DS400/DS600 sub units

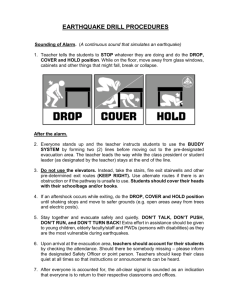

advertisement

<<Contents>> <<Index>> General Specifications DR240 hybrid recorder — expandable type (Style number: S8) DS400/DS600 sub units (Style number: S8) GS 04M01D01-12E Refer to the following cautionary notes before you configure your system. DARWIN is a system comprising a number of data-acquisition equipment components. In the course of system growth, new models, software, various input/output modules and optional features are added to the family to enhance the systems expandability and flexibility. You can check the versions of your equipment and software by referring to the style number: Sn* shown on the nameplate of the main unit. When configuring a system, you must confirm that the style number of each componentunit and software meets the following requirements: * release number in the case of software: Rn (1) The style number of each input/output module must be the same as or lower thanthat of the main unit or sub-unit to which the module is connected. (2) The release number of a dedicated software package must be the same as or higherthan the style number of the main unit or sub-unit where the package is installed and where it performs control. Any equipment/software not meeting these requirements is incompatible with your system configuration. For information on how to upgrade to compatible equipment/ software, consult our sales personnel. The DR240 is a highly reliable process monitor hybrid recorder that contains a high withstand voltage semiconductor relay developed by Yokogawa. It uses small input modules to record measured industrial variables, physical variables such as temperature signals in realtime in the field, and can also transfer the measured data to a personal computer. The main unit of the expandable type can be connected to a maximum of six sub units DS400/DS600. Also, you can freely connect various input/output modules to suit the measurement conditions, and increase the number of measurement points to a maximum of 300. Units can be connected to each other with dedicated cable over a distance of up to 500 m. This makes for reduced wiring and speedier wiring work, and enables you to configure a flexible remote measurement and recording system. In addition, by using the dedicated package software, the measurement conditions can be set and continuous data acquisition performed easily. (1) Compact: Occupies only about one half of the size (depth) of the HR2500E. (2) High speed: Can measure 300 channels/500 ms. (3) A large variety of inputs: Universal (DC voltage, thermocouple, RTD, contact), DC V/TC/DI dedicated inputs, mA, power monitor, strain, pulse, DI. (4) Superb environmental toughness (input modules): –10°C to 60°C (5) Remote measurement: The sub unit is designed to be connected to the main unit with dedicated cable, enabling it to be located up to 500 m away from the main unit. ■ Outline of DR240 hybrid recorder (1) The DR240 main unit can set and control the sub units to which it is connected with dedicated cable. (2) The DR240 main unit controls, communications module and DI/ DO module to which it is connected. (3) Data measured using the input modules is collected by the DR240 main unit, via sub units. (4) Measured phenomena can be displayed and recorded by means of the DR240 main unit. (5) The measured results collected by the DR240 main unit can be transferred to a personal computer via a GP-IB, RS-232-C, RS422-A/RS-485, Ethernet interface. ■ Outline of sub units The DS400/DS600 sub unit functions as an interface between the expandable version of the DR230/DR240 hybrid recorder and the various input/output modules to which it is connected. A maximum of four input and output modules of various kinds (Max.4 slots/40 channels) can be connected to the DS400, and a maximum of six input and output modules (Max.6 slots/60 channels) can be connected to the DS600. A maximum of six sub units can be connected to one main unit. Both DS400 and DS600 sub units can be connected to the same main unit. The main unit can be connected to the sub units, or the sub units to each other, with dedicated cable, enabling them to be separated by up to 500 m. The sub units have excellent environmental toughness and can be installed very easily, enabling them to be installed over a wide area without environmental restrictions. (1) Setting and control of the connected input/output modules (by means of commands from the DR230/DR240 main unit. (2) Measured values output to the DR230/DR240 main unit. GS 04M01D01-12E © Copyright November 1995 (YK) 12th Edition: Feb. 2012 (KP) <<Contents>> <<Index>> ■ Configuration Unit configuration Recorder main unit + sub units DS400/DS600 + Various input/output modules + Communication interface module The main unit of the DR240 expandable type can set and control various input and output modules. Component units DR240 expandable type recorder main unit Available module groups You can freely configure a DR240 expandable type hybrid recorder system for different functions by selecting modules from the following module groups and connecting them to the main or sub units. Input modules: Universal (DC voltage, thermocouple, RTD, contact), DC V/TC/DI dedicated input modules, mA, power monitor, strain, pulse, DI input. Alarm modules: 4 channels (transfer contact) or 10 channels (make contact) (The number of alarm channels can be increased in module units.) Communications modules: Select one type from GP-IB, RS-232-C, RS-422-A/RS-485, Ethernet. DI/DO modules: Alarm 2-point output (transfer contact) and fail/ chart end output and remote control input modules Extension module: For remote measurement DS400 sub unit b -/B -/A ■ Package software CH1 b -/B -/A CH1 CH2 b CH2 CH3 -/B -/A CH1 b CH4 CH3 CH5 CH4 CH6 CH5 CH7 CH6 CH8 CH7 CH9 CH8 CH10 CH9 -/B -/A CH1 CH2 • DARWIN DAQ 32 (Standard Package) • DARWIN DAQ 32 Plus (Optional Package) General DAQ 32 and DAQ 32 Plus are software packages developed by Yokogawa specially for the DARWIN series. These packages run on a personal computer, achieving highly dependable data acquisition using DARWIN series units (DA100, DC100, DR130, DR230, and DR240) and superb operability. The main differences between the two packages are in the monitoring functions. The DAQ 32 only offers two display formats - waveform trend and digital; has 2 groups of 10 channels/window; and does not support alarm display. If simultaneous multi point monitoring or more flexible display forms of data such as level meter, analog meter, and thermometer faceplates, and alarm indications are required, use the optional DAQ 32 Plus. CH2 CH3 STATUS CH3 CH4 CH4 CH5 CH5 CH6 CH10 SUB CH7 CH6 CH8 CH7 CH9 CH8 CH9 CH10 UNIT POWER CH10 100-240 VAC 50/60Hz 70VA MAX DS600 sub unit b -/B -/A CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8 CH9 CH10 b -/B -/A CH1 b CH2 -/B -/A CH1 b CH3 CH2 -/B -/A CH1 b CH4 CH3 CH5 CH4 CH6 CH5 CH7 CH6 CH8 CH7 CH9 CH10 CH8 CH9 CH10 CH2 CH3 -/B -/A CH1 CH2 STATUS CH4 CH5 CH6 CH7 CH3 CH4 CH5 SUB CH7 CH9 CH8 CH10 UNIT CH6 CH8 CH9 POWER CH10 100-240V AC 50/6 0Hz 2 70VA MAX GS 04M01D01-12E GS 04M01D01-12E Input Module Sub unit Main unit Set-up and control software Personal computer DCV Alarm output module I/O module DI/DO module TC Extension module DAQLOGGER RTD Universal DC V/TC/DI module DARWIN DAQ 32 Plus package software Remote measurement DARWIN DAQ 32 DI module Install Contact Status Power module AC ~ mA(current) module Pulse module Dedicated cable (up to 500 m) Communication interface cable Input module No alarm module or DI/DO module can beconnected to theright side of this input module. ■ DR240 Expandable type current A Strain module PULSE GP-IB module RS-232-C module STRAIN RS-422-A/485 module Communication interface module Ethernet module <<Contents>> <<Index>> 3 <<Contents>> <<Index>> ■ Connecting modules ■ Standard Specifications Main unit: Communications modules: Select one type from GP-IB, RS-232-C, RS-422-A/RS-485, and Ethernet. DI/DO modules: Alarm 2-point output (transfer contact) and fail/ chart end output and remote control input modules Alarm output modules: 4ch or 10ch. Connect the input modules directly to the DS400/DS600 sub unit (you cannot connect the input modules directly to the main unit), or remotely to the recorder main unit via sub units. Sub unit DS400/DS600: Input modules: Universal (DC voltage, thermocouple, RTD, contact), DC V/TC/DI dedicated input modules, mA, power monitor, strain, pulse, DI input. Alarm modules: 4-point output (transfer contact) or 10-point output (make contact) (The number of alarm channels can be increased in module units.) DI/DO modules: Alarm 2-point output (transfer contact), remote control input and fail output modules Extension module: For remote measurement Gneral Specifications Definition of number of connections Main unit: The number of input modules connected is 0. Also, 1 communications module, 1 DI/DO module or alarm output module can be connected. Sub unit (DS400): The maximum number of modules per slot that can be connected is 4. Number of input modules + Number of DI/DO modules + Number of alarm modules ≤ 4 Sub unit (DS600): The maximum number of modules per slot that can be connected is 6. Number of input modules + Number of DI/DO modules + Number of alarm modules ≤ 6 all to common: • The alarm output and DI/DO module must be connected on the left side of the input modules. • One DI/DO module can be connected to one expandable type system. • One extension module can be connected to one sub unit. • The standard operating temperature and humidity are different for each module type. Therefore, always make sure to verify this when connecting the module. ■ Connecting sub units Type of sub units DS400 sub unit: For 4 slots DS600 sub unit: For 6 slots Number of sub units to be connected Construction Panel mounting method: DR240: Use the mounting brackets provided. DS400/DS600: When mounting the unit on a panel, install it vertically on the Rack mounting. When mounting it on the floor, widen the stand at the bottom of the main unit so that the panel face is vertical. Materials: Steel plate, aluminum alloy, plastic moldings Paint color: Display: Slate gray light (equivalent to Munsell 0.1 PB 4.6/ 0.2) Core: Lamp black (equivalent to Munsell 0.8Y2.5/0.4) External dimensions: Main unit: Approx. 