Proposal Title: Damping in Present Magnetic Recording

advertisement

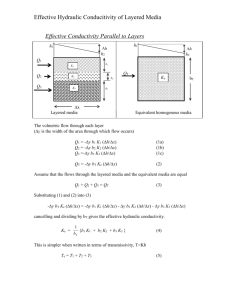

A Proposal to Advanced Storage Technology Consortium (ASTC) Topic Number: MAMR No. 4 Proposal Title: Damping in Present Magnetic Recording Media Principle Investigator: Mingzhong Wu Department of Physics, Colorado State University, Fort Collins, CO 80523 Phone: (970) 491-6312; Fax: (970) 491-7947; E-mail: mwu@lamar.colostate.edu Administrative Contact: Bo Bogdanski Colorado State University Sponsored Programs, Fort Collins, CO 80523-2002 Phone: (970) 491-5574; Fax: (970) 491-6147; E-mail: bo.bogdanski@colostate.edu Project Period: July 1, 2011 – June 30, 2012. Amount: $69,995. Submission date: April 28, 2011 Project Summary Understanding the damping of magnetization precession in magnetic recording media is of both fundamental and practical importance. In practical terms, the damping processes in media not only set a natural limit to switching times and recording data rates, but also play a critical role in microwave-assisted magnetization switching. In spite of such importance, however, the study of damping in recording media is still rather limited. The goal of this project is to use comprehensive ferromagnetic resonance (FMR) measurements and numerical analyses to identify and quantify different physical relaxation processes in present recording media. We will carry out temperature-, frequency-, and angle-dependent FMR measurements in various media samples from the sponsors. We will not only determine the total damping constant α, but will also separate different components in α which are responsible for different damping processes. Our work will also yield detailed information on the temperature dependence of α, the levels of spatial inhomogeneity in the media, and the effects of media properties on α. The research team has extensive experience in studying damping in magnetic materials, including recording media and head materials from the magnetic recording industry, and also in studying microwave-assisted magnetization reversal. These studies were carried out through close collaborations with scientists in the industry and were supported in part through research grants from INSIC, Western Digital, and Seagate. 1 I. Background a. A Big Picture about Damping This section provides an overview of the damping processes in magnetic materials. It serves to simplify the discussions in the following sections. The magnetization in a magnetic material can precess around the direction of a static magnetic field. One can maintain a uniform magnetization precession by the use of an RF magnetic field. Once the RF field is turned off, however, the magnetization will tend to relax back to the static field direction. Figure 1 gives a schematic roadmap for the relaxation (or damping) of uniform magnetization precession. The arrows and numbers indicate different relaxation routes. Generally speaking, there are three main pathways for magnetization relaxation in a magnetic material [1,2,3,4,5,6]: (I) Energy redistribution within the magnetic system through routes 2 and 3; (II) Energy transfer out of the magnetic system to non-magnetic systems through routes 1 and 4; (III) Energy transfer out of the material to external systems through route 5. Possible physical relaxation processes in routes 1-5 are summarized in Table I. The relaxation processes in routes 6 and 8 are similar to those in route 1, and the processes in route 7 are similar to those in route 3. Several phenomenological models have been proposed to describe the relaxation of the uniform magnetization. These models include the Gilbert model (also called the LLG model), the Landau-Lifshitz model, and the Bloch-Bloembergen model. Each model can take into account one or more of the relaxation processes listed in Table I. None of the existing models, however, can take into account all of the processes. For example, the Gilbert model can rigorously describe the magnon-phonon and magnonelectron scattering processes, but fails to describe the two-magnon scattering process. In the two- magnon scattering process, the longitudinal component of the magnetization is unchanged, and the length of the magnetization vector decreases. As a result, this process can only be described by the T2 term in the Bloch-Bloembergen equation. In this sense, it is incorrect if one attempts to describe all the relaxation processes in a material with a single damping parameter, such as the Gilbert constant α. 3 5 4 1 2 6 7 8 FIG. 1. A roadmap for the relaxation of uniform magnetization precession in magnetic materials 2 Table I. Physical Relaxation Processes in Magnetic Materials Route Relaxation Process Magnon-phonon scattering Charge transfer relaxation 1 Slowly relaxing impurity Rapidly relaxing impurity Eddy current 2 3 Two-magnon scattering Three-magnon scattering Four-magnon scattering Spin-flip magnonelectron scattering 4 Breathing Fermi surface 5 Spin pumping Brief Description For this process, one views the uniform precession modes as magnons with zero wavenumbers. Those magnons scatter with phonons (lattice vibration modes) and pass their energy to the phonons. 