Springer Handbook of Experimental Solid Mechanics: Chapter 3

advertisement

49

Mechanics of

3. Mechanics of Polymers: Viscoelasticity

Wolfgang G. Knauss, Igor Emri, Hongbing Lu

3.1

3.2

Historical Background ...........................

3.1.1 The Building Blocks of the Theory

of Viscoelasticity ..........................

49

Linear Viscoelasticity .............................

3.2.1 A Simple Linear Concept: Response

to a Step-Function Input ..............

3.2.2 Specific Constitutive Responses

(Isotropic Solids) ..........................

3.2.3 Mathematical Representation of

the Relaxation and Creep Functions

3.2.4 General Constitutive Law for Linear

and Isotropic Solid: Poisson Effect ..

3.2.5 Spectral and Functional

Representations ...........................

51

3.2.6 Special Stress or Strain Histories

Related to Material Characterization

3.2.7 Dissipation

Under Cyclical Deformation............

3.2.8 Temperature Effects ......................

3.2.9 The Effect of Pressure

on Viscoelastic Behavior

of Rubbery Solids .........................

3.2.10 The Effect of Moisture and Solvents

on Viscoelastic Behavior................

3.3

3.4

50

51

Measurements and Methods ..................

3.3.1 Laboratory Concerns .....................

3.3.2 Volumetric (Bulk) Response ...........

3.3.3 The CEM Measuring System ............

3.3.4 Nano/Microindentation

for Measurements

of Viscoelastic Properties

of Small Amounts of Material.........

3.3.5 Photoviscoelasticity ......................

Nonlinearly Viscoelastic Material

Characterization ...................................

3.4.1 Visual Assessment

of Nonlinear Behavior...................

3.4.2 Characterization

of Nonlinearly Viscoelastic Behavior

Under Biaxial Stress States ............

56

63

63

68

69

69

70

71

74

76

83

84

84

85

53

3.5

Closing Remarks ...................................

89

53

55

3.6 Recognizing Viscoelastic Solutions

if the Elastic Solution is Known..............

3.6.1 Further Reading ...........................

90

90

55

References ..................................................

92

3.1 Historical Background

During the past five decades the use of polymers has

seen a tremendous rise in engineering applications. This

growing acceptance of a variety of polymer-based de-

signs derives in part from the ease with which these

materials can be formed into virtually any shape, and

in part because of their generally excellent performance

Part A 3

With the heavy influx of polymers into engineering

designs their special, deformation-rate-sensitive

properties require particular attention. Although

we often refer to them as time-dependent materials, their properties really do not depend on

time, but time histories factor prominently in the

responses of polymeric components or structures.

Structural responses involving time-dependent

materials cannot be assessed by simply substituting time-dependent modulus functions for their

elastic counterparts. The outline provided here is

intended to provide guidance to the experimentally inclined researcher who is not thoroughly

familiar with how these materials behave, but

needs to be aware of these materials because

laboratory life and applications today invariably

involve their use.

50

Part A

Solid Mechanics Topics

Part A 3.1

in otherwise normally corrosive environments. This recent emergence is driven by our evolving capabilities

during the last seven decades to synthesize polymers in

great variety and to address their processing into useful

shapes.

Historically polymers have played a significant role

in human developments, as illustrated by the introductory comments in [3.1]. Of great consequence for

the survival or dominance of tribes or nations was the

development of animal-derived adhesives for the construction of high-performance bows, starting with the

American Indian of the Northwest through the developments by the Tartars and leading to the extraordinary

military exploits of the Turks in the latter Middle

Ages [3.2]. In principle, these very old methods of

producing weaponry continue to aid today in the construction of modern aerospace structures. While the

current technology still uses principles exploited by our

ancestors many years ago, the advent of the synthetic

polymers has provided a plethora of properties available for a vast range of different engineering designs.

This range of properties is, indeed, so large that empirical methods are no longer sufficient to effect reliable

engineering developments but must now be supported

by optimum analytical methods to aid in the design

process.

One characteristic of polymers is their relative sensitivity to load exposure for extended periods of time

or to the rate of deformations imposed on them. This

behavior is usually and widely combined under the

concept of viscoelastic behavior, though it is sometimes characterized as representing fading memory of

the material. These time-sensitive characteristics typically extend over many decades of the time scale

and characteristically set polymers apart from the

normal engineering metals. While the strain-rate sensitivity [3.3] and the time dependence of failure in

metals [3.4] are recognized and creep as well as creep

rupture [3.5–10] of metals is well documented, one

finds that the incorporation of rate-dependent material

properties into models of time-dependent crack growth

– other than fatigue of intrinsically rate-insensitive materials – still stands on a relatively weak foundation.

Metallic glasses (i.e., amorphous metals) are relatively

newcomers to the pool of engineering materials. Their

physical properties are at the beginning of exploration,

but it is already becoming clear through initial studies [3.11, 12] that their amorphous structure endows

them with properties many of which closely resemble

those of amorphous polymers. While these developments are essentially in their infancy at this time it is

well to bear in mind that certain parts of the following

exposition are also applicable to these materials.

Because the emphasis in this volume is placed on

experimental methods, rather than on stress analysis

methods, only a cursory review of the linearized theory

of viscoelasticity is included. For the reader’s educational benefit a number of books and papers have been

listed in the Further Reading section, which can serve

as resources for a more in-depth treatment. This review of material description and analysis is thus guided

by particular deformation histories as a background

for measurements addressing material characterization

to be used in engineering design applications. Although the nonlinearly viscoelastic characteristic of

these materials are not well understood in a general,

three-dimensional setting, we include some reference to

these characteristics in the hope that this understanding

will assist the experimentalist with properly interpreting

laboratory measurements.

3.1.1 The Building Blocks of the Theory

of Viscoelasticity

Forces are subject to the laws of Newtonian mechanics, and are, accordingly, governed by the classical laws

of motion. While relativistic effects have been studied in connection with deforming solids, such concerns

are suppressed in the present context. Many texts deal

with Newtonian mechanics to various degrees of sophistication so that only a statement of the necessary

terminology is required for the present purposes. In the

interest of brevity we thus dispense with a detailed presentation of the analysis of stress and of the analysis of

strain, except for summarizing notational conventions

and defining certain variables commonly understood in

the context of the linear theory of elasticity. We adhere

to the common notation of the Greek letters τ and ε denoting stress and strain, respectively. Repeated indices

on components imply summation; identical subscripts

(e.g., τ11 ) denote normal components and different ones

shear (e.g., τ12 ). The dilatational components of stress,

τii , are often written as σkk , with the strain complement being εkk . Because the viscoelastic constitutive

description is readily expressed in terms of deviatoric

and dilatational components, it is necessary to recall the

components Sij of the deviatoric stress as

1

Sij = τij − τkk · δij ,

3

(3.1)

where δij denotes the Kronecker operator. Similarly, the

corresponding deviatoric strain e is written in compo-

Mechanics of Polymers: Viscoelasticity

nent form as

1

eij = εij − εkk · δij .

(3.2)

3

For further definitions and derivations of measures

of stress or strain the reader is referred to typical texts.

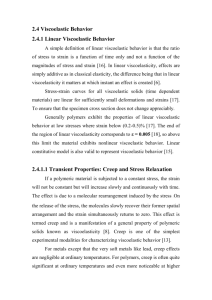

3.2 Linear Viscoelasticity

51

The remaining building block of the theory consists

of the constitutive behavior, which differentiates viscoelastic materials from elastic ones. The next section

is devoted to a brief definition of linearly viscoelastic

material behavior.

3.2 Linear Viscoelasticity

face (boundary) of a viscoelastic solid. Specification of

such a quantity under uniaxial relaxation is not particularly useful, except to note that in the limit of short

(glassy) response its value is a limit constant, and also

under long-term conditions when the equilibrium (or

rubbery) modulus is effective, in which case the Poisson’s ratio is very close to 0.5 (incompressibility).

