KOLEJ UNIVERSITI TEKNOLOGI TUN HUSSIEN ONN

advertisement

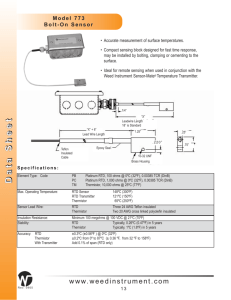

ii AUTOMATIC DETECTION TEMPERATURE TRANSMITTER FOR CALIBRATION PROCESS USING RTD MUSTAQIM BIN HAZMI This thesis is submitted as partial fulfillment of the requirements for the award of the Bachelor of Electrical Engineering (Electronics) Faculty of Electrical and Electronics Engineering UNIVERSITI MALAYSIA PAHANG 29 NOVEMBER 2010 iii “I hereby acknowledge that the scope and quality of this thesis is qualified for the award of the Bachelor Degree of Electrical Engineering (Electronics)” Signature : ______________________________________________ Name : NAJIDAH BINTI HAMBALI Date : 29 NOVEMBER 2010 iv “All the trademark and copyrights use herein are property of their respective owner. References of information from other sources are quoted accordingly; otherwise the information presented in this report is solely work of the author.” Signature : ____________________________ Author : MUSTAQIM BIN HAZMI Date : 29 NOVEMBER 2010 vi ACKNOWLEDGEMENT First of all, I am grateful to ALLAH S.W.T for blessing me in completion of my final year project (PSM) with success in achieving my objectives to finishing this project. The project also has been complete on the time given. Secondly, I want to thank my family for giving morale support and encouragement in completing my project. I also would like to thank my supervisor Puan Najidah Bt Hambali for guiding and supervising my final year project. I really apologize to her for any mistakes, and things that I done wrong while doing my project. I, myself are fully in dept with Faculty of Electrical and Electronics Engineering (FKEE) for providing me the necessary instruments, hardware and all information for my project. Without their helped, this project was deeming to be unfinished. Last but not least, I want to thank my entire friend especially Muhamad Farid Bin A. Wahab, that given me advice, helps, and encouragement in completing my project. To En. Shahrizal Bin Saat and En. Muhammad Hamka Bin Embong, thanks for your support and your time to teach us about calibration of the instruments and all connection of the hardware. Thank you very much to all and May ALLAH bless you. vii ABSTRACT The purpose for this project is to detect temperature for Calibration Process using Resistive Thermal Device (RTD) automatically. This project will be used Visual Basics (VB) programmed to develop Graphical User Interface (GUI). An RTD will be use as temperature sensor in this Calibration Process. The software and the temperature sensor will be interfaced by using a Data Acquisition (DAQ) card. Proportional–Integral– Derivative (PID) controller will be purpose for automatic detection for temperature system. The expected result for this project is an automatic detection system for temperature measure during the Calibration Process. The accuracy of the measurement will be monitor beside the analysis of uncertainty and confidence limit. viii ABSTRAK Projek ini adalah bertujuan untuk mengesan suhu bagi proses kalibrasi menggunakan Thermal Device Resistive (RTD) secara automatik. Projek ini akan menggunakan Visual Basics (VB) yang diprogram untuk membina Graphical User Interface (GUI). Sebuah RTD akan digunakan sebagai pengesan suhu dalam proses kalibrasi. Perisian dan pengesan suhu akan dihubungkan dengan menggunakan kad Data Acquisition (DAQ). Proportional Integral Derivative (PID) bertujuan untuk pengesanan automatik kepada sistem suhu. Keputusan yang dijangkakan dalam projek ini adalah sistem pengesanan automatik pengukuran suhu dalam proses kalibrasi. Ketepatan pengukuran akan dipantau, di samping analisis ketidakpastian dan had keyakinan. ix TABLE OF CONTENTS ELEMENTS PAGES TITLE ii SUPERVISOR’S DECLARATION iii STUDENT’S DECLARATION iv DEDICATION v ACKNOWLEDGEMENT vi ABSTRACT vii ABSTRAK viii TABLE OF CONTENTS ix LIST OF TABLES xii LIST OF FIGURES xiii LIST OF SYMBOLS xv LIST OF ABBREVIATIONS xvi CHAPTER 1 INTRODUCTION 1.1 Background 1 1.2 Introduction to the Project 2 1.3 Problem Statement 3 1.4 Objectives 4 1.5 Scope of the Project 5 1.6 Thesis Overview 6 x CHAPTER 2 CHAPTER 3 LITERATURE REVIEW 2.1 Infrared Temperature Detection 8 2.2 Temperature Transmitter 9 2.3 Temperature Measurement and Control System 9 2.4 ULTRA-Accurate Temperature Measurement 10 2.5 Temperature Coefficient 10 2.6 Ge-Film Resistance and Si-Based Diode sensors 12 2.7 Temperature Measurement via Laser Fluorescence 12 2.8 Thin Film Resistance Temperature Sensors 13 METHODOLOGY 3.1 Introduction 14 3.2 Resistance Temperature Detector (RTD) 15 3.3 Four Wires RTD 17 3.4 Dry Block Calibrator (furnace) 17 3.5 Temperature Transmitter 19 3.6 Calibrate a HART Temperature Transmitter 20 3.7 Advantech USB-4716, PC-Lab Card. 21 xi 3.8 Visual Basic (VB) 28 3.9 Software Development 29 4.0 Calibration Technique 42 CHAPTER 4 RESULT AND DISCUSSION 48 CHAPTER 5 CONCLUSION AND RECOMMENDATION 5.1 Conclusion 58 5.2 The Obstacles and Recommendations 59 REFERENCES APPENDICES 61 A Student’s t-distribution table 63 B Advantech USB-4716 specification 64 C HART Calibration Data Sheet 67 D Furnace Data Sheet 69 E Pt100 Resistance Table 73 F Yokogawa YTA110 Data Sheet 75 G Source Code for the Software 80 xii LIST OF TABLES TABLE NO. TITLE PAGES 3.1 Pins Function of every port in DAQ card. 24 3.2 Table of draft UUT calibration data. 43 3.3 Five point calibration table. 