2+ 3+ This process is also called the valence-exchange or Fe -Fe relaxation and 2+ 3+ occurs in crystals with Fe and Fe ions on equivalent sites. When there is a net spin alignment, the site degeneracy is split slightly. Via spin-orbit coupling, the precession leads to the breathing of the energy level of each site, resulting in the hopping of a 3d electron from one iron ion to another. The impurities are usually rare-earth elements. The relaxation relies on the exchange coupling between the spins of magnetic elements and those of impurity and the coupling of the impurity spins to the lattice. The exchange coupling is anisotropic. As a result, the splitting of the two lowest energy levels depends on the instantaneous direction of the magnetization, leading to the transitions of the impurity between the two energy levels. This is similar to the slowly relaxing impurity mechanism. The difference is that the exchange coupling is isotropic and the energy levels do not breathe. The impurities absorb energy from the magnetization precession and changes from the ground state to the excited state. This involves a loss of energy of the uniform precession to the lattice through the conduction electrons. The eddy-current damping increases with the square of the linear sample dimension, such as the film thickness. This process involves the scatting of zero-wavenumber magnons with inhomogeneities, such as grain-to-grain fluctuations, grain boundaries, small pores, and surface defects. After each scattering, the initial magnon is annihilated and a new magnon is created. The new magnon has a frequency which is the same as the initial magnon and a wavenumber which correlates with the spatial variation of the inhomogeneities. This process includes three-magnon confluence and three-magnon splitting. In a confluence process, two magnons scatter with each other and are annihilated, and one new magnon is created. In a splitting process, one magnon is annihilated and two new magnons are created. In each scattering process, two magnons scatter with each other and are destroyed, and two new magnons are created. When a “spin-up” free electron scatters with a magnon, it absorbs the energy of the magnon, destroys the magnon, and changes into a “spin-down” electron. With an increase in temperature, the electron lifetime decreases and the electron Fermi level broadens. As a result, the magnon-electron scattering probability increases and the damping increases. This process is also called intraband magnon-electron scattering. Via spin-orbit coupling, the magnetization precession changes the energy of the free electron states, pushing some occupied states above the Fermi level and some unoccupied states below the Fermi level. As a result, the electron-hole pairs are produced near the Fermi level. These pairs exist for some lifetime before relaxation through scattering with the lattice. The energy dissipated to the lattice depends on how far the system gets from equilibrium, and the latter increases with the electron lifetime. At a ferromagnet/normal metal interface, the magnetization precession in the ferromagnet produces a spin current that flows into the normal metal. This spin current carries spin angular momentum out of the ferromagnet. 3 b. Ferromagnetic Resonance Ferromagnetic resonance (FMR) is probably the most widely used technique for the study of the damping of uniform precession. The left diagram in Fig. 2 shows a schematic representation of the FMR effect, where the magnetization M absorbs energy from the microwave magnetic field h and maintains a fixed angle of precession around the static magnetic field H. The FMR effect manifests itself in a peak response in the measurement of the Power absorption z power absorption in the material as a H function of the static magnetic field, as shown by the right diagram in Fig. 2. M This peak response is, more or less, Lorentzian in shape. The full width at the half maximum of this so-called h x y FMR