Jigs and Fixtures Design -

advertisement

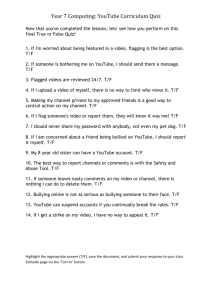

MECH152-L25 - 1 Tool Design MECH152-L25 - 2 Types yp of Tools • • • • • • • Material Cutting Tools Workholding Devices Pressworking Tools Bending, Forming and Drawing Dies http://www youtube com/watch?v=gkHbRVUvFgw&feature=channel page http://www.youtube.com/watch?v=gkHbRVUvFgw&feature=channel_page Tool Design for Inspection and Gaging T lD Tool Design i ffor JJoining i i P Process Tooling g for Casting g http://www.youtube.com/watch?v=z4D76vMqwD4&feature=channel_page http://www.youtube.com/watch?v=3ciyG_hidhE&feature=channel_page http://www.youtube.com/watch?v=4Pw_tcgIiTQ&feature=channel_page MECH152-L25 - 3 General Considerations • • • • • • • Safety and Ergonomics Tool Materials Heat Treatment Surface Roughness and Finish Tolerances and Fits T li E Tooling Economics i Material Handling g MECH152-L25 - 4 Safety y and Ergonomics g ((I)) • Safety should be built into the design with ith d due respectt tto legal l l requirements i t • Sufficient clamping p g and rigidity g y of the tool design is necessary • Guards should be introduced to movable parts of the machine • Limit switches to protect workers and product against moving parts • Electrical equipment should be properly grounded MECH152-L25 - 5 Safety y and Ergonomics g ((II)) • Exhaust system for air polluting system • All adjustments and clamping should be y accessible easily • Quick release or emergency braking mechanism may be needed for special cases • Prevent severe burns or eye injury for welding or thermal process • Provision for f handling pressurized and toxic equipment MECH152-L25 - 6 Tool Materials (I) () • Tool steels (principal materials) – Tool T l and d Di Die St Steell (t (typical i lh hardness d RC40 RC40~60) 60) • • • • • • • • • • W, Water-Hardening Tool-Steels O, Oil Oil-Hardening Hardening Tool-Steels Tool Steels A, Air-Hardening Medium Alloy Die-Steels D, High-Carbon High-Chromium Die Steels S Sh S, Shock-Resisting k R i ti T Tool-Steels l St l H, Hot-Work Die Steels P,, Low-Carbon Mold Steels T and M, Tungsten and Molydenum High-Speed Steels L, Low-Alloy Tool-Steels F Carbon-Tungsten F, Carbon Tungsten Finishing Steels (http://www.efunda.com/materials/alloys/tool_steels/tool.cfm) • Cast Iron • Stainless Steel MECH152-L25 - 7 Tool Materials (II) ( ) • Non-ferrous materials - limited productions only (Aluminum, g , Zinc,, Lead,, Beryllium, y , Magnesium, Bismuth) • Composite materials – soft tools for limited run MECH152-L25 - 8 Workholding g Devices Workholding Devices – All devices that hold, grip, or chuck a workpiece in a prescribed manner of firmness and p location, to perform on it a manufacturing operation operation. MECH152-L25 - 9 Fixture & Jig g Fixture: - Hold and accurately position a http://www youtube com/watch?v=ujKyRrf Z1M&feature=channel page workpiece http://www.youtube.com/watch?v=ujKyRrf-Z1M&feature=channel_page Jig: - Also be used to hold and position a workpiece. - Provides some means for guiding th cutting the tti tool t l http://www.youtube.com/watch?v=2ikkuZe0zQU&feature=channel_page MECH152-L25 - 10 Examples p -I • High Rise Clamps http://www.carrlane.com/Catalog/index.cfm High-Rise Clamps can be stacked on Narrow Riser Blocks and Spacer Blocks to reach tall workpieces MECH152-L25 - 11 Examples p II http://www.steelsmith.com/ • Swing Clamp Please refer to the price list also! ARM: MODULAR IRON PER ASTM A536 GRADE 65-45-12, 65 45 12 ZINC PLATED CLEAR CHROMATE ALL OTHER PARTS: MILD STEEL, BLACK OXIDE FINISH MECH152-L25 - 12 Examples p III Automatic Reversible Cam Action Workholding Assemblies http://www.youtube.com/watch?v=vrrjLYn-6WY Methods of Location 3 2 1 Principle 3-2-1 MECH152-L25 - 13 http://www.youtube.com/watch?v=wTs_IaD0JWU&feature=PlayList&p=3AFB507B668AF162&index=35 - A workpiece will be completely confined when banked against: - 3 points in one plane 2 points in another plane 1 point i t iin a thi third d plane l If the planes are perpendicular to each other - Buttons should be as far apart p as possible - Greater spread, spread Less alignment error MECH152-L25 - 14 Methods of Location I 12 degrees of freedom 3 pins arrest 5 dof MECH152-L25 - 15 Methods of Location II 5 pins arrest 8 dof Horizontal workpiece 6 ppins arrest 9 dof Vertical Ve c workpiece MECH152-L25 - 16 Methods of Location III Radical location with i h internal i l pins i or plug Radical