the time series <1, 3, 5, 4, 3, 2>. Table 3 shows how this series is converted 1

3

into a set of (x,y) pairs by shifting it relative to itself. The y column consists of the time series

3

5

shifted up one position with respect to the x column, and the missing values at the top of the x

5

4

column and bottom of the y column are then made up by duplicating the first or last value,

4

3

respectively, of the series (shown as italicized numbers in the Table). More sophisticated use of

3

2

time delay plots includes different amounts of shift, and constructing triplets or higher-order data

2

2

points by a similar mechanism, but the single shift is sufficient to illustrate the approach.

t(i)

t(i)

Figure 2 shows the results of plotting these artificial pairs. The trajectory begins at the lower left corner of the plot

with (1,1), and proceeds clockwise.

1

5

What would less-structured data

look like? Figure 3 shows such a

0.8

4

time-delay plot generated from 100

0.6

3

points randomly generated from a

uniform distribution on the interval

0.4

2

[0,1].

0.2

1

0

0

0

0

1

2

3

4

5

t(i-1)

Figure 2: Time Delay Plot of Table 3

7/17/00 12:14 PM

Copyright © 1995, Industrial Technology Institute

All Rights Reserved

0.2

0.4

0.6

0.8

1

t(i-1)

Figure 3: Plot of a Random

Series

Page 3

The Heartbeat of the Factory

5

2.3 Plotting the Transit

Data

0.3

4

3

0.2

0.1

0

0

0.05

0.1

0.15

0.2

0.25

0.3

t(i-1)

Figure 5: Transits < 1 Day

0.07

0.06

0.05

0.04

t(i)

Figure 5 shows several large squares reminiscent of the two in Figure

4. It also contains some “imperfect” squares, and a distinctive diagonal

clump at the lower left corner. We can focus in on this latter feature by

restricting ourselves to transits less than .07 day, or about an hour and

a half(1610 points), in Figure 6.

t(i)

t(i)

Contrast the disorder generated by

2

only 100 points in Figure 3 with

Figure 4, the time delay plot for all

1

1685 points of the transit data. The

0

two weekend shutdowns produce

0

1

2

3

4

5

large square trajectories that

t(i-1)

dominate the display, but there

Figure 4: Full Data Set

appears to be some orderly structure

in the mass of points at the lower

left. To explore this region further, we eliminate from the data all

transit times greater than one day. The remaining 1660 points produce

Figure 5.

0.03

# of High Values

Figure 6 is still much simpler than the random plot in Figure 3, even

0.02

though it contains more than sixteen times as many points. In addition

0.01

to the familiar squares, the plot shows a strong, clearly defined

diagonal band. Points within the diagonal band result from successive

0

transits that are close to the same duration, while points off the

0

0.01 0.02 0.03 0.04 0.05 0.06 0.07

diagonal result from successive transits that differ widely from one

t(i-1)

another in duration. This observation suggests that we compute the

Figure 6: Transits < .07 Day

difference in transit between each successive pair of points, and

observe how the resulting differences are distributed.

900

Figure 7 plots the number of pairs of successive

800

700

points differing by more than a threshold value, as a

600

function of that threshold. For example, the point at

500

(x,y) = (.001, 900) means that 900 pairs of successive

400

points have transits differing by at least .001. The

300

resulting curve has a sharp elbow at about .005. The

200

right-hand leg of the curve (with pairs differing by

100

more than .005 in transit time) produces the squares

0

0

0.001 0.002 0.003 0.004 0.005 0.006 0.007 0.008 0.009 0.01

on Figure 6, while the left-hand leg of the curve

Threshold

produces the diagonal. The values on the left-hand

Figure

7:

Number

of

Transit

Differences > Threshold

leg are higher than those on the right-hand leg,

corresponding to the higher density of points along the

900

diagonal of Figure 6.

800

The empirical differences between the squares and the

diagonal on Figure 6 (shape, density of points, fit to

7/17/00 12:14 PM

700

# of High Values

Figure 8 shows the result of fitting straight lines by

least squares to the two legs of Figure 7. The fit to the

left-hand portion is y = -233828x + 1117, and the fit to

the right-hand portion is y = -12703x + 159. The

straightness of the individual legs and their sharp elbow

emphasize the distinctness of the two regions in Figure

6, and the location of the elbow shows where the edge

of the diagonal band lies.