absorption curve is usually taken ∆HFMR HFMR Static magnetic field H FIG. 2. Schematic of ferromagnetic resonance (FMR) as the FMR linewidth ∆HFMR. The origin of the FMR linewidth differs significantly in different materials. In general, one can express the linewidth as ∆H FMR = ∆H i + ∆H 0 (1) i where ∆Hi denotes the contribution from a certain relaxation process i and ∆H0 takes into account the inhomogeneity-caused line broadening. It is important to emphasize that the inhomogeneity line broadening is not a loss. It arises from the simple superposition of several local FMR profiles for different regions of the sample. Those local FMR profiles are shifted in field because of some change in the magnetic properties of the different regions. At the first glance, it might seem difficult to obtain useful information on damping from ∆HFMR measurements, since the linewidth ∆HFMR consists of many terms. In practice, however, FMR techniques have proved to be an extremely useful tool for the identification and even quantification of different physical damping processes in a great variety of materials. This is possible due to three facts as follows. (1) For a specific material, not all the processes listed in Table I are involved in the relaxation. Rather, only a few of the processes take place or play important roles. In a high-resistivity ferrite, for example, the relaxation via the magnon-phonon scattering and charge transfer processes are possible, but the eddy current and magnon-electron scattering effects are negligible. (2) Many of the relaxation processes show unique temperature or frequency dependences. In some cases, this makes it fairly easy to distinguish one process from another. (3) Some of the processes can be easily turned on or off through a change in FMR configurations, such as the direction and magnitude of the static field. For magnetic thin films, for example, one can suppress the two-magnon scattering simply by applying the static field normal to the film plane. c. Possible Damping Processes in Recording Media Understanding the damping of magnetization precession in real magnetic recording media is of both fundamental and practical importance. In practical terms, the relaxation processes in media not only set a natural limit to switching times and recording data rates, but also play a critical role in microwave- 4 assisted magnetization switching [7]. In spite of such importance, however, studies on the damping in magnetic recording media materials are still rather limited. The only work reported to date was done on granular Co-Cr films by Professor Carl Patton’s group [8]. The work showed that, when the magnetic field was applied perpendicular to the film plane, the only important process was the magnon-electron scattering, which could be characterized by a small damping constant of α=0.004. It also showed that, when the field was applied in a direction away from the film normal, there was also a grain-to-grain twomagnon scattering process, which played a more significant role in the relaxation than the magnonelectron scattering. The granular films studied in this work, however, differ significantly from real media materials. First, the films were “soft”, with a net perpendicular anisotropy field of only 0.61 kOe. Second, the films consisted of only a single magnetic layer, while the present media consists of a relatively complex structure, such as the so-called ECC (exchange coupled composite) structure. What are actual physical damping processes in the present media? Table II shows the possibility for each relaxation process listed in Table I to contribute to the damping of magnetization precession in media materials. The justifications were based mainly on the mechanism of each process (see Table I) and our very recent study on the damping in a commercial-like perpendicular media disk provided by Western Digital [9]. Table II. Possibilities for Occurrences of Different Relaxation Processes in Recording Media Relaxation Process Possibility Justification Magnon-phonon scattering Yes This process takes place in almost all magnetic materials. Charge transfer relaxation No This process exists in ferrites, not metals. Slowly relaxing impurity No There are no rare-earth elements in media materials. Rapidly relaxing impurity No There are no rare-earth elements in media materials. Eddy current No The eddy current damping is negligible in very thin films. Two-magnon scattering Maybe This depends on the field/film configuration. Three-magnon scattering Maybe This depends on the field/film configuration. Four-magnon