444 (W) × 288 (H) × 308 (D) mm DS400 sub unit: Approx. 336 (W) × 165 (H) × 100 (D) mm DS600 sub unit: Approx. 422 (W) × 174 (H) × 100 (D) mm Weight: Main unit: Approx. 12 kg DS400 sub unit: Approx. 2.5 kg (with 4 input/output modules installed) Approx. 0.9 kg* DS600 sub unit: Approx. 3.5 kg (with 6 input/output modules installed) Approx. 1.1 kg* *the weight of each unit without modules installed. Input Measurement range: NOTE Refer to “Standard connection modules” in GS 04M01E01-11E for detailed specifications of the measurement range of each input module. Measurement interval: Select an interval from 0.5, 1, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30 and 60 seconds. It depends on the minimum measurement interval of input modules installed (when modules with different minimum intervals are installed together, the measurement interval is determined by whichever module has the maximum interval). Max 300 channels/500 ms (with sub units installed) A/D integration period: Selectable or automatic switchover between 20 ms (50 Hz), 16.7 ms(60 Hz) and 100 ms (10 Hz) However AUTO (automatic selection) does not function on the DC power supply model. Expandable type: A maximum of six sub units can be connected. (This also applies when 4-slot sub units and 6-slot sub units are connected to the same main unit.) Method of connecting sub units A sub unit can be connected to either the main unit or another sub unit with dedicated cable. NOTE Refer to “Standard connection modules” in GS 04M01E01-11E for detailed specifications of the above modules. 4 GS 04M01D01-12E <<Contents>> <<Index>> Recording Recording method: Raster scan method, 10-color wire dot recording Number of recording points: Measurement results: 300 points Computation results: 60 points Recording paper: Ordinary recording chart, Z-fold chart (total width 342.5 mm, total length 30 m) Effective recording width: 250 mm (when dot-print recording) Recording accuracy: Dot recording: ±(0.1% of recording span + measurement accuracy) Digital print: Depends on measurement accuracy. Max recording resolution: Dot recording: ±0.1 mm Digital print: Depends on measurement resolution Recording color: Analog trend mode Dot recording: Purple, red, green, blue, brown, black, navy blue, yellow-green, red-purple, orange (You can specify a color for each channel.) Digital printing: black Alarm printing: Red (Alarm release mark : blue) Logging mode Digital printing: Purple Recording interval: Analog recording interval for analog trend recording FIX: Recording takes place at intervals of between 2 and 60 seconds (Min 2 s) Skipped recording in case of 0.5/1 s scan AUTO: Linked to chart speed and measurement interval(Min 2 s) Digital printout interval for analog trend recording MULTIPLE: Specify for each channel from 6 kinds of intervals (Specify in 1-minute intervals between 1 minute and 24 hours.) SINGLE: Determined automatically from the chart speed and the number of channels used to print digital values. Digital value printing interval in the logging mode: MULTIPLE: Specify for each channel from 6 kinds of intervals. (Specify in 1-minute intervals between 1 minute and 24 hours.) SINGLE: Common to all points (Specify in 1-minute intervals between 1 minute and 24 hours.) Recording interval change: 2 kinds Changes by event / action function Chart paper feed: Chart speed: 1 to 1500 mm/hour Chart speed change: 2 kinds (Changes by event / action function) Chart method: Pulse motor Chart feed accuracy: ±0.1% of length (When recording is performed continuously for at least 1000 mm; Does not include elongation or shrinkage of paper.) GS 04M01D01-12E Recording modes: Normal: Starting and stopping of recording by means of a key operation Alarm channel trend: TRIGGER ... Recording starts only for the channel in which an alarm was detected. Recording stops when a key operation is performed. LEVEL ... Recording takes place only for the channel in which an alarm was detected. (Recording starts when the alarm is detected, and stops when the alarm is cleared.) Group trend: The measurement channels are grouped, and recording performed only for channels that belong to the specified group. The selection of the group to be recorded can be changed over by means of event / action function. printing function: Relation between the chart speed and recording interval (analog trend mode): Chart speed (mm/hour) × dot recording interval (s) must be no more than 3000. Chart speed 1 to 9 mm/h 10 to 1500 mm/h Channel No. TAG Record enabled Record enabled Digital print Record disabled Record enabled Alarm scale message Record enabled Record enabled Recording interval for digital printout and cart speed when the recording interval is SINGLE: Cart speed (mm/hour) × dot recording interval must not exceed 3000. when the recording interval is MULTIPLE :set by timer Number of digital print rows (Unit: hour) Chart speed 1row 2row 3row 4row 10 to 24 mm/h 25 to 49 mm/h 50 to 99 mm/h 100 to 1500 mm/h 24 8 4 2 12 4 2 1 8 4 2 1 6 2 1 1 Time printing: Hours and minutes Unit printing (UNIT): Can be set freely using no more than 6 characters. Channel or TAG No. printing: 7 characters to 16 characters selectable. Alarm printing: Channel No., alarm kind, ON/OFF time (Hours and minutes) Scale value printing: 0, 100%/0, 50, 100%/every 20% Message printing: 12 kinds of messages (16 characters) and the time are recorded. Printing is started by a periodic printing command, key operation, event / action function. 