3.2.1 A Simple Linear Concept:

Response to a Step-Function Input

It is convenient for instructional purposes to consider

that the stress can be described, so that the strain follows from the stress. The reverse may hold with equal

validity. In general, of course, neither may be prescribed

a priori, and a general connection relates them. The

structure of the linear theory must be completely symmetric in the sense that the mathematical formulation

applies to these relations regardless of which variable is

considered the prescribed or the derived one. For introductory purposes we shall use, therefore, the concept of

a cause c(t) (input) and an effect e(t) (output) that are

connected by a functional relationship. The latter must

be linear with respect to (a) the amplitude (additivity

with respect to magnitude) and (b) time in the sense that

they obey additivity independent of time.

It is primarily a matter of convenience that the

cause-and-effect relation is typically expressed with the

aid of a step-function cause. Other representations are

Table 3.1 Nomenclature for viscoelastic material functions

Type of loading

Shear

Bulk

Uniaxial

extension

μ(t)

J(t)

μ (ω)

μ (ω)

J (ω)

J (ω)

K (t)

M(t)

K (ω)

K (ω)

M (ω)

M (ω)

E(t)

D(t)

E (ω)

E (ω)

D (ω)

D (ω)

Mode

Quasistatic

Relaxation

Creep

Strain prescribed

Harmonic

Stress prescribed

Storage

Loss

Storage

Loss

Part A 3.2

The framework for describing linearly viscoelastic

material behavior, as used effectively for engineering applications, is phenomenological. It is based

mathematically on either an integral or differential formulation with the material representation described

realistically in numerical (tabular) or functional form(s).

The fundamental equations governing the linearized

theory of viscoelasticity are the same as those for

the linearized theory of elasticity, except that the

generalized Hooke’s law of elasticity is replaced by

a constitutive description that is sensitive to the material’s (past) history of loading or deformation. It will be

the purpose of the immediately subsequent subsections

to summarize this formalism of material description in

preparation for various forms of material characterization. Little or no reference is made to general solution

methods for viscoelastic boundary value problems. For

this purpose the reader is referred to the few texts available as listed in Sect. 3.6.1.

Rather than repeating the theory as already outlined

closely in [3.13] we summarize below the concepts

and equations most necessary for experimental work; if

necessary, the reader may consult the initially cited reference(s) (Sect. 3.6.1) for a more expansive treatment.

In brief, the viscoelastic material functions of first-order

interest are given in Table 3.1.

Note the absence of a generic viscoelastic Poisson

function, because that particular response is a functional

of the deformation or stress history applied to the sur-

52

Part A

Solid Mechanics Topics

Part A 3.2

feasible and we shall address a common one (steadystate harmonic) later on as a special case. For now,

let E(t, t1 ) represent a time-dependent effect that results from a step cause c(t1 ) = h(t1 ) of unit amplitude

imposed at time t1 ; h(t1 ) denotes the Heaviside step

function applied at time t1 .

For the present we are concerned only with nonaging materials, i. e. with materials, the intrinsic properties of which do not change with time. (With this

definition in mind it is clear that the nomenclature timedependent materials in place of viscoelastic materials is

really a misnomer; but that terminology is widely used,

nevertheless.) We can assert then that for a non-aging

material any linearity of operation, or relation between

an effect and its cause, requires satisfaction of

Postulate (a): proportionality with respect to amplitude,

and

Postulate (b): additivity of effects independent of the

time sequence, when the corresponding

causes are added, regardless of the respective application times.

Condition (a) states that, if the cause c(0) elicits E(t, 0), then a cause of different amplitude, say

c1 (0) ≡ α · h(0), with α a constant, elicits a response

α · E(t, 0). Under the non-aging restriction this relation

is to be independent of the time when the cause starts

to act, so that c1 (t1 ) ≡ α · h(t1 ) → αE(t, t1 ); t > t1 also

holds. This means simply that the response–effect relation shown in the upper part of Fig. 3.1 holds also

for a different time t2 , which occurs later in time

than t1 .

Condition (b) entails then that, if two causes

c1 (t1 ) ≡ α1 · h(t1 ) and c2 (t2 ) ≡ α2 · h(t2 ), imposed at

different times t1 and, t2 act jointly, then their corresponding effects α1 · E(t, t1 ) and α2 · E(t, t2 ) is their sum

while observing their proper time sequence. Let the

common time scale start at t = 0; then the combined

effect, say e(t), is expressed by

c(t) ≡ c1 (t1 ) + c2 (t2 ) → e(t) = α1 · E(t − t1 )

+ α1 · E(t − t2 ) .

(3.3)

Specifically, here the first response does not start until

the time t1 is reached, and the response due to the second cause is not experienced until time t2 , as illustrated

in Fig. 3.1.

Having established the addition process for two

causes and their responses, the extension to an arbitrary

number of discrete step causes is clearly recognized as

a corresponding sum for the collective effects e(tn ), up

to time t, in the generalized form of (3.3), namely

(3.4)

e(t) =

αn E(t − tn ) ; (tn < t) .

This result may be further generalized for causes

represented by a continuous cause function of time,

say c(t). To this end consider a continuously varying function c(t) decomposed into an initially discrete

approximation of steps of finite (small) amplitudes.

With the intent of ultimately proceeding to the limit of

infinitesimal steps, note that the amplitude of an individual step amplitude at, say, time τn is given by

(3.5)

αn → Δc(τn ) = (Δc/Δτ) Δτ ,

τn

Stress

which, when substituted into (3.4), leads to

e(t) =

E(t − tn )(Δc/Δτ) Δτ .

Strain

τn

t1

Time

Stress

t1

Time

Strain

In the limit n → ∞ (Δτ → dτ), the sum

Δc e(t) = lim

E(t − tn )

Δτ ,

Δτ τn

(3.7)

passes over into the integral

2

t

2

1

(3.6)

e(t) =

1

E(t − τ)

dc(τ)

dτ .

dτ

(3.8)

0

t1

t2

Time

t1

t2

Time

Fig. 3.1 Additivity of prescribed stress steps and corres-

ponding addition of responses

Inasmuch as this expression can contain the effect of

a step-function contribution at zero time of magnitude

c(0), this fact can be expressed explicitly through the

Mechanics of Polymers: Viscoelasticity

alternate notation

3.2 Linear Viscoelasticity

53

effect, one obtains the inverse relation(s)

t

e(t) = c(0)E(t) +

E(t − τ)

0+

dc(τ)

dτ ,

dτ

(3.9)

3.2.2 Specific Constitutive Responses

(Isotropic Solids)

For illustrative purposes and to keep the discussion

within limits, the following considerations are limited to

isotropic materials. Recalling that the stress and strain

states may be decomposed into shear and dilatational

contributions (deviatoric and dilatational components),

we deal first with the shear response followed by the

volumetric part. Thermal characterization will then be

dealt with subsequently.

Shear Response

Let τ denote any shear stress component and ε its

corresponding shear strain. Consider ε to be the cause

and τ its effect. Denote the material characteristic E(t)

for unit step excitation from Sect. 3.2.1 in the present

shear context by μ(t). This function will be henceforth

identified as the relaxation modulus in shear (for an

isotropic material). It follows then from (3.8) and (3.9)

that

t

dε(ξ)

(3.10)

dξ

τ(t) = 2 μ(t − ξ)

dξ

0

t

= 2ε(0)μ(t) + 2

0+

μ(t − ξ)

dε(ξ)

dξ .

dξ

(3.11)

The factor of 2 in the shear response is consistent with

elasticity theory, inasmuch as in the limits of short- and

long-term behavior all viscoelasticity relations must revert to the elastic counterparts.

If one interchanges the cause and effect by letting

the shear stress represent the cause, and the strain the

t

J(t − ξ)

dτ

dξ

dξ

(3.12)

0

t

1

1

= τ(0)J(t) +

2

2

J(t − ξ)

0+

dτ

dξ ,

dξ

(3.13)

where now the function E ≡ J(t) is called the shear

creep compliance, which represents the creep response

of the material in shear under application of a step shear

stress of unit magnitude as the cause.