scattering Maybe This depends on the field/film configuration. Spin-flip magnon-electron scattering Yes This process takes place in materials with free electrons. Breathing Fermi surface Yes This process takes place in materials with free electrons. Spin pumping No This effect occurs in the presence of a neighboring normal metal. As shown in Table II, there are six processes that might contribute to the damping in a media material. One, however, can narrow down them to two processes only with the two considerations as follows. (1) The occurrence of the two-, three-, and four-magnon scattering processes relies on the availability of degenerate spin-wave modes. One can suppress the number of the degenerate modes and, thereby, exclude these magnon scattering processes by conducting FMR measurements with a static magnetic field perpendicular to the film (or disk) plane. (2) In metallic materials, the contributions of the magnon- 5 electron scattering and breathing Fermi surface mechanisms to the relaxation are much larger than the contribution from the magnon-phonon scattering. As a result, it is appropriate to ignore the contribution from the magnon-phonon scattering. With these considerations, one can take into account only the spinflip magnon-electron scattering (MES) and breathing Fermi surface (BFS) mechanisms. Therefore, for perpendicular FMR on recording media, the linewidth can be expressed as (2) ∆ H FMR = ∆ H MES + ∆ H BFS + ∆ H 0 where ∆HMES and ∆HBFS describe the contributions from the MES and BFS processes, respectively. d. Damping Constant α It is known that both the spin-flip magnon-electron scattering and breathing Fermi surface mechanisms can be described by the Gilbert model, which is also called the LLG model. As a result, one can rewrite Equation (2) as ∆H FMR = 2α MES γ ωFMR + 2α BFS γ ωFMR + ∆H 0 (3) where ωFMR is the FMR frequency and γ is the absolute value of the gyromagnetic ratio. αMES and αBFS are the damping constants responsible for the MES and BFS processes, respectively, and can be expressed as [10] α MES 1 T =A γ M s 300 2 300 T 2 α BFS = B 1 γ Ms (4) (5) where Ms is the saturation magnetization, T is temperature (K), and A and B are two constants with the unit of frequency. The summation of αMES and αBFS yields an overall damping constant α, which is the very damping parameter appearing in the Gilbert equation (or the LLG equation). II. Proposed Research This section provides essentials for the proposed research project. research approaches and planned works. Subsections b-e describes Subsection f lists the likely outcomes of the project. Subsection g gives the time line of the project. a. Objectives of This Project The goal of this project is to use comprehensive FMR measurements and numerical analyses to identify and quantify relaxation processes and determine the damping constant α in present magnetic recording media provided by the magnetic recording industry. b. Approaches for Damping Constant Determination We will use two approaches to determine the damping constant of the media materials. The results from the two approaches will be compared. Such comparison will allow us to confirm and refine each approach and, thereby, to obtain highly-reliable damping constants. 6 As discussed in Section I.c, the dominant damping mechanisms in perpendicular recording media are the spin-flip magnon-electron electron scattering (MES) and breathing Fermi surface (BFS) processes. These processes show opposite temperature dependences, as can be seen in Equations (4) and (5). The inhomogeneity line broadening ∆H0 can be evaluated as [11] ∂H FMR ∆H u ∆H 0 = Hu ∂H u H u (6) where Hu is the effective perpendicular anisotropy field and the ratio ∆Hu/Hu describes the level of the spatial variation in Hu. Note that the derivative term essentially equals to one for perpendicular FMR measurements; the ratio is independent of temperature temperature; and the dependence of Hu on temperature temp can be measured experimentally. For this reason reason,, one can determine the damping constant through temperature-dependent dependent FMR measurements and the fitting of FMR linewidth data with the following equation ∆H FMR (T ) = 2 2 2ωFMR 1 T 2ωFMR 1 300 ∆H u + B A + γ γ M s 300 γ γ M s T H u Hu (7) The equation is obtained simply by substituting Equations (4) (4)-(6) (6) into Equation (3). One can see that there are three fitting parameters: A A, B, and ∆Hu/Hu. It is known that the value of ∆H0 is independent of frequency [12]. For this reason, one can also rewrite Equation (3) as ∆H FMR (ω ) = 2 (α MES + α BFS ) γ ω + ∆H 0 or ∆H FMR (ω ) = 2α γ ω + ∆H 0 (8) This equation suggests another approach, namely, that one can obtain the damping constant through frequency-dependent dependent FMR measurements and the fitting o off the FMR linewidth with Equation (8). In this case, one has two fitting parameters: α and ∆H0. c. Damping Determination through Temperature Temperature-Dependent Measurements This approach involves the following steps. The fitting of ∆HFMR(T) with three models is illustrated in Fig. 3. (1) Measure the saturation magnetization Ms of the sample over a wide temperature range (for example, T=100K-400K); (2) Performance field-swept swept FMR measurements over the same temperature range; (3) Determine the FMR field HFMR values from the FMR data; (4) Calculate the anisotropy field Hu values with the Kittel equation and the Ms and HFMR data; (5) Determine the FMR linewidth ∆HFMR values from the FMR data; (6) Fit the ∆HFMR vs. T response with Equation (7) and obtain fitting parameters A,, B, and ∆Hu/Hu; FIG. 3. Fitting of temperature-dependent temperature FMR linewidth data with three contributions: magnon-electron electron scattering linewidth ∆HMES, breathing Fermi surface linewidth ∆HBFS, and inhomogeneity line broadening ∆H0. 7 (7) Calculate the damping constants with Equations (4) and (5). There are five important points to be noted. (1) The FMR measurements should be done with a magnetic field perpendicular to the film plane so that the magnon-magnon magnon scattering processes are prohibited, as discussed in Section I.c I.c. (2) This approach will yield the values of αMES, αBFS, and α as a function of T,, although we are mainly interested in the values at room temperature. (3) This approach allows us to determine not only the value of α, but also the weights of αMES and αBFS in α. (4) The work will also yield the ratio ∆Hu/Hu. This ratio describes the level of anisotropy field fluctuation in the media and, thereby, is of great interest to our industry collaborators who make recording media. In the case that our collaborators can provide this ratio, the fitting parameters wil will be reduced from three to two. (5) In certain media materials, the inhomogeneity might consist of spatial variations in both the strength of anisotropy field and the anisotropy axis. This will be considered in numerical analyses. It is important to mention ntion that, w with this approach, we have recently succeed in determining the values of αMES, αBFS, and α in a commercial commercial-like like perpendicular ECC media disk provided by Western Digital [9]. This previous experience will greatly help the implementation of this new project. d. Damping Determination through Frequency Frequency-Dependent Measurements This approach involves three steps steps: (1) Run field-swept FMR measurements at different frequencies frequencies; (2) Determine the FMR linewidth ∆HFMR values from the FMR data; and (3) Fit the ∆HFMR vs. ω response with Equation ((8) and obtain fitting parameters α and ∆H0 (or ∆Hu/Hu). The fitting of ∆HFMR(ω) is illustrated in Fig. 4. We will compare the results from this approach with those obtained with the first approach. This his will allow us to refine our numerical analyses. We want to mention that we have previous experiences with frequency-dependent dependent FMR measurements FIG. 4. Linear fit to frequency-dependent frequency FMR linewidth data. and (a) (b) 150 Cr 700 600 Ta 500 Ti 400 Cu 300 Pt 100 Inhomogeneity line broadening 75 50 Intrinsic damping 25 200 100 12 Grain-boundary two-magnon scattering 125 FMR linewidth (Oe) FMR linewidth (Oe) 800 Ru 13 14 15 16 Frequency (GHz) 0 17 18 8 10 12 14 16 Frequency (GHz) 18 20 Grain-grain twomagnon scattering FIG. 5. (a) FMR linewidth as a function of frequency for Fe65Co35 films on different seed layers, as indicated. (b) Experimental (circles) and theoretical (solid curve) FMR linewidths for a Fe65Co35 film on a Ru seed layer. The dashed curves in (b) show four contributio contributions to the overall linewidth. (unpublished) 8 numerical analyses in a number of different sets of materials, including those thin film materials from Seagate [13] and Western Digital [14]. We believe those experiences will be valuable for the work proposed here. Figure 5 shows representative frequency-dependent FMR linewidth data and corresponding numerical results [13]. Note that the FMR measurements were done with an in-plane field and, therefore, the FMR linewidth contains substantial contributions from two-magnon scattering processes. e. Other Work We plan to study