Unit 5-Respiration Lab Report

advertisement

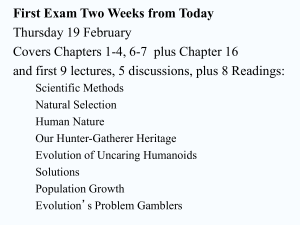

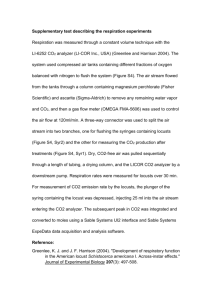

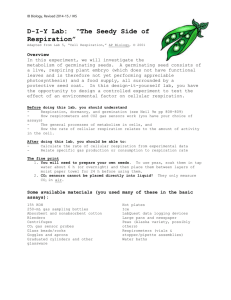

Effects of Varying Condition and Temperature on L. odoratus Design aspect 1: Research Question Research Question: How does temperature(ºC+.5) with 10ºC increments(10ºC and 20ºC) affect the final CO2 concentration(ppm+50), CO2 concentration difference(ppm+100), the rate of CO2 production(ppm/s), and the mean rate of CO2 production(ppm/s) in germinating Lathyrus odoratus(ppm/s)? How does the condition of seeds(germinating/dormant) affect the final CO2 concentration(ppm+50) and CO2 concentration difference(ppm+100) and ultimately, the mean rate of CO2 production in Lathyrus odoratus(ppm/s)? Background Knowledge: All kinds cells in living organisms do cellular respiration either aerobically or anaerobically depending on the environment they are in. In this case, as the plant cells of the Lathyrus odoratus(L. orodatus) are placed in water, which consists of oxygen, the plant cells go through aerobic cellular respiration. In aerobic respiration, the cell first does glycolysis in the cytoplasm where 2 ATP molecules are invested in the 6-carbon sugar in form of phosphorylation causing the sugar to be lysed into two 3-carbon molecules. The 2 ADP molecules are phosphorylated by the 3-carbon molecule to create 2 ATP per 3-carbon molecule with a total of 4 ATP and a net gain of 2 ATP. As the phosphorylation of the ADP proceeds, an NAD+ molecule is reduced to an NADH+H+ molecule for each 3-carbon molecule which creates a total of 2 NADH+H+ molecules. As a result of glycolysis, the 6-carbon molecule is oxidized into pyruvate and 2 ATP(net gain) and 2NADH+H+ molecules are created. After glycolysis, each pyruvate molecule(3-carbon molecule) goes through a link reaction at the mitochondria(matrix) where the pyruvate is decarboxylated(loses CO2) and an NAD+ molecule is once again reduced to NADH+H+ resulting in the creation of 2 NADH+H+ molecules and an acetyl group that is picked up by coenzyme A. This is followed with the Krebs Cycle where the coenzyme A releases the acetyl group to combine with a 4 carbon molecule that resulted from the previous Krebs cycle to form citric acid(6-carbon molecule). This citric acid goes through decarboxylation twice and reduces NAD+ into NADH+H+ 3 times with an additional reduction of FAD to FADH2. Since each acetyl group goes through the Krebs Cycle, this results in the creation of 2 oxaloacetic acid(4 carbon molecule), 6 NADH+H+ molecules, 2 FADH2 molecules, and 4 CO2 molecules. At this point, there is a total of 6 CO2 molecules that are created. Hence it makes sense to measure CO2 concentration change in order to measure the rate of aerobic respiration. Once the Krebs cycle is completed, there is a total of 10 NADH+H+ and 2 FADH2 molecules created as a result of the Krebs cycle and glycolysis. Each of these NADH+H+ molecules are attracted to the inner mitochondrial membrane to transport 2 protons or 2H+ molecules to the inter mitochondrial space and release 2 electrons to the electron transport carriers(ETC). The 2 electrons go through 2 more ETC to attract 2H+ molecules at each ETC and transport them to the inter mitochondrial space. As a result of the 2 electrons passing a total of 3 ETC for each NADH+H+, three 2H+ protons are transported to the inter mitochondrial space. Because one 2H+ molecule results in the creation of one ATP, 1 NADH+H+ molecule results in the creation of 3 ATP. Since the 2 electrons from a FADH2 molecule pass through only 2 ETC, only two 2H+ molecules are transported. As a result, a total of 34 ATP are produced through oxidative phosphorylation. Since 2 ATP are created at both glycolysis and at the Krebs Cycle, a total of 38 ATP are produced as a result of aerobic respiration for one glucose molecule(6-carbon sugar) (Allot, & Mindorff, 2012). The equation that best describes this is the following: (Biology Through Inquiry, 2009) 1 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus Hypothesis Alternative Hypothesis(HA): As temperature(ºC+0.5) increases, the CO2 concentration Effects of Varying Condition and Temperature on L. odoratus Hypothesis Alternative Hypothesis(HA): As temperature(ºC+0.5) increases, the CO2 concentration difference(ppm+100) will increase, and therefore, the mean rate of CO2 production(ppm/s) will also increase for the germinating L. odoratus. Meanwhile, when the condition of the L. odoratus is germinating, the CO2 concentration difference(ppm+100) will be greater, and therefore, the mean rate of CO2 production(ppm/s) will also be greater relative to that of a dormant/dry condition. -The germinating process basically involves the suspension of water and hence, the function of enzymes in the seed needed for aerobic cellular respiration. On the other hand, theoretically, seeds in a dry condition do not have those enzymes working and therefore, aerobic cellular respiration shouldn’t occur at all. As a result, the germinating seeds will have a larger CO2 concentration difference(ppm+100) and higher mean rate of CO2 production(ppm/s). -Enzymes are usually affected by temperature and have an optimal temperature at which they work most efficiently, carrying out the most reactions possible. However, once this optimal temperature is exceeded, the enzymes start to work less efficient. Although this optimal temperature