Bulk or Dilatation Response

Let εii (t) represent the first strain invariant and σ jj (t) the

corresponding stress invariant. The latter is recognized

as three times the pressure P(t), i. e., σ jj (t) ≡ 3P(t). In

completely analogous fashion to (3.12) and (3.13) the

bulk behavior, governed by the bulk relaxation modulus

K (t) ≡ E(t), is represented by

t

σ jj = 3

K (t − ξ)

dεii (ξ)

dξ

dξ

(3.14)

0

t

= 3εii (0)K (t) + 3

K (t − ξ)

0+

dεii (ξ)

dξii .

dξ

(3.15)

Similarly, one writes the inverse relation as

1

εii =

3

t

M(t − ξ)

dσ jj (ξ)

dξ

dξ

(3.16)

0

1

1

= σ jj (0)M(t) +

3

3

t

M(t − ξ)

0+

dσ jj (ξ)

dξii ,

dξ

(3.17)

where the function M(t) ≡ E(t) represents now the dilatational creep compliance (or bulk creep compliance);

in physical terms, this is the time-dependent fractional

volume change resulting from the imposition of a unit

step pressure.

3.2.3 Mathematical Representation

of the Relaxation and Creep Functions

Various mathematical forms have been suggested and

used to represent the material property functions

Part A 3.2

where the lower integral limit 0+ merely indicates that

the integration starts at infinitesimally positive time so

as to exclude the discontinuity at zero. Alternatively, the

same result follows from observing that for a step discontinuity in c(t) the derivative in (3.5) is represented by

the Dirac delta function δ(t). In fact, this latter remark

holds for any jump discontinuity in c(t) at any time, after and including any at t = 0. In mathematical terms

this form is recognized as a convolution integral, which

in the context of the dynamic (vibration) response of

linear systems is also known as the Duhamel integral.

1

ε(t) =

2

54

Part A

Solid Mechanics Topics

Part A 3.2

analytically. Preferred forms have evolved, with precision being balanced against ease of mathematical

use or a minimum number of parameters required.

All viscoelastic material functions possess the common characteristic that they vary monotonically with

time: relaxation functions decreasing and creep functions increasing monotonically. A second characteristic

of realistic material behavior is that time is (almost)

invariably measured in terms of (base 10) logarithmic

units of time. Thus changes in viscoelastic response

may appear to be minor when considered as a function of the real time, but substantial if viewed against

a logarithmic time scale.

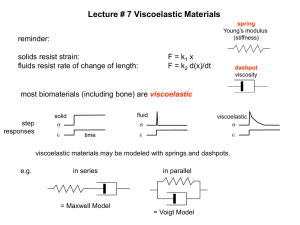

Early representations of viscoelastic responses were

closely allied with (simple) mechanical analog models (Kelvin, Voigt) or their derivatives. Without delving

into the details of this evolutionary process, their generalization to broader time frames led to the spectral

representation of viscoelastic properties, so that it is

useful to present only the rudiments of that development. The building blocks of the analog models

are the Maxwell and the Voigt models illustrated in

Fig. 3.2a,b. In this modeling a mechanical force F

corresponds to the shear stress τ and, similarly, a displacement/deflection δ corresponds to a strain ε. Under

a stepwise applied deformation of magnitude ε0 – separating the force-application points in the Maxwell

model – the stress (force) abates or relaxes by the

relation

τ(t) = ε0 μm exp(−t/ξ) ,

F

a)

b)

(3.18)

c)

F

μ

μ

η

η

μ1

η1

μ2

η2

μ3

η3

F

F

F

d)

μ∞

F

μ1

μ2

μ3

μj

η1

η2

η3

ηj

F

where ξ = ηm /μm is called the (single) relaxation time.

Similarly, applying a step stress (force) of magnitude

to the Voigt element engenders a time-dependent separation (strain) of the force-application points described

by

τ0

[1 − exp(−t/ς)] ,

(3.19)

ε(t) =

μν

where ς = ην /μν is now called the retardation time

since it governs the rate of retarded or delayed motion.

Note that this representation is used for illustration purposes here and that the retardation time for the Voigt

material is not necessarily meant to be equal to the

relaxation time of the Maxwell solid. It can also be

easily shown that this is not true for a standard linear solid either. By inductive reasoning, that statement

holds for arbitrarily complex analog models. The relaxation modulus and creep compliance commensurate

with (3.18) (Maxwell model) and (3.19) (Voigt model)

for the Wiechert and Kelvin models (Fig. 3.2c,d) are,

respectively

μn exp(−t/ξn )

(3.20)

μ(t) = μ∞ +

n

and

J(t) = Jg +

Jn [1 − exp(−t/ςn )] + η0 t ,

where Jg and η0 arise from letting η1 → 0 (the first

Voigt element degenerates to a spring) and μn → 0 (the

last Voigt element degenerates to a dashpot). These series representations with exponentials are often referred

to as Prony series.

As the number of relaxation times increases indefinitely, the generalization of the expression for the shear

relaxation modulus, becomes

∞

dξ

(3.22)

,

μ(t) = μ∞ + H (ξ) exp(−t/ξ)

ξ

0

where the function H (ξ) is called the distribution function of the relaxation times, or relaxation spectrum, for

short; the creep counterpart presents itself with the help

of the retardation spectrum L(ζ ) as

∞

μj

ηj

J(t) = Jg +

L(ζ )[1 − exp(−t/ζ )]

0

F

Fig. 3.2a–d Mechanical analogue models: (a) Maxwell,

(b) Voigt, (c) Wiechert, and (d) Kelvin

(3.21)

n

dζ

+ ηt ,

ζ

(3.23)

Note that although the relaxation times ξ and the retardation times ζ do not, strictly speaking, extend over the

range from zero to infinity, the integration limits are so

Mechanics of Polymers: Viscoelasticity

3.2 Linear Viscoelasticity

assigned for convenience since the functions H and L

can always be chosen to be zero in the corresponding

part of the infinite range.

3.2.5 Spectral and Functional

Representations

3.2.4 General Constitutive Law for Linear

and Isotropic Solid: Poisson Effect

A discrete relaxation spectrum in the form

H (ξ) =

μn ξn δ(ξn ) ,

One combines the shear and bulk behavior exemplified in (3.13), (3.16) and (3.19), (3.20) into the general

stress–strain relation

t 2

∂εkk

K (t − τ) − μ(t − τ)

dτ

σij (t) = δij

3

∂τ

t

+2

0−

μ(t − τ)

∂εij

dτ ,

∂τ

(3.24)

where δij is again the Kronecker delta.

Poisson Contraction

A recurring and important parameter in linear elasticity is Poisson’s ratio. It characterizes the contraction/expansion behavior of the solid in a uniaxial stress

state, and is an almost essential parameter for deriving

other material constants such as the Young’s, shear or

bulk modulus from each other. For viscoelastic solids

the equivalent behavior cannot in general be characterized by a constant; instead, the material equivalent

to the elastic Poisson’s ratio is also a time-dependent

function, which is a functional of the stress (strain)

history imposed on a uniaxially stressed material sample. This time-dependent function covers basically the

same (long) time scale as the other viscoelastic responses and is typically measured in terms of 10–20

decades of time at any one temperature. However, compared to these other functions, its value changes usually

from a maximum value of 0.35 or 0.4 at the short

end of the time spectrum to 0.5 for the long time

frame. Several approximations are useful. In the nearglassy domain (short times) its value can be taken as

a constant equal to that derived from measurements

well below the glass-transition temperature. In the long

time range for essentially rubber-like behavior the approximation of 0.5 is appropriate, though not if one

wishes to convert shear or Young’s data to bulk behavior, in which case small deviations from this value

can play a very significant role. If knowledge in the

range between the (near-)glassy and (near-)rubbery domain are required, neither of the two limit constants

are strictly appropriate and careful measurements are

required [3.14–16].

(3.25)

where δ(ξn ) represents the Dirac delta function, clearly

leads to the series representation (3.20) and can trace

the modulus function arbitrarily well by choosing the

number of terms in the series to be sufficiently large;

a choice of numbers of terms equal to or larger

than twice the number of decades of the transition

is often desirable. For a history of procedures to

determine the coefficients μn see the works by Hopkins and Hamming [3.17], Schapery [3.18], Clauser

and Knauss [3.19], Hedstrom et al. [3.20], Emri and

Tschoegl [3.21–26], and Emri et al. [3.27, 28], all of

which battle the ill-conditioned nature of the numerical

determination process. This fact may result in physically inadmissible, negative values (energy generation),

though the overall response function may be rendered

very well. A more recent development that largely

circumvents such problems, is based on the trust region concept [3.29], which has been incorporated into

MATLAB, thus providing a relatively fast and readily available procedure. The numerical determination of

these coefficients occurs through an ill-conditioned integral or matrix and is not free of potentially large errors

in the coefficients, including physically inadmissible

negative values, though the overall response function

may be rendered very well.