the effects of various media parameters and properties on the relaxation processes and the damping constant. These parameters and properties include film thickness, grain size, and the strength of the “granular layer” to “capping layer” coupling. This work will be done through close collaborations with our industry partners. We will also study the damping properties in media materials where the damping might involve other relaxation processes (other than the magnon-electron scattering and breathing Fermi surface processes considered above). For example, for materials with nonmagnetic metallic layers, one might need to consider the spin pumping effect; for materials containing rare-earth elements, one might need to take into account the slow relaxing impurity process. For the FMR measurements proposed above, the magnetic field will be applied along the film normal direction. Work is also planned to use polar-angle-dependent FMR measurements to study magnon-magnon scattering processes in certain media materials. f. Outcomes of Proposed Project The likely outcomes from the above-proposed work include the following: (1) Damping constant α of various media samples provided by the sponsors; (2) Physical relaxation processes involved in damping and corresponding contributions to and weight in the total damping constant α ; (3) Temperature dependence of the damping constant α and its components; (4) Level of inhomogeneity or level of spatial variation in the anisotropy field; (5) Effects of material parameters and properties on the damping constant α ; (6) Contributions of magnon-magnon scattering processes to the relaxation (for fields pointed away from the film normal direction); (7) Research opportunities for two graduate students, two undergraduate students, and one high school student; (8) Three quarter reports and one final report; (9) Two or more joint publications with industry partners; (10)Development and enhancement of collaborations with recording industry. g. Time Line Table III gives the work schedule for the proposed project. As the project proceeds, we will redefine this schedule according to our progress to maximize the output of this project. 9 Table III. Schedule for proposed work Task Quarter 1 2 3 Temperature-dependent FMR measurements and numerical analyses X X X X X Frequency-dependent FMR measurements and numerical analyses Effects of media parameters and properties on damping X Polar-angle-dependent FMR measurements and numerical analyses Reporting 4 X X X X X X III. Research Resources a. Qualification of Research Team The PI’s group at Colorado State University (CSU) is ideally suited to implement the proposed project. There are three main reasons as follows. (1) The PI’s group has extensive experiences in studying damping in magnetic materials, including media and head materials from the magnetic recording industry [9,13,14], and in studying microwave assisted magnetization reversal (MAMR) [15,16,17,18,19]. The PI has published over 80 technical papers in the field of microwave magnetics, which include nine recent papers in Physical Review Letters. (2) The team has previous and ongoing collaborations with many scientists in the recording industry in the field of damping and MAMR. These collaborations were supported in part by research grants from Western Digital, Seagate, and the Information Storage Industry Consortium (INSIC). (3) The team has sufficient facilities for FMR measurements over a wide range of magnetic fields (up to 2 T), as a function of field angle (-90° to 90°), over a wide range of frequencies (up to 75 GHz), at low and high power (up to 2000 W), and as a function of temperature (100 K to 400 K). Key equipment in PI’s laboratory includes a 110 GHz vector network analyzer, a 67 GHz vector network analyzer, a 26 GHz spectrum analyzer, a 40 GSa/s 12 GHz oscilloscope, a 2000 W 8-18 GHz TWT amplifier, a 60 GHz microwave probe station, and various microwave generators, pulse generators, and electromagnets. b. Resources Required to Perform Project The research team for this project will consist of the PI, two graduate students, two undergraduate students, and one high school student. The team has sufficient experimental resources for the proposed work, which include seven FMR systems, a SQUID magnetometer, a MOKE system, and a vibrating sample magnetometer. The temperature-dependent FMR measurements will be done with either the X-band EPR system or the K-band low-temperature FMR system. For the measurements with the EPR system, one first magnetizes the sample to saturation with a