44 4.1 Result from software implementation 54 4.2 The comparison between software and manual calculation 56 xiii LIST OF FIGURES FIGURE NO. TITLE PAGES 2.1 Sensitivity as a function of temperature for sample low, moderate, and high resistance CX-1030s samples and CX1050s samples used in this analysis. 11 3.1 The system roughly interconnection base on picture and the flow of the data. 15 3.2 Circuit design for 4-wires RTD Pt100. 17 3.3 Isotech Jupiter 650B, the Dry Block Calibrator as a furnace. 18 3.4 The temperature controller of Isotech Jupiter 650B. 18 3.5 Yokogawa YTA110, temperature transmitter. 19 3.6 HART documenting process calibration by section 20 3.7 HART calibrator. 21 3.8 Data Acquisition (DAQ) card. 22 3.9 Software installation for Advantech USB-4716. 22 3.10 Pins Assignments for DAQ card Advantech USB-4716. 23 3.11 The Advantech Device Manager. 25 3.12 Advantech Device Test, Analog Output. 26 3.13 Advantech Device Test, Analog Input reading. 27 3.14 Connection of instruments, hardware and software. 28 xiv 3.15 Selecting device. 30 3.16 Capture data for Data Analog in Voltage and Degree Celsius data. 31 3.17 GUI for Data Storage for the software system. 34 3.18 GUI for generate graphs for the project. 35 3.19 Average graph for the calibration. 36 3.20 Error graph. 37 3.21 Voltage input versus Temperature. 38 3.22 Data Progress shows the input data in volts. 39 3.23 Uncertainty calculation in the software. 40 3.24 Flow chart for software implementation. 41 3.25 Calibration technique. 42 3.26 Flow chart of the project. 47 4.1 Data Storage as a last result after running the system. 49 4.2 Average graph from the data storage. 50 4.3 Error graph. 51 4.4 Voltage input versus average temperature. 52 4.5 Uncertainty value for 95.45% of confident interval. 53 4.6 Uncertainty for 99.00% of confident interval. 54 xv LIST OF SYMBOLS γ Degree of Freedom Ω Ohms ∞ Infinity xvi LIST OF ABBREVIATIONS RTD Resistance Temperature Detector DAQ Data Acquisition VB Visual Basic software USB Universal Serial Bus GUI Graphical User Interface HART Highway Addressable Remote Transducer 3D Three Dimension PID Proportional Integral Derivative Ni Nickel Pt Platinum Ge Germanium PSM Power Sensor Microsystem PSM Final Year Project (Projek Sarjana Muda) PV Process Variable LRV Lower Range Value URV Upper Range Value PC Personal Computer AGND Analog Ground AI0 Analog Input 0 xvii LED Light Emitting Diode V Volts mA Mille-Ampere IDE Integrated Development Environment MSU Master Standard Unit UUT Unit Under Test Std Dev Standard Deviation Mean Median or Average TUR Test Uncertainty Ration U Uncertainty A Maximum Error 1 CHAPTER 1 INTRODUCTION 1.1 BACKGROUND In this thesis there is a basic idea to recognize a temperature measurement system that has instrumentation or control considerations in addition to simple temperature measurement considerations. The need for temperature calibration is obvious, and the need for instruments to bring about that calibration control is also obvious. The limits of calibration control, the acceptable variations in temperature for process, are less obvious. The types of instrumentation involve so many combinations of precision, cost, reliability, and utility that is impossible to present a suitable analysis without analyzing a particular system to make sure the temperature calibration system is accurate [1]. Although temperature sensors are usually checked as part of a calibration of the connected device, it may be necessary to check a suspect temperature sensor or to verify the accuracy of a new RTD. The principles of this Automatic Detection Temperature Transmitter for Calibration process using RTD, would apply to any sensor type. All modern test equipment performs the temperature compensation, but it is important to verify. The calibration process in this thesis is used RTD that connected to the transmitter to make sure resistance value of RTD are converted into ampere value. In order to interfacing, using DAQ card that only receive voltage, a 250 Ω resistor needed to make 2 sure the voltage reading is from 1V minimum and 5V maximum, with it respect current 4 mA until 20 mA. 1V will represent minimum temperature and 5V represent maximum value of temperature. When the calibration is heading for measurements, there is a chance that errors in the measurement influence the decision. The primary purpose of uncertainty analysis is to provide a measure of that influence and likelihood of presented a wrong decision. Uncertainty analysis requires understanding of the measurement, usually in terms of mathematical models of the various influence effects that cause errors. This thesis is running a systematic error that occurs when the value is recorded in repeatedly. The result of the accuracy of the RTD is present with it uncertainty to make sure the error is estimated in the result. 