differs for every single enzyme, assuming that 20ºC has not exceeded the enzymes’ optimal temperature, the seeds at 20ºC should have a greater CO2 concentration difference(ppm+100) and higher mean rate of CO2 production(ppm/s). Null Hypothesis(H0): There is no relationship between condition(dry or germinating) temperature(ºC+0.5) and CO2 concentration difference(ppm+100) and therefore, rate of CO2 production(ppm/s). Figure 1: The predicted effect of seed condition(dormant/germinating) on mean rate of CO2 production(ppm/s) of L. odoratus at 20.0ºC+.5 2 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus Figure 2: The predicted effect of temperature(ºC+.5) on mean rate of CO2 production(ppm/s) of L. odoratus in germinating condition Independent Variables Independent Variable: Temperature(ºC+0.5) and Condition(Dry/Dormant or Germinating) The independent variable will be measured in celcius(ºC) with ranges of 10ºC(+.5) to 20ºC(+.5) in 10ºC increments. The dry/dormant seeds will be seeds that are untouched. Meanwhile, the germinating seeds will be prepared by having 20 seeds be The equipment used to measure temperature is a non-mercury thermometer. Meanwhile, the condition of L. odoratus will be manipulated(germinating process) by the following: First, leaving a total of 40 seeds Dependent Variables Dependent Variable: Direct-Final CO2 Concentration(ppm+50) Indirect-a) CO2 Concentration Difference(ppm+100) -b) Rate of CO2 Production(ppm/s) -c) Mean Rate of CO2 Production(ppm/s+95% CI) The direct dependent variable will be measured with a CO2 sensor(Model Number: PS-2110). The measurement will be done in SI units of ppm with an uncertainty of +50ppm. The indirect dependent variable will not be measured but calculated using Microsoft Excel Software(2011). Indirect DV a) will be calculated by subtracting the initial CO2 concentration(ppm+50) from the final CO2 concentration(ppm+50) in units of ppm with an uncertainty of +100. Indirect DV b) will be calculated by dividing the CO2 concentration difference(ppm+100) for each trial by 600 seconds(10mins) in SI units of ppm/s. In addition, the Software(2011). Indirect DV a) will be calculated by subtracting the initial CO2 concentration(ppm+50) from the final CO2 concentration(ppm+50) in units of ppm with an uncertainty of +100. Indirect DV b) will be calculated by dividing the CO2 concentration difference(ppm+100) for each trial by 600 seconds(10mins) in SI units of ppm/s. In addition, the uncertainty will vary depending on the percent uncertainty for each trial. 3 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus Finally, indirect DV c) will be calculated by finding the average of b) for each IV. Average in this cause would indicate the division of the sum of all trials for a certain IV by its sample size. The SI unit for c) will also be ppm/s but with a 95%CI as the uncertainty. Formula: a) CO2 Concentration Difference(ppm+100) b) Rate of CO2 Production(ppm/s) c) Mean Rate of CO2 Production(ppm/s+95% CI) Control Variables Table 1: Effects and method of controlling controlled variables Variables Effect Control/Method Number of Seeds If not controlled, number of seeds would vary, and Controlled: The because all seeds do cellular respiration, theoretically, number of seeds(L. more seeds indicate greater CO2 concentration odoratus) put in for every trial for each IV difference(ppm+100) and higher mean rate of CO2 production(ppm/s). This would inhibit the comparison will be set to 10 of data amongst IV, hence, if this variable is controlled, seeds. the data can be compared with others as direct impact of temperature and condition could be observed. Time of Cellular Although dependent upon the condition, more time of Controlled: The time Respiration/Data data collection/cellular respiration indicates more CO2 allowed for the seeds Collection production(theoretically for germinating) and a greater to do cellular respiration will be set CO2 concentration difference(ppm+100) and higher mean rate of CO2 production(ppm/s). Hence, time must to 10 minutes or 600 seconds. be controlled for temperature and condition’s impact on data could be observed and compared. Calibration CO2 As a result of going through the method of calibration, Controlled: Calibrate the CO2 gas sensor is standardized to the CO2 in the the sensor by pressing sensor atmosphere(approximately 400ppm). This allows for the calibrate button and pressing it again the recording of a valid measurement for CO2 after 3 seconds. concentration(ppm+50) Equilibration of the L. odoratus seeds Starting the experiment right after the insertion of the Controlled: After CO2 gas sensor is quite unreliable for data collection as putting the CO2 gas the seeds themselves must be at the temperature of the sensor inside the water bath(10.0ºC or 20.0ºC+.5). By controlling this, sample bottle, wait the seeds are set at those particular IV temperatures. for 3 minutes 4 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus Table 2: Effects of uncontrollable variables/Potential Sources of Error Uncontrollable Variables Uncontrollable VariableBiological Variation: Effect If the sizes and shapes of the L. odoratus seeds have large variation, the number of cells and Table 2: Effects of uncontrollable variables/Potential Sources of Error Uncontrollable Variables Uncontrollable VariableBiological Variation: Quantity and rate of CO2 production of each L. odoratus Potential