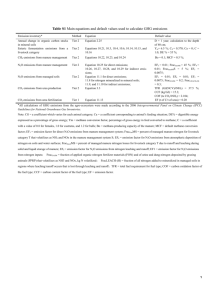

Selection and specification of technical and management

advertisement