Although expressions as given in (3.22) and (3.23)

render complete descriptions of the relaxation or creep

behavior once H (ξ) or L(ξ) are determined for any

material in general, simple approximate representations

can fulfill a useful purpose. Thus, the special function

μ0 − μ∞ ξ0 n

exp(−ξ0 /ξ)

(3.26)

H (ξ) =

Γ (n)

ξ

with the four parameters μ0 , μ∞ , ξ0 , and n representing

material constants, where Γ (n) is the gamma function,

leads to the power-law representation for the relaxation

response

μ(t) = μ∞ +

μ0 − μ∞

.

(1 + t/ξ0 )n

(3.27)

This equation is represented in Fig. 3.3 for the parameter values μ∞ = 102 , μ0 = 105 , ξ0 = 10−4 , and

n = 0.35. It follows quickly from (3.22) and the figure that μ0 represents the modulus as t → 0, and μ∞

Part A 3.2

0−

55

56

Part A

Solid Mechanics Topics

3.2.6 Special Stress or Strain Histories

Related to Material Characterization

log modulus

6

For the purposes of measuring viscoelastic properties in

the laboratory we consider several examples in terms of

shear states of stress and strain. Extensional or compression properties follow totally analogous descriptions.

5

4

3

2

Part A 3.2

1

–10

–5

0

5

10

log t

Fig. 3.3 Example of the power-law representation of a relaxation modulus

its behavior as μ(t → ∞); ξ0 locates the central part

of the transition region and n the (negative) slope. It

bears pointing out that, while this functional representation conveys the generally observed behavior of the

relaxation phenomenon, it usually serves only in an approximate manner: the short- and long-term modulus

limits along with the position along the log-time axis

and the slope in the mid-section can be readily adjusted

through the four material parameters, but it is usually

a matter of luck (and rarely possible) to also represent

the proper curvature in the transitions from short- and

long-term behavior. Nevertheless, functions of the type

(3.26) or (3.27) can be very useful in capturing the essential features of a problem. With respect to fracture

Schapery draws heavily on the simplified power-law

representation.

An alternative representation of one-dimensional

viscoelastic behavior (shear or extension), though not

accessed through a distribution function of the type

described above, is the so-called stretch exponential

formulation; it is often used in the polymer physics

community and was introduced for torsional relaxation

by Kohlrausch [3.30] and reintroduced for dielectric

studies by Williams and Watts [3.31]. It is, therefore, often referred to as the KWW representation.

In the case of relaxation behavior it takes the form

(with the addition of the long-term equilibrium modulus μ∞ ),

μ(t) = μ∞ + μ0 exp −(t/ξ0 )β .

Unidimensional Stress State

We call a stress or strain state unidimensional when it

involves only one controlled or primary displacement

or stress component, as in pure shear or unidirectional

extension/compression. Typical engineering characterizations of materials occur by means of uniaxial

(tension) tests. We insert here a cautionary note with

respect to laboratory practices. In contrast to working

with metallic specimens, clamping polymers typically

introduces complications that are not necessarily totally resolvable in terms of linear viscoelasticity. For

example, clamping a tensile specimen in a standard

test machine with serrated compression claps introduces a nonlinear material response such that, during

the course of a test, relaxation or creep may occur under the clamps. Sometimes an effort is made to alleviate

this problem by gluing metal tabs to the end of specimens, only to introduce the potential of the glue line

to contribute to the overall relaxation or deformation.

If the contribution of the glue line to the deformation

is judged to be small, an estimate of its effect may be

derived with the help of linear viscoelasticity, and this

should be stated in reporting the data.

For rate-insensitive materials the pertinent property

is Young’s modulus E. For viscoelastic solids this constant is supplanted by the uniaxial relaxation modulus

E(t) and its inverse, the uniaxial creep compliance D(t).

Although the general constitutive relation (3.24) can

be written for the uniaxial stress state (σ11 (t) = σ0 (t),

say, σ22 = σ33 = 0), the resulting relation for the uniaxial stress is an integral equation for the stress or

strain ε11 (t), involving the relaxation moduli in shear

and dilatation. In view of the difficulties associated with

determining the bulk response, it is not customary to follow this interconversion path, but to work directly with

the uniaxial relaxation modulus E(t) and/or its inverse,

the uniaxial creep compliance D(t). Thus, if σ11 (t) is

the uniaxial stress and ε11 (t) the corresponding strain,

one writes, similar to (3.10) and (3.12),

(3.28)

Further observations and references relating to this

representation are delineated in [3.13].

t

σ11 (t) = ε11 (0)E(t) +

0+

E(t − ξ)

dε11 (ξ)

dξ

dξ

Mechanics of Polymers: Viscoelasticity

ε

ε

ε0

t0

+

t0

t

t0

t

t

modulus (3.22) together with the convolution relation

(3.10) to render, with ε̇(t) = const = ε̇0 and ε(0) = 0, the

general result

t

0+

We insert here a cautionary note with respect to

laboratory practices: In contrast to working with metallic specimens, clamping polymers typically introduces

complications that are not necessarily totally resolvable

in terms of linear viscoelasticity. For example, clamping

a tensile specimen in a standard test machine with serrated compression clamps introduces nonlinear material

response such that during the course of a test relaxation or creep may occur under the clamps. Sometimes

an effort is made to alleviate this problem by gluing

metal tabs to the end of specimens, only to introduce

the potential of the glue-line to contribute to the overall relaxation or deformation. If the contribution of the

glue-line to the deformation is judged to be small an estimate of its effect may be derived with the help of linear

viscoelasticity, and such should be stated in reporting

the data.

Constant-Strain-Rate History. A common test method

for material characterization involves the prescription of

a constant deformation rate such that the strain increases

linearly with time (small deformations). Without loss

of generality we make use of a shear strain history in

the form ε(t) = ε̇0 t (≡ 0 for t ≤ 0, ε̇0 = const for t ≥ 0)

and employ the general representation for the relaxation

τ

µ (t)

Error

ε0

t0

t

t0

t

Fig. 3.5 Difference in relaxation response resulting from

step and ramp strain history

μ(t − ξ)ε̇0 dξ

τ(t) = 2

0

t

= 2ε̇0

∞

μ∞ +

0

H (ς) exp −

0

t − ξ dς

du

ς

ς

(3.29)

t

= 2με̇0

μ(u) du = 2ε̇0 t ·

0

1

t

t

μ(u) du

0

= 2ε(t)μ̄(t) ; t − ξ ≡ u .

(3.30)

t

Here μ̄(t) = 1t 0 μ(u) du is recognized as the relaxation

modulus averaged over the past time (the time-averaged

relaxation modulus).

Ramp Strain History. A recurring question in viscoelas-

tic material characterization arises when step functions

are called for analytically but cannot be supplied experimentally because equipment response is too slow

or dynamic (inertial) equipment vibrations disturb the

input signal: In such situations one needs to determine

the error if the response to a ramp history is supplied

instead of a step function with the ramp time being t0 .

To provide an answer, take explicit recourse to postulate (b) in Sect. 3.2.1 in connection with (3.29)/(3.30)

to evaluate (additively) the latter for the strain histories

shown in Fig. 3.4. To arrive at an approximate result as

a quantitative guide, let us use the power-law representation (3.27) for the relaxation modulus. Making use of

Taylor series approximations of the resulting functions

for t 0 one arrives at (the derivation is lengthy though

straightforward)

n t0 /ξ0

τ(t)

= μ(t) 1 +

(3.31)

+...

2ε0

2 (1 + t/ξ0 )

Part A 3.2

and the inverse relation as

t

dσ11 (ξ)

ε11 (t) = σ11 (0)D(t) + D(t − ξ)

dξ .

dξ

ε

57

Fig. 3.4 Superposition of linear functions to generate a ramp

ε

=

3.2 Linear Viscoelasticity

58

Part A

Solid Mechanics Topics

Part A 3.2

as long as μ∞ can be neglected relative to μ0 (usually

on the order of 100–1000 times smaller). The derivation is lengthy though straightforward. The expression

in the square brackets contains the time-dependent error

by which the ramp response differs from the ideal relaxation modulus, as illustrated in Fig. 3.5, which tends to

zero as time grows without limit beyond t0 .