600

500

400

300

200

100

0

0

0.001 0.002 0.003 0.004 0.005 0.006 0.007 0.008 0.009

0.01

Thre shold

Figure 8: Straight-Line Fits

Copyright © 1995, Industrial Technology Institute

All Rights Reserved

Page 4

The Heartbeat of the Factory

different underlying straight lines) suggest that they result from different underlying causes.

These simple examples show the ability of the time-delay plot to call our attention to patterns in shop data that would

escape our notice if we averaged out the time component or worked only with trend charts. In the next section, we

will learn what these various patterns mean.

2.4 Interpreting Patterns

The simple device of a time-delay plot graphically reveals two qualitatively different kinds of time-varying behavior

in our data. One manifests itself as squares of varying degrees of symmetry. The other generates a strong diagonal

band of points. By examining more carefully the data behind these plots, we can understand these behaviors in ways

that can help us manage a factory more efficiently.

2.4.1 Squares: Line Stoppages

It is helpful to walk through the events that generate the smaller square on Figure 4, corresponding to the weekend of

Nov. 18-19, 1989. Just before the line stops for the weekend, the transit times are small (about .01 day) compared

with the length of the weekend. When the last carrier clears sensor 17 before the weekend, its transit time, t(i = 580),

is close to that of the one before it, t(i-1 = 579), generating a point in the lower left corner of the plot. When the line

stops, fourteen carriers have passed sensor 12 but not yet reached sensor 17, so their transit time (about 2.25 days

each) includes the shutdown. For the first carrier to arrive at sensor 17 after the line restarts, t(i = 581) is large, but

t(i-1 = 580) is small (being the transit time of the last carrier to clear before the weekend), generating the upper left

corner of the plot. The other thirteen carriers that passed sensor 12 but not sensor 17 before the weekend all have

similar transit times to the first one, since the length of the weekend swamps any variation in their actual travel time.

Thus t(582) through t(594) are large and about the same as t(581), generating the upper right corner of the plot. At

the lower right corner, t(i-1 = 594) still records the transit time of the last weekend carrier, but t(i = 595) now records

the much lower transit time of the first carrier to pass sensor 12 after the shutdown. Since subsequent carriers also

have transit times much shorter than two days, subsequent points return to the lower left corner of the plot.

This analysis leads us to recognize other squares in the plots as resulting from similar conditions. A trajectory forms

a symmetrical square when all carriers have been in the segment for periods of time that are much larger than their

usual transit times, and when the differences between those periods are small (on the order of usual transits). This

condition could result from a downstream stoppage alone if the segment were full when the stoppage began, thus

keeping upstream processes from adding carriers. A square can also result if the segment is not full, as long as

upstream processes shut down before or concurrently with downstream ones, and stay down until the downstream

starts up again.

Four of the squares in Figure 5 have the same structure as the large squares in Figure 4: a one-step rise from a low

value to a high one (0.26 for t(789) through t(793), .2 for t(986) - t(990), .16 for t(167) and t(168), .12 for t(407) and

t(408)), followed by a one-step drop back to a low value. These squares suggest shutdown of the line for periods of

time comparable to their magnitudes, and in fact all occur between midnight and 8 AM, probably representing

maintenance shutdowns.

2.4.2 Imperfect Squares: Interacting Stoppages

0.5

0.4

0.3

t(i)

Figure 9 and Figure 10 show two imperfect squares that result from timing

interactions between stoppages upstream and downstream of the 12-17

segment. To understand these patterns, we need to distinguish the relative

timing of upstream and downstream stoppages, and whether or not the

segment is full when the downstream process stops. The upstream process

might not stop at all, or its stoppage might overlap the downstream stoppage

in four different ways, illustrated in Figure 11. Thus we have a total of ten

possible conditions to consider, which together generate four different

patterns, as illustrated in Figure 12.