5 <<Contents>> <<Index>> Others Recording time specification: The starting and stopping times of recording can be set. Manual printing: One scan’s worth of data can be digitally printed by a key operation, remote control signal or by an alarm status. Analog trend recording is interrupted. Header printing: A character string consisting of 80 characters × 5 lines is printed (it is interrupted while measured values are being recorded). Printing is started by a key operation, event / action function. List printing: The set contents are printed. Zone recording: The recording width and recording positions (0% and 100% positions) can be set in mm units for each point. Partial compression: Can be set for each channels (1 break point) Event/Action function: Recorning can be stared,or the chart speed changed by alarm output status/remote control/ signal/chart end signal/timer or key operation. Memory Function Data Save/Load Function Media for data save/load: Buffer memory (internal SRAM) Capacity: 512 Kbytes Data backup: Around 10 years (backup with lithium battery, at room temperature while power is off) Specified data length: 10, 20, 30, 40, 50, 100, 200, 300, 400, 500, 1 k, 2 k, 3 k, 4 k, 5 k, 10 k, 20 k, 30 k, 40 k, and 50 kdata/ch (Total memory lengt must be within the free memory size.) 3.5-inch floppy disk Number of drives: 1 Disk types: 2HD, 2DD Supported formats: 1.2 Mbytes, 1.44 Mbytes, and 720 Kbytes Applicable data: Setting values, measured values, and computed values (only possible when optional math function is specified) The data calculated by /M3 report option can not be stored in the buffer memory and FD. Method to save to the floppy disk: Copies data stored in the buffer memory to the floppy disk, except for setting values which can be directly saved to the floppy disk. Method to load from floppy disk: Copies data from the floppy disk to the buffer memory except for settin values which can be directly loaded from the floppy disk. Printing and outputing loaded data: Able to print captured data saved in the buffer memory or output to a communication interface. Data save format: Setting values: ASCII Measured/computed values: binary (except ASCII (CSV Format) is also possible when saving to floppy disk.) 6 Data capacity Setting values: Expandable type: Maximum about 250 kbytes (in case when saving the setting values of an operation mode with 300ch inputs and 60ch computations.) Measured values: Binary data: 2 bytes/1 data ASCII data: 12 bytes/1 data Computed values: Binary data: 4 bytes/1 data ASCII data: 12 bytes/1 data Equation to calculate the total data capacity: Expandable type: 576 + 64 × (number of measured channel + number of computation channel) + (number of measured channel × 2 + number of computation channel × 4 + 6) × specified data length Save interval of measured/computed values: Measurement interval of the recorder, or select from 1 min/2 min/5 min/10 min (By combining with the event/action function, it can also sample 1 data at a time e.g. at each M.FUNC key or remote control signal input.) Selection of the saving method of measured/computed values (WRITE MODE): Direct: Start saving the data when key operation occurs. After saving specified length of data, stop the saving process. Trigger single: Start saving the data when the trigger condition is met. After saving a specified length of data, stop the saving process. Trigger repeat: Start saving the data when the trigger condition is met. Repeat the process of saving a specified length of data to 1 file, until there is no more area in the memory. Trigger condition: All Trigger conditions are configured with the event/action/ function. Trigger condition when saving the measured/computed values: Event/actio function (such as key operation, remote control signal, alarm status, and chart end) Trigger condition when loading the measured/computed values (from buffe memory): Event/action function (such as key operation, remote control signal, and alarm status) Pretrigger: 0 to 100% (can be specified in 10% intervals) Filename when saving data: 8 ASCII characters input. However, when saving the measured/ computed values using trigger repeat, 5 ASCII characters input (last 3 letters are set automatically from 001 to 208.) Data converion When specify with DARWIN DAQ 32 software File conversion: Conversion to Lotus 1-2-3 (R1A), ASCII (CSV), Excel (Ver. 4.0). Range of Conversion: specify for data points. GS 04M01D01-12E <<Contents>> <<Index>> Display function Display section: Display: VFD display (5 × 7 dot matrix, 3 rows) Number of characters: 22 characters (large/1 row), 40 small characters (2 rows) Displayed contents: Digital value display: Data for freely selected channels can be displayed on each line (1 channel per line, max 5 rows). The CH/TAG No. (7 characters), and also the alarm status, measured value