location by external pins MECH152-L25 - 17 Methods of Location IV 7 dof d f arrested by V locator with stop pin Workholder with multiple l i l V locators l MECH152-L25 - 18 Tool Forces I Pin-type yp drill fixture resisting torque and thrust Tapping fixture resisting i i torque and thrust MECH152-L25 - 19 Tool Forces II Workholder for b broaching hi operation i Cutting Forces resisted by solid jaw j of vise Cuttingg force resisted only by friction MECH152-L25 - 20 Tool Forces III Mechanical methods of transmitting and multiplying force (A) Screw (B) Cam C (C) Wedge (D) Toggle link (E) Lever (F) Combined screw andd wedge d MECH152-L25 - 21 Clamping p g Forces I Fixture components p MECH152-L25 - 22 Clamping p g and Support pp http://www.youtube.com/watch?v=l-V4mplHjZ8 Clamping and support of large workpiece k i MECH152-L25 - 23 Fixture Components p MECH152-L25 - 24 Fixture Components p Toggle clamp http://www.youtube.com/watch?v=H4r8hUyZMUY http://www.youtube.com/watch?v=ZefYGTMKRUw http://www.youtube.com/watch?v=nheuik2YHkI Quick-acting screw Jigs and Fixture Design Principles MECH152-L25 - 25 • Review the workpiece to determine the manufacturing processes • Decide on the number of setups • Determine for each setup – Reference surface – Workpiece p location – Workpiece clamping and rigidity – Ergonomics and safety http://www.youtube.com/watch?v=ujKyRrf-Z1M&feature=channel Fixture for Rectangular Components MECH152-L25 - 26 Cl Clamping i action ti • Location and holding for flat surface • Base plate - reference surface for setup • Clamp – quick action cam-based clamp Fixture for Rectangular Components MECH152-L25 - 27 • H Hydraulic d li clamp l ffor llarger clamping l i fforce • Swing g clamp p http://www.youtube.com/watch?v http://www youtube com/watch?v=1RMqoQlZ-2c 1RMqoQlZ 2c http://www.youtube.com/watch?v=jkAINXgZaCk Fixture for Rectangular Components MECH152-L25 - 28 Magnetic chuck http://www.youtube.com/watch?v=WzawhEUBLL8&feature=PlayList&p=CAC636741CCDCCB0&playnext=1&playnext_from=PL&index=4 http://www.youtube.com/watch?v=S-xKCAHpU-4&feature=PlayList&p=CAC636741CCDCCB0&playnext=1&playnext_from=PL&index=6 http://www youtube com/watch?v=8pabjZp4D2Y http://www.youtube.com/watch?v=8pabjZp4D2Y V cuu Vacuum chuck htt // http://www.youtube.com/watch?v=xr3lfAvQuJs&feature=related t b / t h? 3lfA Q J &f t l t d http://www.youtube.com/watch?v=2jcQZ5W4ED4 Fixture for Rectangular Components MECH152-L25 - 29 Electrostatic chuck Vacuum chuck Fixture for Circular Components Round workpiece held with strap clamp and T bolts Fixture for straddle milling connecting rod MECH152-L25 - 30 Fixture for Circular Components MECH152-L25 - 31 Workpiece W k i held h ld in i a 44 jaw chuck for a boring operation http://www.youtube.com/watch?v=npJfKhkS0QE Nut arbor Fixture for Circular Components V block MECH152-L25 - 32 Drill jig – V block, quickacting clamp, and drill bushing combination http://www.youtube.com/watch?v=QFH2kUorn88 Fixture for Circular Components MECH152-L25 - 33 IInternal t l andd endwise chucking Between B t centers t and combination with chucking Fixture for Circular Components S lid mandrel Solid d l MECH152-L25 - 34 Roll lock type expanding mandrel Fixture for Circular Components Split p busing g and split collet MECH152-L25 - 35 Axial location by collet Collet with stopper http://www.youtube.com/watch?v=bJIIeN4rg3E Fixture for Circular Components MECH152-L25 - 36 Collet C ll t with ith immediate i di t bushing to eliminate axial shift Collet for internal chucking MECH152-L25 - 37 Rigid g and Elastic Workholding g Rigid workholding Elastic and spring workholding Rigid/hydraulic workholding MECH152-L25 - 38 Accuracy y of Work Location A Accuracy off work k llocation ti Concentricity of workpiece by collet Workholders for Irregular Workpiece MECH152-L25 - 39 Pump type jigs Pump-type MECH152-L25 - 40 Workholding g Selection Workpiece rotation Tool rotation MECH152-L25 - 41 Workholding g Selection Steady to reduce workpiece p vibration Minimizing cutting force by applying holding force close to ppoint of tool application pp http://www.youtube.com/watch?v=2o74aR0JL1k MECH152-L25 - 42 Cutter Setup p MECH152-L25 - 43 Box-Type yp Drill Jigs g MECH152-L25 - 44 Milling g Fixture MECH152-L25 - 45 Milling g Fixture MECH152-L25 - 46 Milling g Fixture I d i fixture Indexing fi t http://www.youtube.com/watch?v=JkftVHaMQSs Key slot milling MECH152-L25 - 47 Milling g Fixture