1.2 INTRODUCTION TO THE PROJECT Temperature is the one parameter that needs to measure their value and the accuracy in the calibration process. A system must be developing using software to make the system to detect and calculate all the uncertainty and provide the value of temperature with it accuracy. The major change occurring at the present is the increasing number of user friendly software that make it possible for user to experience new and fast ways of learning. In minutes, simulation, controller and real world interfacing can be created instantly. In this project, the software is developed to help user to learn and explore the calibration and uncertainty process with an interesting and interactive way in order to reduce the human error. The Data Acquisition (DAQ) card will be use for interfacing process between temperature instrumentation and the software. Besides that, the temperature measurement calibration will consume a long process compared to pressure measurement calibration due to measurement repeatability and therefore, it needs the monitoring of the operator until the process is finish. Therefore, the automatic detection temperature measurement 3 from the temperature source using the Resistance Temperature Detector (RTD) is proposed in this project. The computer software is menu-based to give the user flexibility and ease of use. The user needs no programming experience to operate the systems. This project is to detect temperature for Calibration Process using RTD sensor automatically. All the reading that comes from the calibration system will be display by the computer. The best measurement capabilities in temperature calibrations by comparison strongly relate to some particular and some typical uncertainty contributions. In general there are four main uncertainty contributions in calibration of thermometers; repeatability, uncertainty of a calibration furnace, uncertainty of a reference thermometer and uncertainty of a measuring devices [2]. All the uncertainty need to measure to know the accuracy of the value that has been provided. 1.3 PROBLEM STATEMENT Most of the industry using a machine that provide heating process whether it to soldering, melting an iron or just to provide the optimum temperature for the element. Temperature is one of the most frequently measured parameters in process system. The electrical thermometer is used, to sense and control the process temperatures. Regular calibration of these thermometers is critical to ensuring consistent quality of product manufactured, as well as providing regulatory compliance for some industries. The industry needs an automatic detection for the temperature sense by the electrical thermometer. Thus, this project comes to solve the problem in industrial by provided temperature detection using electrical thermometer, this project used RTD and a system that provided the measurement of the uncertainty to make sure the degree of accuracy is high. 4 1.4 OBJECTIVES The objectives of this project are: i. To develop software application to help in student learning process. Visual Basic (VB) 2008 Express Edition will be used as a main programming language. The software is developed to be interactive and user friendly for student. Student can understand well about the flow of the program when it’s running. ii. To interface the temperature transmitter output using Resistance Temperature Detector RTD to Visual Basic application. The interface process is done with Data Acquisition process (DAQ). Advantech USB-4716 DAQ card will be used to interface between instrument and the computer. All the hardware is connected to input of the DAQ and then the USB to the computer. The value of the temperature can be received by the computer after interfacing is done properly. iii. To design an automatic detection of temperature measurement in the software from the temperature source port within the range of the setting temperature. All the complete set of the temperature readings will be used directly for the calibration and uncertainty calculation process. The program is developed to make sure all the data can be captured by the software and it can transfer it to calculate the uncertainty for the calibration. 5 1.5 i. SCOPES OF PROJECT Develop a programming language using Visual Basic in software application for the project. The software is to develop GUI to describe how the program runs. It will help the person to save all the data needed. The data is saved in the table and also can be saved in Microsoft Office Excel. The software also can generate all the graph needed from the data obtain. It also develops to calculate the uncertainty for three reading; each reading is in five point calibration. ii. DAQ card is used to interface between computer and temperature instrument such as temperature transmitter, HART communicator, etc. The DAQ card is to connect inputs or outputs for the hardware to interface with the software. So, the software can receive the reading from the hardware. DAQ card can receive a change of voltage only. So, transmitter is needed to convert the resistance reading from RTD to current and then the converter is used to convert the current to voltage before connected to the DAQ card. iii. The Resistive Temperature Detector (RTD) will use as an input device to detect temperature changes. RTD is a sensor to detect the change of the temperature. The RTD will be inserted into the furnace to read the value of the temperature inside it. RTD Pt100 is giving the reading in value of resistance. When it gives 100 Ω reading it mean the temperature is at 0 oC. That is how the RTD Pt100 works. 