By way of example, if n = 1/2 and an error in the

relaxation modulus of maximally 5% is acceptable, this

condition can be met by recording data only for times

larger than t/t0 = 5 − ς0 /t0 . Since ς0 /t0 is always positive the relaxation modulus is within about 5% of the

ramp-induced measurement as long as one discounts

data taken before 5t0 . To be on the safe side, one typically dismisses data for an initial time interval equal to

ten times the ramp rise time.

In case the time penalty for the dismissal of that

time range is too severe, methods have been devised

that allow for incorporation of this earlier ramp data

as delineated in [3.32, 33]. On the other hand, the wide

availability of computational power makes an additional

data reduction scheme available: Using a Prony series (discrete spectrum) representation, one evaluates

the constant-strain-rate response with the aid of (3.30),

leaving the individual values of the spectral lines as unknowns. With regard to the relaxation times one has two

options:

(a) one leaves them also as unknowns, or

(b) one fixes them such that they are one or two per

decade apart over the whole range of the measurements.

The second option (b) is the easier/faster one and provides essentially the same precision of representation

as option (a). After this choice has been made, one fits

the analytical expression with the aid of Matlab to the

measurement results. Matlab will handle either cases (a)

or (b). There may be issues involving possible dynamic

overshoots in the rate-transition region, because a test

machine is not able to (sufficiently faithfully) duplicate

the rapid change in rate transition from constant to zero

rate, unless the initial rate is very low. This discrepancy

is, however, considerably smaller that that associated

with replacing a ramp loading for a step history.

Mixed Uniaxial Deformation/Stress Histories

Material parameters from measured relaxation or creep

data are typically extracted via Volterra integral equations of the first kind, i. e., of the type of (3.20)

or (3.21). A problem arises because these equations

are ill-posed in the sense that the determination of

the kernel (material) functions from modulus or creep

data involving Volterra equations of the first kind

can lead to sizeable errors, whether the functions

are sought in closed form or chosen in spectral or

discrete (Prony series) form [3.18, 19, 27]. On the

other hand, Volterra equations of the second kind do

not suffer from this mathematical inversion instability

(well-posed problem). Accordingly, we briefly present

an experimental arrangement that alleviates this inherent difficulty [3.28]. At the same time, this particular

scheme also allows the simultaneous determination

of both the relaxation and creep properties, thus circumventing the calculation of one from the other. In

addition, the resulting data provides the possibility of

a check on the linearity of the viscoelastic data through

a standard evaluation of a convolution integral.

Relaxation and/or creep functions can be determined from an experimental arrangement that incorporates a linearly elastic spring of spring constant ks

as illustrated in Fig. 3.6, readily illustrated in terms of

a tensile situation. The following is, however, subject

to the assumption that the elastic deformations of the

test frame and/or the load cell are small compared to

those of the specimen and the deformation of the added

spring. If the high stiffness of the material does not

warrant that assumption it is necessary to determine

the contribution of the testing machine and incorporate it into the stiffness ks . Similar relations apply for

a shear stress/deformation arrangement. In the case of

lb

Δl b0

ls

ls

Δl

Δl s0

Fig. 3.6 Arrangement for multiple material properties de-

termination via a single test

Mechanics of Polymers: Viscoelasticity

bulk/volume response the spring could be replaced by

a compressible liquid, though this possibility has not

been tested in the laboratory, to our knowledge. For

a suddenly applied gross extension (compression) of the

spring by an amount Δl = const, both the bar and the

spring will change lengths according to

Δlb (t) + Δls (t) = Δl ,

(3.32)

where the notation in Fig. 3.6 is employed (subscript

‘b’ refers to the bar and “s” to the spring). The correspondingly changing stress (force) in the bar is given

by

(3.33)

which is also determined by

Fb (t) =

Ab

lb

t

E(t − ξ)

d

[Δlb (ξ)] dξ

dξ

0

Ab 0

Δl E(t) ,

+

lb b

(3.34)

which, together with (3.32), renders upon simple

manipulation

Ab

Δlb (t)

+

εb (0)E(t)

Δl

ks Δl

t

E(t − ξ)

+

d

[εb (ξ)] dξ = 1 .

dξ

(3.35)

0

This is a Volterra integral equation of the second kind,

as can be readily shown by the transformation of variables ξ = t − u; it is well behaved for determining the

relaxation function E(t).

By measuring Δlb (t) along with the other parameters in this equation, one determines the relaxation

modulus E(t).

Similarly, one can cast this force equilibrium equation in terms of the creep compliance of the material and

the force in the spring as

ks lb

Fb (t) +

Ab

t

D(t − ξ)

d

[Fb (ξ)] dξ

dξ

0

Time-Harmonic Deformation

A frequently employed characterization of viscoelastic

materials is achieved through sinusoidal strain histories

of frequency ω. Historically, this type of material characterization refers to dynamic properties, because they

are measured with moving parts as opposed to methods

leading to quasi-static relaxation or creep. However, in

the context of mechanics dynamic is reserved for situations involving inertia (wave) effects. For this reason,

we replace in the sequel the traditional dynamic (properties) with harmonic, signifying sinusoidal. Whether one

asks for the response from a strain history that varies

with sin(ωt) or cos(ωt) may be accomplished by dealing

with the (mathematically) complex counterpart

ε(t) = ε0 exp(iωt) · h(t)

0

(3.36)

It is clear then that, if both deformations and the stress

in the bar are measured, both the relaxation modulus

(3.38)

so that after the final statement has been obtained one

would be interested, correspondingly in either the real

or the imaginary part of the result. Here h(t) is again

the Heaviside step function, according to which the real

part of the strain history represents a step at zero time

with amplitude ε0 . The evaluation of the appropriate response may be accomplished with the general modulus

representation so that substitution of (3.22) and (3.38)

into (3.12) or (3.13) renders, after an interchange in the

order of integration,

∞

dς

τ(t) = 2ε0 μ∞ + H (ς) exp(−t/ς)

ς

t

t −ξ

+ 2ε0 iω H (ς)

exp −

ς

0

0

dς

× exp(iωξ) dξ

ς

∞

0

+ Fb (0)D(t) = ks Δl .

and the creep compliance can be determined and the

determination of the Prony series parameters proceeds

without difficulty [3.21–26]

The additional inherent characteristic of this (hybrid) experimental–computational approach is that it

may be used for determining the limit of linearly viscoelastic behavior of the material. By determining the

two material functions of creep and relaxation simultaneously one can examine whether the determined

functions satisfy the essential linearity constraint, see

(3.62)–(3.64)

t

D(t − ξ)E(ξ) dξ = t .

(3.37)

59

Part A 3.2

Fb (t) = Fs (t) = kb (t)Δls (t) = ks [Δl − Δlb (t)] ,

3.2 Linear Viscoelasticity

60

Part A

Solid Mechanics Topics

t

+ 2ε0 iωμ∞

exp(iωξ) dξ ,

(3.39)

0

which ultimately leads to

τ(t) = 2ε0 [μ(t) − μ∞ ]

∞

iωH (ς)

− 2ε0

exp(−t/ς) dς

1 + iως

0

∞

iωH (ς)

dς .

+ 2ε(t) μ∞ +

1 + iως

(3.40)

Part A 3.2

0

The first two terms are transient in nature and (eventually) die out, while the third term represents the

steady-state response.

For the interpretation of measurements it is important to appreciate the influence of the transient terms on

the measurements. Even though a standard linear solid,

represented by the spring–dashpot analog in Fig. 3.7

does not reflect the full spectral range of engineering

materials, it provides a simple demonstration for the decay of the transient terms. Its relaxation modulus (in

shear, for example) is given by

μ(t) = μ∞ + μs exp(−t/ζ0 ) ,

(3.41)

where ζ0 denotes the relaxation time and μ∞ and μs

are modulus parameters. Using the imaginary part of

(3.40) corresponding to the start-up deformation history

ε(t) = ε0 sin(ωt)h(t) one finds for the corresponding

stress history

ωζ0

μs

τ(t)

=R=

(cos ωt + ωζ0 sin ωt)

2μ∞ ε0

μ∞ 1 + ω2 ζ02

ωζ0

μs

e−t/ζn .