Source of ErrorInstrumental Error of CO2 gas sensor Effect If the sizes and shapes of the L. odoratus seeds have large variation, the number of cells and certainly, the number of enzymes would differ for each seed. Consequently, the amount of cellular respiration that occurs for each seed would have large variations as it would lead to the collection of unreliable data. This is however, minimized by the usage of seeds with similar sizes and shapes. The variability of the instrument and the variation in the variability of the instrument is certainly a potential source of error especially when the data is shared amongst groups. Although it may in reality not be the variability that is the source of error and instead, the high sensitivity of the instrument, it is still a potential source of error. However, since the whole purpose is to record change in CO2 concentration, this potential source of error is minimized up to a certain extent. Figure1: General Setup of the Experiment CO2 gas sensor Clamp Water Bath Sample Bottle Germinating Seeds Dormant for 2 trials Seeds Ring Stand 5 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus Design aspect 2: Method Equipment: -Large water bath(1000mL) -Sampling Bottle -Ring Stand -Clamp -30 L. odoratus seeds -Ice(crushed/cubed) -CO2 gas sensor (PS-2110) Part 1: Preparation of Germinating L. odoratus (Seeds) 1. Place 20 germinating seeds in water for 24 hours in an environment with no light for the suspension of water in the seeds for the functioning of the enzymes 2. Rap 10 seeds each in moist paper towels and leave in environment with no light for 1. Place 20 germinating seeds in water for 24 hours in an environment with no light for the suspension of water in the seeds for the functioning of the enzymes 2. Rap 10 seeds each in moist paper towels and leave in environment with no light for another 24 hours to allow the seeds to be exposed to air for the purpose of having the seeds do aerobic cellular respiration For each of the three treatments: 1. Adjust the temperature of the water bath. 2. Calibrate the CO2 sensor with the sensor outside the sample bottle. 3. Add 20 (dormant or germinating)seeds (dry the germinating seeds) to the sample bottle. 4. Insert the sensor to the sample bottle and place sample bottle and sensor into water bath and hold it using ring stand and clamp 5. Equilibrate the CO2 sensor for 3 minutes 6. Record the initial CO2 concentration(ppm+50) reading at t0; Record the final CO2 concentration (ppm+50) after 10 minutes (t10). 7. Rinse and dry the sample bottle between treatments. Part 2: Respiration of Germinating Seeds at 20.0ºC+.5 1. Adjust the temperature of the water bath to 20.0ºC 2. Do steps 1 to 7 from “For each of the three treatments:” Part 3: Respiration of Germinating Seeds at 10.0ºC+.5 1. Adjust the temperature of the water bath to 10.0ºC by adding ice to water bath 2. Do steps 1 to 7 from “For each of the three treatments:” Part 4: Respiration of Dormant Seeds at 20.0ºC+.5 1. Adjust the temperature of the water bath to 20ºC 2. Do steps 1 to 7 from “For each of the three treatments:” 6 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus Part 5: Processing and Sharing 1. Collaborate with other groups and share data to produce sufficient(total 6) data/trial for initial and final CO2 concentration(ppm+50) 2. Calculate the Change in CO2 concentration(ppm+100) by subtracting the initial CO2 concentration(ppm+50) from the final CO2 concentration(ppm+50) for each trial 3. Calculate the rate of CO2 production(ppm/s) for each trial by dividing the change in CO2 concentration(ppm+100) for each trial by 600 seconds(10 minutes). 4. Calculate the mean CO2 production rate by taking the sum of the CO2 production rate for each IV and dividing it by the number of trials(6). Table 3: Variables and its unit of precision and error/uncertainty Variable Type Variable Unit of precision Independent Temperature xx.x ºC Variable(IV) Condition(Dormant/Germinating) None Dependent Variable(DV) Error / Uncertainty +0.5 ºC None Final CO2 Concentration(Direct) x ppm +50 ppm CO2 Concentration Difference x ppm +100 ppm Rate of CO2 Production x.xx Processed and Indirect DV, Variable(DV) Final CO2 Concentration(Direct) CO2 Concentration Difference x ppm +100 ppm Rate of CO2 Production x.xx ppm/s x.xx ppm/s Processed and Indirect DV, hence no uncertainty included Mean Rate of CO2 Production Design aspect 3: Sufficiency of data: There are two independent variables(IV) for this experiment. One being condition(dormant or germinating), and the other being temperature(ºC+.5). Condition is manipulated as being either dormant/dry or germinating. Meanwhile, temperature is manipulated to have a range of 10.0ºC+.5 to 20.0ºC+.5 with increments of 10.0ºC. The conditions were set to either dormant or germinating with a controlled temperature of 20.0ºC+.5 for both IV because part of the purpose of this experiment is to explore the effects of condition(dry/dormant or germinating) on the rate of cellular respiration which is judged by mean rate of CO2 production(ppm/s). Meanwhile, the lower limits of temperature was set to 10.0ºC+.5 because 10ºC would be a typical temperature that plants would live through during a winter season. The upper limit was set to 20.0ºC+.5 because 20ºC is a typical temperature that plants would live through in other seasons such as spring or summer. Ultimately, it is reasonable to set the range to 10.0ºC to 20.0ºC as these are temperatures that plants experience in nature and it makes sense to compare the rate of cellular respiration or growth that occurs in a temperature that is relatively similar to that experienced in nature. 