0.2

0.1

0

0

0.1

0.2

0.3

0.4

0.5

t(i-1)

Figure 9: t(1206) - t(1226)

7/17/00 12:14 PM

Copyright © 1995, Industrial Technology Institute

All Rights Reserved

Page 5

The Heartbeat of the Factory

0.15

0.1

t(i)

As noted in the previous section, a perfect square (Figure 12a) results any time

the segment is full to capacity when the downstream stoppage begins, whether or

not upstream processes stop. This is a fairly uncommon circumstance, and the

more likely cause of a perfect square is a stoppage of the upstream processes that

includes the complete downstream stoppage.

0.05

When the segment still has room and the upstream stoppage overlaps the

downstream one (that is, ends before the downstream stoppage ends), additional

carriers that enter the segment do not need to wait as long as the carriers that

0

were there when the downstream stoppage began. As before, the carriers in the

0

0.05

0.1

0.15

t(i-1)

segment for the full stoppage generate the upper right corner of the square, but

the right side drops only to the age of the first carrier to enter the segment when

Figure 10: t(411) - t(436)

the upstream stoppage ended (Figure 12b). The length of the vertical drop

corresponds to the overlap between the upstream

Downstream Stoppage

and downstream stoppages. Because the first

Upstream Stoppage

carrier from the restarted upstream process still

Overlaps

has to wait for part of the downstream stoppage,

Overlapped

its transit is longer than normal, but not as long as

During

the complete downstream stoppage. Successive

Includes

carriers are delayed even less by the downstream

stoppage, until the stoppage ends completely and

Time

normal transits resume. This situation gives rise to

Figure 11: Timing Relations between Downstream and

Figure 9.

Upstream Stoppages

When an upstream stoppage begins partway through a

Relation of

downstream stoppage, all of the carriers it supplied to the

Upstream to

segment between the start of the downstream stoppage and the

Downstream

start of its own stoppage must wait in the segment for a length

Stoppage:

of time equal to the overlap between the two stoppages. Again,

Includes

the right-hand corner of the square represents carriers in the

a

segment when the downstream process stopped. Since the

upstream process was still active at that point, the next several

carriers have transit times only incrementally shorter, but all at

b

Overlaps

least as long as the overlap. The final drop of the right-hand

side corresponds to the size of this overlap (Figure 12c). This

situation gives rise to Figure 10.

Overlapped

c

While we have not identified an example in the data, an

upstream stoppage contained completely within a downstream

stoppage would be expected to yield a combination of the

previous two figures, with the large half-box on the right-hand

side corresponding to the upstream stoppage (or perhaps

starting earlier if the segment fills) (Figure 12d).

During

d

(None)

The explanation we have just developed requires further

refinement. The stairsteps on Figure 9 and Figure 10 are much

Full

Not Full

larger than would be generated by the differences in arrival

Segment when Downstream Stops

rates of carriers under normal conditions. The size of these

Figure 12: Varieties of Perfect and Imperfect

normal rates can be seen in the fine detail at the lower-left and

Squares

upper-right corners of Figure 10. The larger steps in fact

reflect repeated intermittent stoppages of the upstream process (“upstream stuttering”) that group the late-arriving

carriers into batches. All the carriers in a batch arrive at about the same time, and generate a single step. In Figure 9,

these stoppages occur as the upstream processes restart, and reflect difficulty in bringing the system up after a

prolonged shutdown. In Figure 10, the steps occur at the beginning of a system-wide shutdown rather than its end,

and reflect a pattern of cascading system breakdown.

7/17/00 12:14 PM

Copyright © 1995, Industrial Technology Institute

All Rights Reserved

Page 6

The Heartbeat of the Factory

0.2

0.15

t(i)

Figure 13 exhibits a new phenomenon: stairsteps up as well as

down. The upward stairsteps result when one downstream

stoppage is followed by another before the backlog from the first

has cleared the segment. Just before the first stoppage, the

segment fills with sixteen carriers. When the line restarts, only

two are able to escape before the line stops again, generating the

first step at about 0.1. Another carrier arrives during this time,

leaving the segment with a population of fifteen carriers. Of these

fifteen, fourteen are resident during both stoppages, while one is

resident only for the second stoppage. When the line again

restarts after the second stoppage, the first fourteen carriers to

exit have transit times equal to the total time between the first

stoppage and the second resumption, leading to the second

upward step. The next carrier to exit has been in the segment

through the second stoppage, so the plot drops down only part

way. The remaining steps down are due to upstream stutter, as

observed in Figure 9.