(3.42)

−

μ∞ 1 + ω2 ζ02

F

μ

η

μ0

F

The last term is the transient. An exemplary presentation with μs /μ∞ = 5, ωζ0 = 1, and ζ0 = 20 is shown

in Fig. 3.8. For longer relaxation times the decay lasts

longer; for shorter ones the converse is true. One readily

establishes that in this example the decay is (exponentially) complete after four to five times the relaxation

time. The implication for real materials with very long

relaxation times deserves extended attention. The expression for the standard linear solid can be generalized

by replacing (3.41) with the corresponding Prony series

representation.

1 ωζn μn

τ(t)

=

(cos ωt + ωζn sin ωt)

2μ∞ ε0

μ∞ n 1 + ω2 ζn2

1 ωζn μn −t/ζn0

e

.

(3.43)

−

μ∞ n 1 + ω2 ζn2

Upon noting that the fractions in the last term sum do

not exceed μn /2 one can bound the second sum by

1 ωζn μn −t/ζn0

e

μ∞ n 1 + ω2 ζn2

1 1 μ(t)

−t/ζn0

≤

μn e

=

−1 .

(3.44)

2μ∞ n

2 μ∞

This expression tends to zero only when t → ∞, a time

frame that is, from an experimental point of view, too

long in most instances. For relatively short times that

fall into the transition range, the ratio of moduli is not

small, as it can be on the order of 10 or 100, or even

larger. There are, however, situations for which this error can be managed, and these correspond to those cases

when the relaxation modulus changes very slowly during the time while sinusoidal measurements are being

R

6

5

4

3

2

1

0

–1

–2

–3

–4

–5

–6

0

20

40

60

80

100

120 140 160

Normalized time

Fig. 3.7 Standard

Fig. 3.8 Transient start-up behavior of a standard linear

linear solid

solid under ε(t) = h(t) sin(ωt)

Mechanics of Polymers: Viscoelasticity

τ(t)

= μ∞ +

2ε(t)

∞

0

iωH (ς)

dς .

1 + iως

Both the strain ε(t) and the right-hand side are complex

numbers. One calls

μ∗ (ω) ≡ μ∞ +

∞

0

iωH (ς)

dς

1 + iως

Stress:

(3.46)

τ (t)

sin[ωt +Δ(ω)]

2ε0 μ(ω)

Strain:

1

the complex modulus μ∗ = μ (ω) + iμ (ω) with its real

and imaginary parts defined by

∞

(ως)2

μ (ω) = μ∞ +

H (ς) dς

(3.47)

1 + (ως)2

0

(the storage modulus) and

∞

ως

μ (ω) =

H (ς) dς

1 + (ως)2

(3.48)

0

(the loss modulus), respectively.

Polar representation allows the shorthand notation

μ∗ = μ(ω) exp[iΔ(ω)] ,

(3.49)

where

μ (ω)

and

μ (ω)

μ(ω) ≡ |μ∗ (ω)| = [μ (ω)]2 + [μ (ω)]2 ,

tan Δ(ω) =

(3.50)

so that, also

μ (ω) = μ(ω) cos Δ(ω) and

μ (ω) = μ(ω) sin Δ(ω) .

(3.51)

The complex stress response (3.45) can then be written,

using (3.50), as

τ(t) = 2ε(t)μ∗ (ω) = 2ε0 exp(iωt)μ(ω) exp[iΔ(ω)] ,

(3.52)

(3.45)

ε (t)

= sin ωt

ε0

t

Δω

Fig. 3.9 Illustration of the frequency-dependent phase

shift between the applied strain and the resulting stress

61

which may be separated into its real or imaginary part

according to

τ(t) = 2ε0 μ(ω) cos[ωt + Δ(ω)] and

τ(t) = 2ε0 μ(ω) sin[ωt + Δ(ω)] .

(3.53)

Thus the effect of the viscoelastic material properties

is to make the strain lag behind the stress (the strain is

retarded) as illustrated in Fig. 3.9. It is easy to verify

that the high- and low-frequency limits of the steadystate response are given by μ∗ (ω → ∞) = μ(t → 0) =

μ0 , the glassy response, and μ∗ (ω → 0) = μ(t → ∞) =

μ∞ , as the long-term or rubbery response (real).

An Example for a Standard Linear Solid. For the stan-

dard linear solid (Fig. 3.7) the steady-state portion of the

response (3.52) simplifies to

ω2 ς02

,

μ (ω) = μ∞ + μs

1 + ω2 ς02

ως0

μ (ω) = μs

,

(3.54)

1 + ω2 ς02

ως0

tan Δ(ω) =

. (3.55)

μ∞ /μs + (1 + μ∞ /μs )(ως0 )2

Part A 3.2

made. This situation arises when the material is near

its glassy state or when it approaches rubbery behavior.

As long as the modulus ratio can be considered nearly

constant in the test period, the error simply offsets the

test results by additive constant values that may be subtracted from the data. Clearly, that proposition does not

hold when the material interrogation occurs around the

middle of the transition range.

There are many measurements being made with

commercially available test equipment, when frequency

scans or relatively short time blocks of different frequencies are applied to a test specimen at a set

temperature, or while the specimen temperature is being changed continuously. In these situations the data

reduction customarily does not recognize the transient

nature of the measurements and caution is required so as

not to interpret the results without further examination.

Because viscoelastic materials dissipate energy,

prolonged sinusoidal excitation generates rises in

temperature. In view of the sensitivity of these materials to temperature changes as discussed in Sects. 3.2.7

and 3.2.8, care is in order not to allow such thermal

build-up to occur unintentionally or not to take such

changes into account at the time of test data evaluations.

Consider now only the steady-state portion of (3.40)

so that

3.2 Linear Viscoelasticity

62

Part A

Solid Mechanics Topics

which, upon using the transformation t − ξ = u, yields

Log of functions

3

τ(t)

= iω

2ε(t)

2

∞

μ(u) e−iωu du = μ∗ (ω) .

−∞

If one recalls that the integral represents the Fourier

transform F {μ(t), t → ω} of the modulus in the integrand one may write

1

0

μ∗ (ω) = iωF {μ(t), t → ω}

–1

Part A 3.2

–2

–1.5

(3.59)

(3.60)

along with the inverse,

–1

–0.5

0

0.5

1

1.5

2

2.5

Log frequency

Fig. 3.10 Steady-state response of a standard linear solid to

sinusoidal excitation, (μ0 = 1, μ = 100, μ/η = ς0 = 0.1).

Symbols: μ (ω); short dash: μ (ω); long dash: tan Δ(ω)

While this material model is usually not suitable for representing real solids (its time frame is far too short),

this simple analog model represents all the proper limit

responses possessed by a real material, in that it has

short-term (μ0 + μs , glassy), long-term (μ∞ , rubbery)

as well as transient response behavior as illustrated

in Fig. 3.10. Note that, with only one relaxation time

present, the transition time scale is on the order of at

most two decades. The more general representation of

the viscoelastic functions under sinusoidal excitation

can also be interpreted as a Fourier transform of the

relaxation or creep response.

Complex Properties as Fourier Transforms. It is often

desirable to derive the harmonic properties from monotonic response behaviors (relaxation or creep). To effect

this consider the strain excitation of (3.38),

ε(t) = ε0 exp(iωt)h(t) ,

(3.56)

and substitute this into the convolution relation for the

stress (3.11),

t

μ(t − ξ)

τ(t) = 2ε(0)μ(t) + 2

0−

dε(ξ)

dξ ,

dξ

(3.57)

and restrict consideration to the steady-state response.

In this case, the lower limit is at t → −∞ so that the

integral may be written as

t

μ(t − ξ) eiωξ dξ ,

τ(t) = lim 2ε0 iω

t→∞

−t

(3.58)

1

μ(t) =

2π

∞

−∞

μ∗ (ω) −iωt

dω .

e

iω

(3.61)

Thus the relaxation modulus can be computed from

the complex modulus by the last integral. Note also that

because of (3.60) μ and μ are derivable from a single

function, μ(t), so that they are not independent. Conversely, if one measures μ and μ in a laboratory they

should obey a certain interrelation; a deviation in that

respect may be construed either as unsatisfactory experimental work or as evidence of nonlinearly viscoelastic

behavior.

