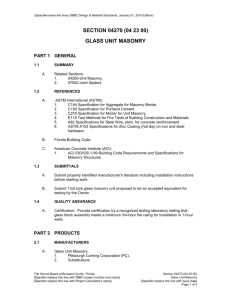

- The Masonry Society

advertisement