0.1

0.05

0

0

0.05

0.1

0.15

0.2

t(i-1)

Figure 13: t(1421) - t(1445)

Thus the large squares that pervade the data tell a detailed story of the patterns of equipment shutdown that

characterize a facility. We have extracted considerable information from the patterns in only a single segment of the

conveyor system. These patterns could easily be detected by automatic systems to isolate repeated correlations

between the failure of different processes, and thus could help focus maintenance activity more efficiently.

2.4.3 The Diagonal: Dynamic Congestion

7/17/00 12:14 PM

81

81

91

71

71

41

41

61

31

31

61

21

21

51

11

11

51

1

6

5

4

3

2

1

0

91

Population

What is the origin of this periodicity? Figure 15

shows essentially the same pattern in the

population of the 12-17 segment over the same

set of transits. As the population of the segment

builds up, newly-arrived carriers must wait for

the earlier ones to be processed, and their transit

time becomes greater than the transit time for a

carrier that arrives when the segment is relatively

empty. The oscillation of period 60 that generates

the diagonal band in Figure 6 appears to be due

to “traffic-jam dynamics,” the effect of crowding

1

Transit

Our data shows not only squares of varying degrees of symmetry, but also a distinct diagonal band, in which transit

times vary in small steps (less than .005 day, which is about 7 minutes). The elbow in Figure 7 suggests that these

small steps may have a different origin

3.00E-02

than the big ones that generate squares. To

explore further, we select a series of 96

2.50E-02

points (t(1096) through t(1191)) within

2.00E-02

which there are no transitions greater than

.005 day. Even without large shifts, the

1.50E-02

transit times vary by a factor of more than

1.00E-02

four, from a maximum of .029 to a

minimum of .0068. Figure 14 shows how

5.00E-03

the lengths of these transits vary from one

0.00E+00

to the next. The first 30 or so transits

successively shrink in length. The next 30

Index

or so increase successively, and then there

Figure 14: Variation in t(1096) - t(1191)

appears to be another period of reduction,

though not as sharp as the first. The

8

difference in clock time covered by the first sixty

transits is about four hours.

7

Index

Figure 15: Segment Population in t(1096) - t(1191)

Copyright © 1995, Industrial Technology Institute

All Rights Reserved

Page 7

The Heartbeat of the Factory

within the segment. Further study is needed to determine the cause of this oscillation. It might be driven by the

timing of neighboring processes. It might also result from the combination of a random impulse (such as a

momentary line stoppage due to a machine failure) and the finite capacity of the 12-17 segment. Any physical

segment has an upper limit to its population, which imposes a nonlinear term in the recurrence relation governing its

population, and such a nonlinearity can lead to oscillation under the right circumstances.

2.5 Discussion

Using only a single simple tool of dynamical systems analysis, and concentrating on only a single segment of a

complex material transport system, we can peel away layers of behavior from shop floor data and distinguish

different sorts of dynamic behavior, including

•

system-wide shutdowns;

•

timing relations between upstream and downstream stoppages;

•

intermittent “stuttering” of selected processes, either when the line is started up or as a precursor to a shutdown;

•

periodic fluctuations in traffic density at selected locations in the line (“traffic-jam dynamics”).

These phenomena can easily be tracked and monitored automatically, enabling factory managers to distinguish

between two important kinds of obstacles to throughput: those that result from machine failure, and those that result

from dynamic congestion. The remedies to these problems are quite different. Once we can measure the relative

impact of these two problems inexpensively, we can make responsible decisions about allocating resources to

improve throughput. For example, if unplanned machine shutdowns dominate the dynamics of a particular shop,

increased preventive maintenance may be in order. If slowdowns are due to dynamic congestion, machine

maintenance is of little help, and the shop needs to devote attention to improving methods of shop-floor scheduling

and control. Techniques such as these can support decisions about the relative budgets needed by the maintenance

and industrial engineering departments.