Relationships Among Properties

In Sect. 3.2.2 exemplary functional representation of

some properties has been described that are generic

for the description of any viscoelastic property. On the

other hand, the situation often arises that a particular

function is determined experimentally relatively readily, but really its complementary function is needed. The

particularly simple situation most often encountered is

that the modulus is known, but the compliance is needed

(or vice versa). This case will be dealt with first.

Consider the case when the relaxation modulus

(in shear), μ(t) is known, and the (shear) creep compliance J(t) is desired. Clearly, the modulus and the

compliance cannot be independent material functions.

In the linearly elastic case these relations lead to reciprocal relations between modulus and compliance.

One refers to such relationships as inverse relations or

functions. Analogous treatments hold for all other viscoelastic functions. Recall (3.10) or (3.11), which give

the shear stress in terms of an arbitrary strain history.

In the linearly elastic case these inverse relations lead

to reciprocal relations between modulus and compliance. Recall also that the creep compliance is the strain

history resulting from a step stress being imposed in

a shear test. As a corollary, if the prescribed strain

Mechanics of Polymers: Viscoelasticity

history is the creep compliance, then a constant (step)

stress history must evolve. Accordingly, substitution of

the compliance J(t) into (3.10) must render the step

stress of unit amplitude so that

t

h(t) = J(0)μ(t) +

μ(t − ξ)

dJ(ξ)

dξ .

dξ

(3.62)

0+

+

→ 0 , J(0+ )/μ(0+ ) = 1

t

μ(t − ξ)J(ξ) dξ = t .

(3.63)

0

Note that this relation is completely symmetric in the

sense that, also,

t

J(t − ξ)μ(ξ) dξ = t .

(3.64)

0

Similar relations hold for the uniaxial modulus E(t)

and its creep compliance D(t), and for the bulk modulus

K (t) and bulk compliance M(t).

Interrelation for Complex Representation. Because

the so-called harmonic or complex material characterization is the result of prescribing a specific time history

with the frequency as a single time-like (but constant)

parameter, the interrelation between the complex modulus and the corresponding compliance is simple. It

follows from equations (3.45) and (3.46) that

1

2ε0 eiωt

2ε(t)

= ∗

=

= J ∗ (ω) ,

τ(t)

μ (ω)

τ0 ei(ωt+Δ(ω))

(3.65)

where the function J ∗ (ω) is the complex shear compliance, with the component J (ω) and imaginary

component −J (ω) related to the complex modulus by

J ∗ (ω) = J (ω) − iJ (ω) = J(ω)eiγ (ω)

=

1

μ∗ (ω)

=

e−iΔ(ω)

μ(ω)

(3.66)

so that, clearly,

1

and γ (ω) = −Δ(ω) ,

μ(ω)

with J(ω) = [J (ω)]2 + [J (ω)]2 .

J(ω) =

(3.67)

63

Thus in the frequency domain of the harmonic material description the interconnection between properties

is purely algebraic. Corresponding relations for the bulk

behavior follow readily from here.

3.2.7 Dissipation

Under Cyclical Deformation

In view of the immediately following discussion of the

influence of temperature on the time dependence of viscoelastic materials we point out that general experience

tells us that cyclical deformations engender heat dissipation with an attendant rise in temperature [3.34,

35]. How the heat generated in a viscoelastic solid as

a function of the stress or strain amplitude is described

in [3.13]. Here it suffices to point out that the heat

generation is proportional to the magnitude of the imaginary part of the harmonic modulus or compliance. For

this reason these (magnitudes of imaginary parts of the)

properties are often referred to as the loss modulus or

the loss compliance. We simply quote here a typical

result for the energy w dissipated per cycle and unit volume, and refer the reader to [3.13] for a quick, but more

detailed exposition:

∞

2 2mπ

m εm μ

(3.68)

.

w/cycle = π

T

m=1

3.2.8 Temperature Effects

Temperature is one of the most important environmental

variables to affect polymers in engineering use, primarily because normal use conditions are relatively

close to the material characteristic called the glasstransition temperature – or glass temperature for short.

In parochial terms the glass temperature signifies the

temperature at which the material changes from a stiff

or hard material to a soft or compliant one. The major effect of the temperature, however perceived by the

user, is through its influence on the creep or relaxation

time scale of the material.

Solids other than polymers also possess characteristic temperatures, such as the melting temperature in

metals, while the melting temperature in the polymer

context signifies specifically the melting of crystallites

in (semi-)crystalline variants. Also, typical amorphous

solids such as silicate glasses and amorphous metals

exhibit distinct glass-transition temperatures; indeed,

much of our understanding of glass-transition phenomena in polymers originated in understanding related

phenomena in the context of silicate glasses.

Part A 3.2

Note that, as t

so that at time

0+ an elastic result prevails. Upon integrating both sides

of (3.62) with respect to time – or alternatively, using the Laplace transform – one readily arrives at the

equivalent result; the uniaxial counterpart has already

been cited effectively in (3.37).

3.2 Linear Viscoelasticity

64

Part A

Solid Mechanics Topics

Part A 3.2

The Entropic Contribution

Among the long-chain polymers, elastomers possess

a molecular structure that comes closest to our idealized understanding of molecular interaction. Elastomer

is an alternative name for rubber, a cross-linked polymer that possesses a glass transition temperature which

is distinctly below normal environmental conditions.

Molecule segments are freely mobile relative to each

other except for being pinned at the cross-link sites. The

classical constitutive behavior under moderate deformations (up to about 100% strain in uniaxial tension)

has been formulated by Treloar [3.36]. Because this

constitutive formulation involves the entropy of a deformed rubber network, this temperature effect of the

properties is usually called the entropic temperature effect. In the present context it suffices to quote his results

in the form of the constitutive law for an incompressible solid. Of common interest is the dependence of the

stress on the material property appropriate for uniaxial

tension (in the 1-direction)

1

1

subject to λ1 λ2 λ3 = 1 ,

σ = NkT λ21 −

3

λ1

(3.69)

where λ1 , λ2 , and λ3 denote the (principal) stretch ratios of the deformation illustrated in Fig. 3.11 (though

not shown for the condition λ1 λ2 λ3 = 1), the multiplicative factor consists of the number of chain segments

between cross-links N, k is Boltzmann’s constant, and

T is absolute temperature. Since for infinitesimal deformations λ1 = 1 + ε11 , one finds that NkT must equal the

elastic Young’s modulus E ∞ . Thus the (small-strain)

Young’s modulus is directly proportional to the absolute temperature, and this holds also for the shear

modulus because, under the restriction/assumption of

incompressibility the shear modulus μ∞ of the rubber

obeys μ∞ = 13 E ∞ . Thus μ∞ /T = Nk is a material constant, from which it follows that comparative moduli

obtained at temperatures T and T0 are related by

T

μ∞|T = μ∞|T0 or equivalently

T0

T

E ∞|T =

E ∞|T0 .

(3.70)

T0

If one takes into account that temperature changes affect also the dimensions of a test specimen by changing

both its cross-sectional area and length, this is taken into

account by modifying (3.71) to include the density ratio

according to

ρT

μ∞|T0 or equivalently

μ∞|T =

ρ0 T0

ρT

E ∞|T =

E ∞|T0 ,

(3.70a)

ρ0 T0

where ρ0 is the density at the reference temperature and

ρ is that for the test conditions.

To generate a master curve as discussed below it is

therefore necessary to first multiply modulus data by the

ratio of the absolute temperature T (or ρT , if the densities at the two temperatures are sufficiently different) at

which the data was acquired, and the reference temperature T0 (or ρ0 T0 ). For compliance data one multiplies by

the inverse density/temperature ratio.