7 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus I will repeat the measurements just once at any given point in the range to make sure of the reliability of the data. However, since the data will be shared as a class, we will have a total of 6 trials for each IV. Hence, we have a very small sample size of 6 where a very small sample size is defined to be sample sizes between 5-10 samples. The total number of trials is set to 6 because this is the minimum number of trials needed for doing a statistical analysis of standard deviation(s.d.) and therefore, 95% confidence intervals(95% CI). In addition, it was set to 6 for the calculation of a more reliable mean value that is closer to the theoretical value as well. While the direct DV is the final CO2 concentration, the indirect DV is the CO2 concentration difference(ppm+100), rate of CO2 production(ppm/s), and mean rate of CO2 production(ppm/s). The CO2 concentration difference(ppm+100) is calculated by subtracting the initial CO2 concentration(ppm+50) from the final CO2 concentration(ppm+50). The rate of CO2 production(ppm/s) is calculated by dividing each value of CO2 concentration difference(ppm+100) by 600 seconds which is equivalent to 10 minutes(time given for cellular respiration/data collection). The mean rate of CO2 production is calculated by taking the sum of the rate of CO2 production for each IV and dividing it by the number of trials(6). The statistical analysis carried out for this experiment is standard deviation(s.d.) and 95% confidence interval(95% CI). The formulas for the statistical analysis will be presented later, but the general explanation of the formula and reason for carrying out the statistical analysis will be done here to explain the sufficiency of data. The s.d. will be calculated to measure the variability of the data. It is calculated by calculating the square root of the quotient of the sum of the differences between the change in CO2 concentration(ppm+100) and mean change in CO2 concentration(ppm) or between the rate of CO2 production(ppm/s) and mean rate of CO2 production(ppm/s) for a particular IV divided by a value that is one less than the sample size(61=5) of the IV. The 95% CI will be calculated in order to judge whether there is a significant difference between two sets of mean values. In this case, the purpose of the 95% CI is to determine whether the mean rate of CO2 production for germinating seeds at 10.0ºC+.5 and 20.0ºC+.5 are different and whether the mean rate of CO2 production for dormant seeds and germinating seeds(at 20.0ºC+.5) are significantly different. If the error bars of the two points overlap, it indicates that the two points are not significantly different whereas, if they do not overlap, they are significantly different. Therefore, if all points’ error bars overlap, the alternative 20.0ºC+.5 are different and whether the mean rate of CO2 production for dormant seeds and germinating seeds(at 20.0ºC+.5) are significantly different. If the error bars of the two points overlap, it indicates that the two points are not significantly different whereas, if they do not overlap, they are significantly different. Therefore, if all points’ error bars overlap, the alternative hypothesis is rejected and the null hypothesis is accepted where if the all points on the error bars do not overlap, the alternative hypothesis is accepted. However, if the error bars of some points overlap and some do not, then the alternative hypothesis is accepted with limitations. The 95% confidence interval is calculated by adding or subtracting the product of t(on the t-chart when p=0.05 and df=sample size-1) when multiplied with the quotient of s.d.(for the particular IV) divided by the square root of the sample size to or from the mean rate of CO2 production(ppm/s) or mean CO2 concentration difference(ppm). In reality, this calculation is what determines the upper and lower bounds of the error bars and so, the error bar itself is calculated without adding or subtracting the mean(mean rate of CO2 production(ppm/s) or mean CO2 concentration difference(ppm)). 8 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus DPP aspect 1: Results – Raw Data Qualitative Observations: The shape of the seeds were all round in a sphere like shape. They all had similar sizes. However, the color of the germinated seeds were rather whitish or light green due to the loss of pinkish color which was absorbed by the paper towels that were initially rapped around the germinating seeds. The dry seeds had a pink color. Raw Data: Table 4: The effect of seed condition(dormant/germinating) and temperature(ºC+.5) on final CO2 concentration(ppm+50) of L. odoratus Initial CO2 Final CO2 Seed Temperature/ °C Trial concentration/ ppm concentration/ ppm Condition + 0.5 +50 +50 Dormant 20.0 1 505 541 2 261 285 3 534 610 4 423 412 5 220 234 6 420 395 mean s.d. 95%CI Germinated 20.0 1 2 594 930 1266 1561 3 629 1844 4 1153 2058 5 449 1562 6 670 1502 mean s.d. 95%CI 10.0 1 400 612 2 1165 1580 3 457 833 4 253 473 10.0 1 400 612 2 1165 1580 3 457 833 4 253 473 5 399 688 6 587 931 mean s.d. 95%CI 9 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus DPP aspect 2: Processing