and unit for each channel are displayed simultaneously. Measured value bar graph display: The data is displayed as 0 to 100% in the specified lines. Auxiliary data: Clock, alarm status, alarm relay status, battery consumption, record ON/OFF, key lock ON/OFF, recorder operation (print format) Alarms Number of settings: Up to four settings can be made for each channel. Kinds of alarms: Selection from higher limit, lower limit, difference higher limit, difference lower limit, higher limit of rate of change, lower limit of rate of change However, only upper limit and lower limit alarms are output for totalized results. Rate of change alarm time interval: Can be set to measurement interval × 1 to 15 (Common to both rising and falling limits.) Output mode: Excitation/non-excitation selection, AND/OR mode selection, and output hold/non-hold specification can be made. (common to all channels) A maximum of 6 reflash alarm output points can be specified. Number of alarm output points: DR240 main unit:0 points.Alarm modules can not be connected to the DR240 main unit. DS400/DS600: The alarm points are increased in module units. By increasing the number of subuits. Alarm data recording: Analog Trend mode: The channel number, kind of alarm and ON/OFF time (hours and minutes) are printed in the right margin. Logging mode: The kind of alarm is printed when the measured data are recorded. Display alarm data: Alarm status indication: When an alarm is detected, the status indicator lights. The indicator can also be made to flash depending on the setting. Alarm acknowledge indication: The alarm indicator stops flashing when a key operation is performed. Standard computation functions Kinds of computation: Difference between arbitrarily selected channels, linear scaling (scaling), moving average GS 04M01D01-12E Linear scaling: Scalable range: DC voltage, thermocouple, RTD, contact Scaling range: –30000 to +30000 Decimal point: Arbitrarily set Measurement accuracy for scaling: Measurement accuracy for scaling (digits) = Measurement accuracy (digits) × Scaling span (digits)/Measurement span (digits) + 2 digits (Numbers below the decimal point are rounded up.) Moving average: The moving average results for between 2 to 64 scans are computed. Fail, chart end output Fail output: Outline of functions: If an abnormality is found in the main unit of the recorder, the fail output terminal is de-energized. Contact mode: A contact (normally open and common terminal) Can be switched between excited and nonexcited. Contact capacity: 250 VDC/0.1 A (resistive load) 30 VDC/2 A (resistive load) 250 VAC/2 A (resistive load) Withstanding voltage: Between the output terminal and ground 2300 VAC (50/60 Hz) for 1 minute Chart end output: Outline of functions: The chart end output terminal is energized if the recording paper in the recorder breaks. Contact mode: A contact (normally open and common terminal) Can be switched between excited and nonexcited. Contact capacity: 250 VDC/0.1 A (resistive load) 30 VDC/2 A (resistive load) 250 VAC/2 A (resistive load) Withstanding voltage: Between the output terminal and ground 2300 VAC (50/60 Hz) for 1 minute Power supply section Rated supply voltage: AC power supply :100 to 240 VAC (free supply voltage selection) DC power supply : 12 to 28 VDC (only for the subunit (DS400/DS600) of a DC power supply model) Usable supply voltage range: AC power supply :90 to 250 VAC DC power supply : 10 to 32 VDC (only for the subunit (DS400/DS600) of a DC power supply model) Rated supply frequency: 50/60 Hz Power consumption: DR240 main unit ... Max approx. 130 VA DS400 sub unit ... Max approx. 55 VA (when 4 connectable input/output modules are installed) max. approx. 25 VA (DC power supply) DS600 sub unit ... Max approx. 70 VA (when 6 connectable input/output modules are installed), max. approx. 25 VA (DC power supply) 7 <<Contents>> <<Index>> Others Clock: With calendar function (Western calendar) Clock accuracy: ±100 ppm. However, this does not include the delay (less than 1 second) caused when the power is switched ON and OFF once. System fault alarm: Contact output Set value backup: Lithium battery backup (approx. 10 years at ambient temperature of 23°C), excluding clock function Key Lock: Software setting Insulation resistance: At least 20 MΩ between the power supply and ground, between each terminal and ground, and between each input terminal (measured with 500 VDC) Withstand voltage: Between the input terminals and the DR230 main unit ground 1500 VAC (50/60 Hz) for 1 minute Between the output terminals and the DR230 main unit ground 2300 VAC (50/60 Hz) for 1 minute Between AC power supply terminals and the DR240 main unit ground 1500 VAC (50/60 Hz) for 1 minute Between AC power supply terminals and the DS400 sub unit ground 1500 VAC (50/60 Hz) for 1 minute Between AC power supply terminals and the DS600 sub unit ground 1500 VAC (50/60 Hz) for 1 minute Normal Operation Conditions Supply voltage: 90 to 250 VAC Supply frequency: 50 Hz ± 2%, 60 Hz ± 2% Ambient temperature: DR242 main unit When panel-mounted : 0 to 50°C When Floppy disk operation : 5 to 40°C DS400/DS600 sub unit When floor-mounted and