strong magnetic field along the media film normal direction and then run FMR measurements with a field which is opposite to the direction of the magnetization. This 10 arrangement allows for the observation of FMR responses in the X-band frequency range. It is also relevant to practical data writing processes where one always applies an opposite field in order to switch the magnetization. The frequency-dependent FMR measurements will be done with a high-sensitivity microwave probe station, which was developed very recently in the PI’s laboratory under a financial support from the U.S. National Institute of Standard and Technology (NIST). The key components of this station includes a 110 GHz vector network analyzer system, 50 Ω 67 GHz coplanar waveguide structures and calibration kits, 50 Ω 67 GHz probes, 67 GHz low-noise cables with a shielding effectiveness of -120 dB, a 2.4 T electromagnet, and a pneumatically isolated table for vibration reduction. We will also consider the use of microwave cavities of different frequencies. High-Q cavities available for this project include a 9.45 GHz cavity, a 9.48 GHz cavity, and a 17.3 GHz cavity. c. Resources Other Than ASTC Funding Dedicated to Perform Project Below is a list of the current support of the PI, which will support either directly or indirectly the implementation of this new project. Title: New Faculty Startup Funds Source of Support: Colorado State University Starting Date: 09/16/2007 Ending Date: 08/15/2012 Amount: $333,000 Principal Investigator: Mingzhong Wu Title: Nonlinear spin waves in magnetic films: new concepts and applications Source of Support: The U.S. National Science Foundation Project Location: Department of Physics, Colorado State University Award Amount: $330,000 Starting Date: 09/01/2009 Ending Date: 08/31/2012 Principal Investigator: Mingzhong Wu Co-Principal Investigator: Lincoln Carr Project Title: Novel magnetic nano films and devices for millimeter wave communications Source of Support: The U.S. National Science Foundation Project Location: Department of Physics, Colorado State University Award Amount: $328,000 Starting Date: 09/01/2007 Ending Date: 08/31/2011 Principle Investigator: Mingzhong Wu Co- Principle Investigator: Carl E. Patton 11 Project Title: Measurement/characterization of nanometer-scale magnets for post-CMOS electronics Source of Support: The U.S. National Institute of Standard and Technology Project Location: Department of Physics, Colorado State University Award Amount: $962,440 Starting Date: 01/01/2010 Ending Date: 12/31/2012 Principal Investigator: Kristen Buchanan Co-Principal Investigator: Mingzhong Wu Co-Principal Investigator: Carl Patton Project Title: High-frequency measurements and analysis on Western Digital materials and devices Source of Support: Western Digital Technologies, Inc. Project Location: Department of Physics, Colorado State University Award Amount: $10,000 Starting Date: 01/04/2011 Ending Date: 06/30/2011 Principle Investigator: Mingzhong Wu d. Resources Requested from ASTC Table IV gives a summary of the budget for this project. The Colorado State University’s federally negotiated indirect cost rates for research is 48.0%, modified to exclude capital equipment and tuition. The fringe rates for the faculty, graduate research assistants, and students hourly are 25.3%, 4.9%, and 0.8%, respectively. The budget includes the following items. (1) Support is requested for 0.25 summer month salary for the PI, 10 months for one graduate student, and 3 months for another graduate student. Support is also requested for one undergraduate “work study” student and one undergraduate “non-work study” student. One high school student will also participate in this research project, but under support from the summer Research Engineering Apprenticeship Program (REAP) of the U. S. Army Research Office. (2) Monthly operating costs are requested for materials, supplies, and facility use fees. The materials and supplies include supplies for sample preparations, electronic components for measurement systems, and computer software for numerical analyses. (3) Tuition cost is requested for one semester of in-state graduate tuition. (4) Travel funds are requested to partially support the PI and the students to present the results at ASTC meetings and other conferences. 