data Processed Data: Table 5: The effect of seed condition(dormant/germinating) and temperature(ºC+.5) on final CO2 concentration(ppm+50), ∆CO2 concentration(ppm+100), and rate of CO2 production(ppm/s) of L. odoratus Initial CO2/ Final CO2/ ∆CO2/ Rate of CO2 Seed Temperature/ °C Trial ppm ppm ppm Condition + 0.5 Production (ppm/s) +50 +50 +100 Dormant 20.0 1 505 541 36 0.06 2 261 285 0.04 24 Germinated 20.0 10.0 3 534 610 76 0.13 4 423 412 -11 -0.02 5 220 234 14 0.02 6 420 395 -25 -0.04 mean 19 0.03 s.d. 36 0.06 95%CI 29 672 0.05 1 2 594 930 1266 1561 631 1.12 1.05 3 629 1844 1215 2.03 4 1153 2058 905 1.51 5 449 1562 1113 1.86 6 670 1502 832 1.39 mean 895 1.49 s.d. 234 0.39 95%CI 187 0.31 1 400 612 212 0.35 2 1165 1580 415 0.69 3 457 833 376 0.63 4 253 473 220 0.37 5 399 688 289 0.48 6 587 931 344 0.57 mean 309 0.52 s.d. 83 0.14 6 587 931 344 0.57 mean 309 0.52 s.d. 83 0.14 95%CI 0.11 67 *Initial CO2/ ppm+50, Final CO2/ ppm+50, ∆CO2/ ppm+100 indicates Initial CO2 concentration /ppm+50, Final CO2 concentration/ ppm+50, ∆CO2 concentration/ ppm+100 Table 6: The effect of seed condition(dormant/germinating) on mean rate of CO2 production(ppm/s) of L. odoratus at 20.0ºC+.5 Seed Condition Dormant Germinating Mean Rate of CO2 production(ppm/s) 0.03 1.49 +95%CI 0.05 0.31 10 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus Table 7: The effect of temperature(ºC+.5) on mean rate of CO2 production(ppm/s) of L. odoratus in germinating condition. Temperature/ ºC +.5 10.0 20.0 Mean Rate of CO2 production(ppm/s) 0.52 1.49 +95%CI 0.11 0.31 Calculations: 1) ∆CO2(ppm+100) ---CO2 concentration difference This calculation was done in order to find how much CO2 was produced over the 10 minutes of cellular respiration in terms of concentration. This value is calculated also for the calculation of rate of CO2 production for each trial where each of the value for CO2 concentration difference is divided by 600seconds(10 minutes) to find basically, how much CO2 is produced in one second. Formula: e.g. Trial 1 of IV: Dormant Propagation of Uncertainty: 2) Rate of CO2 Production(ppm/s) This value was calculated in order to compare the quantity of CO2 produced in one second for each kind of seed in different conditions and temperature. Ultimately, this allows to make a valid deduction of how condition and temperature affects the rate of CO2 production and therefore, rate of cellular respiration. Formula: e.g. Trial 1 of IV: Dormant 3) Mean Rate of CO2 Production(ppm/s)…+95% CI This value was calculated in order to compare a single, generalized or simplified value of the L. odoratus seeds with 6 trials of differing conditions. This allows for the comparison of a single value rather than a multitude of these values. Formula: This value was calculated in order to compare a single, generalized or simplified value of the L. odoratus seeds with 6 trials of differing conditions. This allows for the comparison of a single value rather than a multitude of these values. Formula: e.g. IV: Germinating(10.0ºC+.5) 11 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus 4) Standard Deviation(.s.d.) The standard deviation was determined in order to measure the variability in the data. s.d. values that are large indicate data with great variability and therefore, low reliability where as those with low values indicate low variability and hence, greater reliability. Formula: x=rate of CO2 production =mean rate of CO2 production n=sample size e.g. Dormant 5) 95% Confidence Interval(95% CI) The 95% confidence interval was measured in order to judge whether two sets of points on the graph are significantly different or not. This is done by judging whether the errors bars of the data points, the 95% CI, overlap to each other or not. If the error bars of the data points overlap, this signifies that the two set of points are not significantly different. On the other hand, if the data points do not overlap, the two set of points are significantly different. Ultimately, it allows to make a judgment of whether to accept or reject the hypothesis. If, on the graph, some of the error bars overlap and some do not, the alternative hypothesis is accepted with limitations. If all the error bars overlap, then the null hypothesis is accepted. The calculation of 95% CI is done 12 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus using Microsoft Excel(2011). However, since the formula presented below is not the same as the one used in Excel, the value calculated will not be the same as the one calculated in the table 5 and 6. Instead, the upper and lower bounds of the error bars will be presented Formula: =Mean rate of CO2 production t=Degree of freedom(df) for n-1 n=number of samples/trials s=standard deviation t=Degree of freedom(df) for n-1 n=number of samples/trials s=standard deviation e.g. Dormant ---As all IVs have 6 as their sample size(n), the value for t will be for when the degrees of freedom is 5. Hence, t=2.571 13 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus DPP aspect 3: Presentation of processed data Figure 3: The effect of seed condition(dormant/germinating) on mean rate of CO2 production(ppm/s) of L. odoratus at 20.0ºC+.5 (Error Bars: +95% CI) Figure 4 :The effect of temperature(ºC+.5) on mean rate of CO2 production(ppm/s) of L. odoratus in germinating condition (Error Bars: +95% CI) 14 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus CE aspect 1: Conclusion Based