As interesting as these observations are, they are only examples of a single technique in a single context. The larger

point is that dynamical systems analysis is a tool with great potential for understanding and managing the operation

of complex manufacturing facilities, particularly those that must handle changing mixes of different products. The

lessons of this exercise can be generalized in two directions: techniques and application domains. There are many

more techniques whose applicability should be explored, and the domains to which they are relevant include not only

shop floor, but also supply chains and other closely-coupled networks of trading partners.

3. What Needs to be Done?

Analysis techniques for nonlinear systems hold considerable promise for manufacturing systems engineering, but to

date the research community has not devoted much attention to this application area. In this section we survey some

of the problems that need to be addressed, and suggest some next steps to advance our abilities in this domain.

3.1 Problems to be Solved3

Figure 16 proposes an overall roadmap of the techniques we need to develop to apply dynamical systems analysis to

manufacturing enterprises. First, we need ways to measure the state of the enterprise. Then we need to interpret the

resulting information to yield insights about what is right or wrong. Finally, we need to implement these insights by

taking action in the enterprise itself.

3

The insights in this section were developed by a discussion panel at the workshop on Enhanced Manufacturing

Technologies, sponsored by Sandia National Laboratories, JAST, ARPA, and the Department of Energy in

Albuquerque, NM, Oct 1995.

7/17/00 12:14 PM

Copyright © 1995, Industrial Technology Institute

All Rights Reserved

Page 8

The Heartbeat of the Factory

3.1.1 Measurement: Gathering Data from the

Enterprise

Enterprise

Initially, the challenge in understanding manufacturing

dynamics may not be lack of information, but how to select

Implementation

Measurement

from the abundance of information that is available. The

example analyzed in this paper illustrates the kind of

information that can be routinely collected, and is often

gathered now in order to compute time-averaged performance

Insight

Information

statistics. To select from this jungle of information, we need

some idea of what different kinds of measurements can tell us

Interpretation

about the system. For example, the series of transit times

between sensors 12 and 17 yield useful patterns that do not

Figure 16: A Roadmap for Manufacturing

emerge as readily from the interarrival times at a single

System Dynamics

sensor. In some cases, theoretical approaches may suggest

that some measurements will be more “information-rich” than others, but in general, researchers need to conduct the

equivalent of a biologist’s collecting trip in the jungle of factory data to learn what sorts of information will be most

valuable.

The value of data will depend heavily on how it is organized, which in turn depends on the organizational structure

from which the numbers are gathered. [Packer 95] reports that useful management of the F16 JAST case study

depends on partitioning the enterprise in such a way that the behavior of organizational units directly impacts the

metrics by which they are evaluated, a process dubbed “getting the beans in the box.” Different measurements will

be appropriate for different organizational functions (e.g., production vs. field service). It is an open question which

measurements useful at one level of a given function will be appropriate for other levels. Patterns of transit times are

likely to be informative both between stations on the factory floor and between successive partners in a supply chain,

but each of these domains probably has important metrics that are less relevant to the other.

While much useful data may be available essentially for free, important insights may depend on information that is

not currently being gathered, for which new collection mechanisms need to be established. Thus in addition to

learning to assess the value that can be derived from information of a given kind, we need to quantify the cost

associated with collecting each class of measurement.

3.1.2 Interpretation: Making Management Decisions

Like raw data, some analysis procedures for dynamical systems are available off-the-shelf, having been developed

for applications other than manufacturing. For example, delay plots, power spectra, BDS and the related Savit delta

statistic, phase space and Poincaré plots, and computation of Lyapunov exponents and various measures of fractal

dimension, have been applied to many different kinds of data and can readily be adapted to manufacturing

information. Just as some data are more useful for our purposes than others, we need to learn which techniques are

most appropriate to the complex noisy information available in manufacturing. In some cases, the unique challenges

of manufacturing may suggest the development of new methods.

It is not enough to characterize a manufacturing system in terms of its formal dynamics. Simply knowing that a

process has an attractor of a particular shape or dimensionality does not lead to business decisions. As we learn to

characterize the dynamics of manufacturing systems, we must correlate particular dynamical patterns with business

performance, thus forming the basis for dynamically-based decisions support tools. The problem is inherently multidimensional. We cannot usefully optimize any single dimension, but need to learn how to combine different

characterizations to reach useful recommendations. In general, observation of real-world operations will provide data

for only some of the conditions of interest, and we will rely on simulation to explore the effects of changing various

operating parameters.