Time–Temperature Trade-Off Phenomenon

A generally much more significant influence of

temperature on the viscoelastic behavior is experienced

in connection with the time scales under relaxation or

creep. To set the proper stage we define first the notion

of the glass-transition temperature Tg . To this end consider a measurement of the specific volume as a function

Volume

λ1

λ3

λ2

B

A

Equilibrium line

Fig. 3.11 Deformation of a cube into a parallelepiped. The

unit cube sides have been stretched (contracted) orthogonally in length to the stretch ratios λ1 , λ2 , and λ3

Tg

Temperature

Fig. 3.12 Volume–temperature relation for amorphous

solids (polymers)

Mechanics of Polymers: Viscoelasticity

log G (t)

Experimental

window

sensitive properties, at least for polymers. For ease

of presentation we ignore first the entropic temperature effect discussed. The technological evolution of

metallic glasses is relatively recent, so that a limited

amount of data exist in this regard. However, new data

on the applicability of the time–temperature trade-off

in these materials have been supplied in [3.12]. Moreover, we limit ourselves to considerations above the

glass-transition temperature, with discussion of behavior around or below that temperature range reserved for

later amplification.

Experimental constraints usually do not allow the

full time range of relaxation to be measured at any

one temperature. Instead, measurements can typically

be made only within the time frame of a certain experimental window, as indicated in Fig. 3.13.

This figure shows several (idealized) segments as

resulting from different temperature environments at

a fixed (usually atmospheric) pressure. A single curve

may be constructed from these segments by shifting the

temperature segments along the log-time axis (indicated

by arrows) with respect to one obtained at a (reference)

temperature chosen arbitrarily, to construct the master

curve. This master curve is then accepted as the response of the material over the extended time range at

the chosen reference temperature. Because this time–

temperature trade-off has been deduced from physical

measurements without the benefit of a time scale of

unlimited extent, the assurance that this shift process

is a physically acceptable or valid scheme can be derived only from the quality with which the shifting or

P = P0

T1

T0 = T3

⎛ σ 273 ⎛

⎜ (psi)

⎝ ε0 T ⎝

log0 ⎜

5

T3

Temperature (°C)

–30.0

–25.0

–22.5

–22.0

–17.5

–15.0

–12.5

–7.5

–5.0

–2.5

5.0

T2

T4

T5

log aT4

4

Master curve

at T3

3

ε0 = 0.05

T1 < T2 < ··· <T5

log t

Fig. 3.13 Illustration of the temperature shift phenomenon.

Segments of G(t) measured at different temperatures, and

corresponding master curves

2

–2

–1

0

1

2

3

log10 t (min)

Fig. 3.14 Relaxation modulus for a polyurethane formula-

tion measured at various temperatures in uniaxial tension

65

Part A 3.2

of temperature. Typically, such measurements are made

with a slowly decreasing temperature, curve A in

Fig. 3.12, because the rate of cooling has an influence on

the outcome. Figure 3.12 shows a typical result, which

illustrates that at sufficiently low and high temperatures

the volume dependence is linear, with a transition connecting the two segments.

The glass-transition temperature is defined as the

intersection of two linear extensions of the two segments roughly in the center of the transition range. As

also indicated in Fig. 3.12, an increase in the rate of

cooling causes reduced volume shrinkage as a result

of the unstable evolution of a molecular microstructure

that consolidates with time, curve B in Fig. 3.12. This

phenomenon is associated with physical aging [3.37–

44]. In practical terms the lowest – most stable – response curve is determined basically by the patience of

the investigator, though substantial deviations must be

measured in terms of logarithmic time units: Relatively

little may be gained by reducing the cooling rate from 1

to 0.1 ◦ C/h.

We turn next to the effect of temperature on the

time scale and present this phenomenon in terms of

a relaxation response, say, in shear. The discussion is

generic in the sense that it applies, to the best of the

collective scientific knowledge, to all time- and rate-

3.2 Linear Viscoelasticity

66

Part A

Solid Mechanics Topics

superposition can be accomplished. To examine this

quality issue requires that test temperatures are chosen sufficiently closely, and that the measurements vary

as widely as feasible over the log-time range to afford

maximum overlap of the shifted curve segments.

The amount of shifting along the log-time axis is

recorded as a function of the temperature. This function

is usually called the temperature-dependent shift factor,

or simply the shift factor for short; it is a material characteristic, and is often designated by φT . Figures 3.14

and 3.15 illustrate the application of the shift principle

for a polyurethane elastomer, together with the associated shift factor φT in Fig. 3.16.

Part A 3.2

The Role of the Entropic Contribution

Having demonstrated the shift phenomenon in principle,

it remains to address the effect of the entropic contribution to the time-dependent master response. Recall that

the entropic considerations were derived in the context

of purely rubbery material behavior, and specifically in

the absence of viscoelastic effects. Thus any modulus

variation with temperature is established, strictly speaking, only in the long-term time domain when rubbery

behavior dominates, so that (3.70) applies. Various arguments have been put forward [3.45] to apply a similar

reduction scheme to data in the viscoelastic transition

log (shift factor)

8

region. Two arguments dominate, but they are based

on pragmatic rather than rigorously scientific principles. The first argument states that, even in the transition

region, the polymer chain segments experience locally

elastic behavior in accordance with the theory of rubber

elasticity. Accordingly, all curve segments obtained at

the various temperatures should be multiplied by their

respective ratios of the reference temperature and the

test temperature, i. e., T0 /T , in the case of modulus

measurements, and with the inverse ratio in the case of

compliance measurements, regardless of by how many

log-time units the material behavior is removed from

the rubbery (long-term) domain. The alternative view

asserts that the entropic correction does not apply in

the glassy state and, accordingly should decrease continuously from the long-term, rubbery domain as the

glassy or short-term behavior is approached. The rule

by which this change occurs is not established scientifically either, but is typically taken to be linear with the

logarithmic time scale throughout the transition. Ultimately one needs to decide on the basis of the precision

in the data whether one or the other scheme produces

the better master curve. The crucial argument in that decision is whether the mutual overlap of the segments

derived from measurements at different temperatures

provides for the most continuous and smoothest master

curve.

The Shift Factor

While several researchers have contributed significantly

to clarifying the concept and the importance of the

6

4

log10 (273/T ) E (t) (psi)

5

2

4.5

Reference temperature

T0 = 0 °C

5% strain

4

0

3.5

–2

3

–4

– 40

–30

–20

–10

0

10

20

Temperature

Fig. 3.15 Time–temperature shift factor for reducing the

polyurethane data in Fig. 3.14 to that in Fig. 3.16.

Tg = −18 ◦ C The solid line represents the WLF-equation

log10 φT =

−8.86(T − 32 ◦ C)

− 4.06

101.6 + (T − 32 ◦ C)

2.5

2

–9 –8 –7 –6 –5 –4 –3 –2 –1 0

1

2

log10 t/φT (min)

Fig. 3.16 Temperature-reduced uniaxial relaxation modulus for a polyurethane formulation derived from data in

Fig. 3.14 and with the shift factors in Fig. 3.15

Mechanics of Polymers: Viscoelasticity

log(aT ) =

c1 (T − Tref )

,

c2 − (T − Tref )

(3.71)

where Tref denotes an arbitrarily chosen reference

temperature typically about 50 ◦ C above the glasstransition temperature of the polymer under consideration. The constants c1 and c2 vary from polymer

to polymer, but for many take on values around

c1 ∼

= 8.86 and c2 ∼

= 101.6. In terms of the relaxation data

in Fig. 3.14, the shift procedure renders the composite

or master curve as shown in Fig. 3.16.

Time–Temperature Trade-Off

under Transient Temperature Conditions

While the time–temperature shift principle is observed

in the laboratory under different temperatures, which

are however constant during the measurements, there

are many situations in the engineering environment

in which temperatures vary more or less continuously

while creep or relaxation processes occur. To assess how

such thermal changes affect the viscoelastic response,

Morland and Lee proposed [3.54], following the ideas

promulgated in the practice developed for the silicate

glasses, that the time–temperature shift relation applies

instantaneously. Let T0 denote the reference temperature at which the master curve has been established and

let T be the temperature at which the material behavior

is desired. Then the developments in Sect. 3.2.8 above

state that the time (scale) at a temperature T , and designated by t , is related to the time (scale) t at the reference

temperature by

t =

t

.

φT (T )

(3.72)

Instantaneous obeyance to this rule requires then

that (3.72) apply differentially as the temperature

changes with time, namely

dt

or alternatively that

dt =

φt (T (t))

t

dt

t =

.

φT (T (t))

67

(3.73)

0