on table 5, 6, and figure 3, which show that the mean rate of CO2 production(ppm/s) is higher for germinating L. odoratus(seeds) relative to the dormant seeds at 20.0ºC+.5, we can conclude that when the condition of the seeds are set to be germinating, the mean rate of CO2 production(ppm/s) and therefore, the rate of cellular respiration is higher than that of the dormant condition. In addition, based on table 5, 7, and figure 4, which show a higher mean rate of CO2 production(ppm/s) when temperature(ºC+.5) is 20.0ºC+.5 relative to than that of 10.0ºC+.5, we could come to a conclusion that as temperature(ºC+.5) increases, the mean rate of CO2 production(ppm/s) also increases and therefore, the rate of cellular respiration is higher at a higher temperature relative to the rate at a low temperature. Based solely on the data, we could deduce that the independent variable of temperature(ºC+.5) is directly proportional to the DV of mean rate of CO2 production(ppm/s) and therefore, the rate of cellular respiration. At the same time, based solely on the data, we could deduce that the independent variable of condition when germinating results in a higher DV of mean rate of CO2 production(ppm/s) and could deduce that the independent variable of temperature(ºC+.5) is directly proportional to the DV of mean rate of CO2 production(ppm/s) and therefore, the rate of cellular respiration. At the same time, based solely on the data, we could deduce that the independent variable of condition when germinating results in a higher DV of mean rate of CO2 production(ppm/s) and therefore, the rate of cellular respiration. From this conclusion, we can clearly state that the data certainly supports my alternative hypothesis(HA). In the data from table 5, there are some outliers. This includes the 4th and 6th trials of the IV of dormant condition at 20.0ºC+.5. With the assumption that the cork on the CO2 gas sensor does not allow the exit of CO2 or any substances, it is impossible to get a negative value. Hence, it makes sense to deduce that this outlier is due to a systematic, instrumental error. Otherwise, for my first research question which seeks to investigate the effect of the condition(germinating or dormant) on the rate of cellular respiration, all other data(table 5, 6, and figure 3) fully supports the conclusion and alternative hypothesis. In fact, all other values of IV for dormant seeds at 20.0ºC+.5 are lower than that of the IV for germinating seeds at 20.0ºC+.5. Even when observing the values from table 6, the dormant seeds have a mean rate of CO2 production of 0.03ppm/s while the germinating seeds(from table 6, which are at 20.0ºC+.5) have a mean rate of CO2 production of 1.49ppm/s. From this set of data, we could calculate that the germinating seeds produce CO2 about 50 more times efficiently relative to the dormant seeds. In addition, we could come to the same conclusion by observing the mean values projected for the difference in CO2 concentration(ppm+100). While the value for IV of dormant is 19+100, the value for germinating(at 20.0ºC+.5) is 895+100. This data also supports my conclusion because it shows that the values for the germinating seeds are greater than that of the dormant as it proves the germinating seeds to have gone through more cellular respiration. As stated in my reasoning for the alternative hypothesis, the biological reasoning or scientific explanation for the germinating seeds to have a higher mean rate of CO2 production(ppm/s) is because the suspension of water in the cells of the seeds is a requisite for the functioning of enzymes to carry out the process of aerobic respiration. Since the germinating seeds were placed in water and the dry seeds were not, the germinating seeds were the ones with a higher mean rate of CO2 production and therefore, faster rate of cellular respiration. Meanwhile, the dry seeds are theoretically supposed to not have any enzymes functioning to carry out aerobic respiration, hence, theoretically, no CO2 difference should even be observed although in reality, they have rates of CO2 production(ppm/s) with just 2 digits. Perhaps reasons for this would be because some of the cells in the seeds picked up water in the air causing some of the enzymes to be able to carry out aerobic respiration and ultimately, production of small molecules of CO2. 15 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus For the other research question which seeks to investigate the effect of temperature(ºC+.5) on the rate of cellular respiration in germinating seeds, we could also see that all data supports my alternative hypothesis as well. My alternative hypothesis being, that the increase in temperature(ºC+.5) causing the mean rate of CO2 production(ppm/s) and therefore, rate of cellular respiration to increase. Referring to the mean values of the rate of CO2 production(ppm/s) on table 7, we see that the value for the germinating seeds in 10.0ºC+.5 is 0.52ppm/s where as the value for 20.0ºC+.5 is 1.49ppm/s. In addition, when referring back to the mean values of the difference in CO2 concentration(ppm+100), the data supports my alternative hypothesis as well. While the mean value for germinating seeds at 10.0ºC+.5 is 309ppm+100, the value for the germinating seeds at 20.0ºC+.5 is 895ppm+100. As the CO2 production is greater for the IV of 20.0ºC+.5 relative to the 10.0ºC+.5 over the identical given time of 10minutes, it is clear