6 1.6 THESIS OVERVIEW This thesis is consist seven chapters. There are the topics that include in this thesis: CHAPTER 1: Introduction This chapter introduce about the thesis is all about. Why the thesis is operated. It also includes the objective of the project and all the scope in this project. CHAPTER 2: Literature review This chapter discuss about published information from other experiment in this subject area. CHAPTER 3: Methodology All the method used to construct the project is arranged in the flow of the step that is consisted all the important point below: i. It included how the hardware, software and the GUI work. How to interface between software and hardware; get the value of the temperature. It also includes mathematical method use in this project. ii. Introduction of the instruments used in the project. iii. Hardware Implementation. It discussed about the interface used and how it implements. 7 iv. Software Development. It discussed about the software use and how it implements. v. Formulas use in this project especially for the development of the software. Uncertainty calculation. CHAPTER 4: Result and discussion It presents the result from this experiment and the related discussions on the result obtain in this project. CHAPTER 5: Conclusion This chapter discussed the project overview and how to improve the project. 8 CHAPTER 2 LITERATURE REVIEW 2.1 3D Device of Infrared Temperature Detection. In a certain field, it is important to measure temperature information in variable direction at the same time. However, there are few instruments to accomplish the function now. To implement the measure in 3 dimensions, an experimental table of temperature detection by infrared is designed. It is the integration of detection, control and monitor. The infrared device in the table can detect and measure temperature in real time and the three dimension electric motional device can adjust the detection distance by the user. The mechanical bar for displacement is controlled by a circuit with the control button. The infrared temperature sensor is fixed on the bar, so it can move along with the bar controlled by the circuit. The method of temperature detection is untouched, so it can detect small object and its tiny variable temperature, which cannot be detected by the thermometer or the electronic temperature sensor. In terms of the 3-D parallel motion control, the device can implement temperature measurement in variable directions. According to the results of the temperature values, the 3-D temperature distributed curve can be described. By using of the detection device, temperature of some special objects can be detected, such as the live anatomical animal, small sensor, nondestructive object, and so on [3]. 9 2.2 Temperature Transmitter with On-Line Calibration Using Johnson Noise. The relationship between resistance of a RTD and temperature tends to change over time. These changes can be periodically calibrated out of the system to maintain accuracy of the temperature measurement. For example, periodically an operator may be required to journey into the field to calibrate the transmitter. The transmitter is calibrated by placing the RTD sensor in a bath of a known temperature and monitoring output from the temperature transmitter. The difference between the actual temperature of the temperature bath and the output temperature is used as a calibration factor and stored in memory for subsequent use by the microprocessor. The transmitter injects a current into the RTD and the resultant voltage drop across the RTD is used to measure resistance. The voltage is converted into a digital format using an analog to digital converter and provided to a microprocessor. The microprocessor converts the measured voltage into a digital value representative of temperature [4]. 2.3 Designing a Temperature Measurement and Control System for Constant Temperature Reciprocator Platelet Preservation Box Based on LabVIEW. On LabVIEW, a temperature measurement and control system for constant temperature reciprocator platelet preservation box is designed based on Fuzzy-PID control. For temperature measurement part, we use multi-sensor data fusion algorithm to optimization data, and output fault early warning signal for sensors; Using Fuzzy-PID control algorithm to control the system, that will make the system has good dynamic characteristics, and has more ideal steady-state quality; Using LabVIEW software developing the temperature measurement and control system, that will make the measurement and control charts real-time display; Real-time state monitoring functions guarantee system security operation. And compared with traditional design method, using virtual technology allows the system to operation simply, to set up or reconstruct easily,