Desk-top : 0 to 50°C When panel-mounted : –10 to 60°C When Rack-mounted : 0 to 50°C Ambient humidity: Temperature Humidity 0 to 40°C 20 to 80% RH 40 to 50°C 10 to 50% RH DS400 –10 to 40°C 20 to 80% RH DS600 40 to 50°C 10 to 50% RH subunit 50 to 60°C 5 to 30% RH DR242 main unit * no ice formation Vibration: Shock: Magnetic field: Position: Warmup time: 8 10 to 60 Hz 0.2 m/s2 Not allowed 400 A/m max (50/60 Hz) The unit should be mounted left-right horizontally or vertically, as a general rule. At least 30 minutes after switch-on. Installation location: Room Installation height: Altitude up to 2,000 m Installation category: II (according to CSA22.2 No.1010.1) Measurement category: II (according to IEC61010-1) Degree of pollution: 2 Standard Performance Measurement and recording accuracy Measurement accuracy: Standard operation state: 23 ± 2°C, 55 ± 10% RH, supply voltage: 90 to 250 VAC, supply frequency: 50/60 ± 1%, Warmup: At least 30 minutes; When operating, the system must not adversely affect the operation of other measuring instruments by generating vibration, for example. NOTE Refer to “Standard connection modules for the DR230/DR240 hybrid recorder” in GS 04M01E01-11E for detailed specifications of the measurement accuracy. Effect of Operation Conditions Ambient temperature: Variation for a temperature change of 10°C within ±(0.1% of rdg + 1 digit) ±(0.2% of span + 1 digit) for Cu 10 Ω Voltage variation: Within ±1 digit over the range of 90 to 132, or 180 to 250 VAC (frequency 50/60 Hz) External magnetic field: Variation with respect to AC (50/60 Hz) and DC magnetic fields of 400 A/m ... Within ± (0.1% of rdg + 10 digits) Radio wave: Within ±(1% of span) at 1 m from 150 MHz or 460 MHz field Signal source resistance: Variation with respect to signal source resistance + 1 kΩ change (1) Voltage 2 V range or below ... Within ±10 µV 6 V range or above ... Within ±0.1% of rdg (2) Thermocouple Within ±10 µV; However, it must be within ±100 µ when burnout is specified. (3) RTD Variation with respect to change of 10 Ω per wire (when all three wires are the same resistance value) Indication ... Within ±(0.1% of rdg + 1 digit) Variation in indication with respect to a difference of 40 MΩ in the resistance between conductors (max difference between 3 wires) ... Approx. 0.1°C Mounting position: Variation when the unit is mounted horizontally on a panel ... Within ±(0.1% of rdg + 1 digit) excluding RJC error Vibration: Variation when sinusoidal vibration of acceleration 0.2 m/s2 is applied for 2 hours in each of the 3 axial directions over a frequency range of 10 to 60 Hz ... Within ±(0.1% of rdg + 1 digit) GS 04M01D01-12E <<Contents>> <<Index>> Transportation and Storage Conditions ■ Optional specifications Number of channels for computing (Number of channels that can be allocated for computational purposes.): Stand-alone type: 30ch maximum Expandable type: 60ch maximum Computation interval: Every measurement interval (except when the computation becomes too difficult to be processed every measured interval, in which case an alarm is generated) Significant digits during computation: ±1038 Significant digits of the computed result: –9999999 to +99999999 (Decimal point can be set to have 1 to 4 digits on the right of the decimal point) Input from communication interface: Digital value (ASCII numerical array) input from the communication interface can be handled as computational data Computation start/stop: Can be controlled by communication commands, M.FUNC key operation, and event/action function (such as M.FUNC key operation, remote control signal, time specified, and alarm status) Other functions included in the math function: Remote RJC Input type: Thermocouple (TC) Accuracy: (Twice the measurement accuracy of the standard thermocouple input) + (temperature difference between the terminal of the remote terminal section and thermocouple section for measuring the remote terminal temperature) Thermocouple burnout: not selectable Optional specifications must be specified using the type number code. They cannot be specified for the DS400 or DS600 sub unit. /M3: Report Function These refer to the environmental conditions existing during transportation and storage from the time of shipment from the factory until commencement of use, and also during transportation and storage in the case of a temporary period of non-use. If the environmental conditions are maintained within the specified range, the unit will not incur permanent damage, and can be returned to a normal working condition (re-adjustment may be required in some cases). Ambient temperature: –25 to 60°C Humidity: 5 to 95% RH Vibration: 10 to 60 Hz 4.9 m/s2 max Shock: 392 m/s2 max (in packed condition) Supported standards CSA UL CE C-Tick Obtained CSA22.2 No.1010.1, Installation category (Overvoltage category): II, Degree of pollution: 2 Obtained UL3111-1 (CSA NRTL/C) EMC directive EN61326 EN61000-3-2 EN61000-3-3 EN55011 Class A Group 1 Low voltage EN61010-1 directive Measurement category: II, Degree of pollution: 2 AS/NZS 2064 Class A Group 1 /H1: Internal Illumination Clear internal illumination for easy distinction of traces. /D2: Deg. F