that more aerobic respiration occurs at 20.0ºC+.5. This basically shows that when the germinating seeds are in environments of 20.0ºC+.5, the rate of cellular respiration is about 3 times faster than when it is in an environment of 10.0ºC+.5. However, what is interesting is that as the temperature(ºC+.5) increased by twice the original temperature, the mean rate of CO2 production(ppm/s) increased by 3 times more. This signifies that the rate of increase is not identical to each other. In other words, from this, we could imply that the relationship between temperature(ºC+.5) and mean rate of CO2 production(ppm/s) is either linear or partially exponential. Though overall, this relationship makes sense because in terms of a biological analysis, enzymes tend to function more efficiently when the temperature of its environment is at the enzyme’s optimal temperature at which it functions best. However, once relationship between temperature(ºC+.5) and mean rate of CO2 production(ppm/s) is either linear or partially exponential. Though overall, this relationship makes sense because in terms of a biological analysis, enzymes tend to function more efficiently when the temperature of its environment is at the enzyme’s optimal temperature at which it functions best. However, once this temperature is exceeded, the function of the enzyme starts to become highly inefficient. As 10~20ºC is a temperature that is experienced in nature, it made scientific sense to judge that neither are temperatures exceeding the seed’s enzyme’s optimal temperature. Therefore, the data makes sense for the mean rate of CO2 production(ppm/s) and therefore, the rate of aerobic cellular respiration to be greater at a higher temperature(ºC+.5). Now we could also comment that the strength of my conclusion itself is quite high as well. This could be stated based on the 95% CI error bars. When observing the bar graphs for figure 3 and 4, we observe that the error bars, despite having to be large for the IV of germinating seeds in 20.0ºC+.5, do not overlap for both bar graphs. This signifies, that each of these data points or bars, are significantly different to each other and therefore, allowing the alternative hypothesis to be accepted without limitations. There are certain outliers as mentioned previously and variability is also a factor that must be taken into consideration when commenting on the overall reliability of data but that will be done in the next evaluation. Based on this published data from PASCO, we could see that the green, which is the germinating seeds, have a higher rate of increase in rate of CO2 production(ppm/s) where as the dormant seeds have a small rate of increase. (PASCO, 2013) 16 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus CE aspects 2 & 3: Evaluation and Improvements When referring back to tables 5, we see values for s.d. and 95% CI which are statistical test that are significant for the purpose of evaluating the reliability of the data. Although the s.d. and 95% CI for the difference in CO2 concentration, since it is a value used for the calculation of the mean rate of CO2. However, as its uncertainty is also huge, this will be mentioned as well. Although it is difficult to comment on the 95%CI as the data for difference of CO2 concentration(ppm+100) is not graphed, the s.d. is something that is quite significant. As we see from table 5 that the s.d. for the dormant IV is 36. For most data for this IV, the s.d. is basically greater than or equal to 50% of the actual data. In other words, it shows that each of these data points are highly unreliable. Since some of these values even are unreliable to the extent that a negative value was observed, this unreliability is evident. Similarly, the s.d. for the germinating seeds at 20.0ºC+.5 is 234 which is in fact, greater than or equal to 25% of the actual data sets or samples in this IV. Hence, we could deduce that this set of data is not as unreliable as the IV for the dormant seeds, however, is still a relatively unreliable set of data. Likewise, the s.d. for the IV of the germinating seeds at 10.0ºC+.5 is 83 as this is also more than or equal to about 17%. Since there are other points in which the s.d. is actually about 45% of the actual data, it cannot be stated that these values are reliable. This goes the same for the s.d. of the rate of CO2 production(ppm/s) as well. The s.d. of the IV for dormant seeds, germinating(20.0ºC+.5), germinating(10.0ºC+100) was the following: 0.06, 0.39, 0.14. Once again, each s.d. relative to the actual data collected, is a large portion of the data. In other words, there is a large variability for each set of IV data. And this makes sense because the error of the instrument(CO2 gas sensor) was +50. Since there is a huge uncertainty, there definitely is a high variability in all data. As a result, the s.d. would tend to potentially, give a huge impact on the evaluation of the data. Though in terms of 95% CI, which would be used to assess the validity of the conclusion or alternative hypothesis, was quite supportive for the alternative hypothesis. In other words, as I previously mentioned, the 95% CI did not overlap with each other at all for both graphs. Hence, it was only reasonable to accept the alternative hypothesis without limitations and reject the null hypothesis. This supports my perception that the results or conclusions were quite valid and in fact, also supports the biological interpretation, theories, and concepts which underlie the alternative hypothesis. hypothesis. This supports my perception that the results or conclusions were quite valid and in fact, also supports the biological interpretation, theories, and concepts which underlie the alternative hypothesis. 