12 Expected technical cooperation with the sponsors: We expect that the sponsors will provide recording media samples and relevant information about the samples, such as saturation magnetizations, anisotropy fields, film thicknesses, and grain sizes. Table IV. Budget summary PERSONNEL SALARIES Academic Faculty: Fringe Rate Administrative Professional: Fringe Rate State Classified: Fringe Rate Post-Doctorates: Fringe Rate Non-Student Hourly: Fringe Rate Student Hourly: Fringe Rate GRA's: Fringe Rate $1,958 $495 $0 $0 $0 $0 $0 $0 $0 $0 $6,000 $40 $22,750 $1,115 TOTAL SALARY: TOTAL FRINGE: $30,708 $1,650 TOTAL PERSONNEL: $32,358 DOMESTIC TRAVEL: $2,000 INTERNATIONAL TRAVEL: $0 MATERIALS AND SUPPLIES $10,236 OTHER DIRECT COSTS In-State Tuition: Out-State Tuition: Publications: Participant Stipends: Participant Allowances: Participant Travel: Equipment Use Fees: Animal Care: Consultants: Other: $3,996 $0 $0 $0 $0 $0 $0 $0 $0 $0 TOTAL OTHER DIRECT: $3,996 SUBCONTRACTS: $0 EQUIPMENT: $0 TOTAL DIRECT COSTS: $48,590 Facilities & Administrative: $21,405 Consortium F&A TOTAL: $0 $69,995 13 Expected student internships: We expect that the sponsors will provide a summer internship opportunity for one of the two graduate students in this project. IV. Biographical Sketch of Principal Investigator Dr. Mingzhong Wu is an Assistant Professor in the Department of Physics, Colorado State University (CSU). His research group is interested in many topics in microwave magnetics. The current research areas include ferromagnetic resonances and relaxation, magnetization reversal dynamics, spintronics, microwave and millimeter wave magnetic materials and devices, multiferroic heterostructures, and nonlinear spin waves. Dr. Wu has been a Senior Member of the Institute of Electrical and Electronic Engineers (IEEE) since 2006. He has been on the Education Committee of the IEEE Magnetics Society since 2009 and on the Editorial Review Board of IEEE Magnetics Letters since 2010. He serves as a proposal reviewer for six research foundations, and he also serves as a reviewer for 28 international journals. He has served on organizing and program committees for a number of international conferences. He received the Early Career Faculty Excellence in Undergraduate Teaching or Mentoring Award from the CSU College of Natural Sciences in 2011. Dr. Wu has authored and co-authored over 80 publications in archival technical journals. V. References 1 M. Sparks, Ferromagnetic-Relaxation Theory (McGraw Hill, New York, 1964). 2 A. G. Gurevich and G. A. Melkov, Magnetization Oscillations and Waves (CRC-Press, Boca Raton, 1996). 3 V. Kambersky, Phys. Rev. B 76, 134416 (2007). 4 K. Gilmore, Y. U. Idzerda, and M. D. Stiles, Phys. Rev. Lett. 99, 027204 (2007). 5 S. S. Kalarickal, N. Mo, P. Krivosik, and C. E. Patton, Phys. Rev. B 79, 094427 (2009). 6 B. Heinrich and G. Woltersdorf, J. Supercond. Novel Magn. 20, 83 (2007). 7 J. Zhu, X. Zhu, and Y. Tang, IEEE Trans. Magn. 44, 1 (2008). 8 P. Krivosik, S. S. Kalarickal, N. Mo, S. Wu, and C. E. Patton, Appl. Phys. Lett. 95, 052509 (2009). 9 L. Lu, M. Wu, M. Mallary, G. Bertero, K. Srinivasan, and R. Acharya, “Ferromagnetic resonance and damping in perpendicular recording media,” in preparation. 10 J. Kunes and V. Kambersky, Phys. Rev. B 65, 212411 (2002). 11 N. Mo, J. Hohlfeld, M. ul Islam, C. S. Brown, E. Girt, P. Krivosik, W. Tong, A. Rebei, and C. E. Patton, Appl. Phys. Lett. 92, 022506 (2008). 12 S. S. Kalarickal, P. Krivosik, J. Das, K. S. Kim, and C. E. Patton, Phys. Rev. B. 77, 054427 (2008). 13 “Effects of seed layers on ferromagnetic resonance linewidths of Fe65Co35 thin films,” Lei Lu, Ke Sun, Mingzhong Wu, Jared Young, Christoph Mathieu, and Matthew Hadley, the 2009 APS Four Corners Section Fall Meeting, Golden, Colorado, October 23-24, 2009. 14 14 “Origins of damping in ultra-thin ferromagnetic films,” Lei Lu, Zihui Wang, Griffin Mead, Mingzhong Wu, Christian Kaiser, and Qunwen Leng, the 2010 APS Four Corners Section Fall Meeting, Ogden, Utah, October 15-16, 2010. 15 “Simulation of microwave assisted magnetization reversal in perpendicular-anisotropy thin films,” rd Mingzhong Wu, Zihui Wang, and Corneliu Nistor, the 53 Annual Conference on Magnetism and Magnetic Materials, Austin, Texas, November 10-14, 2008. (Invited talk) 16 “Observation of microwave-assisted magnetization reversal in magnetic films through ferromagnetic resonance absorption measurements,” Mingzhong Wu, Zihui Wang, Corneliu Nistor, and Ke Sun, the th 20 Magnetic Recording Conference, Tuscaloosa, Alabama, October 5-7, 2009. (Invited talk) 17 Z. Wang and M. Wu, J. Appl. Phys. 105, 093903 (2009). 18 C. Nistor, K. Sun, Z. Wang, M. Wu, C. Mathieu, and M. Hadley, Appl. Phys. Lett. 95, 012504 (2009). 19 Z., Wang, K. Sun, W. Tong, M. Wu, M. Liu, and N. Sun, Phys. Rev. B 81, 064402 (2010). 15