Display function This function converts measured data into °F, and displays it on the display monitor of a DR. /M1: MATH Function Computation types: Types: Four arithmetical operations, SQR (square root), ABS (absolute value), LOG (common logarithm), LN (natural logarithm), EXP (exponent), statistical computation*, logical computation (AND, OR, NOT, and XOR), relational computation, exponentiation, previouslymeasured value reference, hold**, reset, clear, and remote RJC. *Statistical computation CLOG: Computation process of simultaneously measured values within a group (total, maximum, minimum, average, and maximum - minimum) TLOG: Computation process of a specific channel over time axis (total, maximum, minimum, average, and maximum - minimum) Statistical computation interval: Set by the event/action function **Temporary hold of the computed result Can be controlled by event/action function (such as key operation, remote control signal, time specified, and alarm status). GS 04M01D01-12E Refer to the GS 04M01B01-31E Outline: This function assigns measurement and/or computation channels as report channels, and creates statistical information. The report computation can be selected from an hourly, daily, or monthly report. Chart printing takes place automatically whenever the report creation time (in the case of the DR recorder) is reached. The results of report computation can also be output by communication. Kinds of report computations: Hourly report: Statistical information for one hour (starting on the hour) Daily report: Statistical information for one day (starting from a reference time) Monthly report: Statistical information for one month (starting from a reference date and time) Each of the hourly, daily, and monthly reports can be set to ON or OFF. NOTE The data calulated by this option can not be stored in the buffer memory and FD of the DR recorders. /L1: Winter/Summer Time Winter and summer time can be set. 9 <<Contents>> <<Index>> ■ Type name and specification code Main unit Model DR242 Suffix Code Memory -0 -1 Optional Code Description 250 mm, panel mount hybrid recorder No memory device 3.5” FD Software 0 2 No DARWIN DAQ 32 software DARWIN DAQ 32 software (English) specify No. of Inputs -00 Power Supply Power Inlet Always-00 100 VAC to 240 VAC -1 W Optional Features /M1 /M3 Screw terminal, without cord Math function (including RRJC) Report function /H1 /L1 /D2 Internal illumination Winter/Summer time Deg. F display /FC DARWIN DAQ 32 is supplied with floppy disks Subunit DS400/DS600 Model DS400 DS600 Type Description Optional Code Suffix Code 4 slots subunit for inputs and alarm output 6 slots subunit for inputs and alarm output Always-00 100 VAC to 240 VAC -00 Power Supply -1 -2 Power Inlet & Power Cable D F H R S W Y 12 VDC to 24 VDC (DC power supply only) 3-pin power inlet w/UL, CSA cable 3-pin power inlet w/VDE cable 3-pin power inlet w/CCC cable 3-pin power inlet w/SAA cable 3-pin power inlet w/BS cable 3-pin power inlet w/screw terminal 2-pin inlet with round-type connector (when power supply suffix code is -2) Input module Model Code DU100-11 DU100-21 DU100-31 DU100-12 DU100-22 DU100-32 DU200-11 DU200-21 DU200-31 DU200-12 DU200-22 DU200-32 DU300-11 DU300-12 DU400-12 DU400-22 DU500-12 DU500-13 DU500-14 DU600-11 DU700-11 10 Description 10ch universal input module (DCV/TC/DI & RTD) 20ch universal input module (DCV/TC/DI & RTD) 30ch universal input module (DCV/TC/DI & RTD) 10ch universal input module (DCV/TC/DI & RTD) 20ch universal input module (DCV/TC/DI & RTD) 30ch universal input module (DCV/TC/DI & RTD) 10ch DCV/TC/DI input module 20ch DCV/TC/DI input module 30ch DCV/TC/DI input module 10ch DCV/TC/DI input module 20ch DCV/TC/DI input module 30ch DCV/TC/DI input module 10ch mA input module 10ch mA input module Power monitor module for single phase Power monitor module for 3 phase 10ch strain input module (120 Ω) 10ch strain input module (350 Ω) 10ch strain input module (External bridge box) 10ch pulse input module 10ch DI input module Terminal Screw Screw Screw Clamp Clamp Clamp Screw Screw Screw Clamp Clamp Clamp Screw Clamp Clamp Clamp Clamp Clamp NDIS Screw Screw GS 04M01D01-12E <<Contents>> <<Index>> Other module Model Code DT100-11 2 alarm, 12 remote, fail/chart end DT200-11 DT200-21 4 alarm relay output (transfer contacts) 10 alarm relay output (make contacts) DT300-11 DT300-21 GP-IB interface module RS-232-C interface module DT300-31 DT300-41 RS-422-A/RS-485 interface module Ethernet interface module Description Screw terminal Screw terminal Screw terminal Accessories Model Code DV100-011 Description DV100-012 DV200-000 DV200-001 Extension module Extension base unit Extension cable (0.5 m) Extension cable (1 m) DV200-002 DC200-005 DV200-010 Extension cable (2 m) Extension cable (5 m) Extension cable (10 m) DV200-020 DV200-050 DV200-100 DV200-200 Extension cable (20 m) Extension cable (50 m) Extension cable (100 m) Extension cable (200 m) Extension cable (300 m) Extension cable (400 m) Extension cable (500 m) Cable adapter Shunt resistor 10 Ω for screw input terminal Shunt resistor 10 Ω for clamped input terminal DV200-300 DV200-400 DV200-500 DV250-001 DV300-011 