17 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus Table 8.1: The effect of errors and limitations on data described with its type and potential modifications Errors and Significance: Type Modification to Limitations Effect on data of method error Limitation in As a result of using the CO2 gas sensor, D A potential solution is DesignE to measure pressure each group realized that the gas sensor Instrumental Error: was either inaccurate or was highly S using a PASCO CO2 gas sensor Xplorer-GLX and sensitive to change. Evidently, the calculating the projected random uncertainty of the sensor is +50. This amount of CO2 variation in ppm limitation is the most likely cause for value outliers such as that of trial 4 and 6 of IV produced by using for the dormant seeds. the real gas law rather than the ideal so that the result of the initial pressure could be compared with the final. Limitation in Due to a very small sample size of 6, D We could conduct the Design-Number of where in reality, each group is only E experiment in Trials/Sample Size: supposed to do 1 trial per IV. As the S individuals rather than Only 6 trials(very variability of each CO2 gas sensor varied groups with each small sample size, amongst all groups, this could have conducting at least 2 at least 6, less than been the cause for such large s.d. trials so that we could 11) were done have at least a total of values for all IV. 20 trials and therefore, a small sample size that is between 20-30 as we are indeed limited with resources. Limitation in When investigating upon the effects of D We could add one or Design-Range of temperature on the rate of cellular E two more IV of 30.0ºC IV: respiration for germinating seeds. It S and 40.0ºC so that we Specifically for would have been better if we could also could investigate on investigation on investigate on the effects of exceeding the effects of going temperature(ºC+.5) the optimal temperature of the enzymes over the optimal effect, only 2 IV inside the L. odoratus seeds. And it temperature. where both are could have also helped to make a more under optimal valid deduction on whether the temperature for relationship is exponential or linear. effect, only 2 IV where both are under optimal temperature for enzyme inside the L. odoratus seeds. And it could have also helped to make a more valid deduction on whether the relationship is exponential or linear. temperature. 18 | P a g e Joel Hayashi December 12, 2013 Effects of Varying Condition and Temperature on L. odoratus Table 8.2: The effect of errors and limitations on data described with its type and potential modifications Limitation in As a possibility of variability in the P Perhaps instead of a cork, we Performance- instrument, the limitation in H could use a cap that would Cork not performance of not firmly fixing the cork R firmly cover up any kind of firmly fixed to of the gas sensor into the sample bottle space that can potentially be not allow loss could be raised. If the gas sensors created as a result of the of CO2, were actually just highly sensitive, then usage of a cork and hence, the cause for the instrumental error prevent any loss of CO2. perhaps CO2 would be the small loss of CO2 through gas sensor the opening of the sample bottle. reacted due to this Limitation in Referring back to the qualitative data D In order to minimize more of Designabout the shape and size of the L. E the random biological Biological odoratus seeds of all trials. We could S variation, we could simply use Variation: see that the random biological variation seeds in which have small Number of is minimized at least with the biological variation. Since the enzymes/cells assumption that shape and size has a best way to minimize biological judging by relationship with the number of cells variation in this case would be size and and enzymes. Hence, it is ranked low size and shape, we could shape of L. in terms of significance. However, it is select a seed which do not odoratus still a source of error as this could also vary in those attributes as contribute to the variability of the data much as the L. odoratus. For as well as each trials’ differing initial example, a basil seed or and final CO2 concentrations pumpkin seed is very small and is associated with very few (ppm+50). differences amongst each other. Key for types of error: D = Design, P = Performance; H = Human, E = Equipment; R = Random, S = Systematic *Ordered in significance or importance References Allot,, A., & Mindorff, D. (2012). OXFORD IB Diploma Progamme: Biology course companion (2nd Edition ed.). OXFORD, UK: Oxford University Press. Biology Through Inquiry (2009). ''Respiration of Germinating Seeds''. Roseville, California: Pasco Scientific The College Board, Educational Testing Service. (1997). Biology Laboratory Manual for Students''. New York, New York: The College Board. New York: The College Board, Educational Testing Service. PASCO. (2013). PASCO. Retrieved from Respiration of germinating peas: http://www.pasco.com/biology/cell-biology/respiration-of-germinating-peas.cfm 19 | P a g e Joel Hayashi December 12, 2013