The initial impetus for a dynamical approach to manufacturing measurements is the growing demand for enterprises

to offer a wide scope of products and the observation that such an enterprise may never reach a steady state. To be

useful in such a context, our metrics must be correlated with the scope of products that an enterprise can offer. We

want to be able to reason in two directions. First, what can a given set of observed dynamics tell us about the scope

7/17/00 12:14 PM

Copyright © 1995, Industrial Technology Institute

All Rights Reserved

Page 9

The Heartbeat of the Factory

that a given enterprise can support? Second, given a proposed scope, can we estimate the resulting dynamics and

thus determine whether we can meet the proposal?

3.1.3 Closing the Loop

Neither information nor abstract insights are sufficient to meet the demands of modern commercial life. We must

move from insight to actual changes in the enterprise as a result of our measurement activity. Making changes

requires identifying the drivers of complex dynamics, learning which levers to pull to move a system’s dynamics

toward a more desirable configuration. These levers are often counter-intuitive. For example, in some cases of

contention for constrained resources, providing decision information too rapidly may lead to instability [Kephart et

al. 89].

The human side of manufacturing presents a particularly challenging implementation issue. Unlike custom

manufacturing equipment, unique skills cannot be reliably replaced on the open market. The ability of multi-skilled

workers to integrate different processes in an enterprise is only one example of a characteristic of human capital that

can be critical to success but difficult to anticipate in advance. The general US practice of “at will” employment

makes a company’s workforce especially liable to unexpected change and complicates our ability to project the

results of certain management decisions.

We need a new generation of management models that take account of the dynamics of changing organizations.

Developing these models will require extensive collection and analysis of data, development of theories, and

modeling and experimentation to validate these theories.

3.2 Next Steps

There is currently no formal program to support research and development in the application of dynamical systems

theory to manufacturing. ERIM has sketched out a research agenda in this domain,4 and is informally cultivating a

network of academic researchers and manufacturing professionals with interest in the area, but real progress depends

on support. A useful first step would be to convene a workshop of interested parties around a common data set such

as the one analyzed here, to illustrate what can be done with current techniques and to set priorities for ongoing

research. Such research will require an infrastructure that includes an archive of operating data from actual shops and

supply chains that researchers can explore for useful dynamical patterns, and validated simulation models of some of

those environments to test theories generated from data analysis.

3.3 Postscript (July 2000)

Since this paper was written, we have applied these techniques beyond the factory floor to the supply network in the

DASCh (Dynamical Analysis of Supply Chains) and SNAP (Supply Network Agility and Performance) projects.

Papers on the DASCh project are available at http://www.erim.org/cec/projects/dasch.htm.

References

[Kempf & Beaumariage 94]

Unpublished working paper.

K.Kempf and T.Beaumariage, "Chaotic Behavior in Manufacturing Systems."

[Kephart et al. 89]

J.O.Kephart, T.Hogg and B.A.Huberman, "Dynamics of Computational Ecosystems."

Physics Review 40A, 404-21.

[Packer 95]

M.Packer, Lockheed/Martin, “Cost Reductions Achieved on the F-16.” Presentation at Workshop

on Emerging Manufacturing Technologies, Albuquerque, 18 October 1995.

[Preiss 95]

K.Preiss, “Mass, Lean, and Agile as Static and Dynamic Systems.” Perspectives on Agility Series,

Vol. PA95-04. Agility Forum.

4

A white paper on “Complexity Theory in Manufacturing Engineering: Conceptual Roles and Research

Opportunities” is available at http://www.erim.org/~vparunak/3roles.pdf .

7/17/00 12:14 PM

Copyright © 1995, Industrial Technology Institute

All Rights Reserved

Page 10

The Heartbeat of the Factory

[Takens 81]

F.Takens, “Detecting strange attractors in turbulence.” Dynamical Systems and Turbulence,

Warwick 1980, Lecture Notes in Mathematics 898, Springer-Verlag, 366-81.

7/17/00 12:14 PM

Copyright © 1995, Industrial Technology Institute

All Rights Reserved

Page 11