DV300-012 DV300-101 DV300-102 DV300-251 DV300-252 DV400-011 DV400-012 DV400-051 DV450-001 Shunt resistor 100 Ω for screw input terminal Shunt resistor 100 Ω for clamped input terminal Shunt resistor 250 Ω for screw input terminal Shunt resistor 250 Ω for clamped input terminal Rack mount kit (DA100 exp./DS400) for ANSI Rack mount kit (DA100 stand./DS600) for ANSI Power cable: Supplies Subunit with the power form the DR extension model DIN-NDIS strain conversion cable Package software Model Code DP120-13 WX102/CD1 WX101/CD1 GS 04M01D01-12E Description DARWIN DAQ 32 software (Windows XP/Vista/7) (comes standard) DARWIN DAQ 32 Plus software (Windows 2000/XP/Vista/7) (optional) DAQLOGGER for multi-channel data logging software (Windows 2000/XP/Vista/7) (optional) 11 <<Contents>> <<Index>> ■ Dimensions unit: mm Panel cutting dimensions At least 520 281 At least 80 424 425+20 40 203 64.8 280 288 444 ■ Rear panel (Name of parts) Vacant slot with cover (for communication interface, alarm, or DI/DO modules) Failure output terminals Chart end output terminals Power fuse(located in the main unit) Heat sink fins AC outlet(Auxiliary for DS400/DS600) Power terminals with a cover Function grounding terminal 12 GS 04M01D01-12E <<Contents>> <<Index>> Subunit DS400 20 115 145 unit: mm 290 336 320 100 22 40 50 165 50 8 145 20 115 Subunit DS600 369 100 422 156 162 22 20 176 168 55 If not specified, the tolerance is ±3%, However, in cases of less than 10 mm, the tolerance is ±0.3 mm. GS 04M01D01-12E 13 <<Contents>> <<Index>> ■ Names of Parts Subunit DS400 Module connector Lid covering the extension cable connector Switch to set the unit number Status indicator Screw holes for module installation Installation holes Power switch Function grounding terminal (below power switch) Power connector Feet Holes for fastening the feet Subunit DS600 Installation holes Module connector Lid covering the extension cable connector Screw holes for module installation Status indicator Switch to set the unit number Power switch Function grounding terminal (below power switch) Feet Power connector Holes for fastening the feet Rack Mount fitting (ANSI/EIA) 14 6.8 14.7 177 101.6 6.8 unit: mm 482.6 453.2 37.7 37.7 177 101.6 14.7 482.6 453.2 GS 04M01D01-12E <<Contents>> <<Index>> Location and Location Number (Channel Number, Alarm Output Relay Number, DI/DO Number) The location numbers correspond to channel numbers for locations where the input module is connected, to alarm output numbers for locations where the alarm module is connected, and to DI/DO numbers for locations where the DI/DO module is connected. Modules are mounted on a unit in slots. The number of each module is the same as that of the slot. As shown below, input/output location numbers are assigned related to the unit number (the main unit number is fixed at I) and module location. Module 0 (Location numbers:I01 to I10) Main unit DR242 Input modules cannot be connected. Unit No.:I Module 5 (Location numbers:051 to 060) Module 4 (Location numbers:041 to 050) Module 3 (Location numbers:031 to 040) Module 2 (Location numbers:021 to 030) Module 1 (Location numbers:011 to 020) Module 0 (Location numbers:001 to 010) Subunit DS600 Unit No.:0 Module 3 (Location numbers:131 to 140) Module 2 (Location numbers:121 to 130) Module 1 (Location numbers:111 to 120) Module 0 (Location numbers:101 to 110) Subunit DS400 Unit No.:1 Note When the following handling is done, it is necessary to carry out “system construction” to operate the instrument correctly. After executing system construction, confirm the module information. · Connection (including addition or replacement)/removal of subunits, or unit number setting · Mounting (including addition or replacement)/removal of modules GS 04M01D01-12E 15 <<Contents>> <<Index>> Wiring Input Signal Lines (to Universal and DCV/TC/DI input modules) Terminals Screw type terminal b - + B A Clamp type terminal DC voltage • TC • contact RTD* CH1 CH2 *There are no RTD input terminals on the DCV/TC/DI input module. A + B b CH2 CH10 CH1 CH4 CH3 CH10 CH9 Wiring Diagram DC voltage input/DI input (contact) + DC input - + + DC voltage input - TC input - + DC current input - RTD input b B + Shunt resistor Note:For 4 to 20 mA input, shunt resistance value should be 250 Ω ± 0.1% A A b B Compensation lead 10 Ω* max./leadwire Three wire resistances should be approx. equal. *10 Ω max. for Pt 100 Ω and Pt 50 Ω, 1 Ω max. for Cu 10 Ω. Wiring Output Signal and Remote Control Signal Lines (to DI/DO and Alarm modules) Terminals NO C NC DT100-11 Terminal arrangement Failure output (transfer-contact) Chart end output (transfer-contact) Remote control signal input (12 contact terminals) 1 2 ALM output (transfer-contact) NO C NC DT200-11 DT200-21 NO C NO C NC FAIL ● ● ● NO C NC ● ● CHART ● REM 1 ● C ● 2 ● 3 ● C ● 4 ● 5 ● C ● 6 ● 7 ● C ● 8 ● 9 ● C ● 10 ● 11 ● C ● 12 ● NO C NC ALM1 ● ● ● NO C NC ALM2 ● ● ● 1 Alarm output 2 (transfer contact) 1 2 Alarm output (make contact) 3 4 Alarm output (transfer contact) 10 Output contact rating: 250 VDC/0.1 A (resistive load), 250 VAC/2 A (resistive load), 30 VDC/2 A (resistive load) 16 Subject to change without notice. GS 04M01D01-12E